5

Technical Description

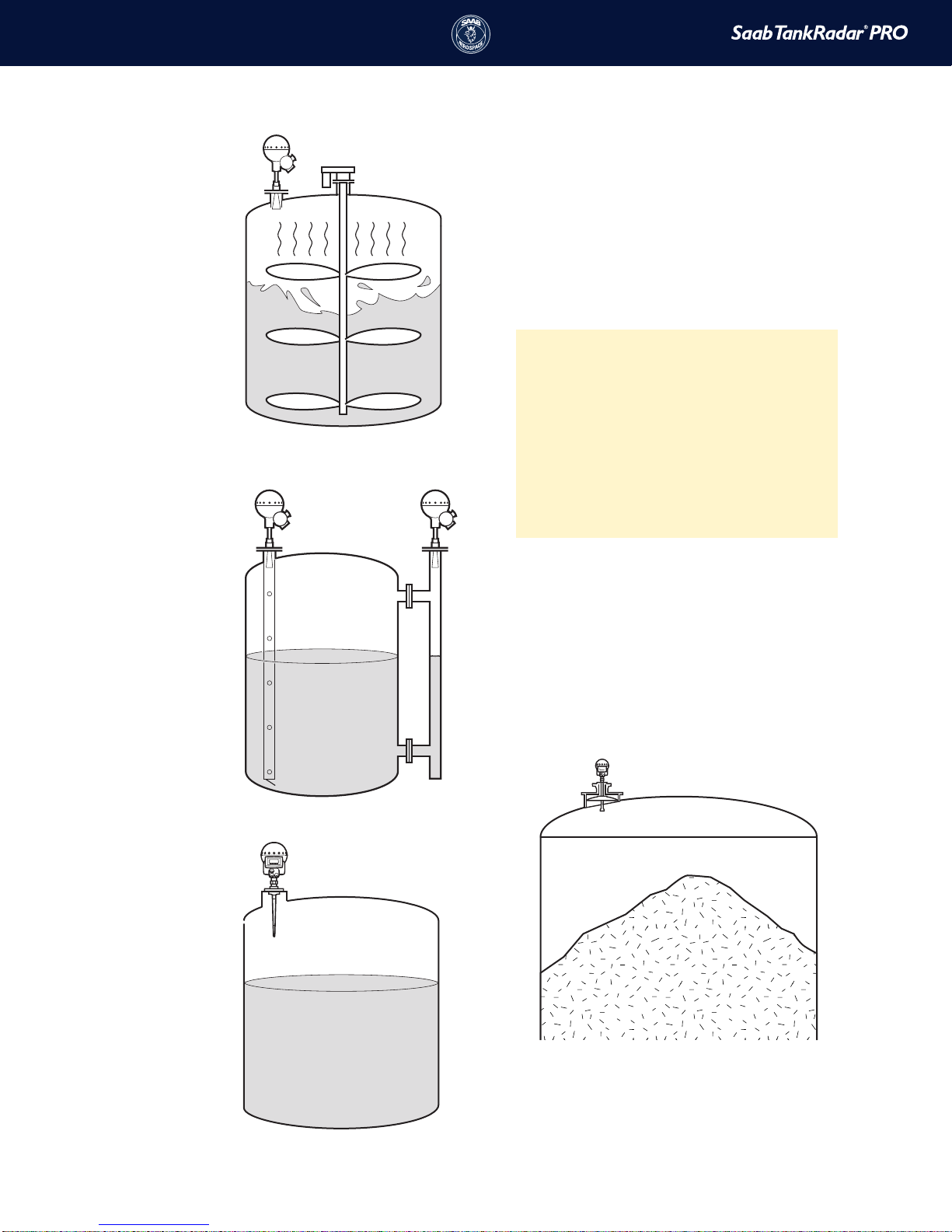

;IEXLIVTVSXIGXMSR

)PIGXVSRMGLSYWMRK

(MWTPE]TERIP

.YRGXMSRFS\)\I

'EFPIKPERHW

.YRGXMSRFS\)\M

8EROGSRRIGXMSR

%RXIRRE

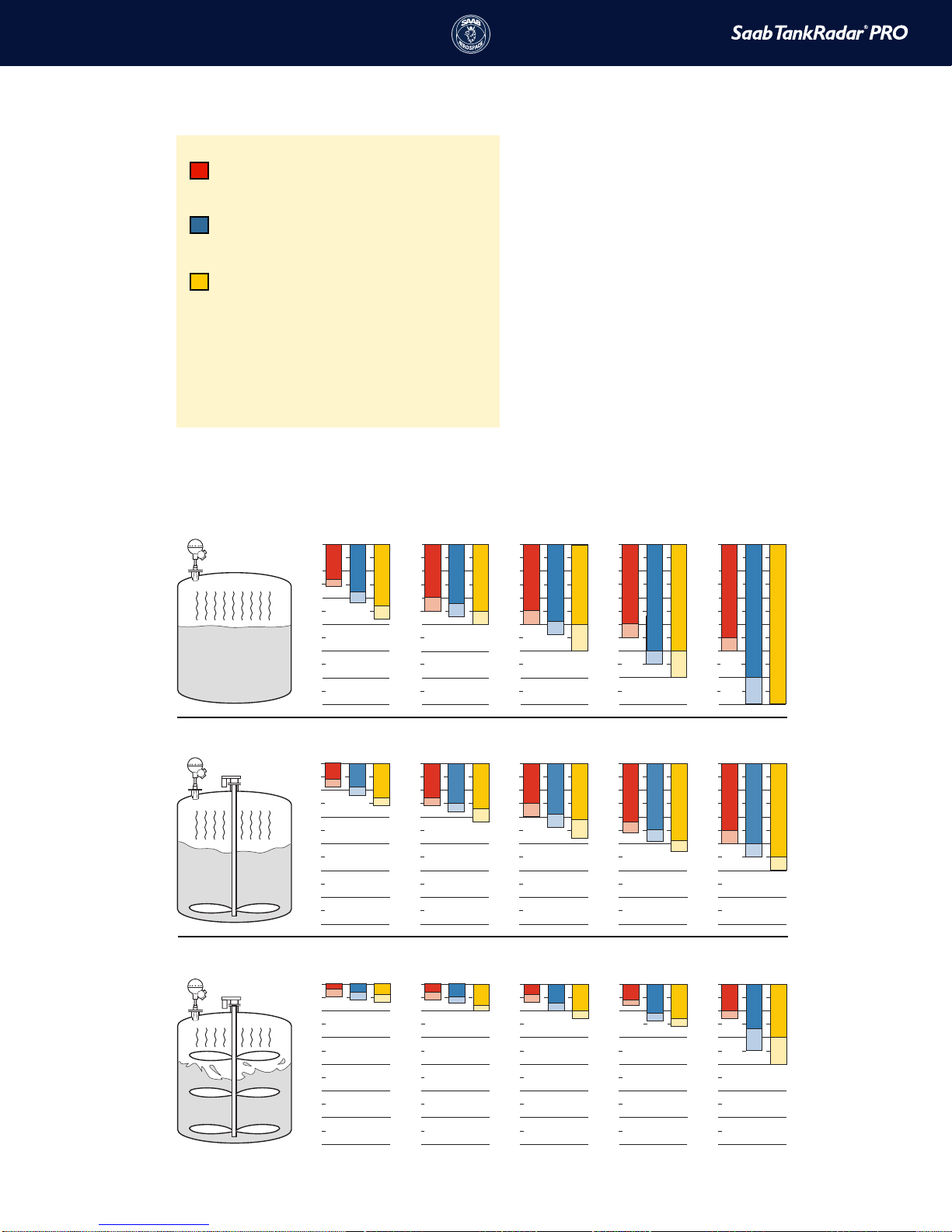

Select the right Pro gauge

A TankRadar Pro gauge consists of a Transmit-

ter Head (TH) and a tank connection including

antenna. The TH, as well as the electronics in-

side, is interchangeable without opening the

tank.

The Transmitter Head is available in three

basic versions:

§Lite

Intended for applications in non-hazardous

areas only.Suitable for tanks without

internal structures and agitators,e.g.certain

storage tanks,water,dam applications etc.

The Lite version has only FFT calculations

enabled providing an instrument accuracy

of ±10 mm (±0.4").Echofixer,FHAST and

MET are available as options.

§Standard

For hazardous applications,suitable for

most tanks,also with internal structures,

spherical and bullet tanks.The Standard

version includes the Echofixer software

which more accurately than standard FFT

maps all microwave interference sources.

Standard instrument accuracy is ±10 mm

(±0.4") which can be improved to ±5 mm

(±0.2") using the optional software

modules.

§Gold

Gold is the most advanced version for

difficult applications in tanks with agitators,

heating coils and other disturbances. It

includes the Echofixer software,FHAST™

software for increased accuracy plus

MET™ software for further increased

disturbance echo handling. Instrument

accuracy is ±5 mm (±0.2").

Volume calculation for symmetrical tanks is

included in all versions. Strapping table for

non-symmetrical tanks is available as an op-

tion.

Various options make it possible to optimize the

gauge for different applications:

§Fast FourierTransformation (FFT)

Fast FourierTransformation is a signal

processing technique used to map the

echo structure of the tank.

§Echofixer

A software module that makes it

possible to measure on the surface in

spite of strong disturbance echoes from

mechanical structures such as agitators

and baffles.

§Fast HighAccuracy Signal

Technology (FHAST™)

A module that improves the efficiency of

the signal processing by limiting the

region to be analyzed around the surface.

This results in an improved accuracy of

±5 mm (±0.2").

§Multiple EchoTracking (MET™)

Improves the resolution and accuracy in

echo disturbed regions and close to the

tank bottom.Continuous measurement

on multiple disturbing echoes facilitates

identification of the actual surface echo.

All software options are possible to upgrade in

the field without any changes in electronics.

Upgrades are made by entering a new start

code in the gauge and can be done on a

temporary basis for trial purposes.

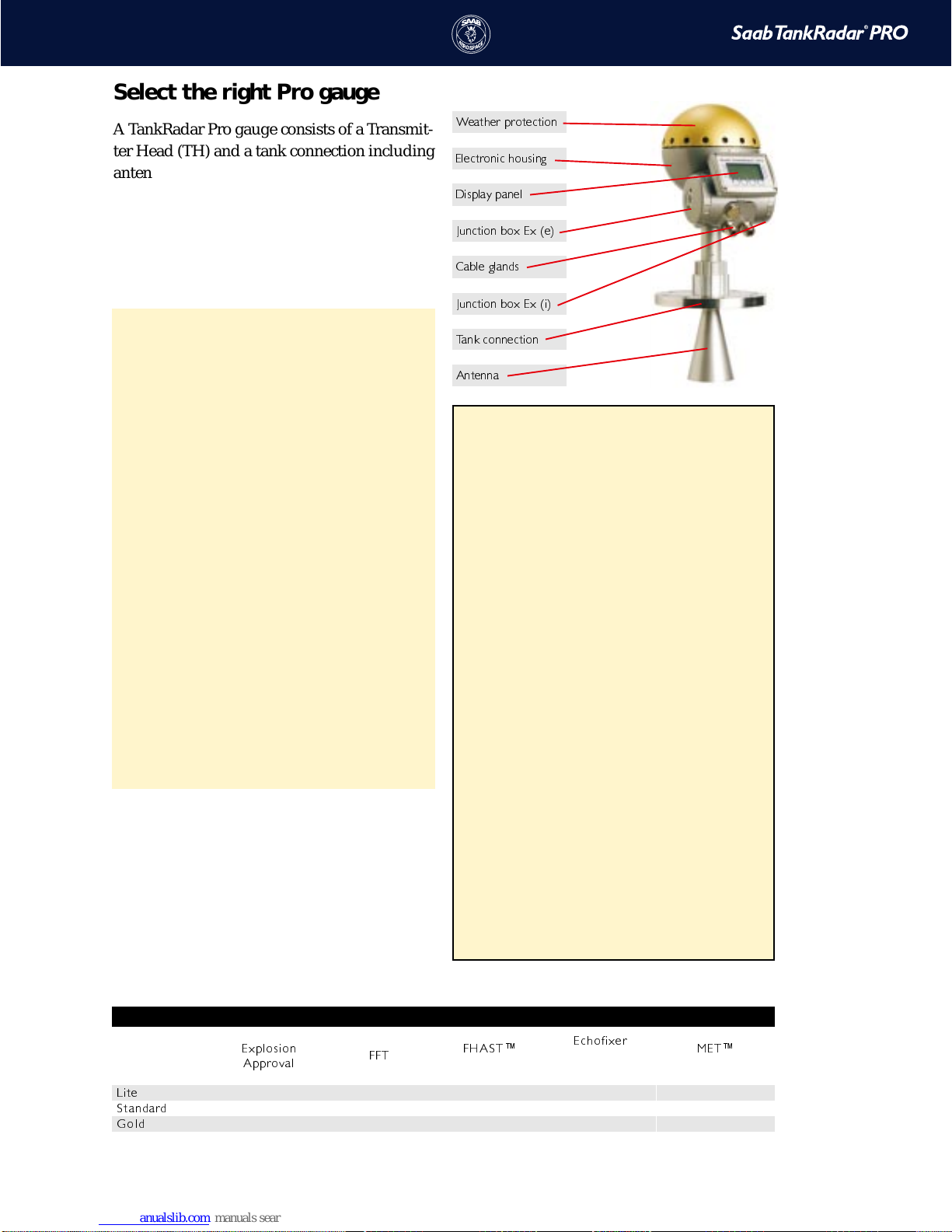

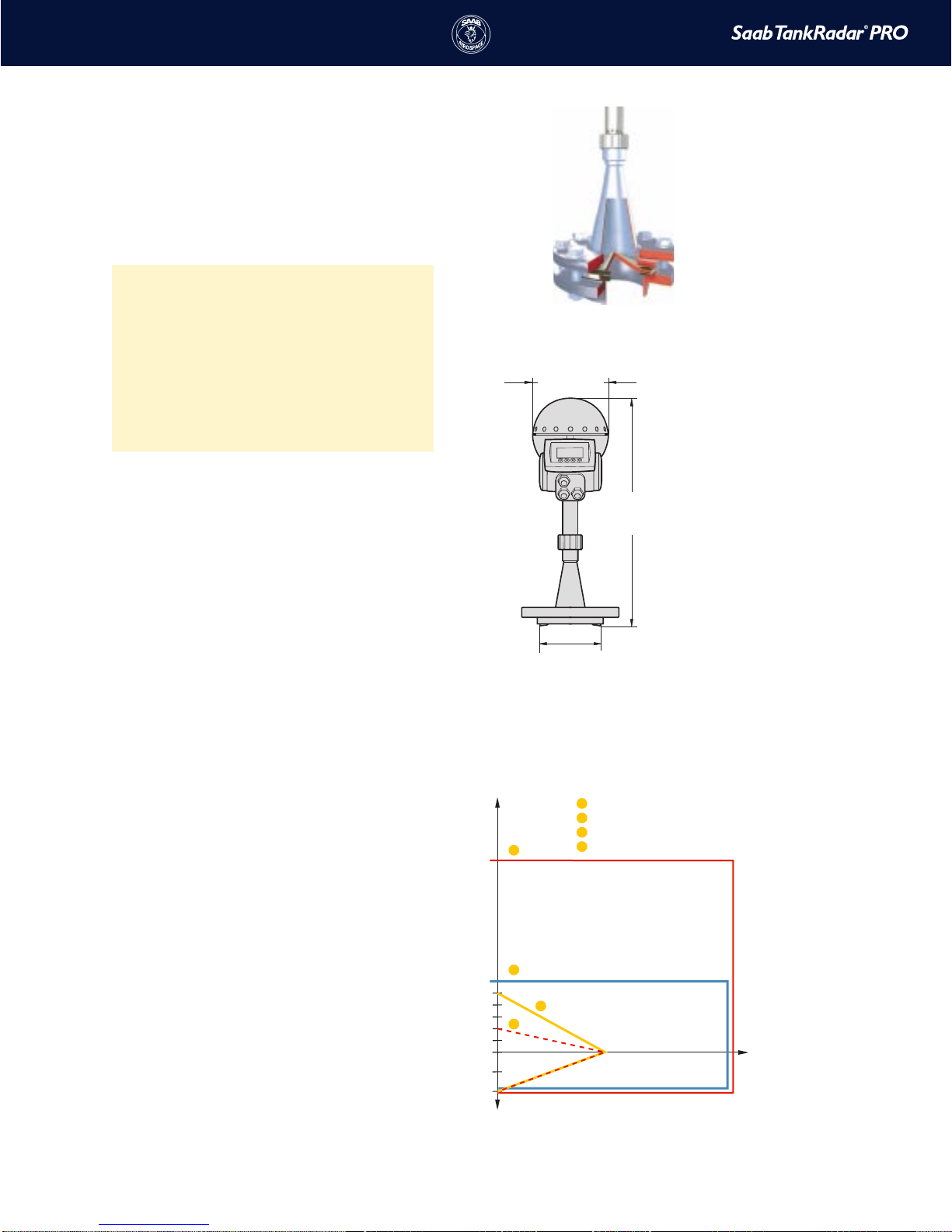

Software modules

Software modules in available Pro versions

)\TPSWMSR

%TTVSZEP **8 *,%78¬

Increased Accuracy

)GLSJM\IV

Disturbance echo

handling

1)8¬

Improved resolution

0MXI

xOption Option Option

7XERHEVH

xxOptionxOption

+SPH

x x x x x