S:FLEX FLAT DIRECT User manual

S:FLEX FLAT DIRECT

For foil, bitumen and sandwich roofs

- WITHOUT roof penetration

1

© S:FLEX GmbH 04/2020/ Technical changes reserved

Assembly Instructions

Photovoltaic Fastening Systems

S:FLEX GmbH • Reinbeker Weg 9 21029 Hamburg Tel. +49 (0)40 688 93 17 0 • Elsässer Str. 12 79189 Bad Krozingen Tel. +49 (0)761 888 56 08 0

info@sex.com www.sex.com © S:FLEX GmbH 04/2020/ Subject to technical modications

Table of contents

2

Introduction1

1.1 Intended use 3

1.2 About this document 3

1.3 Warnings 4

1.4 General information — standards and guidelines 4

1.5 Description of the system 6

Installation - S:FLEX FLAT DIRECT2

2.1 System components 10

2.2 Installing the ground rail 12

2.3 Installing the mounting rails ST-AK 7/47 13

2.3.1 Foil and bitumen roofs 14

2.3.2 Sandwich roofs 15

Disassembly and disposal3

3.1 Disassembly 36

Terms of use and warranty4

4.2 Warranty / disclaimer 37

2.4 Installing the splice 16

2.5 Ridge connector 18

2.6 Ballast block 19

2.7 Option 1: Counterweight 20

2.8 Option 2: Roof fastening 22

3.2 Disposal 36

4.1 User agreement for the S:FLEX FLAT DIRECT 37

2.10 Covering cable duct 34

2.11 Final inspection 35

2.7.1 Counterweight with double-sided module layout and ridge connection 20

2.7.2 Counterweight with ballast and ridge connection 21

2.8.1 Assembly post 23

2.8.2 Solar fasteners 26

2.9 Module assembly 29

S:FLEX GmbH • Reinbeker Weg 9 21029 Hamburg Tel. +49 (0)40 688 93 17 0 • Elsässer Str. 12 79189 Bad Krozingen Tel. +49 (0)761 888 56 08 0

info@sex.com www.sex.com © S:FLEX GmbH 04/2020/ Subject to technical modications

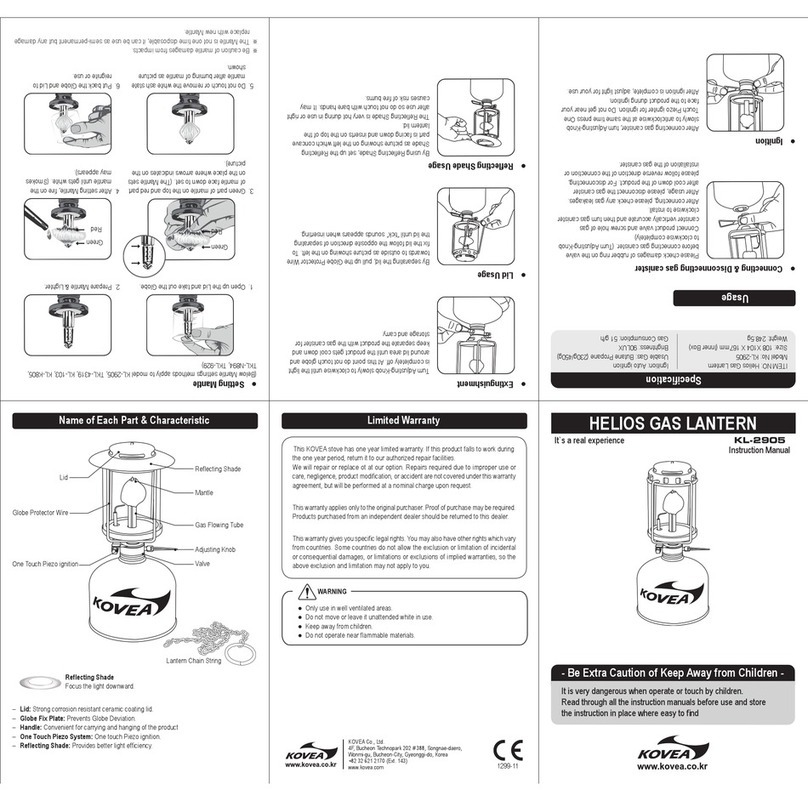

1 Introduction

Read these installation guidelines carefully before installing the S:FLEX mounting system and retain

them for future reference! These installation guidelines are only complete with the project-specic

implementation plans (project report)!

The S:FLEX FLAT DIRECT system for at roofs and low roof pitches up to 30° is an aerodynamic frame system for the

installation of PV modules without roof penetration. It includes prefabricated aluminium ground rails with glued on

sponge rubber pads, which ensure maximum material compatibility and excellent friction coecients at the same time.

S:FLEX FLAT DIRECT can be installed on almost all roof shapes with roof pitches up to 30° using commercially available

modules.

All components are generally made of aluminium and stainless steel. The high degree of corrosion resistance ensures a

long service life and oers the possibility of complete recycling.

1.1 Intended use

The S:FLEX FLAT DIRECT system is designed to accommodate PV modules. The system is suitable for use on roofs with

a pitch up to 30° and the following roong: Foil roofs, bitumen roofs, sandwich roofs.

Any other use in this regard is considered misuse of the product. Observance of the information in these installation

guidelines in particular, is a prerequisite for intended use.

The project report is part of the installation instructions and is created on a project-specic basis. All of the information

contained in the project report must be strictly observed. The project report contains the location-based static calculations.

The S:FLEX mounting system must be designed and created with the S:FLEX software (Solar.Pro.Tool).

S:FLEX GmbH is not liable for damages that result from not observing the installation guidelines or from the improper

and not intended use of the product.

1.2 About the document

These installation guidelines describe the installation of the S:FLEX FLAT DIRECT system on roofs with a roof pitch of

up to 30°.

It must be ensured that only current and complete installation guides are used for the installation process.

2 3

Single pitch roof with ridge connection

Single pitch roof with counterweight

Buttery roof with counterweight on the ridge side

Saddle roof with ridge connection on both sides

Saddle roof with counterweight on one side

Saddle roof with ridge connection on one side

Buttery roof with ridge connection

Buttery roof with ridge connection /counterweight

on both sides

S:FLEX GmbH • Reinbeker Weg 9 21029 Hamburg Tel. +49 (0)40 688 93 17 0 • Elsässer Str. 12 79189 Bad Krozingen Tel. +49 (0)761 888 56 08 0

info@sex.com www.sex.com © S:FLEX GmbH 04/2020/ Subject to technical modications

1 Introduction

4

1.3 Warnings

The warning notices used in this installation recommendation indicate safety related information.

They are:

1.4 General information – standards and guidelines

Every photovoltaic system must be installed in accordance with the instructions contained in the respective installation

guidelines and the project report. The installation guidelines provided are based on the latest technology and many

years of experience installing our mounting systems. It is to be ensured that only the current and complete installation

guidelines are used for the installation and that a print-out of the installation guidelines is stored in the immediate

vicinity of the system. The system and these guidelines are subject to technical changes.

Each roof has particular features that must be taken into account. This requires preliminary expert advice. Before

installation, the PV system creator must ensure that the existing roong and roof substructure are suitable for the

additional loads. The condition of the roof substructure and roong must be thoroughly checked (e.g. quality of the

roong, that the roong is adequately secured to the substructure, maximum load-bearing capacity of the roong).

Contact an on-site structural engineer for this purpose.

When installing the PV system, always comply with the module manufacturer’s installation instructions. In particular, it

is necessary to check that the module manufacturer’s instructions regarding the module clamping guidelines (module

clamping surface and clamping range) are complied with. If this is not the case, the customer must obtain a declaration

of consent from the module manufacturer before the installation, or the mounting system must be adjusted according

to the module manufacturer’s guidelines.

The requirements for the protection of PV mounting systems against lightning and surges must be met in accordance

with the DIN and VDE regulations.

The specications of the relevant power supply company must be observed.

During installation, the local re regulations must be observed, e.g. rewalls must not built over and the required

clearances must be maintained.

If the roong is altered, the manufacturer’s guidelines must be observed. During and after installation, the frame

components may not be stepped on or be used as a climbing aid. There is a risk of falling and the roong underneath

could be damaged.

Prior to installation, the creator of the photovoltaic system must ensure that the installation is carried out while strictly

adhering to national and location-specic building regulations, safety and accident prevention regulations, standards

and environmental protection regulations.

Every person who installs the S:FLEX PV mounting systems is obligated to independently inform himself/herself about all

rules and regulations for professionally correct planning and installation, and to comply with said rules and regulations

during the installation process. This also includes compliance with the latest versions of the respective rules and

regulations.

Installation of the PV system may only be carried out by trained specialists.

Unless observed, there is a major risk of

injury as well as a risk of death.

Failure to observe this may lead to

property damage.

S:FLEX GmbH • Reinbeker Weg 9 21029 Hamburg Tel. +49 (0)40 688 93 17 0 • Elsässer Str. 12 79189 Bad Krozingen Tel. +49 (0)761 888 56 08 0

info@sex.com www.sex.com © S:FLEX GmbH 04/2020/ Subject to technical modications

1 Introduction

4 5

Please note: Installation of the S:FLEX substructure and the PV system may only be carried out by

trained specialists.

System components must not be used as step ladders. The modules must not be stepped on.

When working on roofs, there is a risk of falling o and falling through roofs. A fall can result in

injury or death.

Ensure that appropriate climbing aids and fall-protection equipment (e.g. scaolding) are provided

as well as protection from falling parts.

Check the building statics and construction/condition of the roof substructure and roong before

starting the installation. During installation, the instructions in the installation guidelines and

project report must be strictly observed. Failure to observe the installation guidelines and the

project report can result in damage to the PV system and to the building.

S:FLEX GmbH • Reinbeker Weg 9 21029 Hamburg Tel. +49 (0)40 688 93 17 0 • Elsässer Str. 12 79189 Bad Krozingen Tel. +49 (0)761 888 56 08 0

info@sex.com www.sex.com © S:FLEX GmbH 04/2020/ Subject to technical modications

1.5 Description of the system

The S:FLEX Flat Direct system oers suitable solutions for dierent requirements:

System properties

Roof inclination: The S:FLEX FLAT DIRECT is available for a roof pitch up to a maximum of 30°

Roof edge spacing: Roof areas F and G can be used

Module type: Framed modules

Building height: max. 25 m

Wind load: up to 2.4 kN/m²

Snow load: up to 5.4 kN/m²

Materials: extruded aluminium EN AW-6063 T6

Small parts: Stainless steel X5CrNi18-10 A2-70A

Prerequisites: Proof of static load capacity of the roof and the roof insulation must be provided by customer.

General terms / warranty conditions and usage agreement apply.

Roong

The S:FLEX FLAT DIRECT can be installed on the following at-roof coverings:

Foil roof, bitumen roof, sandwich roof.

The S:FLEX FLAT DIRECT does not use conventional protective mats, but special material-compatible foam protective

mats. The system can therefore be used on all conventional roong materials. No plasticisers are released. The material

meets the requirements of DIN EN 13501-1 with the re classication E.

1 Introduction

6

The module manufacturer's installation instructions must always be observed.

S:FLEX GmbH may provide a measuring device in order to determine the project-specic friction

coecient.

S:FLEX GmbH • Reinbeker Weg 9 21029 Hamburg Tel. +49 (0)40 688 93 17 0 • Elsässer Str. 12 79189 Bad Krozingen Tel. +49 (0)761 888 56 08 0

info@sex.com www.sex.com © S:FLEX GmbH 04/2020/ Subject to technical modications

Mounting rails

The S:FLEX mounting rails ST-AK 7/47 feature a hammerhead slot on the side for connection to the fasteners.

The mid clamps and end clamps are mounted from above using one-click technology.

The covering caps are wedged in place for lateral closure of the mounting rails. The covering caps remain rmly seated

without screws.

Splice technology

In addition to the simple installation, the splice technology allows a system orientation without a reduction in the load-

bearing capacity in the area of the splices, since they have the same static values as the associated mounting rail.

When connecting the mounting rails in succession using splices, an earthed connection is possible if the rails are pushed

together ush to the splices with pressure. It is to be ensured that the earthed connection is professionally inspected

on site after installation.

In addition, the splice technology oers the possibility to quickly and easily create expansion joints according to the

conditions of the roof. In this case, no earthed connection exists. This is to be professionally established on site without

restricting the eect of the expansion joint.

ST-AK 7/47

6

1 Introduction

7

S:FLEX GmbH • Reinbeker Weg 9 21029 Hamburg Tel. +49 (0)40 688 93 17 0 • Elsässer Str. 12 79189 Bad Krozingen Tel. +49 (0)761 888 56 08 0

info@sex.com www.sex.com © S:FLEX GmbH 04/2020/ Subject to technical modications

1 Introduction

Cross adapter

Intersection points (for double-layer systems) can be quickly realised in a load-bearing manner with cross adapters

with patented and proven click technology. A cross adapter must be installed on the bottom side of the module rail per

intersection point.

8

Bracket 40 mm M8

For installations on sandwich roofs, a bracket is used instead a cross connector. A bracket must be installed on the

bottom side of the module rail at each crossing point.

Eaves Ridge

Eaves Ridge

Module end clamp (EC) Module mid clamp (MC)

Maximum clamping

surface EC II:

A=8.4*35=294 mm²

Maximum clamping surface MC

II:

A=11*40=440 mm² (per side)

42,6 mm

clambing range

clambing range

Module mid clamps and module end clamps

Height-adjustable module mid clamps and module end clamps with one-click technology allow for maximum exibility

when installing virtually all framed module types with a frame height of 30 – 50 mm. When installing the PV modules to

the rail, always comply with the installation instructions of the module manufacturer.

When performing the fastening by means of the module mid clamp and module end clamp, ensure that these clamp

onto the module frame with the respectively dened clamping surface of the module manufacturer. Every person who

installs the S:FLEX PV fastening systems is obligated to ensure that the existing clamping surfaces correspond with the

installation instructions of the module manufacturer. Mid clamps and end clamps are available in other lengths (e.g. 80

mm) if necessary.

S:FLEX GmbH • Reinbeker Weg 9 21029 Hamburg Tel. +49 (0)40 688 93 17 0 • Elsässer Str. 12 79189 Bad Krozingen Tel. +49 (0)761 888 56 08 0

info@sex.com www.sex.com © S:FLEX GmbH 04/2020/ Subject to technical modications

8

1 Introduction

9

Splice technology for earthing

When connecting the mounting rails in succession using splices, an earthed connection can be created by applying

pressure to push the mounting rails together ush to the splices. It is to be ensured that the earthed connection is

professionally inspected on site after installation.

Earthing

Equipotential bonding between the individual system components must be ensured according to the respective country-

specic guidelines and standards. System-specic properties (see splice technology) among other things can be used

for this purpose.

This installation recommendation does not include an earthing concept and must be calculated or compiled by the

executing installer in accordance with the applicable standards and guidelines.

The S:FLEX Flat Direct mounting system is capable of carrying lightning current in accordance with

DIN EN 62561-1: 2017-12 and can be integrated into the existing or planned lightning protection

system. This may only be installed out by a company specialising in lightning protection systems.

The earthed connection of the mounting rails is established by the splice. Additional earthing of the modules can be

achieved via the grounding plate by mounting it under the mid clamps. Before earthing the module, the corresponding

specifications issued by the module manufacturer must be observed.

The planning and execution of all lightning protection work may only be carried out by appropriately

qualied lightning protection specialists.

S:FLEX GmbH • Reinbeker Weg 9 21029 Hamburg Tel. +49 (0)40 688 93 17 0 • Elsässer Str. 12 79189 Bad Krozingen Tel. +49 (0)761 888 56 08 0

info@sex.com www.sex.com © S:FLEX GmbH 04/2020/ Subject to technical modications 10

2 Installation - S:FLEX Flat Direct

2.1 System components

System components

1

Ground rail

Splices

3

Splice 7

Mounting rails

2

ST-AK 7/47

End clamp

4Mid clamps

5

EH AK II Klick 30-50 MH AK II Klick 30-50 A

Slipping protection set

6

Slipping protection set

Covering caps

7

Covering cap 7

Cross adapter

9

Cross adapter

Cable clips

8

Cable clips

Assembly post

(PVC, bitumen or

bright stainless

steel)

Splice ground

rail

Ridge

connector

Covering (PVC or

bitumen)

Bracket 40 mm, M8

complete

Bracket 60mm, M10

complete

Bracket 60mm, M12

complete

FS 9/40

Screw OMG HD

10

Screw OMG HD

Covering cable duct (optional)

12

Covering cable duct

Bending tool (optional)

13

Bending tool

Ballast block (optional)

11

Ballast block

Solar fastener A 8.4 M10 x 100-50

Solar fastener A 8.4 M10 x 150-50

Solar fastener A 8.4 M10 x 200-50

Solar fastener BZ 8.0 M10 x 100-50

Solar fastener BZ 8.0 M10 x 150-50

Solar fastener BZ 8.0 M10 x 200-50

S:FLEX GmbH • Reinbeker Weg 9 21029 Hamburg Tel. +49 (0)40 688 93 17 0 • Elsässer Str. 12 79189 Bad Krozingen Tel. +49 (0)761 888 56 08 0

info@sex.com www.sex.com © S:FLEX GmbH 04/2020/ Subject to technical modications

10 11

2 Installation - S:FLEX Flat Direct

Decisive factors in determining the distance and layout of the rails and modules are only in the

planning documents. All of the information given in the project report must be strictly observed.

- Number and position of ground rails and mounting rails

- Number and position of the ballast blocks or assembly posts

- Minimum distance between the solar modules and the edge of the roof / verge

- Minimum distance between the solar modules and the ridge / eaves

- Distance between the individual module rows

Any deviations from these specications will falsify and invalidate the underlying static and

aerodynamic calculations.

There is a risk of injury to people, damage to the PV system, the building and the surrounding area.

S:FLEX GmbH is not liable for damages that result from not observing the installation guidelines

and specications in the project report.

S:FLEX GmbH • Reinbeker Weg 9 21029 Hamburg Tel. +49 (0)40 688 93 17 0 • Elsässer Str. 12 79189 Bad Krozingen Tel. +49 (0)761 888 56 08 0

info@sex.com www.sex.com © S:FLEX GmbH 04/2020/ Subject to technical modications

Installation - S:FLEX Flat Direct

2.2 Installing the ground rail

x = Spacing according to

planning documents

All ground rails are provided with an 11 mm thick high-tech protective foam mat. This ensures a free water drainage

and prevents damage to the roof covering due to mechanical impacts and long-term damage from plasticiser migration.

Preparatory work:

Clean the roof surface and clear it of obstructive objects. Measure the roof surface and compare it with planning

documents. Draw the system dimensions.

Procedure:

The ground rails and the splice ground rails must be arranged one after the other in accordance with the planning

documents. The sequence here is from the ridge to the eave. Insert the splice halfway into the ground rail and tighten

the two grub screws. Then insert the ground rails in accordance with the planning documents and tighten both grub

screws. All ground rails are now to be connected to each other according to the planning documents and set up with

the correct spacing.

The grub screws must be screwed in completely (ush with the upper edge of the splice ground rails, countersunk by a

maximum of 1mm). (Please note the MAINTENANCE information).

Correct Incorrect

y

Ridge

x

12

y = ground rail type, sequence

and spacing according to the

planning documents

S:FLEX GmbH • Reinbeker Weg 9 21029 Hamburg Tel. +49 (0)40 688 93 17 0 • Elsässer Str. 12 79189 Bad Krozingen Tel. +49 (0)761 888 56 08 0

info@sex.com www.sex.com © S:FLEX GmbH 04/2020/ Subject to technical modications

12

Installation - S:FLEX Flat Direct

13

Cutting of ground rail:

Please note the following when processing self-cut ground rail:

- Cutting according to planning documents

- the ground rails must be aligned so that the cut edges are always on the inside of the individual rows are arranged

- the ground rail rows must end at the top and bottom with an original glued rail end (no cutting edge on the outer sides)

- the distance between the PE protective mats must not exceed 300mm; if additional PE protective mats are required

paste in

Correct Incorrect

S:FLEX GmbH • Reinbeker Weg 9 21029 Hamburg Tel. +49 (0)40 688 93 17 0 • Elsässer Str. 12 79189 Bad Krozingen Tel. +49 (0)761 888 56 08 0

info@sex.com www.sex.com © S:FLEX GmbH 04/2020/ Subject to technical modications

Installation - S:FLEX Flat Direct

2.3 Installing the mounting rail ST-AK 7/47

2.3.1 Install mounting rails using cross adapters (for foil and bitumen roofs)

Install the mounting rails for each module row using cross adapters crossways on the ground rails. To do this, click the

cross adapter onto the ground rail and use it to secure the mounting rail. Check that the spacing between the mounting

rails is in line with the specied clamping distances for the module.

Ensure that the cross adapter is clicked in on both sides of the ground rail and fasten the screws tightly (torque 8-10

Nm).

The cross adapter must always be attached to lowest point of the roof on the side facing the mounting rail! To do this,

position the mounting rail on the roof surface accordingly!

Correct Incorrect

14

Ridge

S:FLEX GmbH • Reinbeker Weg 9 21029 Hamburg Tel. +49 (0)40 688 93 17 0 • Elsässer Str. 12 79189 Bad Krozingen Tel. +49 (0)761 888 56 08 0

info@sex.com www.sex.com © S:FLEX GmbH 04/2020/ Subject to technical modications

14

Installation - S:FLEX Flat Direct

2.3.2 Rail ST-AK 7/47 using bracket 40 mm M8 (for sandwich roofs)

Mount the bracket 40 mm M8 onto the ground rail using a hammerhead bolt M8x25 and a self-locking nut. Ensure that

the hammerhead bolt is correctly aligned in the ground rail channel (torque 12-15 Nm).

15

Attach the mounting rail to the bracket using a hammerhead bolt M8x25 and a self-locking

nut. Ensure that the hammerhead bolts are correctly aligned in the mounting rail channel

21 mm

Alignment of hammerhead bolt

Force and form t

Create force-t and form-t

connection

Check the alignment of the

hammerhead bolts

It is important to ensure that the groove in the hammerhead bolt is perpendicular (at right angles to

the rail) after installing the clamp. Only then is the head of the hammerhead bolt correctly inserted

in the rail and the bracket is correctly attached.

(torque 12-15 Nm) and that the mounting rails are installed stress-free. To do this,

use the adjustability that is created by the corrugation of the components and

the elongated hole. Ensure that a force-t and form-t connection is created by

interlocking the corrugations. The bracket must always be attached to the lowest

point of the roof on the side facing the mounting rail! To do this, position the

mounting rail on the roof surface accordingly. Select the height of the mounting

rails so that they span the upper ange of the sandwich panels without touching.

The maximum possible height of the mounting rail above the roong = 82 mm.

Eaves Ridge

Use the adjustability due to

corrugation and elongated

hole

S:FLEX GmbH • Reinbeker Weg 9 21029 Hamburg Tel. +49 (0)40 688 93 17 0 • Elsässer Str. 12 79189 Bad Krozingen Tel. +49 (0)761 888 56 08 0

info@s ex.com www.s ex.com © S:FLEX GmbH 04/2020/ Subject to technical modi cations

Installation - S:FLEX Flat Direct

2.4 Installing the splice

To join several rails together, the splice with identical static values to the mounting rail is pushed half-way into the

previously installed mounting rail. Then push the next mounting rail onto the splice. Apply enough pressure to push

the mounting rails ush together and ensure that connection to earth is established. The connection is complete. When

positioning the splices, make sure that the mounting rails always rest on at least two ground rails.

Fix the joined mounting rails to the ground rails as described using a cross adapter or bracket 40 mm M8.

16

Ridge

Push in splice

Check connection to earth

No cantilevers with splices.

Position the splices so that they lie between

2 fastening points.

Cantilever

Push mounting rails together

Complete

S:FLEX GmbH • Reinbeker Weg 9 21029 Hamburg Tel. +49 (0)40 688 93 17 0 • Elsässer Str. 12 79189 Bad Krozingen Tel. +49 (0)761 888 56 08 0

info@s ex.com www.s ex.com © S:FLEX GmbH 04/2020/ Subject to technical modi cations

16

Installation - S:FLEX Flat Direct

17

Completed installation of the upper rail layer

Expansion joint upper layer

Ridge

If the mounting rail is longer than 13.00 m, the module array is to be separated by placing two

end clamps. The rail is to be separated in the area between the end clamps and connected with a

splice to ensure a 2 cm compensation in length (expansion joint). The arrangement of the expansion

joints must be adapted in accordance with the structural conditions of the roof and the expansion

properties of the respective materials.

Modules must not be built over expansion joints.

There is no connection to earth. This is to be established without restricting the e ect of the

expansion joint.

When positioning the splices, make sure that the mounting rails always rest on at least two ground

rails.

Expansion joint

2 cm

S:FLEX GmbH • Reinbeker Weg 9 21029 Hamburg Tel. +49 (0)40 688 93 17 0 • Elsässer Str. 12 79189 Bad Krozingen Tel. +49 (0)761 888 56 08 0

info@sex.com www.sex.com © S:FLEX GmbH 04/2020/ Subject to technical modications

The ridge connector is a stability-relevant

component and must be installed in

every pair of ground rails! Ignoring this

requirement will lead to the exclusion of the

liability and constitute a considerable threat

to the system safety!

Installation - S:FLEX Flat Direct

2.5 Ridge connector

Before the ridge connector is mounted, it must be adjusted to the pitch of the roof using the bending tool. The bending

tool is available separately.

The roof ridge line is to be checked for an even consistent course. Contact of the ridge connector with the roong must

be avoided. If necessary, additional protective mats are to be added.

Using the supplied bending tool, bend the ridge connector to the inclination angle determined on the roof. Insert the

ridge connection into the rst ground rail assembly and tighten. Insert the ground rail on the opposite roof side into the

ridge connection as well and screw together.

The grub screws must be screwed in completely (ush with the upper edge of the splice ground rails, countersunk by a

maximum of 1mm). (Please note the MAINTENANCE information).

18

Push the pitch-adjusted ridge

connector into the ground rail.

On the already installed side of the

roof, connect the ridge connector

using 3 grub screws and washers.

Install ground rails for additional

system components / ballast with 3

grub screws.

Correct Incorrect

S:FLEX GmbH • Reinbeker Weg 9 21029 Hamburg Tel. +49 (0)40 688 93 17 0 • Elsässer Str. 12 79189 Bad Krozingen Tel. +49 (0)761 888 56 08 0

info@sex.com www.sex.com © S:FLEX GmbH 04/2020/ Subject to technical modications

18

Installation - S:FLEX Flat Direct

2.6 Ballast blocks

In general, additional ballast is required to prevent the PV system from lifting, moving or slipping. The quantity and

distribution of the ballast depend on parameters such as location, building height, building surroundings, roong type

and roof pitch. This information is included in the planning documents.

The position of the ballasting must always be carried out in strict adherence to the planning

documents. A dierent distribution or omission of ballast elements may compromise the positional

stability of the entire system and represents a major risk. Deviations from the planning must always

be agreed with S:FLEX GmbH and may only be carried out after written approval.

The position of the ballasting elements must be chosen so that slipping down, tipping or wobbling

are prevented. The ballast must lie completely at. It is insucient to merely lean the ballast.

Install the ballast onto the ground rails according to the planning documents.

Stone slabs with bevelled edges need to be positioned so that the bevelled edges face downwards and the right-angled

edges face upwards. Fix the ballast with end clamps or end and mid clamps accordingly to prevent slipping and moving.

When installing several ballast blocks on top of each other, mid clamps are to be used between the blocks and end

clamps on the upper block (torque mid clamp and end clamp 8-10 Nm). Precise installation details for installing mid

clamps and end clamps are provided in section 2.8 (module assembly).

- Recommended block size for foil and bitumen roofs: 400x400x40mm; max. block height 40 mm

- Recommended block size for sandwich roofs: 500x200/ 250x50 mm; max. block height 50 mm

The ballast must not be clamped in the area directly under the module frame. This has already been taken into account

in the planning documents (ground rail arrangement).

19

Snap in the end clamp...

Push in and tighten

Ridge

Install the end clamp

S:FLEX GmbH • Reinbeker Weg 9 21029 Hamburg Tel. +49 (0)40 688 93 17 0 • Elsässer Str. 12 79189 Bad Krozingen Tel. +49 (0)761 888 56 08 0

info@sex.com www.sex.com © S:FLEX GmbH 04/2020/ Subject to technical modications

Installation - S:FLEX Flat Direct

2.7 Option 1: Counterweight

The module array must be secured to prevent slippage by means of a suitable counterweight or roof fastening. The

type of counterweight depends on the roof shape and the intended module layout. The most common options are the

double-sided module layout with ridge connection (saddle roof), the counterweight with ridge connection (saddle roof)

and the fastening to the roof substructure or ridge connector (saddle roof, single pitch roof, buttery roof). Another

special option is fastening to the rafter ends (single pitch roof, buttery roof) with specially made metal brackets.

The required counterweight and number of fastening points are included in the project report.

20

The module array must always be secured with a counterweight or roof fastening to prevent

slippage.

2.7.1 Counterweight with double-sided module layout and ridge connection

The substructure is installed on both sides of the roof as described in the previous sections. The module array is

connected using the ridge connector and the ground rails.

Table of contents