S.E.P. REV. 1000 E (2+2) User manual

REV. 1000 (2+2)

REV. 1000 E (2+2)

REV. 1000 Diesel (2+2)

REV. 1000 Special (3+2)

REV. 1000 Diesel Special (3+2)

®

USE AND MAINTENANCE MANUAL

GB

GB

REVERSIBLE TWO-WHEEL TRACTORS

REV. 1000 (2+2)

REV. 1000 Diesel (2+2)

REV. 1000 Special (3+2)

REV. 1000 Diesel Special (3+2)

REV. 1000 E (2+2)

BEFORE USING THE TWO-WHEEL TRACTOR

CAREFULLY READ THE INSTRUCTIONS

GIVEN IN THIS MANUAL

2

TABLE OF CONTENTS

Page Page

INTRODUCTION.................................................... 3

SAFETY REGULATIONS ....................................... 3

GENERAL NOTICES............................................. 3

STARTING THE ENGINE ...................................... 4

OPERATING OF THE TWO-WHEEL TRACTOR ... 4

OPERATING OF ATTACHMENTS ........................ 4

MAINTENANCE..................................................... 4

IDENTIFICATION DATA ........................................ 5

TWO-WHEEL TRACTOR IDENTIFICATION .......... 5

ENGINE IDENTIFICATION.................................... 5

EC MARKING ........................................................ 5

TECHNICAL SPECIFICATIONS............................ 9

ENGINE................................................................. 9

STARTING............................................................. 9

ELECTRIC STARTING (upon request) ................. 9

CLUTCH................................................................ 9

SPEEDS ................................................................ 9

TRANSMISSION ................................................... 9

DIFFERENTIAL GEAR (Special versions)............. 9

POWER TAKE OFF (PTO) .................................... 9

COUPLING OF ATTACHMENTS .......................... 9

HANDLEBARS ...................................................... 9

BRAKES (Special versions) .................................. 9

WHEELS/TIRES .................................................... 9

ACCESSORIES..................................................... 10

MASS .................................................................... 10

DIMENSIONS........................................................ 10

SAFETY DEVICES ................................................. 11

REVERSE SPEED SAFETY DEVICE..................... 11

TRANSFER PRINTING - INSTRUCTIONS AND

SAFETY.................................................................. 12

TWO-WHEEL TRACTOR CONTROLS .................. 13

OPERATING THE CONTROLS ............................. 13

PARKING BRAKE.................................................. 15

CONTROLS OF FRONT-MOUNTED

ATTACHMENTS.................................................... 16

OPERATING THE TWO-WHEEL TRACTOR.......... 16

STARTING THE ENGINE...................................... 16

STOPPING THE ENGINE..................................... 17

FITTING FRONT-MOUNTED ATTACHMENTS...... 17

SAFETY DEVICE .................................................. 17

REMOVAL OF 3rd SPEED PRESELECTION

CONTROL LEVER ................................................ 18

REVERSING THE HANDLEBARS ........................ 18

REVERSING THE WHEELS ................................. 18

COUPLING ATTACHMENTS TO THE PTO........... 19

WHEELS................................................................. 19

TRACK ADJUSTMENT ......................................... 19

MAINTENANCE...................................................... 20

ENGINE ................................................................ 20

OIL BATH AIR FILTER .......................................... 20

GEARBOX AND TRANSMISSION ........................ 20

POWER TAKE OFF .............................................. 21

CHECKS AND ADJUSTMENTS............................. 21

CLUTCH LEVER ................................................... 21

DIFFERENTIAL LOCK LEVER (Special versions) 21

BRAKE LEVERS (Special versions) ..................... 21

ROTARY TILLER .................................................... 22

GENERAL............................................................. 22

ROTARY TILLER TECHNICAL

SPECIFICATIONS ................................................ 22

USING THE ROTARY TILLER............................... 22

ROTARY TILLER ADJUSTMENT .......................... 22

ROTARY TILLER MAINTENANCE ........................ 23

CUTTER BAR MOWER .......................................... 25

GENERAL............................................................. 25

CUTTER BAR MOWER TECHNICAL

SPECIFICATIONS ................................................ 26

OPERATING CUTTER BAR MOWERS................. 26

CUTTER BAR MOWER ADJUSTMENT................ 24

CUTTER BAR MOWER MAINTENANCE .............. 28

EC CERTIFICATE OF CONFORMITY

GB

3

INTRODUCTION

•This manual provides Use and Maintenance in-

structions, technical specifications, and safety pre-

cautions for reversible two-wheel tractor:

−model REV. 1000 (2+2)

−model REV. 1000 E (2+2)

−model REV. 1000 Special (3+2)

in the versions with Diesel and gasoline engine.

•For the sake of clarity and ease of identification,

the different two-wheel tractor models are identi-

fied in this manual by means of the following

codes:

−1000 identifies reversible two-wheel tractors

model REV. 1000 (2+2) and REV. 1000 Diesel

(2+2).

−1000 E identifies reversible two-wheel tractors

model REV. 1000 E (2+2).

−1000 Special identifies reversible two-wheel

tractors model REV. 1000 Special (3+2) and

REV. 1000 Diesel Special (3+2)

•The first section of this manual provides technical

specifications and gives instructions relevant to

the machine. The second section of the manual

gives further details on individual attachments,

and provides all specific operating instructions.

•Read this USE and MAINTENANCE Manual care-

fully before using your new two-wheel tractor. This

manual provides the most up-to-date information

on your two-wheel tractor available at the time of

going to press. Manufacturer reserves the right to

modify this document at any time without prior no-

tice.

•AFTER-SALES SERVICE. Use only original spare

parts. The use of non-original parts voids the war-

ranty. When ordering spare parts, specify:

−two-wheel tractor serial number;

−part code of spare part required;

−quantity or number of parts required.

SAFETY REGULATIONS

GENERAL NOTICES

Any engine driven machine can become dangerous if

used incorrectly. Pay particular attention to the in-

structions in this manual marked:

WARNING

This symbol means that failure to observe the regula-

tion could cause injury or even death to the operator.

PRUDENCE

Prudence is the Golden Rule to prevent accidents.

TRAINING

The two-wheel tractor must only be used by respon-

sible people trained in the use of the machine and

duly authorized to use it.

MACHINE AND

ENGINE MANUALS

Read those MANUALS carefully before starting, us-

ing, servicing, refuelling or carrying out any work on

the two-wheel tractor.

DECALS

Read all the decals attached to the two-wheel tractor

and follow their prescriptions before starting, driving,

refuelling or servicing the machine. Replace immedi-

ately any damaged or illegible decals.

SUITABLE CLOTHING

•Do not wear wide and flapping clothes that could

be caught in moving parts.

•Always wear robust gloves when servicing the two-

wheel tractor or coupling attachments.

•Do not operate your two-wheel tractor barefoot,

wearing sandals or shorts. Wear heavy shoes and

trousers.

PHYSICAL CONDITION

Do not drive the two-wheel tractor if your physical

condition is not suitable.

NOISE

In order to reduce the problems deriving from the

noise of the machine:

•Do not work with the engine at maximum RPM

range.

•Keep the blade head and the blade holder ad-

justed.

•When using the machine for a long time, use ear

protections.

ENGINE RPM

Do not interfere with the engine speed governor: run-

ning the engine at a too high speed increases the risk

of accident.

FIRST AID

It is good operating practice to have a first aid box on

the two-wheel tractor.

GB

4

SAFETY DEVICES

•Do not use the two-wheel tractor if the safety de-

vices are missing or defective.

•Do not interfere with safety devices.

STARTING THE ENGINE

•Disengage all control levers before starting the mo-

tor. Keep your feet clear of the attachments fitted to

the two-wheel tractor.

•Do not run the engine in a closed environment

where the exhaust gases can collect. They contain

carbon monoxide that is highly toxic.

•Do not interfere with safety device (engine shut-

off). Do not use the two-wheel tractor if this safety

device is missing or defective.

•When a machine is delivered new, there is no oil in

the air filter. Before using your two-wheel tractor,

add motor oil up to the marked level.

OPERATING OF THE

TWO-WHEEL TRACTOR

•Make sure that you know how to stop the engine in

an emergency. Familiarize yourself with the con-

trols and learn how to use your two-wheel tractor

correctly.

•Do not allow children or inexperienced people to

operate it.

•Do not use your two-wheel tractor in proximity of

other people, and in particular of children. Do not

use it close to animals. Bear in mind that you are

responsible for any damage or injury caused to

people or things.

•Do not use the rotary tiller attachment without its

protection hood and guards.

•Use your two-wheel tractor only in daylight or with

good artificial lighting. Operate it at walking pace.

Do not run.

•Take particular care on slopes; operate only under

safe and stable conditions. Do not work uphill or

downhill; move across the slope instead. Take spe-

cial care when turning.

•For obvious reasons, never work on slopes steeper

than 30°.

•To ensure that gasoline fuelled engines are cor-

rectly lubricated, avoid working for long periods on

slopes steeper than 20°.

•Do not operate the two-wheel tractor if hoods or

other safety devices are missing or defective.

•Keep your hands and feet clear of all attachments.

•Do not lift or transport your two-wheel tractor with

the engine running.

•Inspect the ground before you start working. Clear

it from stones, wood, wires and any other foreign

objects.

OPERATING OF ATTACHMENTS

•Check that the attachment coupled to the PTO

functions correctly before starting the motor.

•Never use attachments coupled to the PTO in prox-

imity of children or animals.

•Keep your hands and feet well clear of the attach-

ment coupled to the PTO.

•Before using an attachment, make sure that the

reverse speed safety device has been set as re-

quired (this can be used when the front-mounted

attachments are fitted, and not when the tiller is ro-

tating).

•When a front-mounted attachment is installed, the

handlebars are rotated through 180°, hence the

gear and PTO levers are reversed.

−The Manufacturer waives any responsibility

arising from improper use of the safety device.

MAINTENANCE

•Stop the engine and disconnect the spark plug

lead:

−before checking or repairing your two-wheel trac-

tor;

GB

5

−in case of excessive vibrations (investigate cause

immediately).

•Stop the engine before adjusting attachments.

•Periodically check that all nuts and bolts are tight.

•Do not leave your two-wheel tractor in closed am-

bient with fuel in the tank. Fuel vapour is a potential

source of danger.

•Keep your two-wheel tractor clean. Do not let grass

and oil residues build up: these are a fire hazard.

•Fuel is highly flammable. Store fuel only in spe-

cifically designed containers. Refuel your two-

wheel tractor in the open. Do not smoke while re-

fuelling.

•Complete refuelling before starting the engine. Do

not remove the fuel cap or refuel when the engine

is running or hot. In case of fuel spillage, do not

start the engine. Push your two-wheel tractor some

distance away from where the spillage occurred

before starting it.

•Replace the exhaust pipe if it becomes worn or

damaged.

IDENTIFICATION DATA

TWO-WHEEL TRACTOR IDENTIFICATION

The serial number is stamped on the engine side of

the gear box of your two-wheel tractor (see fig. 1, item

1).

ENGINE IDENTIFICATION

Refer to the engine Operation and Maintenance Man-

ual.

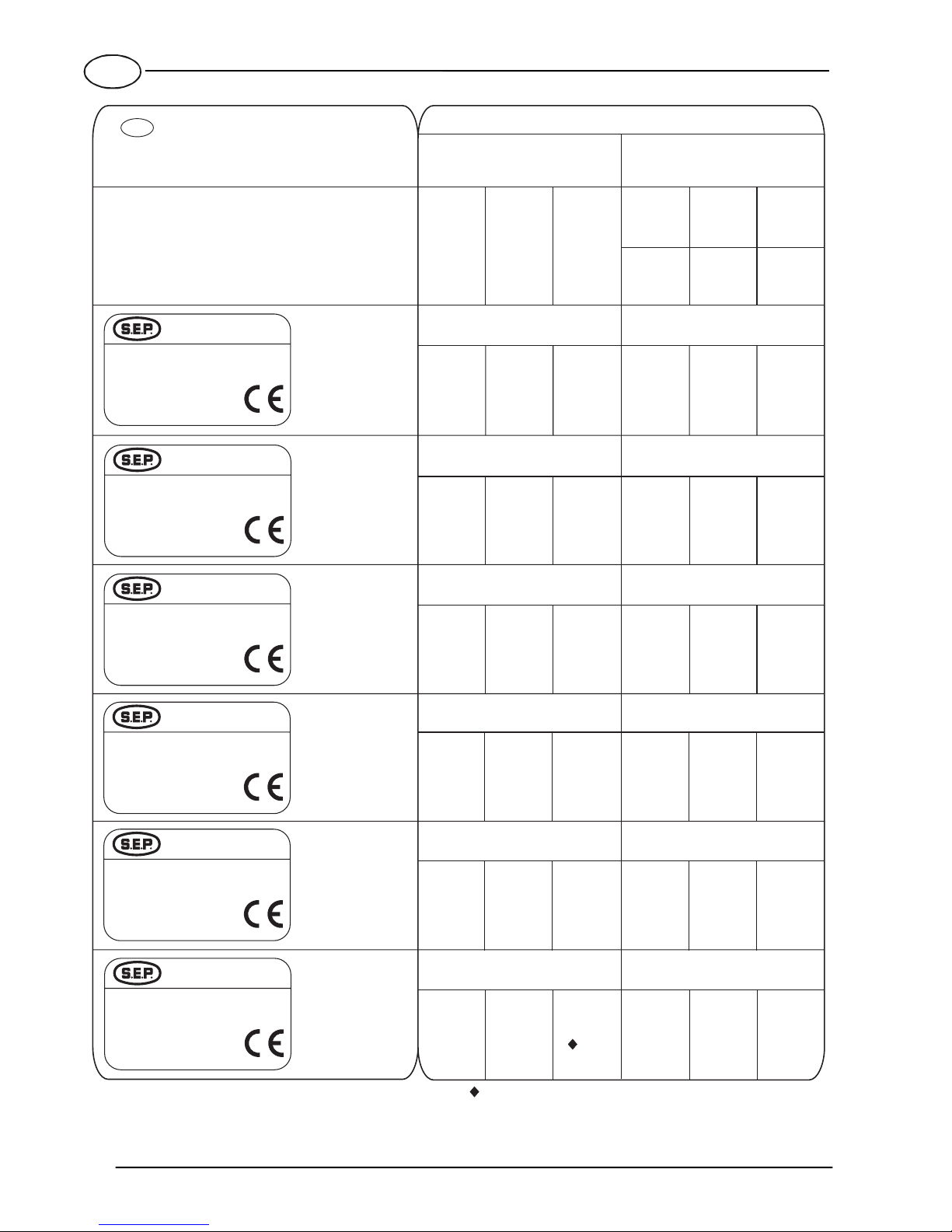

EC MARKING

The two-wheel tractor is marked EC in compliance with

the Directive of the European Community Council

89/392/EEC and further amendments (see fig. 1, item 2).

The summary of the EC marking related to the 1000

and 1000 Special models are indicated below.

GB

6

Test conditions:

- P.T.O.: Disengaged - machinestationary on a

concrete plane surface

Test conditions: - P.T.O.: Engaged

Sound

pressure on

operator’s ears

dB(A)

Sound

pressure on

operator’s ears

dB(A)

(Macchine

stationary

on a grass

surface)

(Macchine

stationary on a

concrete surface

with an interposed

elastic layer)

(Machine

running on a

concrete surface

with an interposed

elastic layer)

Acoustic power

dB(A)

Acoustic power

dB(A)

Acceleration

on hangrip

EN 1033 - 28662/1

m/sec2

Acceleration

on hangrip

EN 1033 - 28662/1

m/sec2

NOISE AND VIBRATIONS

TYPE OF MARKING

TWO-WHEEL TRACTOR 1000 (2+2)

Models:

(punched on the gearbox)

1000 (2+2) - 1000 Diesel (2+2)

Progressiv unit number starting from AG03838

81,5 -86 102,5 -

With SICKLE BAR MOWER cm. 117With ROTARY TILLER cm. 60

Engine:

Mass (weight):

HONDA GX 160

cm. 60

with wheels 4.00-8

with rotary tiller

Modello tipo:

N. Serie:

Mot.:

Potenza: kW/ rpm

Anno di Fabbricazione:

Massa: kg

1000 (2+2)

GX 160

4 3600

83,500

BH25X00000

MT2001-4GB

S/N reading: type of machine

year of manufacturing

000 week of production

00 progressiv n° of production

X

00

000

BH25

VALPADANA

42018 SAN MARTINO IN RIO

REGGIO EMILIA - ITALY

S.p.A.

84,5 -2,63 87,5 103,5 12,48

With SICKLE BAR MOWER cm. 117With ROTARY TILLER cm. 60

Engine:

Mass (weight):

LOMBARDINI 1 IM 359

cm. 60

with wheels 4.00-8

with rotary tiller

Modello tipo:

N. Serie:

Mot.:

Potenza: kW/ rpm

Anno di Fabbricazione:

Massa: kg

1000 (2+2)

1 IM 359

6,6 3600

94,500

BH25X00000

VALPADANA

42018 SAN MARTINO IN RIO

REGGIO EMILIA - ITALY

S.p.A.

89,5 103,5 2,89 89 107,5 12,08

With SICKLE BAR MOWER cm. 117With ROTARY TILLER cm. 60

Engine:

Mass (weight):

LOMBARDINI 15 LD 315

4.00-10

with rotary tiller cm. 60

with wheels

Modello tipo:

N. Serie:

Mot.:

Potenza: kW/ rpm

Anno di Fabbricazione:

Massa: kg

1000 Diesel (2+2)

15 LD 315

5 3600

121,500

BH25X00000

VALPADANA

42018 SAN MARTINO IN RIO

REGGIO EMILIA - ITALY

S.p.A.

<2,5

GB

93 103,6

14

89 107,5 12,08

With SICKLE BAR MOWER cm. 117With ROTARY TILLER cm. 60

Engine:

Mass (weight):

YANMAR L70

4.00-10

with rotary tiller cm. 60

with wheels

Modello tipo:

N. Serie:

Mot.:

Potenza: kW/ rpm

Anno di Fabbricazione:

Massa: kg

1000 Diesel (2+2)

L70

5,7 3600

115,500

BH25X00000

VALPADANA

42018 SAN MARTINO IN RIO

REGGIO EMILIA - ITALY

S.p.A.

100% max peak R.P.M.

6,4

-----

With SICKLE BAR MOWER cm. 117With ROTARY TILLER cm. 60

Engine:

Mass (weight):

HONDA GX 200

cm. 60

with wheels 4.00-8

with rotary tiller

Modello tipo:

N. Serie:

Mot.:

Potenza: kW/ rpm

Anno di Fabbricazione:

Massa: kg

1000 (2+2)

GX 200

4 3600

85,000

BH25X00000

VALPADANA

42018 SAN MARTINO IN RIO

REGGIO EMILIA - ITALY

S.p.A.

-

-----

With SICKLE BAR MOWER cm. 117With ROTARY TILLER cm. 60

Engine:

Mass (weight):

ROBIN EX 27

cm. 60

with wheels 4.00-8

with rotary tiller

Modello tipo:

N. Serie:

Mot.:

Potenza: kW/ rpm

Anno di Fabbricazione:

Massa: kg

1000 (2+2)

EX 27

5,9 3600

90,000

BH25X00000

VALPADANA

42018 SAN MARTINO IN RIO

REGGIO EMILIA - ITALY

S.p.A.

-

GB

7

Test conditions:

- P.T.O.: Disengaged - machinestationary on a

concrete plane surface

Test conditions: - P.T.O.: Engaged

Sound

pressure on

operator’s ears

dB(A)

Sound

pressure on

operator’s ears

dB(A)

(Macchine

stationary

on a grass

surface)

(Macchine

stationary on a

concrete surface

with an interposed

elastic layer)

(Machine

running on a

concrete surface

with an interposed

elastic layer)

Acoustic power

dB(A)

Acoustic power

dB(A)

Acceleration

on hangrip

EN 1033 - 28662/1

m/sec2

Acceleration

on hangrip

EN 1033 - 28662/1

m/sec2

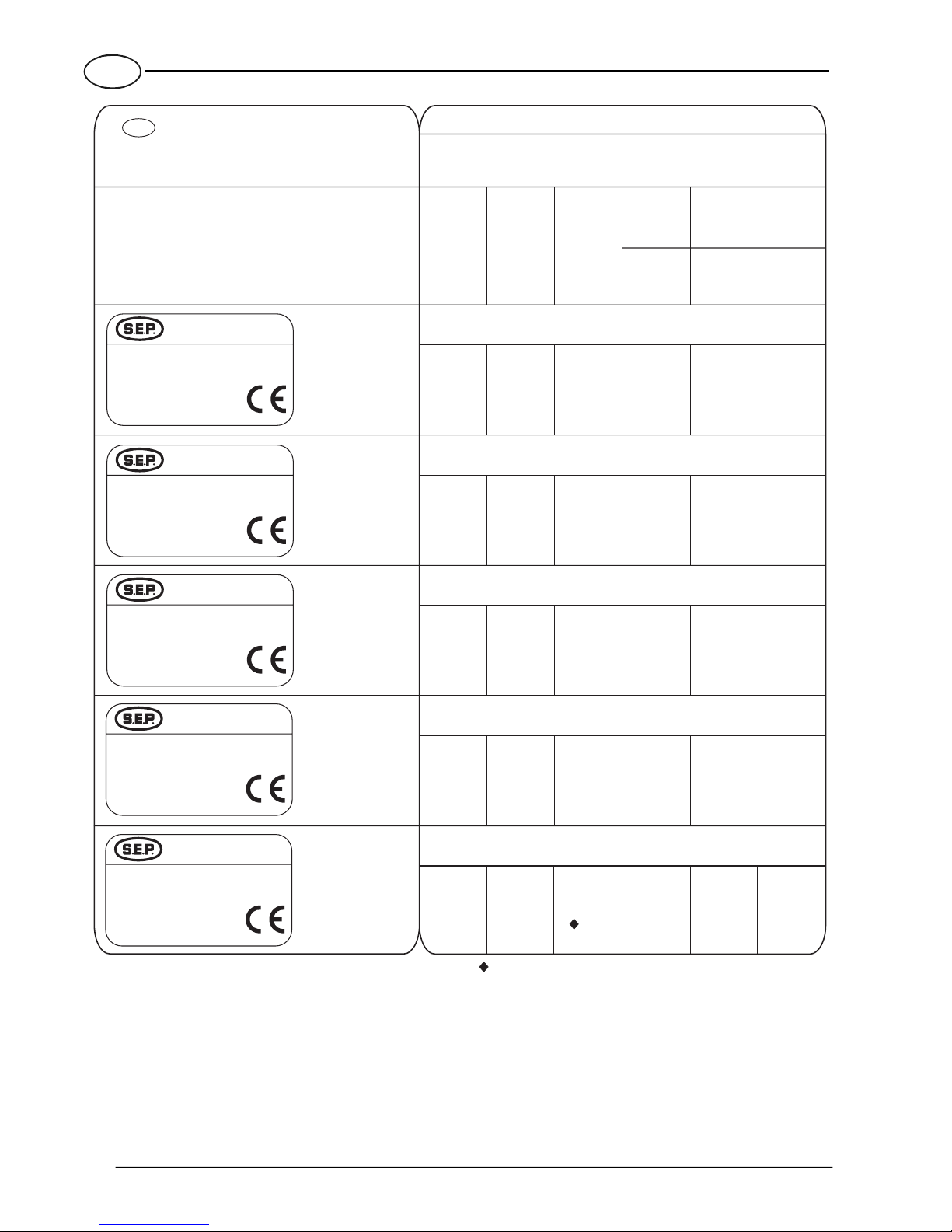

NOISE AND VIBRATIONS

Models:

()

1000 (2+2) E

Progressiv unit number starting from

punched on the gearbox

AG03838

81,5 -86 102,5 12,48

With SICKLE BAR MOWER cm. 117With ROTARY TILLER cm. 50

Engine:

HONDA GC 160

4.00-8

cm. 50

Mass (weight):

with wheels

with rotary tiller

Modello tipo:

N. Serie:

Mot.:

Potenza: kW/ rpm

Anno di Fabbricazione:

Massa: kg

1000 (2+2)

GC 160

3,7 3600

78,000

BH25X00000

S/N reading: type of machine

year of manufacturing

000 week of production

00 progressiv n° of production

BH25

X

00

000

VALPADANA

42018 SAN MARTINO IN RIO

REGGIO EMILIA - ITALY

S.p.A.

<2,5

TYPE OF MARKING

TWO-WHEEL TRACTOR 1000 (2+2) E

GB

GB

8

Modello tipo:

N. Serie:

Mot.:

Potenza: kW/ rpm

Anno di Fabbricazione:

Massa: kg

1000 Special (3+2)

1IM359

6,6 3600

111,000

BH50X00000

Engine:

Mass (weight):

LOMBARDINI 1 IM 359

with wheels 4.00-10

with rotary tiller cm. 60

84,5 2,63 87,5 103,5 12,48

With SICKLE BAR MOWER cm. 117

TYPE OF MARKING

TWO-WHEEL TRACTOR 1000 (3+2)

Models: 1000 Special (3+2) - 1000 Diesel Special (3+2)

Progressiv unit number starting from

(punched on the gearbox)

AD01852

With ROTARY TILLER cm. 60

-

89,5 103,5 2,89 89 107,5 12,08

With SICKLE BAR MOWER cm. 117With ROTARY TILLER cm. 60

Engine:

LOMBARDINI 15 LD 315

cm. 60

Mass (weight):

with wheels 4.00-10

with rotary tiller

Modello tipo:

N. Serie:

Mot.:

Potenza: kW/ rpm

Anno di Fabbricazione:

Massa: kg

15 LD 315

5 3600

133,000

1000 Diesel Special (3+2)

BH50X00000

VALPADANA

42018 SAN MARTINO IN RIO

REGGIO EMILIA - ITALY

S.p.A.

VALPADANA

42018 SAN MARTINO IN RIO

REGGIO EMILIA - ITALY

S.p.A.

Test conditions: - Engine R.P.M.: 85% peak R.P.M.

- P.T.O.: Disengaged - machinestationary on a

concrete plane surface

Test conditions: - P.T.O.: Engaged

Sound

pressure on

operator’s ears

dB(A)

Sound

pressure on

operator’s ears

dB(A)

(Macchine

stationary

on a grass

surface)

(Macchine

stationary on a

concrete surface

with an interposed

elastic layer)

(Machine

running on a

concrete surface

with an interposed

elastic layer)

Acoustic power

dB(A)

Acoustic power

dB(A)

Acceleration

on hangrip

EN 1033 - 28662/1

m/sec2

Acceleration

on hangrip

EN 1033 - 28662/1

m/sec2

NOISE AND VIBRATIONS

GB

93 103,6 89 107,5 12,08

With SICKLE BAR MOWER cm. 117With ROTARY TILLER cm. 60

Engine:

YANMAR L70

cm. 60

Mass (weight):

with wheels 4.00-10

with rotary tiller

Modello tipo:

N. Serie:

Mot.:

Potenza: kW/ rpm

Anno di Fabbricazione:

Massa: kg

L70

5,7 3600

125,500

1000 Diesel Special (3+2)

BH50X00000

MT2002-4GB

S/N reading: type of machine

year of manufacturing

000 week of production

00 progressiv n° of production

X

00

000

BH50

VALPADANA

42018 SAN MARTINO IN RIO

REGGIO EMILIA - ITALY

S.p.A.

14

100% max peak R.P.M.

6,4

Modello tipo:

N. Serie:

Mot.:

Potenza: kW/ rpm

Anno di Fabbricazione:

Massa: kg

1000 Special (3+2)

GX 200

6,5 3600

111,000

BH50X00000

Engine:

Mass (weight):

HONDA GX 200

with wheels 4.00-10

with rotary tiller cm. 60

-----

With SICKLE BAR MOWER cm. 117With ROTARY TILLER cm. 60

-

VALPADANA

42018 SAN MARTINO IN RIO

REGGIO EMILIA - ITALY

S.p.A.

Modello tipo:

N. Serie:

Mot.:

Potenza: kW/ rpm

Anno di Fabbricazione:

Massa: kg

1000 Special (3+2)

EX 27

5,9 3600

116,000

BH50X00000

Engine:

Mass (weight):

ROBIN EX 27

with wheels 4.00-10

with rotary tiller cm. 60

-----

With SICKLE BAR MOWER cm. 117With ROTARY TILLER cm. 60

-

VALPADANA

42018 SAN MARTINO IN RIO

REGGIO EMILIA - ITALY

S.p.A.

GB

9

TECHNICAL SPECIFICATIONS

ENGINE

The two-wheel tractor may be fitted with the following

engines:

−HONDA GC 160; 4 stroke gasoline;

3,7 kW (5 HP); 160 cm3.

−HONDA GX 160; 4 stroke gasoline;

4 kW (5,5 HP); 163 cm3.

−HONDA GX 200; 4 stroke gasoline;

4,8 kW (6,5 HP); 198 cm3.

−ROBIN EX 27; 4 stroke gasoline;

5,9 kW (8 HP); 265 cm3.

−LOMBARDINI 1 IM 359; 4 stroke gasoline;

6,6 kW (9 HP); 349 cm3.

−LOMBARDINI 15 LD 315; 4 stroke Diesel;

5 kW (6,7 HP); 315 cm3.

−YANMAR L70; 4 stroke Diesel;

5,7 kW (7,7 HP); 296 cm3.

STARTING

Rewind start device as standard. Some models may

be fitted with electric starter upon request.

ELECTRIC STARTING (upon request)

Upon request, two-wheel tractors can be fitted with

electric starter with key control.

The 12 V battery has a capacity (40 hours) equal to

28 Ah.

CLUTCH

Multi plate dry clutch with control lever on left han-

dlebar.

SPEEDS

Speeds are engaged through a lever fitted to the col-

umn.

Models 1000 (2+2)

Two-wheels tractor configuration: 2 forward speeds

and 1 reverse speeds.

Configuration with front-mounted attachments: 2 for-

ward speeds and 2 reverse speeds.

MAXIMUM SPEED km/h

MOD. 1000 (2+2) – 1000 E (2+2)

NOTE:

Tyres

4.00-8

Models 1000 (3+2)

Two-wheel tractor configuration: 3 forward speeds

and 1 reverse speeds.

Configuration with front-mounted attachments: 2 for-

ward speeds and 2 reverse speeds.

When the machine is fitted with front-mounted at-

tachments, forward speeds become reverse speeds

and vice versa because of reversal of the direction of

motion. The maximum speed that can be attained in

the different speeds is indicated in the following table.

VELOCITA’ MASSIMA IN km/h

MOD. 1000 (3+2)

NOTA:

Pneumatici

4.00-8

TRANSMISSION

Mechanical oil bath gear box type.

DIFFERENTIAL GEAR

(Special versions)

It can be actuated by a control lever fitted to the left

handlebar (locking/unlocking).

POWER TAKE OFF (PTO)

Mounted attachments are driven via an independent,

single speed PTO engaged by a control lever on the

handlebars.

Maximum PTO speed: 943 rpm (clockwise rotation).

COUPLING OF ATTACHMENTS

Coupling of attachments to the PTO is obtained

through a quick change fitting that provides for fast

installation and removal of the attachments, and does

not require the use of bolts, nuts or spanner.

HANDLEBARS

Adjustable in height and width. Rotate handlebars

through 180° when front-mounted attachments are

used.

BRAKES (SPECIAL VERSIONS)

Mechanical controlled, independent on the two

wheels, applied by levers on the right handlebar.

WHEELS/TYRES

−Tyres with agricultural tread.

−Available sizes:

Mod. 1000 E:

4.00-8.

Mod. 1000 - 1000 Special:

4.00-8, 4.0-10 with adjustable track, 16X6.50-8.

−Inflation pressure: 1.2 bar.

GB

10

NOTE

The instructions covering track adjustment, based on

machine model and type of wheel, are given in a spe-

cific paragraph in this manual.

ACCESSORIES

The two-wheel tractor can be fitted with a wide range

of additional easy-to-fit accessories.

These are, for instance, several types of iron wheels,

watering pumps and sprayers, snow ploughs,

ploughs, trailers, water sprinkling trolleys, etc.

Refer to our catalogue for details about the various

accessories available.

MASS

Refer to the identification plate installed on the ma-

chine.

DIMENSIONS

The overall dimensions of the two-wheel tractor are

shown in fig. 2.

2

MOTOR-MOWER

TWO-WHEEL TRACTOR

590

1735

800

460 Standard

550 Special

950 ÷ 1270 550 900

1850

650 ÷ 1360

500 ÷ 1250

600

GB

11

SAFETY DEVICES

The two-wheel tractor is fitted with the following safety

devices to ensure maximum safety:

−Automatic PTO disengagement device. This is a

mechanical device that prevents shift into reverse

speed when the PTO is rotating (two-wheel tractor

configuration only).

−Engine shut-off. This is an electrical or mechanical

device (Diesel) that stops the engine as soon as

the handlebars are released.

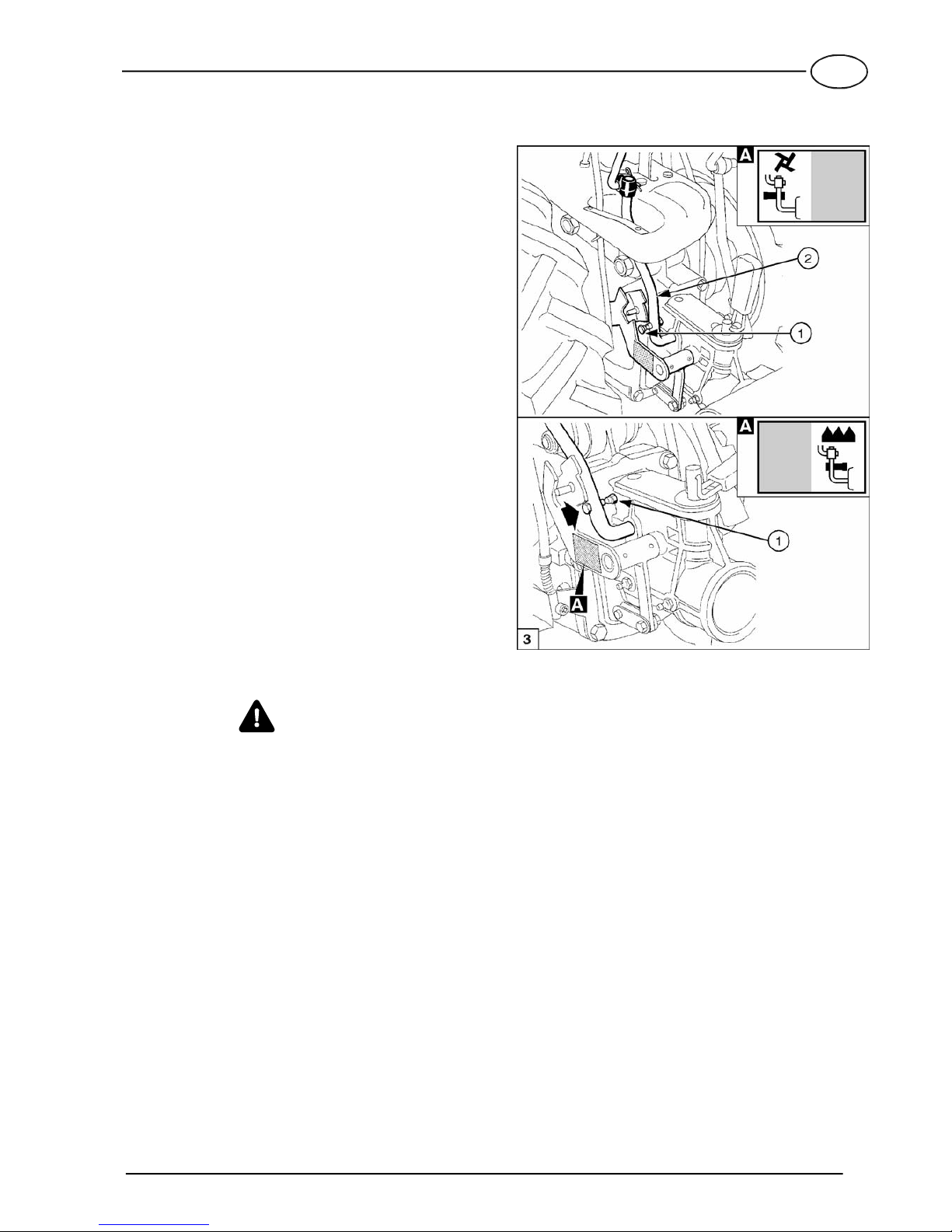

REVERSE SPEED SAFETY DEVICE

The two-wheel tractor is provided with an operator-

adjusted safety device that prevents concurrent use

of reverse speed and attachment when the rotary tiller

is fitted.

This device consists of a pin (see fig. 3, item 1) in-

stalled on the PTO control lever (2).

Disengage the PTO before removing the pin (1) and

adjusting its position.

The placard illustrated in detail A shows the position

of pin (1) as a function of the machine configuration.

−Pin pulled out: when the pin is pulled out, as

shown in the top half of fig. 3, reverse speed can

be engaged only after uncoupling the PTO (ma-

chine in two-wheel tractor version).

−Pin pushed in: when the pin is in the position illus-

trated in the bottom half of fig. 3, reverse speed

can be engaged also when the PTO is operating

(machine fitted with front-mounted attachments).

WARNING

It is mandatory to check that the safety pin is posi-

tioned as required for the selected operating configu-

ration (two-wheel tractor or front-mounted attach-

ments).

The Manufacturer waives any responsibility arising

from the incorrect use of the safety device.

GB

12

TRANSFER PRINTING -

INSTRUCTIONS AND SAFETY

Please find below the adhesive transfer printing shown

on the machine. For accident prevention purposes,

they must always be clearly readable. Should they be

damaged, it is compulsory to replace them by request-

ing the original spare part from the Manufacturer.

GB

13

TWO-WHEEL TRACTOR CONTROLS

See fig. 4.

1. Clutch lever.

2. Engine stop lever.

3. Differential lock lever.

4. PTO control lever (Note 1).

5. Handlebar vertical lock release lever.

6. Gear lever (Note 2).

7. 3rd speed preselection control lever

(versions 3+2).

8. Throttle control lever.

9. R.H. brake lever (Special versions).

10.L.H. brake lever (Special versions).

11.PTO instant adaptor.

NOTE 1: When the machine is fitted with front-

mounted attachments, this lever becomes

the gear lever.

NOTE 2: When the machine is fitted with front-

mounted attachments, this lever becomes

the PTO control lever.

OPERATING THE CONTROLS

Clutch lever

(See fig. 5)

−Lever (1) pulled up: clutch disengaged.

−Lever (1) released: clutch engaged.

Engine stop lever

(See fig. 5)

−Lever (2) pressed down: engine running.

−Lever (2) released: engine stopped.

Differential lock lever

(Special versions)

You can lock the differential when operating on diffi-

cult terrain in order to obtain maximum traction.

CAUTION

Use the differential lock while working in a straight

line only.

To lock and unlock the differential proceed as follows

(see fig. 5):

a. To lock the differential, slow down the two-wheel

tractor, and push the differential lock lever (3) for-

ward.

b. To unlock the differential, pull the clutch lever (1)

and pull the differential lock lever (3) backward.

A plate on the left handlebar (see detail A) illustrates

the use of the differential lock lever.

GB

14

Gear lever

CAUTION

When using the machine as a motor mower, the han-

dlebars must be rotated through 180°.

The gear and PTO control levers therefore inter-

change position. See page 17 for details.

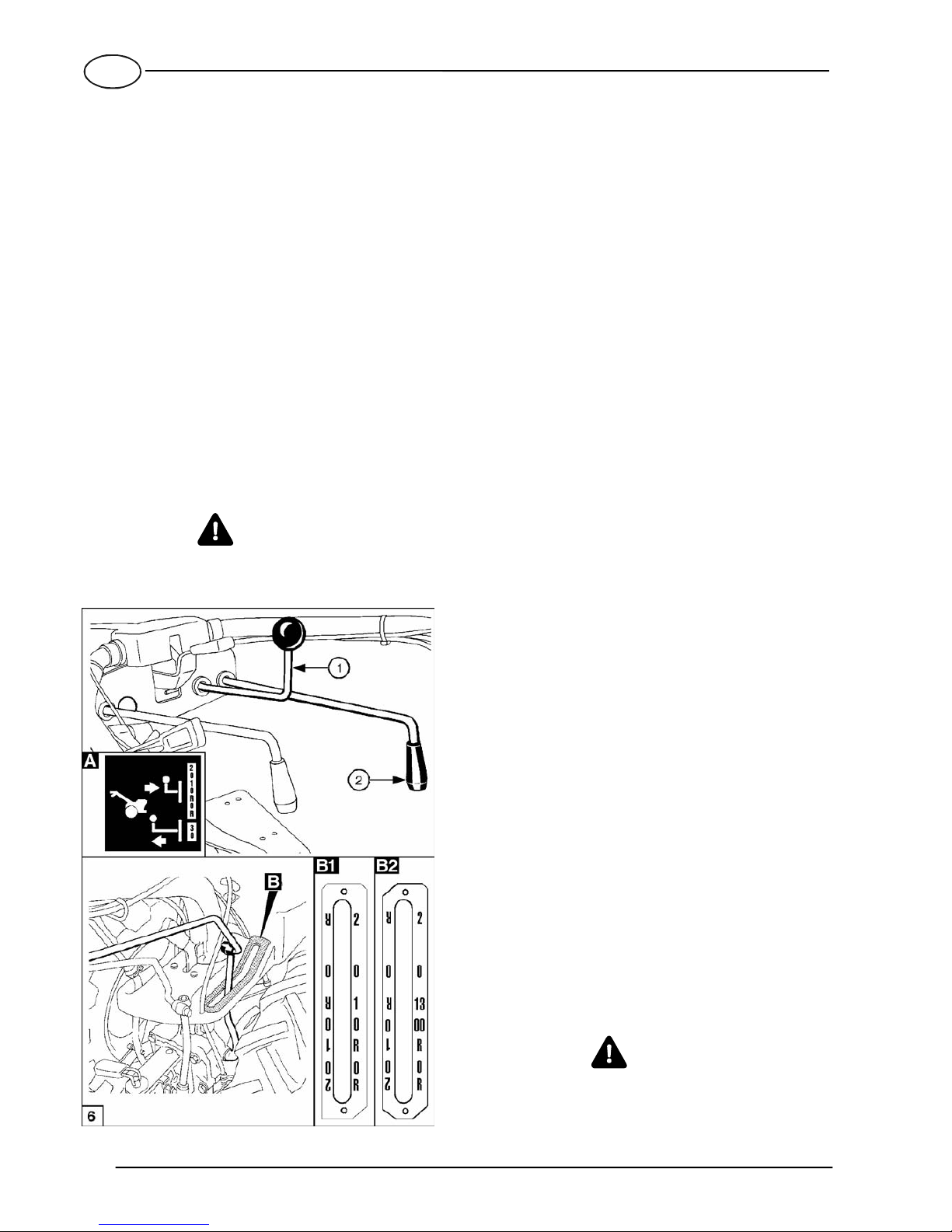

Use the gear lever as shown below (see fig. 6):

a. Turn the throttle control lever to idle position.

b. Pull up clutch lever.

c. Move the lever to the neutral position.

d. Set the speed preselection control lever (1) (only

for versions 3+2) to the fully forward position (see

the placard shown in detail A).

e. Move the gear lever (2) to the required position

(see the plate illustrated in detail B1), and release

it as soon as the gear is engaged.

f. Gradually release the clutch lever while accelerat-

ing the engine.

g. To disengage gear, pull up the clutch lever and

move gear lever (2) to the neutral position.

WARNING

A safety device does not permit reverse speed to be

engaged when the PTO is operating (rotary tilling).

3rd speed preselection control lever

(two-wheel tractor version Special 3+2)

The Special version of the two-wheel tractor is fitted

with a preselection lever for engagement of the 3rd

speed (forward speed only).

The levers are operated as follows (see fig. 6):

a. Turn the throttle control lever to idle position.

b. Pull up clutch lever.

c. Move the gear lever (2) to the neutral position “0”

which is indicated by the YELLOW marking.

d. Pull the 3rd speed preselection control lever (1) to

the fully aft position (see the placard shown in de-

tail A).

e. Move the gear lever (2) to position 3 which is indi-

cated by the YELLOW marking (see the placard

shown in detail B2), and release the lever after en-

gagement is obtained.

f. Slowly release the clutch lever while accelerating

the engine.

g. To disengage the 3rd speed, pull the clutch lever,

and return the lever (2) to position “0” which is in-

dicated by the YELLOW marking.

CAUTION

To return the two-wheel tractor to the configuration of

version 2+2, it is necesssary to move the speed pre-

selection control lever (1) back to the fully forward

position.

Power Take Off (PTO) control lever

(two-wheel tractor configuration)

CAUTION

When using the machine as a motor mower, the han-

dlebars must be rotated through 180°.

The gear lever and PTO control lever therefore inter-

change position. See page 17 for details.

The Power Take Off (PTO) control lever engages the

drive to the rotary tiller.

To engage and disengage drive, proceed as follows

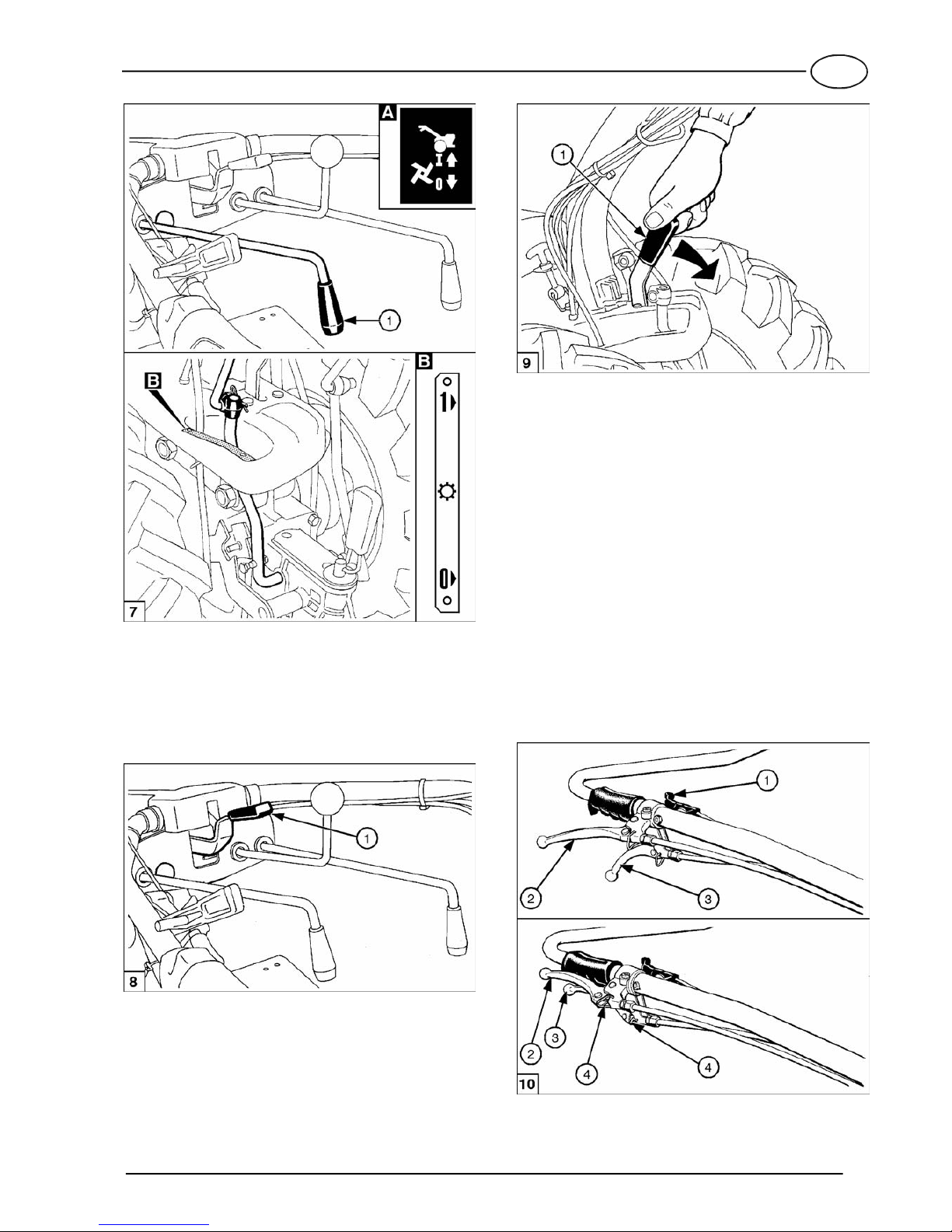

(see fig. 7):

a. Turn throttle control lever to idle position.

b. Pull up clutch lever.

c. Pull PTO control lever (1) and release it when drive

is engaged (see plate in detail A and B).

d. Release the clutch lever while accelerating the en-

gine.

CAUTION

The clutch lever must be released slowly to prevent

damage to the drive. Do not start working with at-

tachment under load.

WARNING

A safety device prevents you from using the rotary

tiller attachment in reverse speed.

Do not use the two-wheel tractor if this safety device

is not correctly installed.

GB

15

Handlebar vertical lock release lever

(See fig. 8)

This allows the handle to be adjusted vertically to suit

driving comfort and tilling depth.

Simply push lever (1) down to release the handles.

Handlebar sideway lock release lever

(See fig. 9)

By releasing the lock, you can rotate the handlebars

to use the front-mounted attachments.

Simply push lever (1) down to release the handle-

bars.

Throttle control lever

(See fig. 10)

−Lever (1) in up position: engine at idle.

−Lever (1) in down position: max engine rpm.

Brake levers

(Special versions)

The brakes act independently on the two wheels, and

can be used separately to assist tight cornering as

well as together to slow the machine in a straight line.

Use the brakes as follows (see fig. 10):

a. To turn right, pull up the right hand brake lever (2).

b. To turn left, pull up the left hand brake lever (3).

PARKING BRAKE

(See fig. 10)

To lock the wheels for parking, pull up both brake lev-

ers (2) and (3), and engage brake locks (4).

GB

16

PTO Instant adaptor

This allows attachments to be coupled and de-

coupled quickly and easily to and from the PTO.

The lever (1) has two positions (see fig. 11):

−Locked position: pull up lever (1).

−Released position: push down lever (1).

A decal (see detail A) near the PTO instant adaptor

lever illustrates operation. See page 18 for instruc-

tions on how to fit the attachments.

CONTROLS OF FRONT-MOUNTED

ATTACHMENTS

When the machine is used with front-mounted at-

tachments, the gear and the PTO levers are reversed

with respect to when the machine is used as a two-

wheel tract. This is due to reversal of the direction of

motion. Lever (fig. 12, item 1) becomes the gear lever,

and lever (2) becomes the PTO control lever.

The symbols shown in figure 12 and applied to the

column, remind the user about the functions of the

levers.

OPERATING THE

TWO-WHEEL TRACTOR

WARNING

Before operating your two-wheel tractor, read care-

fully and commit to memory the instructions given in

the “SAFETY REGULATIONS” paragraph at the be-

ginning of this manual.

STARTING THE ENGINE

NOTE

See the engine Operation and Maintenance Manual

for all informations regarding the engine.

CAUTION

Oil bath air filter (if fitted) - When delivered new,

there is no oil in the air filter.

Before using your two-wheel tractor, add motor oil up

to the marked level.

a. Disengage all control levers before starting the

engine.

b. Gasoline engines: in order to gain access to the

refuelling cap, it is necessary to open the hood.

Unlock the turnbuckle (fig. 13, item 1), open the

hood (2), and rotate the lever (3) upward.

c. Gasoline engines: open the fuel cock.

d. Gasoline engines: if cold starting the engine, use

the choke.

e. Press down the engine stop lever (fig. 14, item 1).

f. Pull clutch lever (2) fully up.

GB

17

g. Lock the clutch lever (2) in position with locking

device (3).

h. Turn throttle control lever (4) for 1/4 turn.

i. Gasoline engines: grip the pull-rope handle and

pull firmly and quickly. When the engine starts, al-

low the rope to wind back onto the reel slowly.

Diesel engines: manually wind the rope on the

reel, and pull firmly and quickly.

j. Turn the throttle control lever (4) to idle position,

and allow the engine to warm up.

NOTE

Do not leave the clutch lever pulled up for an ex-

tended length of time after the engine has started.

This could cause damage to the clutch.

STOPPING THE ENGINE

a. Turn throttle control lever (fig. 15, item 1) to idle

position.

b. Release the engine stop lever (2).

c. Gasoline engines: if you plan not to use your

two-wheel tractor for a long time, shut off the fuel

cock.

d. Gasoline engines: if you plan not to use your

two-wheel tractor for a long time (over a week),

drain the carburettor bowl.

WARNING

The engine stop lever (2) also operates as a safety

device (emergency stop), and stops the engine as

soon as it is released.

FITTING FRONT-MOUNTED

ATTACHMENTS

Before fitting a front-mounted attachment (cutter bar

mower, rotary mower, snow thrower, etc.) you must

set the safety device in “motor mower” configuration,

remove the 3rd speed preselection control lever and

reverse the handlebars and the position of the

wheels.

NOTE

The control cables that are routed to the top part of

the gearbox are the following:

−clutch control cable;

−differential gear control cable;

−right wheel brake control cable;

−left wheel brake control cable.

Check that the position of the cables in the two-wheel

tractor version is as shown in fig. 16.

SAFETY DEVICE

Set the reverse speed safety device in the correct po-

sition as regards the direction of travel (see fig. 3).

WARNING

•Before using the machine, check that the locking

pin is in correct position

•Before using the machine in two-wheel tractor con-

figuration, you must position the locking pin as re-

quired to prevent engagement of the PTO when the

tiller is rotating, as shown in figure 3.

GB

18

REMOVAL OF 3rd SPEED

PRESELECTION CONTROL LEVER

When front-mounted attachments are used, it is nec-

essary to remove the 3rd speed preselection control

lever from the machine. To do this, proceed as follows

(see fig. 17):

a. Move the preselection control lever (1) to the fully

forward position.

b. Release the spring clip (2), and slide the terminal

of the lever (1) out of the control pin (3). Pull up-

ward.

CAUTION

The above operations cannot be carried out if the pre-

selection control lever (1) is not correctly positioned

(it is not pushed to the fully forward position) as inter-

ference with the locking pawl could result.

c. Unscrew the knob (4) from the lever (1).

d. Slide the lever (1) out of its housing on the han-

dlebar support (6).

CAUTION

The joint (5) between the lever (1) and its terminal

must not be disassembled. Keep the lever assembly

in a safe place for reuse when the machine is oper-

ated in two-wheel tractor version.

e. When the machine is used again in two-wheel

tractor version (3rd speed available), reinstall the

preselection control lever assembly (1) by carrying

out the procedure described above in a reverse

order.

REVERSING THE HANDLEBARS

Rotate the handlebars through 180° to operate the

machine in the changed direction of motion.

Proceed as follows (see fig. 18):

a. Remove pins (1) and (2) connecting the gear rod

(3) and the PTO control rod (4).

b. Push lever (5) downward, and rotate the handle-

bars sideways through 180° in clockwise direction.

c. Release lever (5), and lock the handlebars.

d. Connect again the gear (3) and PTO (4) control

rods to the corresponding control levers and se-

cure with pins (1) and (2).

NOTE

While reversing the handlebars, make sure that the

cables do not become tangled or caught.

REVERSING THE WHEELS

Every time you use a front-mounted attachment, the

wheels must be interchanged to keep the tread pat-

tern pointing in the right direction.

Simply remove each wheel from its hub and install it

on the opposite hub.

An arrow on the sidewall of the tire indicates the cor-

rect direction of rotation.

This manual suits for next models

1

Table of contents