10

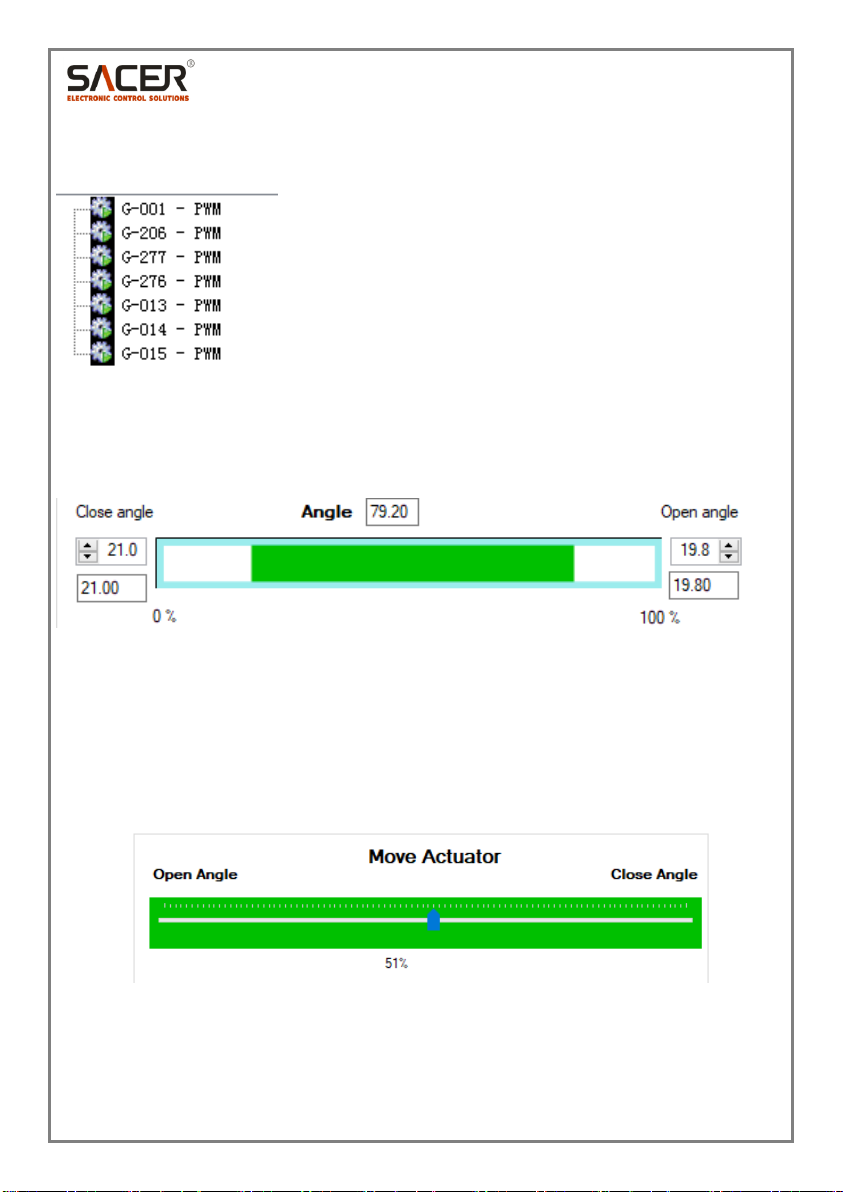

Step 5: Select the corresponding G-number, and then double click to

read the data

Step 6:The software will read the close angle and open angle of the

actuator automatically. The current open and close angles will be

shown on the PC in percentage

Step 7:You can check the if it is the maximum and minimum flow by

changing the slider in the “Move Actuator” box

If yes, you do not need to change any parameter, because it is the best

one already.

If no, you need to adjust the value. See step 8. Adjustment of Angle

Value.

Step 8:Adjustment of Angle Value

1) If move the progress bar to the far right of the “Close angle”, the

flow of the turbo assembly is bigger than expect, then need to

decrease its value. The specified value should be determined by