S.E.F.A SUBLIMAX 1812 User manual

INSTRUCTION MANUAL

SUBLIMAX 1812

S.E.F.A®

Z.I PASTABRAC

11260 ESPERAZA

FRANCE

Tel: 33 (0)4.68.74.05.89 - Fax:33.(0)4.68.74.24.08

Email: [email protected]

V0 6

Page 2

INDEX

INDEX .......................................................................................................................................................... 2

I.

CONDITIONS OF UARANTEE ............................................................................................................ 3

II.

SPECIFICATIONS ................................................................................................................................ 4

III.

OVERVIEW ..................................................................................................................................... 5

IV.

USIN THE MACHINE ......................................................................................................................... 6

.

SAFETY .................................................................................................................................................. 6

2.

INSTALLATION ....................................................................................................................................... 8

A.

Mounting arm assembly left .............................................................................................................................. 8

B.

Mounting arm assembly right ............................................................................................................................ 9

C.

Mounting the support bar ............................................................................................................................... 0

D.

Removing motor pinion .................................................................................................................................. 0

E.

Reassembly motor pinion ................................................................................................................................

F.

Mounting free pinion set ................................................................................................................................. 2

G.

Mounting extraction fan .................................................................................................................................. 3

V.

DESCRIPTION OF THE OPERATIN CYCLE ....................................................................................... 14

.

COMPLETE CYCLE ................................................................................................................................. 4

2.

OPERATING WITH THE TOUCH SCREEN ................................................................................................ 5

3.

PRESS SETTINGS .................................................................................................................................. 8

A.

TEMPERATURE SETTING ................................................................................................................................ 8

B.

TIME SETTING .............................................................................................................................................. 8

4.

PROPPING THE PRESS FOR START CYCLE CONFIGURATION ................................................................... 8

5.

ASPIRATION TIMER SETTING ............................................................................................................... 8

VI.

ELECTRIC DIA RAM ......................................................................................................................... 19

VII.

PNEUMATIC DIA RAM ................................................................................................................. 22

VIII.

ELECTRICAL PANEL ...................................................................................................................... 23

IX.

MAINTENANCE .................................................................................................................................. 24

.

SERVICING ........................................................................................................................................... 24

2.

PARTS SUBJECTED TO WEAR AND TEAR ............................................................................................... 24

3.

QUICK REPAIR ADVICES ....................................................................................................................... 25

4.

MAINTENANCE LOG .............................................................................................................................. 26

V0 6

Page 3

I. CONDITIONS OF UARANTEE

•The guarantee period starts the day of putting the equipment into service at the user’s place, materialized by the

return of the guarantee bill for a duration of two years, 8h per day meaning about 3000 hours.

•The guarantee is strictly limited to our equipments, against the defects of matter and execution, with the buyer’s

responsibility to prove the known defects.

•Our responsibility is limited to the obligation to rectify or replace free of charge the parts acknowledged as faulty

by ourselves, and there will no claim for any indemnity whatever the reason given.

•Parts replaced under the guarantee:

-remain our property

-are the subject of an invoicing of deposit

•A credit of cancellation is activated as soon as the faulty parts are returned.

The return will have to occur ONE MONTH MAXIMUM after the intervention

THE UARANTEE DOES NOT COVER :

•The retail consumables such as:

-Fuses, bulbs, joints, flexible devices, covers, nozzles, filters.....

-The supplies, which are not our own manufacturing, undergo the guarantee of their manufacturer.

THE UARANTEE DOES NOT APPLY :

•To replacements, nor repairs which would result from normal wear and tear of apparatus and machines, of

deteriorations and accidents coming from negligence, defect of monitoring and maintenance, defective use or

modifications without our written agreement.

•In case of vice coming from the material supplied by the buyer, or a design imposed by the latter.

•To repairs which would result from deteriorations or accidents occurred during transport.

•To operations of maintenance and adjustments inherent in the use of the machine, and indicated in the

maintenance manual, such as:

-adjustments of intermediaries

-screwing of piping, etc…

For the pneumatic machines, any trace of detergent oil in the pneumatic circuit inhibits

the conditions of guarantee previously mentioned.

For any technical information or spare parts orders,

please give the reference number of the machine as well as its serial number

V0 6

Page 4

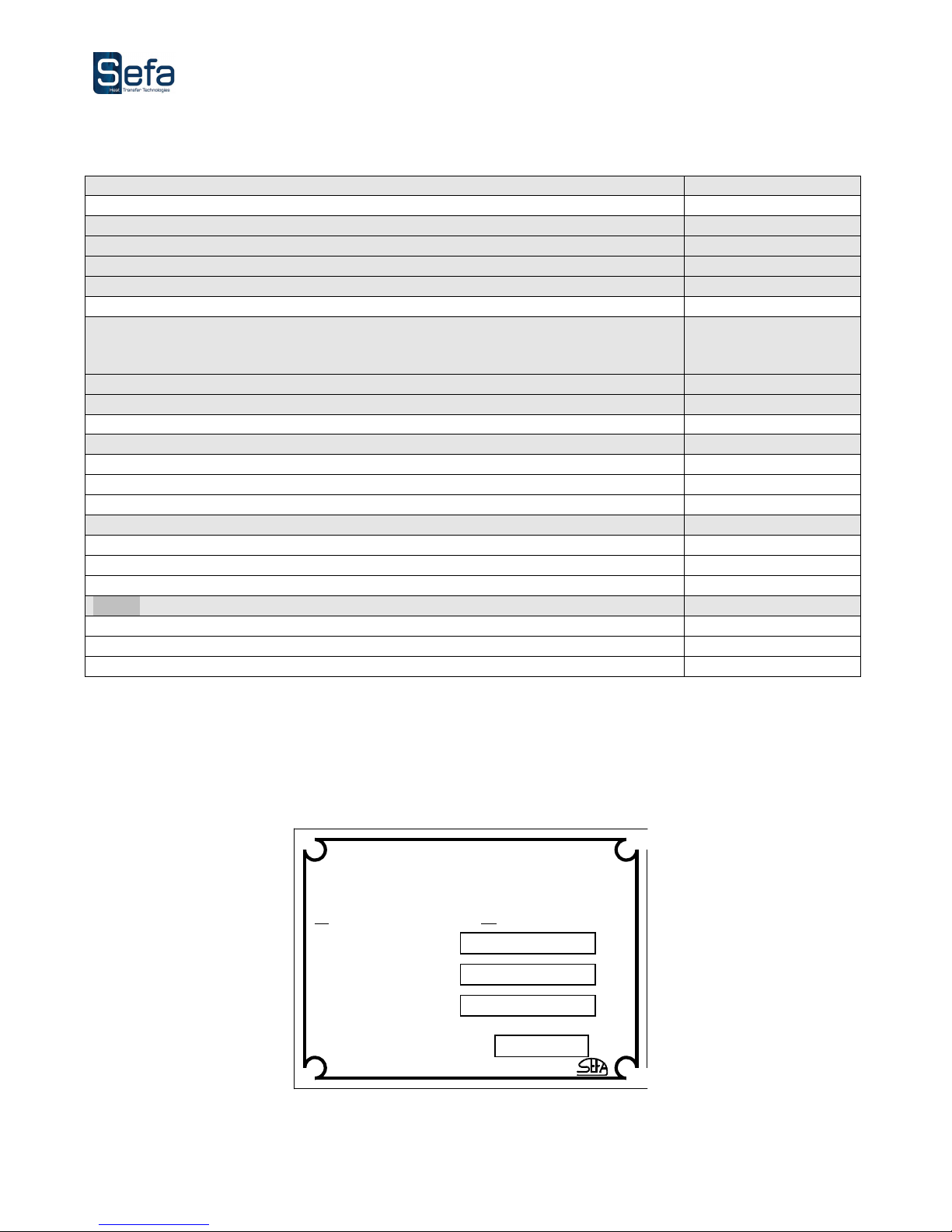

II. SPECIFICATIONS

Weight in running orde

r

1000 kg

Height

1370 mm

Depth

2990 mm

W

idth

1970 mm

Dimension of the heating plate

1800 x 1200 mm

Electric power supply

400 V +

neutral and

earth connections

50/60 Hz

Power

30 KW

Amperage

46 A

Working pressure

Mini

4 bars

Maxi

8 bars

Thermoregulator

Accurate to

+/

-

5%

Range of control

0 à 220°C

Timer

Accurate to

+/

-

2%

Range of control

1 à 30 mn

Non contractual document: according to the technical progress, we reserve the right to modify the characteristics of

our products.

Some of these characteristics are recalled on the nameplate you will find on the machine.

Made in France.by

MODELE

PUISSANCE

Tel

:+33.(0)4.68.74.05.89 Fax :+33(0)4.68.74.24.08

S.E.F.A

®

Z.I PASTABRAC

11 260 ES

PERAZA

–

(France)

N° de Série

Année de Fab.

V0 6

Page 5

III. OVERVIEW

This heat press machine is standard to the labour laws to ensure the security of the user.

It is designed to ensure the production with total reliability.

This press was designed for an operator working in front of the machine.

Touch

screen panel

Reset

Cycle start

button Emergency

stop

Pressure

regulator

Filter

Emergency

stop

Main plug

(400V)

Neutral and

earth

connections

Manometer Safety cells

V0 6

Page 6

IV. USIN THE MACHINE

The press SUBLIMAX 1812 was designed for the application of transfers of all grades.

This equipment has been tested in our workshops to get a one year warranty against manufacturing

defects.

Power settings, mechanical and pneumatic submitted by our technicians in the workshop as well as the

security established on the machine should never be changed. Otherwise, the SEFA ® company will

deny all responsibility on potential problems associated with said machine.

Before starting any pressing operation, it is recommended that you read the safety instructions and the

instructions for use.

The press should be used by an authorized person and having been informed of the risks that may be

caused by improper use of the equipment

1. SAFETY

THIS

EQUIPMENT

IS

DESI NED

FOR

SIN LE

USE

ONLY

USE

BY

QUALIFIED

STAFF

ONLY

I

nternationa

l Symbols

O

OFF HOT SURFACE

I

ON ELECTROCUTION RISK

DANGER, WARNING

You will find most of these symbols on the SEFA equipment.

Important point for security :

Don’t touch the hot parts of the equipment while in use.

During handling action, ensure the operator does not take any risk in terms of burns, electrocution or

other.

Proceed with a daily inspection of the machine before starting the production .

Make sure nobody is around or near the machine before you start it up.

If the machine does not work properly, shut down immediately all energy supplies and search for the

cause by using the book’s « Maintenance » chapter.

V0 6

Page 7

Security devices installed on the machine

The protections and security devices should not be modified.

They should be restored in case of removal for maintenance work.

The must be maintained in good running order during the production.

The press SUBLIMAX 8 2 is equipped with security systems preventing from pinching risk.

The main security devices are:

The emergency off

Located on the left side of the console of the machine as well as on both arms by pressing one of them the machine

is switched off and the cold plate goes down.

The photocell

Situated to the front of the heating plate, it ensures that the operator is remote from the heating plate during the

rise of the pressing plate.

Checking the operation of the safety device :

•Users have to verify the proper functioning of the various safety devices daily.

V0 6

Page 8

2. INSTALLATION

USE

BY

QUALIFIED

STAFF

ONLY

•Lower the machine from its packaging with a forklift

•Place the machine on its operating location.

•Remove all items related to packaging: paper, cardboard, plastic film, wood, etc. ...

•Put the machine level (if necessary) by turning the adjustable feet in height.

•Mount the machine as shown below

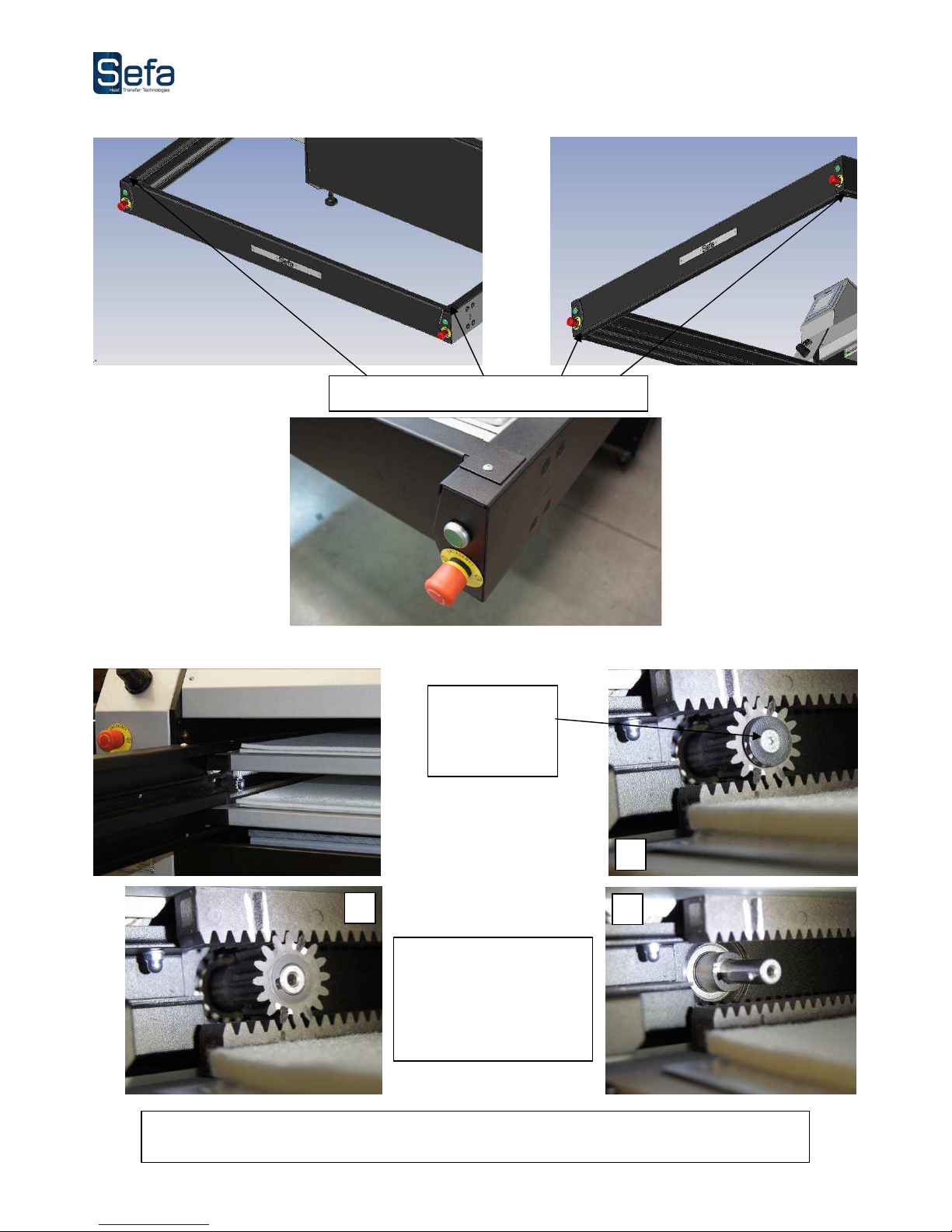

A. Mounting arm assembly left

Handing over the hatch for the arm

support cables within the enclosure

Screw and tighten

the 4 screws

M8

-

2

curved

V0 6

Page 9

B. Mounting arm assembly right

Handing over the door to

accompany the cables to the arm

inside the cap.

Screw and tighten

the 4 screws

M8

-

2

curved

V0 6

Page 0

C. Mounting the support bar

D. Removing motor pinion

Unscrew and

remove the

screw TFM5- 2

+ Washer.

Remove the motor pinion

pulling. If necessary,

relieve the weight of the

upper frame by slightly

raising.

The frames are now free to move. Manually move the frame over the entire course to ensure that

they slide properly.

2

3

Screw and tighten

the 4 screws

curved

M

5

-

2

V0 6

Page

E. Reassembly motor pinion

Position

The upper rear frame (blue in the figure)

And the lower frame at the front (in pink on the drawing)

Reassemble the motor pinion ensuring continuity pins made on both the

pinion and the rack. If necessary, relieve the weight of the upper frame by

lifting slightly.

Then screw and tighten the screw TFM5- 2 + washer (removed in step 4).

V0 6

Page 2

F. Mounting free pinion set

Reassemble the free pinion set through the right door. Ensure continuity

marks made on both the pinion and rack.

And screw the screw TF M5- 6.

V0 6

Page 3

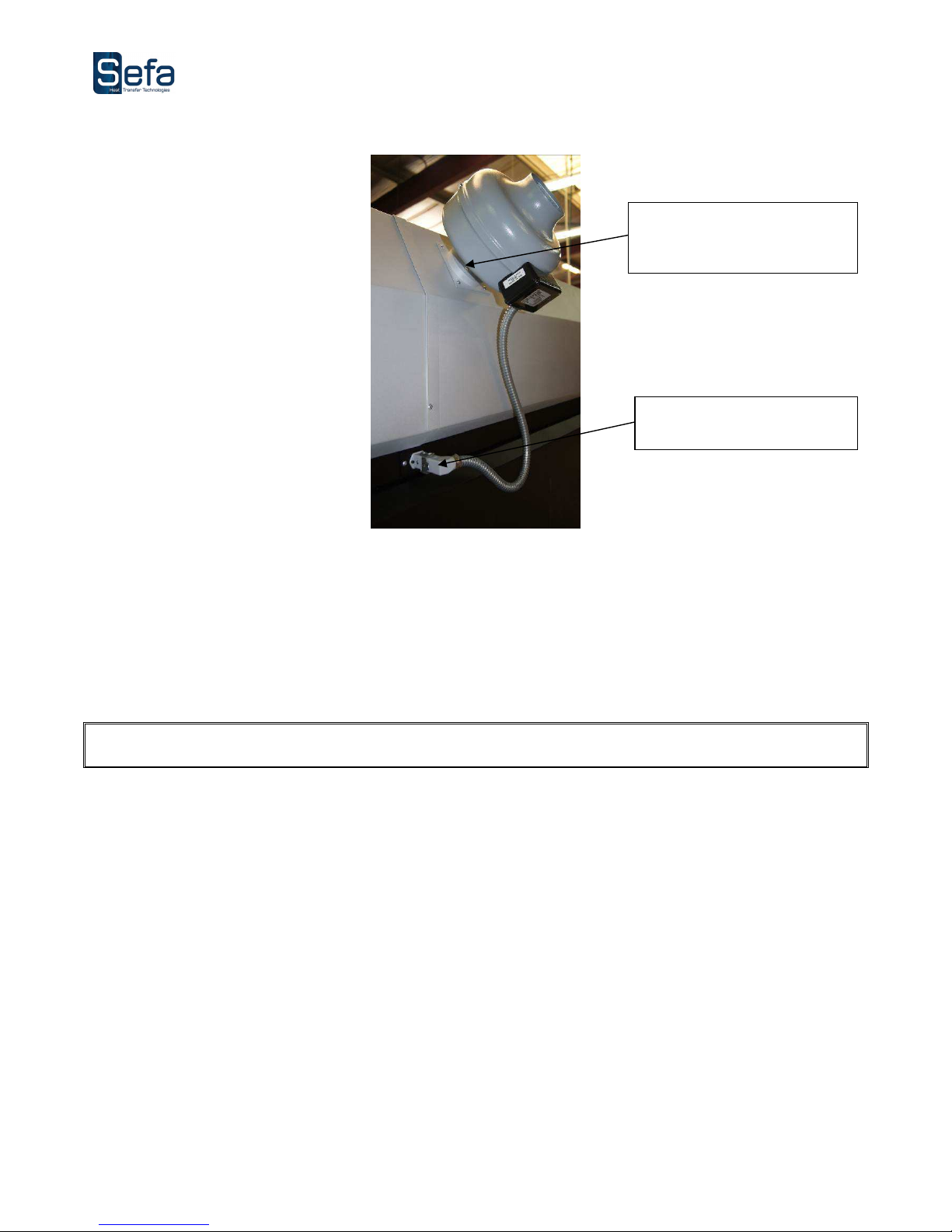

. Mounting extraction fan

HAVIN

DONE

CORRECTLY

THE

ASSEMBLY

AND

POSITIONIN

OF

EQUIPMENT

ON

THE

PLACE

OF

OPERATIONS

:

•Electrically connect the press (380 Volt + Neutral + Earth / 50 or 60 Hertz). The red jack is located on the left side of the

machine.

•Connect pneumatic press your compressed air system (3 mini bar, 0 bar). Connect the air filter on the controller (left side

of the machine).

Place the fan on the flange and

screw the 3 screws curved M5-

2

Connect the ventilator plug

V0 6

Page 4

V. DESCRIPTION OF THE OPERATIN CYCLE

1. COMPLETE CYCLE

1. Turn the machine by flipping the power switch located on the left side of the chassis. Press the push

button reset (screen lights up and displays the home page)

2. Press "control" to enter the temperature and time setting.

3. To start a cycle, carts must always lie in the extreme position, if that is the case, see SETTING MACHINE.

4. Set the temperature on the touch screen (to define the following type of application),

See § the TEMPERATURE ADJUSTMENT page 18

5. Set time pressing on the touch screen (to be defined for the type of application)

See § SETTING TIME page 18

6. Adjust the pressure by the regulator on the front of the electrical box (reading on the pressure gauge)

7. Place the item to be marked on the bottom plate,

8. Adjust the transfer sheet,

9. Press the "Cycle Start" and hold off the truck green button : the carriages move,

0. The cold plate rises and presses the heating, activating the timer board.

. At the end of the timer countdown, cold plate descends down position.

2. Repeat the process from 6 if the settings do not change (except No. 3)

During the cycle: On the touch screen "Stop pressing" allows interrupt pressing and lowers the pressure plate

Pressing the button “cycle start” stops the pressing, lowers the pressure plate and reverse the tray carts.

V0 6

Page 5

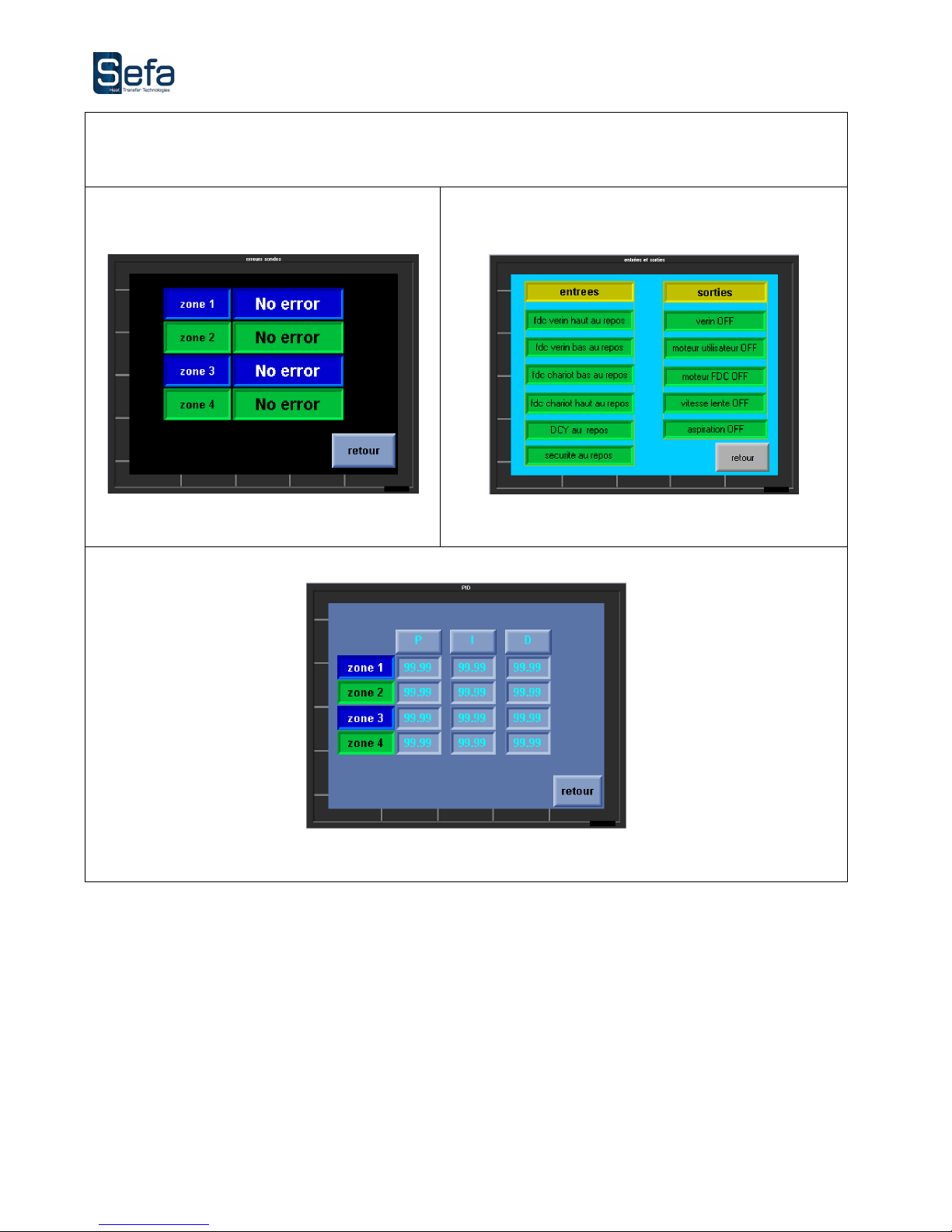

2. OPERATIN WITH THE TOUCH SCREEN

Summary

Dimensions

of the

4

areas

Control

T° adjustment area

T° adjustment area 2

T° adjustment area 3

T° adjustment area 4

Pressing time adjustment

interrupt the pressing cycle without moving

decks

During pressing: interrupts the press and trade

decks.

Off pressing: exchange decks.

2

1

V0 6

Page 6

Settings

Offset

Allows the offset of each zone.

Aspiration

Allows the aspiration motor test and adjust its operation

during the cycle

During the pressing :

stops the pressing cycle

and switches decks.

Off pressing : switches

decks.

Allows to correctly reposition

the deck up under the

heating plate

Allows to correctly reposition

the deck down under the

heating plate

3

4

V0 6

Page 7

Diagnostics

Probe diagnostic

Indicates the faulty probe and the type of error

I/O diagnostic

Indicates the status of sensors and actuators

Shows the parameters used to control each area

V0 6

Page 8

3. PRESS SETTIN S

USE

BY

QUALIFIED

STAFF

ONLY

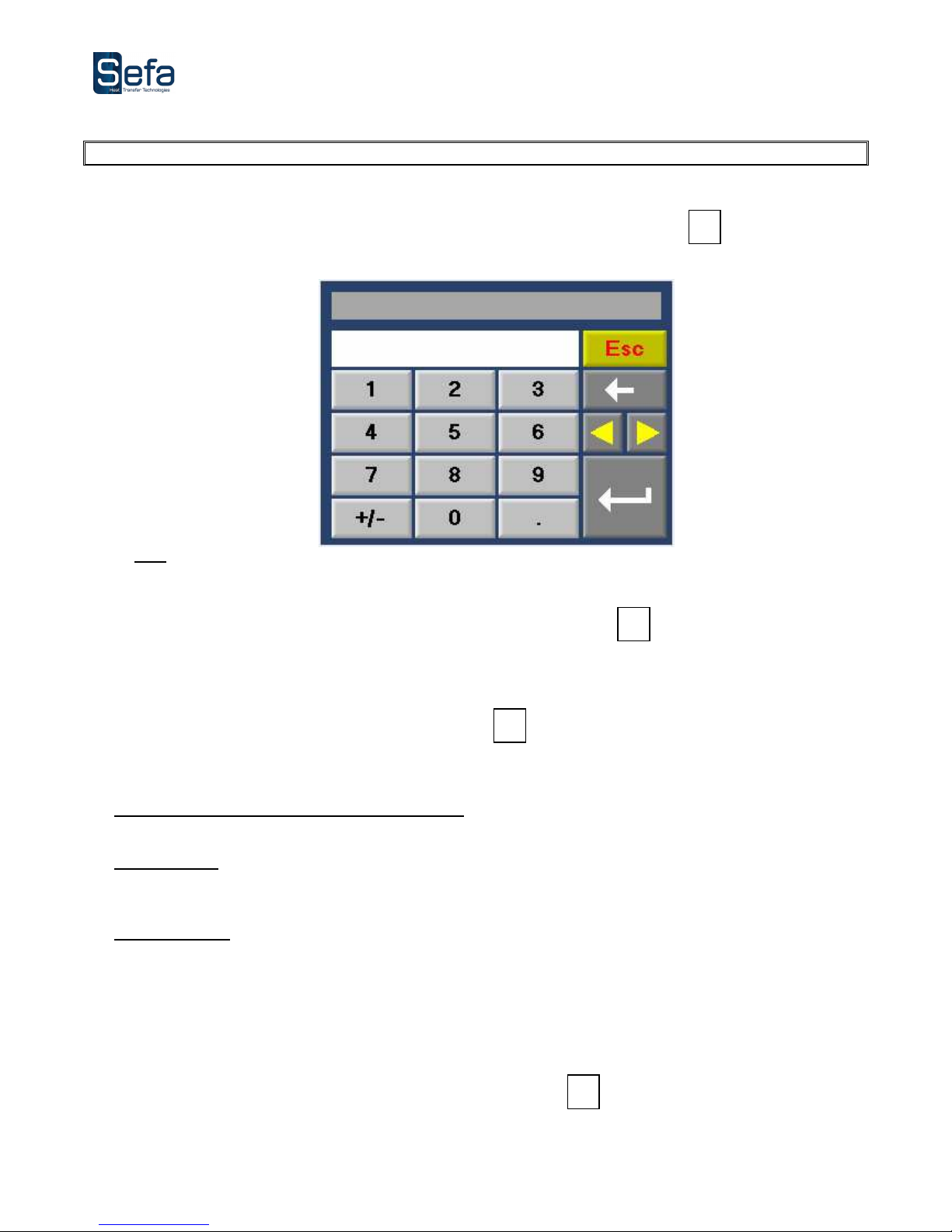

A. TEMPERATURE SETTIN

Set the temperature for each area, refer to the operation of the touch screen, § Controls, note

Pressing the control button brings up the following temperature display :

Nota : This screen is the same for all digital input.

B. TIME SETTIN

Set the pressing time, refer to the operation of the touch screen, § Controls, note

Pressing the control key pressing time that appear identical to that of the temperature setting screen.

4. PROPPIN THE PRESS FOR START CYCLE CONFI URATION

Refer to the operation of the touchscreen § Settings, note

When first unpacking or after pressing one of the safety devices, the following points need to be validated before a

restart cycle :

Unlock 3 emergency stop buttons (if required) :

If an emergency stop button is pressed, you must unlock it by turning in the clockwise direction.

Reset button :

After pressing one of the safety devices, the machine is in "default position", it must be reset by pressing the

(bright yellow) reset button.

Prop the press :

To start a cycle, the decks must be in extreme position. On the touch screen, adjust the buttons "deck up" and

"deck down" for correctly reposition decks.

Nota : Return-is then made at a slow speed to avoid the risk of damage to the machine.

If these three points are validated, the machine is now in "start cycle" configuration.

5. ASPIRATION TIMER SETTIN

Refer to the operation of the touch screen, § Aspiration, note .

The aspiration can be activated during the pressing cycle and / or for a time selected at the end of pressing.

4

3

2

1

V0 6

Page 9

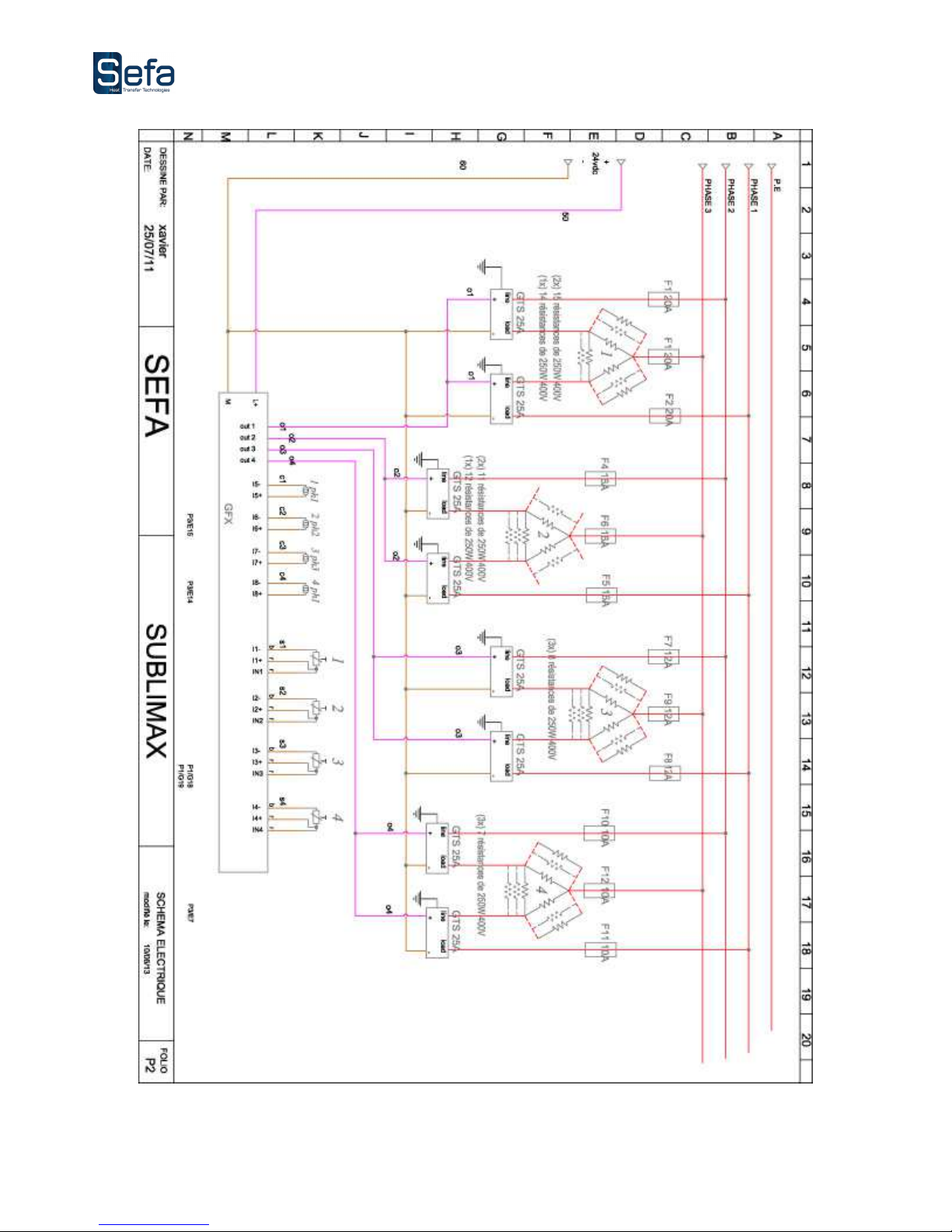

VI. ELECTRIC DIA RAM

V0 6

Page 20

Table of contents

Popular Power Tools manuals by other brands

Klein Tools

Klein Tools BAT20-7161 instruction manual

Larzep

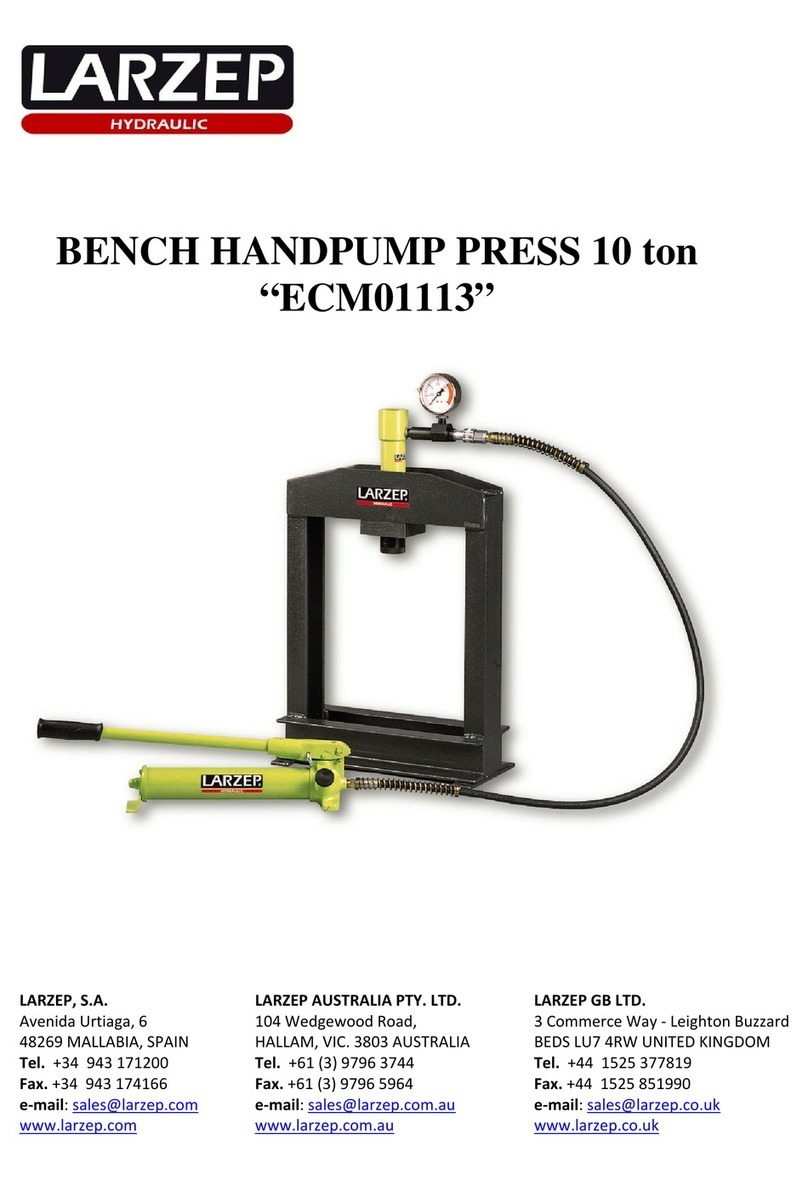

Larzep ECM01113 quick start guide

Würth

Würth 0715 93 92 operating instructions

Sturtevant Richmont

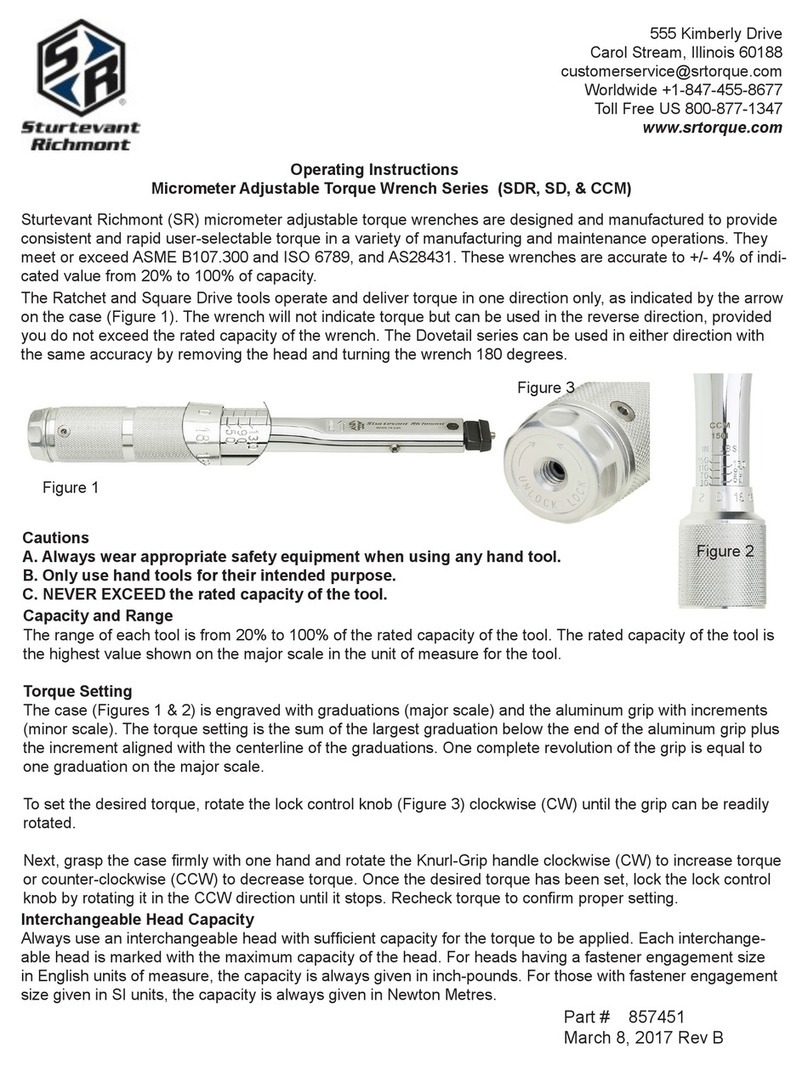

Sturtevant Richmont SD Series operating instructions

Prima

Prima PUNTO PLAST instruction manual

TE Connectivity

TE Connectivity 91904 Series instruction sheet