4

Instruction Manual

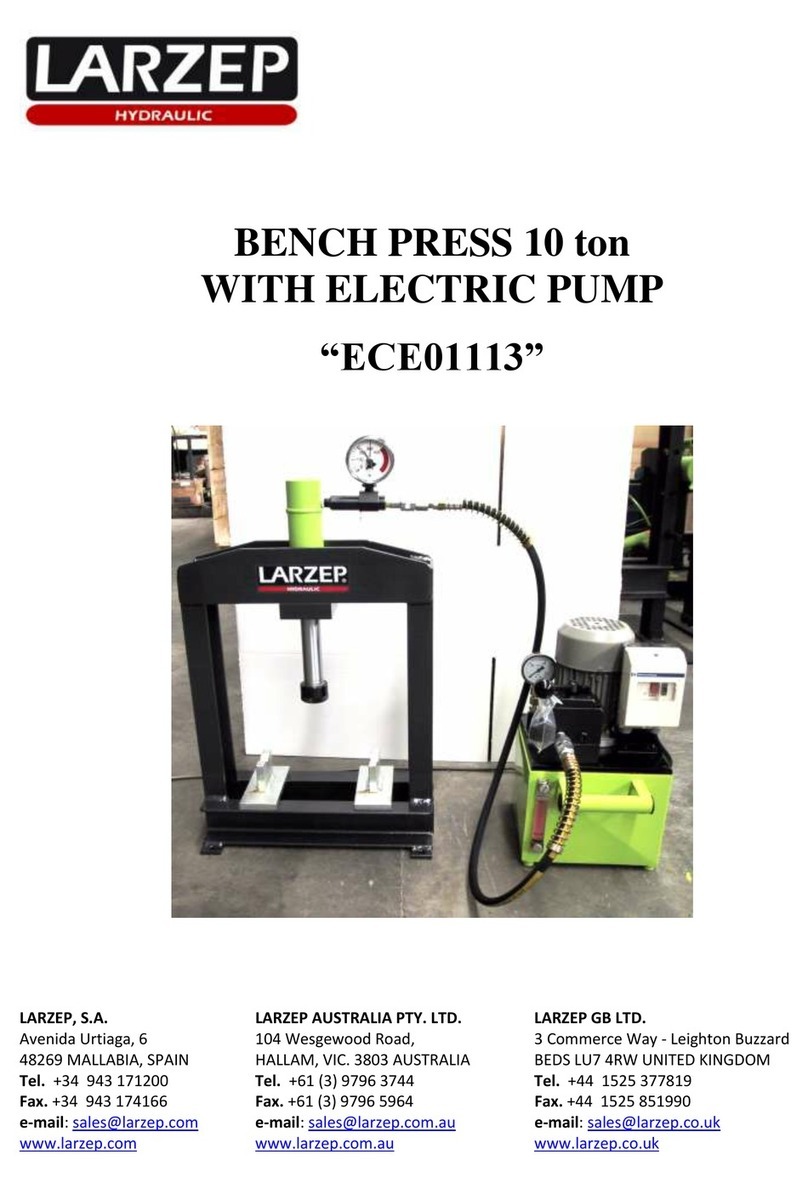

Bench Hand Pump Press 10 ton “ECM01113”

5. MAINTENANCE.

The hydraulic circuit of the press is closed, so in normal conditions no oil leakage should be coming up. In case of oil leakage, after the proper repairing work, you

should fill up the tank with hydraulic oil by LARZEP (Ref. AZ8901); the pump is equipped with an oil level indicator to control the need quantity of oil.

As far as a non-continuous use of the press is concerned (1 hour per day), oil replacement should be done once a year.

To empty the tank, you should remove the cover and take the oil out to another container. Please, bear in mind the existing rules for waste processing

when handling the used oil.

Keep greasy and lubricated the pin bearings, the piston and in general all the parts that might be in friction.

FREQUENT INSPECTION: a visual inspection carried out before and after each operation.

PERIODIC INSPECTION: a thorough examination of the equipment, both externally and internally. The equipment is labelled with the inspection date

and the data is logged in a register.

In a FREQUENT INSPECTION, check for:

•Piston wear, signs of corrosion

•Wear or damage to the cylinder, accessories or pump.

•Cracks, dents or any other damage to the frame, cylinder attachments, work table and its supports

•Oil leaks, loosed or damaged screws or joints

In a PERIODIC INSPECTION, check for the same problems as in a frequent inspection but in addition, the hydraulic equipment should be disassembled and cleaned

by an authorized service dealer so that it may be examined internally.

Periodically clean and lubricate the press’s moving parts, such as the piston, winch, pumping mechanism, etc. This is especially important when working in salty or

humid environments.

Hydraulics equipment, which is subject to the very severe environmental conditions mentioned, previously should be cleaned and lubricated after each use.

To clean the hydraulic equipment, begin by removing the pump’s oil reservoir plug and draining all the oil.

USE ONLY LARZEP HYDRAULIC OIL

Other grades of oils or types of hydraulic fluid (such as brake fluid) may affect the performance of the equipment or cause the deterioration of the seals.

DO NO ATTEMPT TO FILL THE PUMP WITH OIL WHILE IT IS CONNECTED TO A CYLINDER WHICH IS SUSTAINING A LOAD BECAUSE

IT MAY OVERPRESSURIZE THE RESERVOIR WHEN THE PISTON RETRACS AND CAUSE DAMAGE OR INJURY

Always use the original LARZEP parts to prolong the service life of your hydraulic equipment. LARZEP S.A. or your authorized dealer can supply you with

original parts for simple maintenance work.

PROBLEMS CAUSES SOLUTIONS

1. The piston does not advance. - The pump’s relief valve is open. 1. Close the relief valve.

- Air in the hydraulic circuit. 2. Purge the pump.

- No oil in the reservoir. 3. Fill the oil reservoir until the oil level reaches the plug’s orifice.

- Dirt in the hydraulic circuit. 4. Clean the hydraulic circuit.

- Worn or damaged check valve. 5. Take the press to an authorized service dealer.

- Improperly connected hydraulic line 6. Ensure that the hydraulic line is properly connected to the pump and cylinder.

2. The piston advances in spurts. - Air in the hydraulic circuit. See Solution 2.

- Deformed piston. See Solution 5.

3. The piston will not fully extend. - Low oil level. See Solution 3.

- Deformed piston. See Solution 5.

4. The cylinder loses pressure. - Air in the hydraulic circuit. See Solution 2.

- Dirt in the hydraulic circuit. See Solution 4.

- Worn or damaged check valve. See Solution 5.

-Worn or damaged O-rings See Solution 5.

5. Oil leak. - Worn or damaged O-rings See Solution 5.

- Improperly connected hydraulic line See Solution 5.

6. Piston does not fully retract. - Excessive oil in the reservoir. 7. Remove the oil reservoir plug and dump the excess oil.

- Deformed piston See Solution 5.

- Worn or damaged check valve. See Solution 5.

- Dirt in the hydraulic circuit. See Solution 4.

- Damaged return spring. See Solution 5.

7. Piston does no retract. - Relief valve closed. 8. Open the relief valve

- Deformed piston See Solution 5.

- Dirt in the hydraulic circuit. See Solution 4.

- Excessive oil in the reservoir See Solution 7.

- Damaged return spring. See Solution 5.

6. WARRANTY.

LARZEP, S.A. guarantees its products against all design and manufacturing defects for the durations of two years from the date of purchase. This guarantee does not

include the ordinary wear of both metal and non-metal parts, abuse, using the equipment beyond its rated capacity and any wear or damage incurred as a result of

using a hydraulic fluid which is not recommended by LARZEP, S.A.

Please note that if the equipment is disassembled or serviced by anyone other than an authorized service dealer or by LARZEP, S.A., this guarantee is rendered null

and void.

In the event of a warranty claim, return the equipment, to LARZEP, S.A. or the authorized dealer which sold you the hydraulic equipment, LARZEP, S.A. will

repair or replace the faulty equipment, whichever is deemed most appropriate. LARZEP, S.A. shall not be held liable for any consequential damages or losses,

which may occur as a result of faulty equipment