Tektronix, Inc. 326 User manual

INSTRUCTION MANUAL

Tektronix, Inc.

P.0. Box 500

Beaverton, Ore on 97005 Serial Number

070-1578-00 273

, ' - '.,/' ,>'~j z ? ';'‘'? > z r;- ‘. •* --* •" "

RANTY

nts are warranted again

kmanship f r ne year. An'

warranty sh uld be taken up

K J^|d Engineer r representative,

displacem ent parts sh uld be

OIMIX Field Office r representative

rey ur:

tu m ih i^ ^

ithii|t;-|i

i# pjr£pe'

fp^m aferiai

f Oreg n. Printed in the United States f

AmerMa: All rights reserved. C ntents f this publicati n

may n t be repr duced in any f rm with ut permissi n f

Tektr nix, Inc.

U.S.A. and f reign TEKTRONIX pr ducts c vered by U.S.

and f reign patents and/ r patents pending.

TEKTRONIX is a registered trademark f Tektr nix, Inc.

326 (SN 300500-up)

SECTION 1

SECTION 2

SECTION 3

SECTION 4

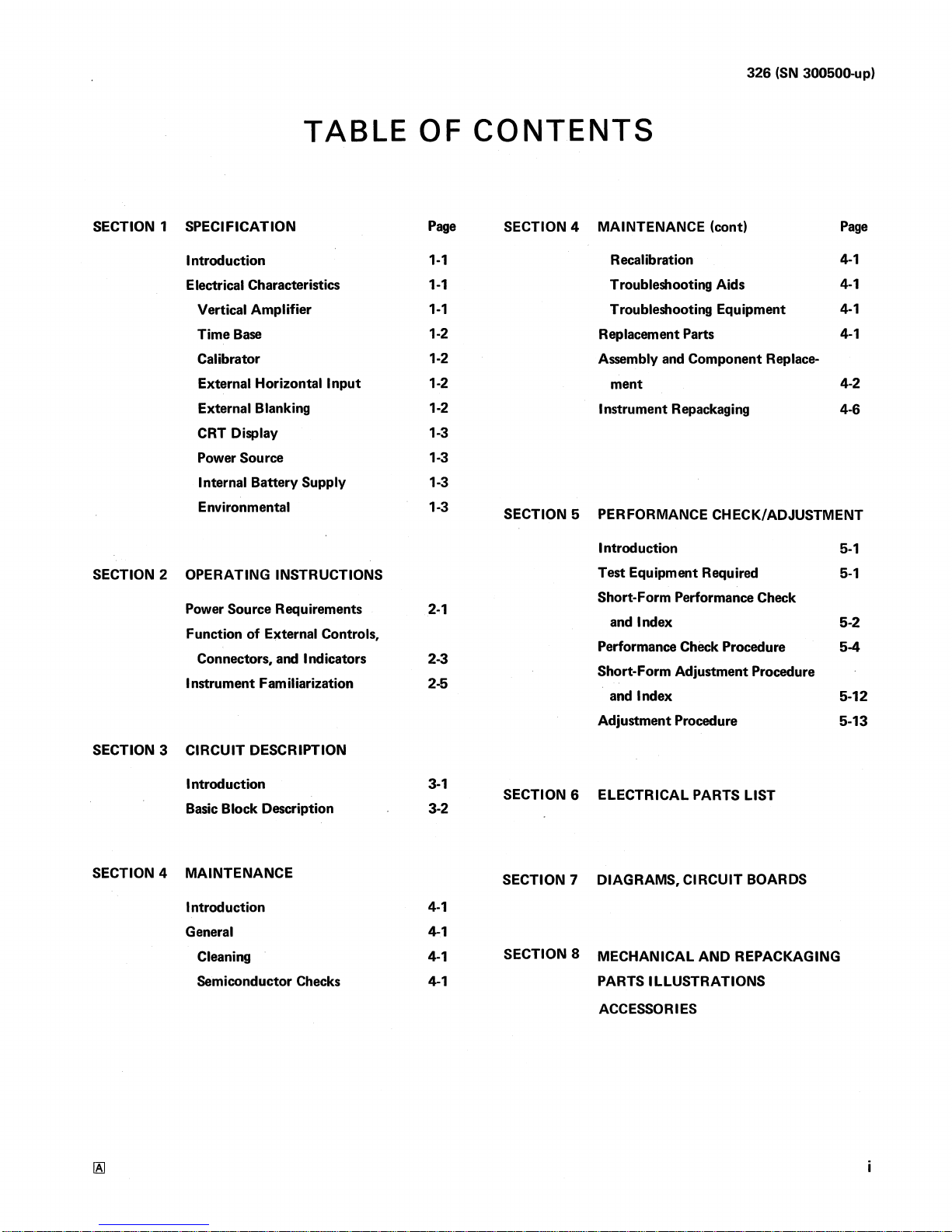

TABLE OF CONTENTS

SPECIFICATION Page SECTION 4 MAINTENANCE (c nt) Page

Intr ducti n 1-1 Recalibrati n 4-1

Electrical Characteristics 1-1 Tr ublesh ting Aids 4-1

Vertical Amplifier 1-1 Tr ublesh ting Equipment 4-1

Time Base 1-2 Replacement Parts 4-1

Calibrat r 1-2 Assembly and C mp nent Replace

External H riz ntal Input 1-2 ment 4-2

External Blanking 1-2 1 nstru ment R epackag i ng 4-6

CRT Display 1-3

P wer S urce 1-3

Internal Battery Supply 1-3

Envir nmental 1-3 SECTION 5 PERFORMANCE CHECK/ADJUSTMENT

Intr ducti n 5-1

OPERATING INSTRUCTIONS Test Equipment Required 5-1

Sh rt-F rm Perf rmance Check

P wer S urce Requirements 2-1 and Index 5-2

Functi n f External C ntr ls, Perf rmance Check Pr cedure 5-4

C nnect rs, and Indicat rs 2-3 Sh rt-F rm Adjustment Pr cedure

Instrument Familiarizati n 2-5 and Index 5-12

Adjustment Pr cedure 5-13

CIRCUIT DESCRIPTION

Intr ducti n 3-1 SECTION 6 ELECTRICAL PARTS LIST

Basic Bl ck Descripti n 3-2

MAINTENANCE SECTION 7 DIAGRAMS, CIRCUIT BOARDS

Intr ducti n 4-1

General 4-1

Cleaning 4-1 SECTION 8 MECHANICAL AND REPACKAGING

Semic nduct r Checks 4-1 PARTS ILLUSTRATIONS

ACCESSORIES

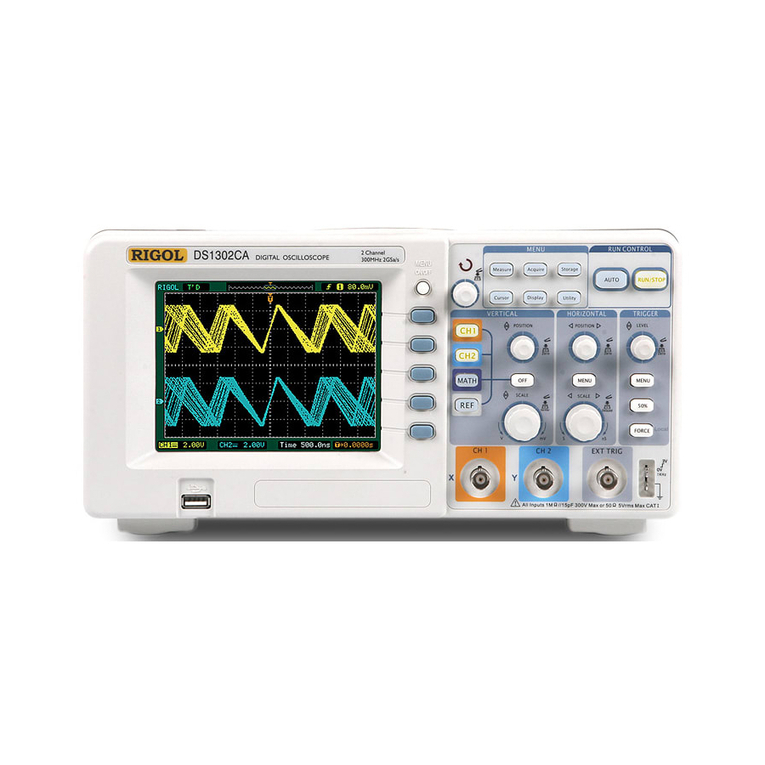

SONY/TEKTRONIX 326 Oscill sc pe.

326 (SN 300500-up)

326 SPECIFICATION

Secti n 1—326 (SIM 300500-up)

Intr ducti n

The SONY/TEKTRONIX 326 Oscilloscope is a solid-

state portable instrument that combines small size and li ht

wei ht with the ability to make precision waveform

measurements.

A dual-trace DC to 10 MHz vertical system provides

calibrated deflection factors from 0.01 Volt/Div to

10 Volts/Div (0.001 Volt/Div minimum with reduced

frequency response).

The tri er circuit provides stable tri erin over the full

vertical bandwidth. A 300 ns delay line in the vertical

system allows the operator to view the portion of the

waveform on which tri erin occurs.

The horizontal deflection system provides calibrated

sweep rates from 1 jUs/Div to 1 s/Div. A 10X ma nifier

extends the sweep rate to 0.1 jiis/Div.

The 326 can be operated from internal battery, an

external DC source, or from the AC line (with battery

char er attached).

The followin electrical characteristics apply over an

ambient temperature ran e of +20°C to +30° C (+68°F to

+86°F). Warmup time for the accuracies iven is approxi

mately 10 seconds.

CHARACTERISTICS

VERTICAL AMPLIFIER

Deflection Factor

Ran es: 10 mV/Div to lOV/Div in XI Gain and

1 mV/Div to 1 V/Div in X10 Gain. 10 steps in a 1-2-5

sequence. Accuracy within 3% over the calibrated ran e.

Variable: Variable between calibrated deflection factor

settin s. Extends the hi hest deflection factor to at least

25 V/Div.

Attenuator Compensation: +1%, —1%, or less, 0°C to

+55°C (+32°F to +131°F). +2%, -2%, or less, -15°C to

0°C (+5°Fto+32°F).

Frequency Response

Bandwidth (Variable Volts/Div at CAL, 4 division

reference) direct coupled: IX Gain, DC to at least

10 MHz (upper —3dB point) with the P6049A Probe.

Capacitively coupled, 4 division reference: from 10 Hz

or less (lower —3 dB point) at all deflection factors. 1 Hz

or less with the P6049A Probe.

Step Response (risetime), 4 division step input: 36 ns or

less in XI Gain and 72 ns or less with X10 Gain.

Aberrations: +2.5%, —2.5% with total of 4% or less in all

modes except ADD ALG. +3%, —3% with total of 6% or

less in ADD ALG Mode.

Input

Maximum Volta e: 500 volts direct coupled (DC + peak

AC) or capacitively coupled DC volta e.

Resistance: 1 M£2, within 2%, direct and 10 M£2, within

2%, with the P6049A Probe.

Capacitance: 47 pF within 4 pF direct and 13.5 pF or

less with the P6049A Probe.

Amplifier

Linear dynamic ran e in Added Mode: Equal to or

reater than 8 times the Volts/Div settin for 10%

distortion.

Common-Mode Rejection: At least 20:1 at 2 MHz for a

common-mode si nal of 80 mV peak-to-peak, Volts/Div

set at 10 mV and CH 2 set for maximum CMRR at

50 kHz and 10 mV.

DC Drift

With Time (short term): 0.2 div or less durin any

minute within the first hour after a 10 second

warmup (with temperature and line volta e constant).

1-1

Chopped Mode

Repetition Rate: 110 kHz within 20%.

Specificati n—326 (SN 300500-up)

TIME BASE

Sweep Time/Div

Calibrated Ran e: 1 s/Div to 1 /is/Div in 19 steps in a

1-2-5 sequence. 10X ma nifier extends the displayed

sweep time to 0.1 jus/Div.

Accuracy, XI Gain: within 3% over the center ei ht

raticule divisions from 1 jus/Div to 0.2 s/Div, increasin

to 4% from 0.5 s/Div to 1 s/Div.

X10 Gain: within 5% over any 2 division interval within

the center ei ht raticule divisions 1.0 jus/Div to

20 ms/Div. Increasin to 6% at 0.5 jus/Div, 0.1 jus/Div,

0.1 s/Div, and 50 ms/Div.

Variable: at least 2.5:1.

Tri er

Internal: DC to 10 MHz on si nals causin 1.0, or more,

division of vertical deflection and to approximately

1.0 MHz on si nals causin 0.3 division of vertical

deflection.

External: DC to 10 MHz on si nals of 500 mV or more,

decreasin to approximately 1.0 MHz on si nals of

150 mV.

Couplin : AC attenuates si nals below 30 Hz; LF REJ

attenuates si nals below 50 kHz.

External Level Ran e: Atten at X I, +0.8 V to -0.8 V;

Atten at X10,+8 V to —8 V.

Maximum Input Volta e: 300 V (DC + peak AC).

CALIBRATOR

Output

Volta e Accuracy (into a load of 1 M£2 or reater):

0.5 V, within 1% from +20°C to +30°C (+68°F to

+86°F), decreasin to within 2% from -15°C to +20°C

(+5°F to +68° F) and +30°C to +55°C (+86° F to

+ 131°F).

Duty Cycle: 40% to 60%.

Resistance: Approximately 10 k£2.

EXTERNAL HORIZONTAL INPUT

Deflection Factor

Horiz Ma X10, Ext Atten IX: 15 mV/Div to

25 mV/Div.

Horiz Ma off. Ext Atten IX: 150 mV/Div to

250 mV/Div.

Horiz Ma X10, Ext Atten 10X: 150 mV/Div to

250 mV/Div.

Horiz Ma off. Ext Atten 10X: 1.5 V/Div to 2.5 V/Div.

Bandwidth

DC to at least 200 kHz (upper —3 dB point).

Dynamic Ran e

At least 20 divisions (+2.5 volts to —2.5 volts) with EXT

TRIG OR HORIZ ATTEN switch set to X10, and EXT

HORIZ Variable control set to CAL.

Variable Ran e

At least 10:1.

EXTERNAL BLANKING

Sensitivity

DCCoupled: +5 volts to +20 volts.

Usable Frequency Ran e

To approximately 100 kHz.

Input Volta e

1-2

Maximum: 50 V (DC + peak AC).

Specification—326 (SIM 300500-up)

CRT DISPLAY 315 jjlA cathode current (full intensity)

Graticule Area Calibrator waveform displayed: 2.5 hours or reater.

8X10 one-fourth inch divisions. 6 divisions of 10 MHz si nal displayed: 1.5 hours

or reater. /

Geometry

Within 0.1 division.

POWER SOURCE

Power Line

Volta e Ran es (Battery Char er): 90 V to 136 V and

180 V to 272 V.

Frequency (Battery Char er): 48 Hz to 440 Hz.

Maximum Power Consumption: 35 VA, with 136 volt

AC line, a 10 MHz 6-division si nal displayed, full

intensity, and full char e rate.

External DC

Volta e Ran e: +9 V to +32 V.

Maximum Power Consumption: 12 watts, with 10 MHz,

6-division si nal displayed and full intensity.

ENVIRONMENTAL

Temperature

Nonoperatin : —40°C to +75°C (—40°F to +167°F).

Operatin : -15°Cto+55°C (+5°F to+131°F).

Char in : 0°C to +40°C (+32°F to +104°F).

Altitude

Nonoperatin : to 50,000 feet.

Operatin : to 15,000 feet. Maximum allowable ambient

temperature decreases by 1°C/1000 feet from 5,000 feet

to 15,000 feet.

INTERNAL BATTERY SUPPLY

Battery

9 size C, 1.5 AH NiCd cells.

Char e Time

MECHANICAL

Construction

Chassis Aluminum Alloy

Panel Aluminum Alloy with Anodized

Finish

Cabinet Blue Vinyl-Coated Aluminum

Full Char e (instrument off): at least 16 hours.

Operatin Time

1.5 to 4 hours, dependin on control settin s and

temperature: +20°C to +25°C (+68°F to +77°F) char e

temperature and +10°C to +30°C (+50°F to +86°F)

operatin temperature;

15 jiiA or less cathode current

Calibrator Waveform displayed: 4 hours or reater.

6 divisions of 10 MHz si nal displayed: 1.8 hours or

reater.

Dimensions and Wei hts

Hei ht 4.0 in 10.2 cm

Width with handle 8.7 in 22.2 cm

Depth, handle not extended

With char er 15.0 in 38.1 cm

Without char er 12.2 in 31.0 cm

Depth, handle extended

With char er 18.2 in 46.2 cm

Without char er 15.8 in 40.1 cm

Net wei ht without accessories

With char er «13lb ~5.9 k

Without char er «10lb ^4.5 k

Domestic shippin wei ht «21 lb ~9.5 k

Export-packed wei ht ~29lb ~13.1 k

1-3

Secti n 2-326 (SN 300500-up)

OPERATING INSTRUCTIONS

(

I

I

I

General

This section explains power source requirements,

describes the functions and uses of controls and connectors,

and ives first time and eneral operatin information.

POWER SOURCE REQUIREMENTS

WARNING I

The cells used in the battery pack are capable of

delivering a large a ount of energy in a short ti e.

Rings, watch bands and other etallic ite s that

ight short circuit the battery can rapidly beco e

hot enough to cause severe burns.

General

The 326 may be powered from either the internal

Battery Pack (nine NiCd cells connected in series) or on an

external DC volta e source ran in from +9 volts to +32

volts.

The internal battery pack is removable and may be

char ed (while in the instrument or externally) by the

battery char er.

Typical operatin time from a fully char ed battery pack

is approximately 4 to 5 hours. Actual operatin time varies

with sweep rate, the displayed si nal frequency and

amplitude, display bri htness, and the ambient temperature

durin cell char e.

Internal Battery Operati n

Slidin the power source switch to the BATT OR AC

ADPT position connects the internal battery to the 326

front-panel POWER switch. Internal battery powered

operation is not possible with the source switch in the EXT

DC POWER position.

Internal battery powered operation should be discon

tinued after the LOW BATT lamp starts flashin . The

battery should immediately be put on char e or the battery

pack should be replaced with a fully char ed pack.

If the internal battery-powered operation is continued

after the LOW BATT lamp starts flashin , the trace will

disappear in a short time and the LOW BATT lamp will

stop flashin ; dama e to some of the NiCd cells mi ht

result.

Cell Rem val (see Fig. 2-1)

1. Remove the three machine screws from the left ed e

of the Battery Pack front panel.

2. Remove two machine screws from the rear (same

ed e as those removed from the front) panel.

“ -.terminal fr m side c nnect r.

** 7. Uns lder p sitive battery tab and

v. rem ve cells as a unit.

If the cells must be removed from the battery pack, use

the followin procedure: Fig. 2-1. Battery Pack cell rem val.

\

2-1

Operating Instructi ns—326 (SN 300500-up)

3. Remove the four machine screws that extend throu h

the pack.

4. Carefully unsolder the copper strap and bare wire

from the connector lu at the front end.

5. Unsolder connector lu from side-panel conductor at

the rear of the pack.

6. Lift the side away from the pack.

7. Unsolder the copper strap from the ne ative

connector lu .

8. Carefully lift the cells (as a unit) away from the case.

Do not allow the copper cell tabs to contact each other

while removin cells.

External DC-P wered Operati n

The instrument can be powered by an external DC

source between +9 and +32 volts. The Power Source switch

must be in the EXT DC POWER position and the external

supply must be connected to the + (red) and — (black)

connectors on the rear panel of the instrument. The

external DC source will not char e the internal battery. For

some Serial Numbers, the LOW BATT indicator lamp does

not function durin External DC powered operation. If

incorrect operation occurs, check the external DC power

source.

Applying external DC power with the polarity

reversed will cause the Power Regulator fuse, F870

on the Horizontal circuit board, to open.

Battery Charger

The internal battery pack may be char ed either within

or outside the instrument. When char in the battery pack

inside the instrument the battery char er attaches to the

rear of the instrument.

Instrument operation can be continued while the

internal battery is char in or a spare battery pack can be

char ed while the instrument operates on internal battery.

The battery pack may be char ed in the instrument

while the instrument is operatin from an AC source.

Slip-on connectors in the battery char er must be

connected to match the line volta e to be used. The

internal fuse must be chan ed when the AC line volta e is

chan ed. Use a 0.4 A fuse for 115-volt operation and a 0.2

A fuse for 230-volt operation. See Fi . 2-2.

Jl. Rem ve three machine screws securing plastic c ver t

I charger.

2. Rem ve plastic c ver.

^ ' ^ '1 L r

C nnect the tw white leads (with square terminal c n-

II nectars) t either the 115-v lt r the 230-v lt square-pin

(terminals.

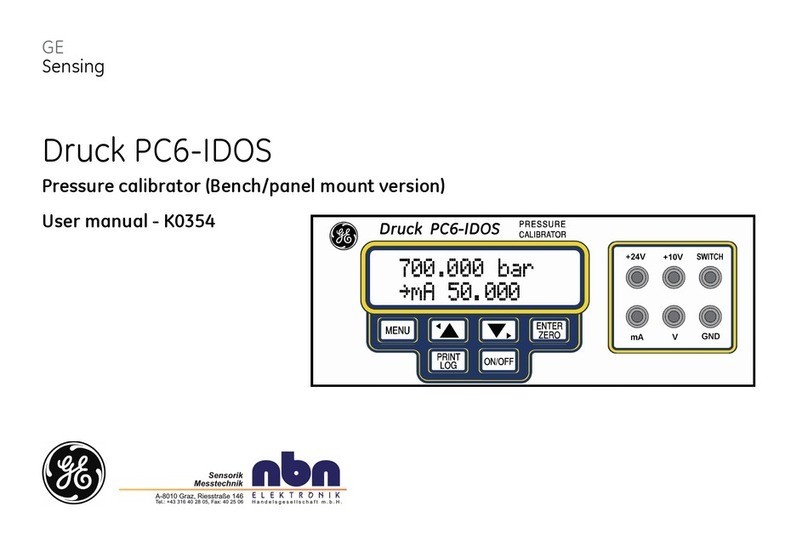

Fig. 2-2. L cati n f line-v ltage selecti n terminals.

2-2

Operating Instructi ns—326 (SIM 300500-up)

Battery Charging

Althou h the battery contained in the 326 is char ed

before packa in , it should be rechar ed for 16 hours at

FULL CHG rate before bein put into service.

every 15 char e/dischar e cycles. Once the battery has been

fully char ed, the char e rate should be set to TRICKLE.

The trickle char e rate provides only enou h current to

offset the internal losses, and will keep the battery fully

char ed.

(

(

The char in characteristics of NiCd cells vary with cell

temperature durin char e. The ener y delivered is inversely

proportional to the cell temperature durin the first

three-fourths to seven-ei hths of the full char e cycle.

If NiCd cells become reverse char ed, their capacity for

rechar in can be impaired or destroyed. An imbalance

between cells in a battery can develop durin operation or

durin partial char in . It is possible for the imbalance to

become so reat that durin dischar e the weakest cells

completely lose their char e and become reverse char ed by

the current from the char ed cells.

To avoid reverse char in one or more cells, fully char e

the battery after each dischar e (16 hours) on FULL CHG.

Althou h partial rechar e is not recommended as a

common practice, occasional rechar es can be tolerated.

About 30 to 45 minutes of operatin time can be expected

for each hour of char e.

In addition, the battery should be char ed at the FULL

CHG rate for 24 hours approximately once a month or

FUNCTION OF EXTERNAL CONTROLS,

CONNECTORS AND INDICATORS

General

The controls, connectors, and indicators listed are

contained on the external surfaces of the 326, and are used

durin routine oscilloscope operation. All other controls are

inside the instrument covers and should be adjusted only

durin instrument calibration.

The external control, connector, and indicator nomen

clature is shown in CAPITAL letters wherever it appears in

this manual.

Fr nt Panel (see Fig. 2-3)

POWER ON-OFF Two position to le switch.

Connects the oscilloscope circuitry

to the power source. Does not

affect battery char in .

Fig. 2-3. 326 Fr nt panel.

2-3

Operating Instructi ns—326 (SN 300500-up)

LOW BATT Indicator lamp. Durin battery

operation, the lamp flashes to

indicate that internal battery vol

Vert Position

ta e is low. If the battery volta e is

sufficiently low the lamp will stop

flashin and the instrument will

stop operatin . To distin uish this

condition from equipment failure,

connect the char er at FULL CHG

X10 GAIN

rate for a few minutes. Then

disconnect the char er and check

for oscilloscope operation and LOW

BATT indicator lamp operation.

(For some serial numbers the LOW

CH 2

BATT Indicator lamp does not

function when External DC power Mode Selector

source is used.) CH 1

CH 1 VOLTS/DIV Selects calibrated deflection factors

from 0.1 Volts/Div to 10 Volts/Div CH 2

(Variable in CAL position and X10

GAIN pushed in). When set to the

5 DIV CAL position, a 5-division

square-wave calibrator si nal is

displayed.

ALT

Variable Varies Volts/Div between calibrated

steps. Ran e is at least 2.5X. The

uncalibrated ran e is extended to

CHOP

25 Volts/Div. ADD

CH 1 Input

Couplin Switch CH 2 INVERT

AC Capacitively couples the input

si nal to the input attenuator.

GND Grounds the input attenuator (both

pushbuttons out) and connects the

si nal throu h 470 k£2 and

0.0185 /zF to round.

NOTE

The GND configuration (both AC

and DC buttons out) provides a

precharge circuit. The input coup

ling capacitor charges to the DC

level of the input signal. This pre

charge feature prevents offscreen

deflection which occurs when

connecting a signal to the input

with the AC button pushed. Always

TIME/DIV

use the precharge feature before

connecting the signal to the input

(with both buttons out, connect

the signal to the input and then

push the AC button).

Variable

DC

2A

Couples the input si nal directly to

the input attenuator.

Vertically adjusts the display

position.

Pull the POSITION control knob to

increase the vertical ain by a factor

of 10. Extends the calibrated

deflection factor to 1 mV/Div.

Bandwidth is reduced to 5 MHz.

VO LTS/D IV , Variable, input

couplin switches, POSITION and

X10 GAIN provide the same func

tions as those of CH 1.

Displays channel 1 only.

Displays channel 2 oniy.

Displays channel 1 and channel 2

alternately. When both channels are

displayed, the channels are

switched electronically durin beam

retrace interval.

Displays channel 1 and channel 2

simultaneously.

Displays the al ebraic sum of the

si nals applied to channels 1 and 2. (

Channel 2 display is inverted with

the INVERT switch in the OUT

position.

Selects the horizontal sweep rate.

Sweep rates are 1 /zs/DIV to

1 s/DIV in a 1-2-5 sequence, plus an

EXT HORIZ position. In the EXT

HORIZ position horizontal deflec

tion depends on si nal applied to

the EXT HORIZ INPUT connector

on the side panel.

NOTE

For external sweep, the EXT

Trigger Selector button ust be

pushed.

Varies the TIME/DIV between cali

brated steps. Ran e is at least 2.5X.

The uncalibrated sweep rate is

extended to 2.5 s/Div. With the

TIME/DIV selector in the EXT

HORIZ position, the Variable (

control attenuates the external '

horizontal si nal from IX to 10X.

POSITION X10

HORIZMAG

EXT (pushbuttons)

AC

DC

I NT (pushbuttons)

AC

LF REJ

CH 1-NORM

(pushbuttons)

LEVEL/SLOPE

Horizontally positions the display.

Pull the POSITION X10 HORIZ

MAG knob to increase the horizon

tal ain by a factor of 10 (the

sweep expands from raticule

center). X10 ma nification extends

the fastest displayed sweep rate to

.IjUs/DIV.

Tri ers the sweep from a tri er

si nal applied to the EXT HORIZ

INPUT (side panel).

Capacitively couples the external

tri er si nal. Low frequency cutoff

is about 30 Hz.

Tri ers on DC level chan es as well

as AC si nals.

Tri ers the sweep on the si nal

applied to the Vertical Input(s).

Capacitively couples the internal

tri er si nal. Low frequency cutoff

is about 30 Hz.

Capacitively couples the internal

tri er si nal. Makes hi h frequency

tri erin more dependable by

rejectin frequency components

below about 50 kHz.

Selects the internal tri erin

source. NORM button selects an

internal si nal, dependent on the

position of the Mode switch. CH 1

button selects Channel 1 only as

the tri er source.

Selects the level and slope of the

displayed si nal on which tri erin

occurs. In the fully ccw position,

tri erin is automatic on the

positive- oin (+) tri er si nal. In

the fully cw position, tri erin is

automatic on the ne ative- oin (-)

tri erin si nal. Between the two

extreme positions the control

selects the tri erin level on either

the + or — slope. AUTO tri erin

provides a baseline in the absence

of tri erin si nal, but tri erin is

normal on recurrent si nals.

Operatin Instructions—326 (SN 300500-up)

INTENSITY Adjusts the display bri htness.

Display bri htness affects battery

operatin time.

FOCUS Adjusts for a sharp, well defined

trace. Interacts somewhat with the

INTENSITY control.

.5 V CAL OUT Source of calibration square wave.

0.5 volts, peak to peak.

Side Panel

EXT TRIG OR HORIZ

INPUT Apply external tri er or external

horizontal input si nal to this BNC

connector.

ATTX1-X10 Selects attenuation factor (XI or

Switch X10) for the external si nal.

INSTRUMENT FAMILIARIZATION

This procedure provides a means of quickly checkin the

operation of the 326.

Preliminary

Preset the front-panel controls as follows:

LEVEL/SLOPE +AUTO

AC-LF REJ AC

CH 1-NORM CH 1

TIME/DIV 1 ms

Variable CAL

Horiz POSITION midran e

X10 HORIZ MAG pushed in

Mode CH 1

CH 1 and CH 2

VOLTS/DIV 5 DIV CAL

Variable CAL

Input AC—DC DC

Vertical POSITION midran e

X10 GAIN pushed in

INTENSITY midran e

FOCUS midran e

Set rear-panel EXT DC POWER-BATT OR AC ADPT

switch to BATT OR AC ADPT.

1. Check Battery Charge Level

a. Switch POWER switch to ON.

2-5

Operatin Instructions—326 (SN 300500-up)

b. CHECK-The LOW BATT Indicator should not flash.

c. If LOW BATT Indicator flashes, char e the battery

pack, replace the battery pack with a fully char ed pack, or

operate on an external DC supply. Proceed with the

checkout.

d. The lower portion of the calibrator si nal should

appear within the raticule area. Adjust FOCUS and

INTENSITY for suitable viewin . Vertically position the

bottom of the display to the bottom raticule line.

Horizontally position the start of the display to the first

raticule line (left).

2. Check Vertical Deflecti n Fact r

a. CHECK—The amplitude of the displayed square wave

should equal 5 divisions.

b. Pull out the CH 1 X10 VERT GAIN control knob.

c. CHECK—The display amplitude should equal 5

divisions.

3. Check Pr be C mpensati n

a. Connect a P6049A Probe to the CH 1 VERT INPUT

connector. Set CH 1 VOLTS/DIV selector to .01 V,

TIME/DIV to 0.5 ms, and Mode to CH 1.

b. Touch the probe tip to the CAL OUT jack and check

the display for proper probe compensation (see Fi . 2-4).

Fig. 2-4. Pr be C mpensati n.

c. If necessary, adjust the probe compensation for the

best front corner response to the square waves as shown in

Fi . 2-4.

4. Check Trigger Sensitivity and P larity

a. Set CH 1 VOLTS/DIV selector to 1 volt, TIME/DIV

to 1 ms, push I NT AC and CH 1 buttons. Pull out the CH 1

X10 VERT GAIN control and apply the CAL OUT si nal

to CH 1 VERT INPUT and to EXT TRIG OR HORIZ

INPUT by means of patch cords.

b. Adjust the CH 1 VOLTS/DIV Variable control for a

3-division display amplitude.

c. CHECK—For stable tri erin on the + slope and on

the — slope of the displayed si nal (turn the LEVEL/

SLOPE control throu hout its ran e and check for proper

tri erin ). Check for stable tri erin in both + AUTO and

- AUTO.

d. Connect the CAL OUT si nal to CH 2. Switch CH 2

VOLTS/DIV to 1 V, Mode to CH 2, and CH 1-NORM to

NORM.

e. Adjust the CH 2 VOLTS/DIV Variable control for a ^

3-division display amplitude.

f. CHECK—For stable tri erin on the + slope and on

the — slope of the displayed si nal, includin the + AUTO

and — AUTO positions.

. Reconnect the CAL OUT si nal to both CH 1 VERT

INPUT and EXT TRIG OR HORIZ INPUT.

h. Switch Mode to CH 1, TRIGGERING to EXT AC,

CH 1-NORM to CH 1.

i. CHECK—For stable tri erin on the + slope and —

slope, includin the+ AUTO and — AUTO positions.

5. Check External H riz ntal

NOTE

In the Ext Horiz ode, the internal sweep is disabled

and the CRT bea is unblanked. Consequently, a

brighter than nor al stationary spot will appear on

the CRT face unless an external sweep is applied. The

INTENSITY setting should be changed to reduce the

brightness level consistent with good viewing.

2-6

Operating Instructi ns—326 (SN 300500-up)

a. Apply the CAL OUT si nal to the EXT TRIG OR

HORIZ INPUT connector usin a patch cord.

b. Set the EXT TRIG OR HORIZ ATTEN to IX.

c. Set the TIME/DIV to EXT HORIZ and TRIG

GERING Couplin to EXT AC.

d. Check for two spots separated by approximately 2.5

divisions.

e. Set the EXT TRIG OR HORIZ ATTEN to 10X.

Horizontally center the display.

f. Note that the distance between the two spots

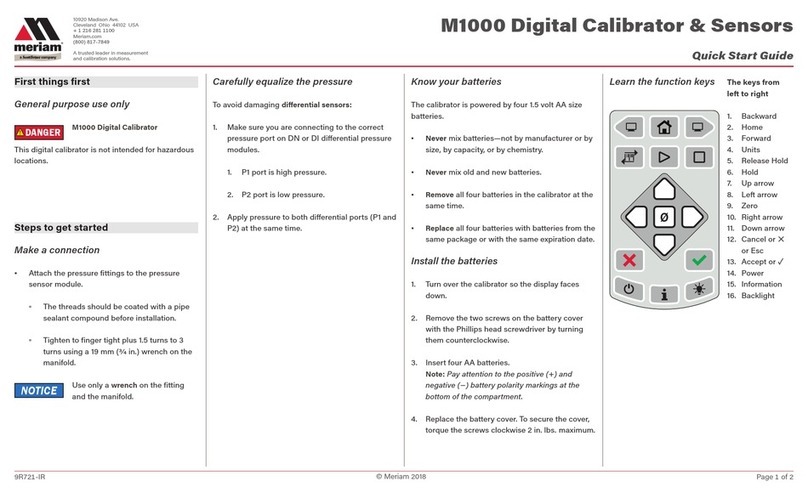

decreases by a factor of 10. Fig. 2-5. Gr und c nnecti n required t charge Battery Pack

utside f instrument.

. Pull the X10 HORIZ MAG. Position horizontally as

necessary to keep the display approximately centered. battery pack that it would be in if char in the battery

pack in the instrument).

h. Note that the distance between spots increases by a

factor of approximately 10.

Charging the Battery (Battery Pack ut f the

Instrument)

Plu the battery char er banana plu s into the battery

pack banana jacks, bein sure that the polarity is correct

(mount the char er in the same position relative to the

Connect a banana-banana patchcord from the ne ative

( nd) battery pack output terminal to the ne ative ( nd)

external DC supply banana jack. See Fi . 2-5.

Plu the AC power cord into the char er and connect to

the power line. Set the FULL CHG—TRICKLE switch to

FULLCHG.

2-7

Secti n 3—326 (SN 300500-up)

CIRCUIT DESCRIPTION

Intr ducti n

This section of the manual contains a description of the

circuitry used in the 326 Oscilloscope. A brief description

of the instrument block dia ram (precedin the foldout

circuit schematics) is followed by a somewhat more

detailed description of the individual blocks. Since the

Power Re ulator contains unique circuits, additional detail

is provided.

If more information is desired on the commonly used

circuits, refer to the followin textbooks:

TEKTRONIX Circuit Concepts Books (order from your

local TEKTRONIX Field Office or representative).

Cathode Ray Tubes, TEKTRONIX Part Number

062-0852-01.

Horizontal Amplifier Circuits, TEKTRONIX Part

Number 062-1144-00.

Oscilloscope Tri er Circuits, TEKTRONIX Part

Number 062-1056-00.

Power Supply Circuits, TEKTRONIX Part Number

062-0888-01.

Sweep Generator Circuits, TEKTRONIX Part Number

062-1098-01.

Vertical Amplifier Circuits, TEKTRONIX Part Number

062-1145-00.

Phillip Cutler, "Semiconductor Circuit Analysis", McGraw

Hill, New York, 1964.

Lloyd P. Hunter, "Handbook of Semiconductor Elec

tronics", second edition, McGraw Hill, New York, 1962.

Millman and Taub, "Pulse, Di ital, and Switchin Wave

forms", McGraw Hill, New York, 1965.

BLOCK DIAGRAM DESCRIPTION

Intrument Bl ck

The block dia ram shows only the basic interconnec

tions between individual blocks (see the foldout Block

Dia ram precedin the Schematic foldouts at the rear of the

manual).

Si nals applied to the vertical inputs are applied to the

Vertical Preamp throu h the input couplin selector switch

and the input step attenuators.

The Vertical Preamps contain ain, balance, and posi

tionin controls as well as controls for settin the CRT

vertical deflection plate DC levels.

A five division calibration si nal is introduced into each

channel via the input attenuators.

Si nal is picked off at channel 1 preamp output for use

as tri erin si nal.

The two vertical channels are switched electronically by

the channel switchin multi and atin diodes to provide

five modes of operation: CH 1, CH 2, ALT, CHOP, and

ADD.

Si nal is picked off ahead of the delay line to provide

tri er si nal from whichever si nal is bein ated throu h

to the output amplifier.

A 300 ns delay line provides sufficient si nal delay to

the CRT vertical deflection plates to allow observation of

the transition which tri ers the sweep.

The Output Amplifier provides hi h frequency compen

sation, and the current capability to drive the vertical

deflection plates.

The Tri er Preamp selects the tri er source and

amplifies the si nal selected to a level compatible with the

tri er enerator input.

3-1

Circuit Descripti n—326 (SN 300500-up)

The tri er source (either the si nal from the Tri er

Preamp or the EXT TRIG) and the method of couplin are

selected in the Tri er Generator. The tri er si nal selected

is coupled to a DC comparator amplifier to select the point

on the si nal at which tri erin occurs. A switch in the

comparator output selects tri er polarity. The si nal is

then shaped in the Schmitt multi and is coupled to the

Sweep Generator to start the sweep volta e runup.

The Sweep Generator is a Miller inte rator (runup)

which provides a linear sawtooth volta e to the horizontal

amplifier. A ate-amplifier circuit provides si nal to the

CRT to blank the trace durin the retrace interval.

The Horizontal Amplifier contains adjustable com

ponents to set horizontal XI Gain, X10 Gain, and

positional re istration in the ma nified mode. The output

circuitry provides drive to the CRT horizontal deflection

plates.

The Power Re ulator derives all of the re ulated

operatin volta es from the DC source volta e (internal

battery or external DC source). Adjustments are provided

to set the CRT beam acceleratin potential, focus, beam

intensity, and the + and — 5-volt supply levels.

The Battery Char er circuit provides current either for

char in the battery in about 16 hours or a trickle char e

which just offsets the internal losses of a fully char ed

battery. An internal adjustment sets the char e current

level.

BASIC BLOCK DESCRIPTION

Intr ducti n

This section describes briefly each of the basic circuits.

The description of each block is keyed to the circuit

schematic (foldout at rear of manual), i. e., (2) indicates

schematic No. 2, CH 1 Vertical Preamplifier.

Ch 1 Vertical Preamplifier (2)

Input Couplin . Determines the method of couplin the

si nal to the amplifier input (AC—DC—GND).

Attenuators. Conventional frequency compensated step

attenuators which maintain the input RC at 1 and

47 pF in each of the 10 switch positions.

Input. CR30 throu h CR33 prevent overdrive to the

input FET, Q31A. R36 permits adjustment for any

differences in the characteristics of Q31A and Q31B, which

are electrically and thermally paired.

The first amplifier sta e is a feedback amplifier con

sistin of the paraphase confi uration Q41A and Q41B and

the common-base section Q51-Q52 and Q53-Q59. R41

(X10 Vert Gain) adjusts the ain in the X10 switch (S40)

position. R37 (Var Volts/Div Bal) adjusts Q41Aand Q41B

collector loads to prevent display shift as the VOLTS/DIV

Variable is rotated throu hout its ran e.

A push-pull emitter follower, Q55-Q57 drives the push-

pull amplifier Q61-Q71. XI Gain calibration and Volts/Div

Variable are adjusted in the comm on-emitter circuit and

display vertical position is adjusted in the collector circuits.

Q81-Q91-Q88-Q99 is a push-pull feedback amplifier in

which the upper and lower deflection plate DC levels are

adjusted.

Q95 and Q98 supply CH 1 si nal to the tri erin

selector circuit.

Calibrator (shown on schematic (1)). The calibrator (an

astable multi, Q1 and Q9, and a precision volta e divider)

provide a 0.5-volt square wave to the front-panel CAL OUT

jack, and to the Input FET via the 5 DIV CAL position of

each (CH 1 and CH 2) attenuator switch.

CH 2 Vertical Preamplifier (dia ram (4)). Same as CH 1

Vertical Preamplifier except for Tri er Pickoff and

Calibrator.

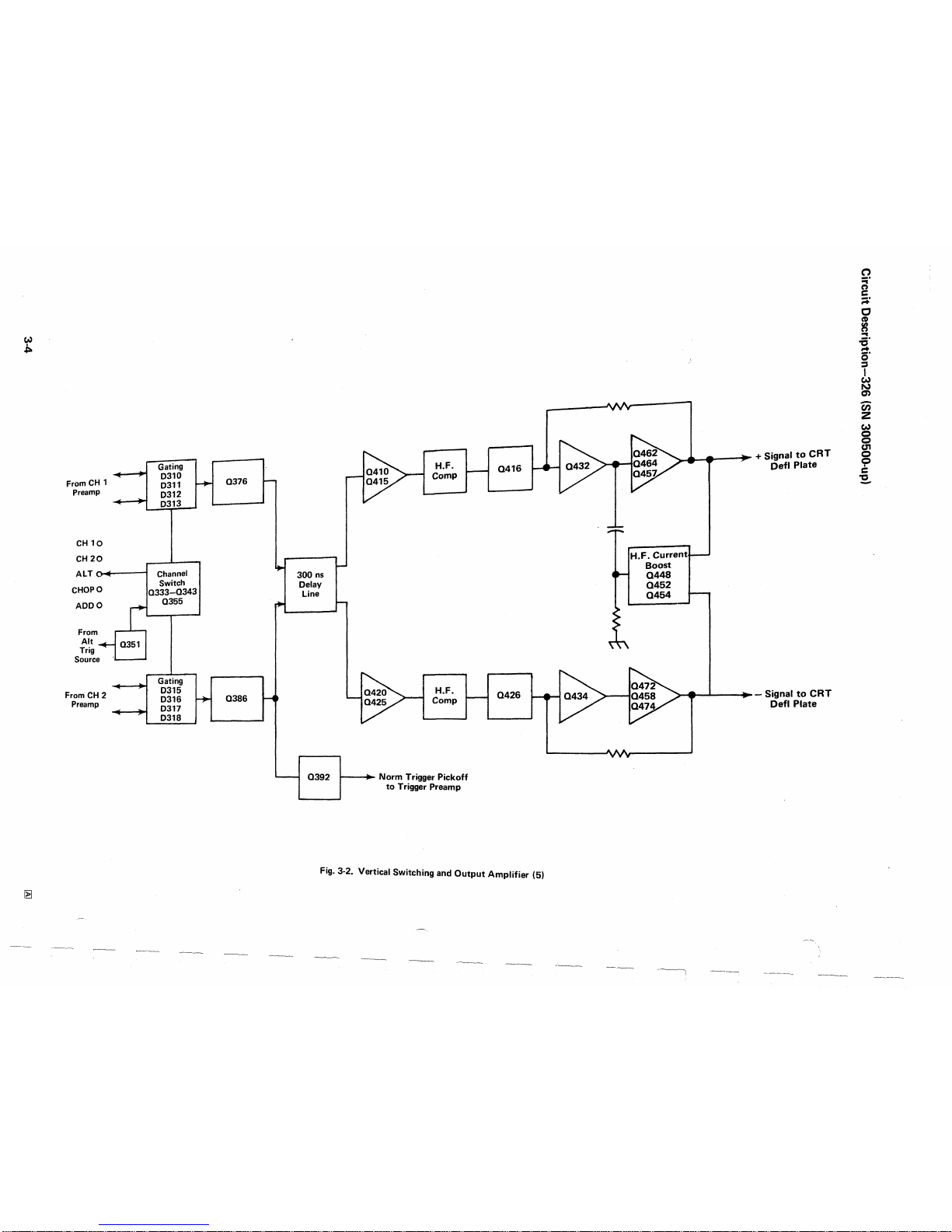

Vertical Switchin and Output (5). Q333-Q343-Q355, a

multivibrator with several operatin modes, provides

channel switchin by atin the si nal throu h the appro

priate diodes in the switchin matrix (CR311 throu h

CR313 and CR315 throu h CR318). The operatin modes

(selected by the Mode switch) are:

CH 1. +5 volts is applied to Q333 base divider resistor,

R342, and to CR316-CR317, blockin CH 2, atin only

CH 1 throu h to the Output Amplifier.

CH 2. Applies +5 volts to Q343 base divider resistor,

R332, and to CR311-CR312, blockin CH 1, atin only

CH 2 throu h to the Output Amplifier.

CHOP. Applies +5 volts to the junction of R335-R345.

The switchin circuit operates as an astable (free runnin )

multi at a 110 kHz rate, alternately atin CH 1 and CH 2

into conduction. Since the switchin rate is fixed (not

dependent on tri er si nal) both si nals are displayed

simultaneously on the viewin screen. A si nal is taken

3-2 El

j Vert X10 X I Vert

I Gain Gain

j R41 R65

i

Var V lts/Div

CH 2 Preamp identical except f r Bal

trigger pick ff and calibrat r cir- R37

cuits.

Fig. 3-1. CH 1 Vertical Preamplifier (2)

Circuit Descripti n—326 (SN 300500-up)

3-4

Fig. 3-2. Vertical Switching and Output Amplifier (5)

Circuit Descripti n—326 (SN 300500-up)

Table of contents

Other Tektronix, Inc. Test Equipment manuals