1

WARNING:

Read and understand all instructions. Failure to

follow all instructions listed below, may result in electric

shock, re, and/or serious personal injury.

SAVE THESE INSTRUCTIONS

Read these instructions and the instructions for the power

head thoroughly before using pruner.

Know the tool. Read and understand the operator’s

manual and observe the warnings and instruction labels

afxed to the tool.

Do not allow children or untrained individuals to use this

unit.

Wear safety glasses / goggles and hearing protection that

are marked to comply with standards when operating this

product.

Wear heavy long pants, boots, and gloves. Do not wear

loose tting clothing, short pants, jewelry of any kind, or

go barefoot.

Secure long hair so it is above shoulder level to prevent

entanglement in any moving parts.

Keep all bystanders, children, and pets at least 15 m

away.

Stay alert, watch what you are doing, and use common

sense when operating a power tool. Do not use tool while

tired or under the inuence of drugs, alcohol, or medica-

tion. A moment of inattention while operating power tools

may result in serious personal injury.

Do not operate in poor lighting.

Do not overreach. Keep proper footing and balance at all

GENERAL SAFETY RULES

times. Proper footing and balance enables better control

of the tool in unexpected situations.

Keep all parts of your body away from any moving part.

Do not touch areas around the mufer or cylinder of the

power head. These parts get hot from operation. Failure to

heed this warning could result in possible serious personal

injury.

Always stop the engine and remove the spark plug wire

and/or ensure that the engine cut off switch remains in

the off position before making any adjustments or repairs

except for carburetor adjustments.

Inspect unit before each use for loose fasteners and

damaged or missing parts. Correct before using the

attachment. Failure to do so can cause serious injury.

Use only original manufacturer’s replacement parts. Fail-

ure to do so may cause poor performance, possible injury,

and will void your warranty.

Do not, under any circumstance, use any attachment or

accessory on this product, which was not provided with

the product, or identied as appropriate for use with this

product in the operator’s manual.

Avoid dangerous environments. Do not use the attachment

in damp or wet locations. Do not use in rain.

Use the right attachment. Do not use attachment for any

job except that for which it is intended.

Keep hands away from cutting area. Keep hands away

from the cutting chain. Do not reach underneath, work

around or over the cutting chain while the chain is rotating.

Do not attempt to remove cut material whilst the cutting

chain is moving.

The cutting chain may coast momentarily after the power

head has been turned off.

Kickback is a dangerous reaction that can lead to serious

injury. Kickback may occur when the moving chain con-

tacts an object at the upper portion of the tip of the guide

bar or when the wood closes in and pinches the chain

in the cut. Contact at the upper portion of the tip of the

guide bar can cause the chain to dig into the object and

stop the chain for an instant. The result is a lightning fast,

reverse reaction which kicks the guide bar up and back

toward the operator. If the chain is pinched along the top

of the guide bar, the guide bar can be driven rapidly back

toward the operator. Either of these reactions can cause

loss of tool control which can result in serious injury. Do

not rely exclusively upon the safety devices built into the

tool. As a pruner user, you should take several steps to

keep your cutting jobs free from accident or injury.

SPECIFIC SAFETY RULES

With a basic understanding of kickback, you can reduce

or eliminate the element of surprise. Sudden surprise

contributes to accidents.

Make sure that the area in which you are cutting is free

from obstructions. Do not let the nose of the guide bar

contact a log, branch, fence, or any other obstruction while

you are operating the unit.

Always cut with the engine running at full speed. Fully

squeeze the throttle trigger and maintain a steady cutting

speed.

Follow the sharpening and maintenance instructions for

the chain.

Use only the replacement guide bars and low kickback

chains specied for this unit.

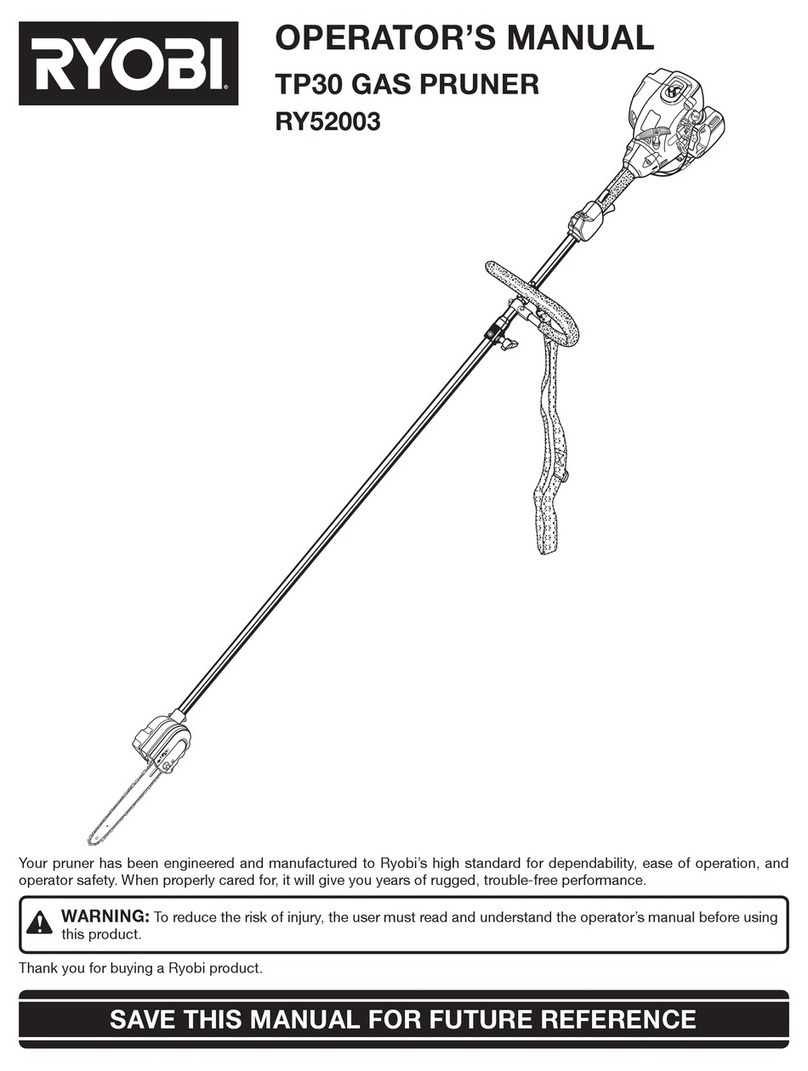

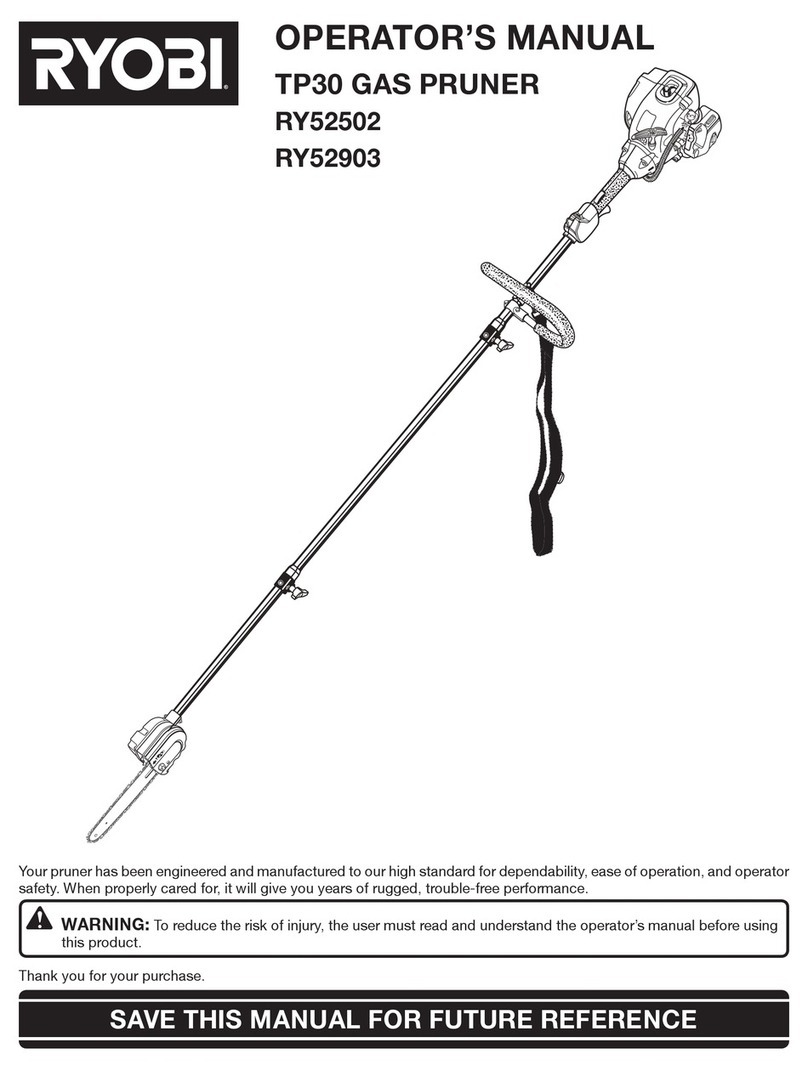

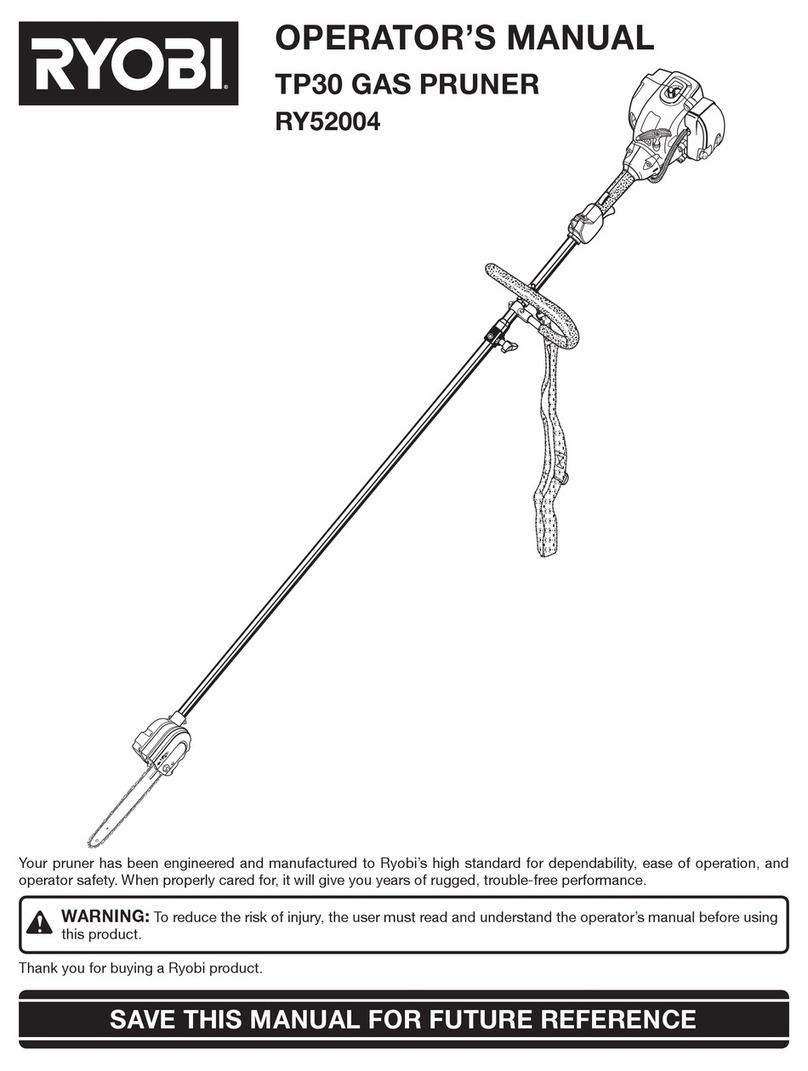

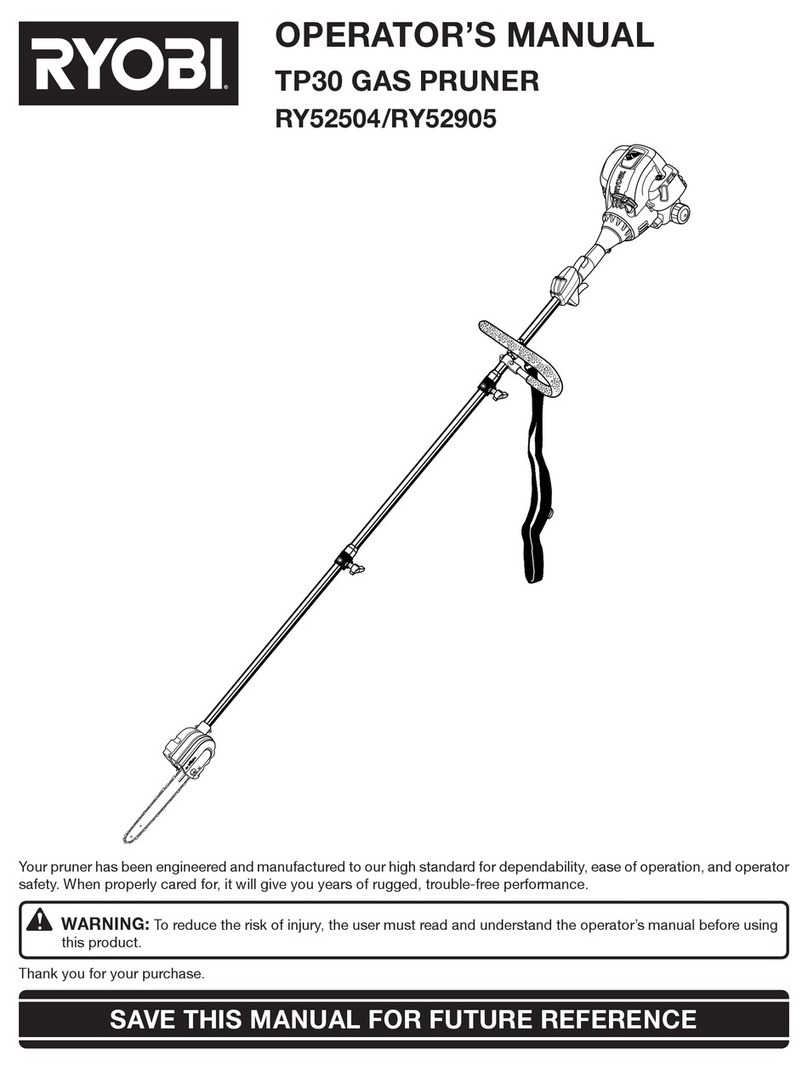

INTRODUCTION

This product has many features for making its use more pleasant and enjoyable. Safety, performance, and dependability

have been given top priority in the design of this product making it easy to maintain and operate.