Content

1. SAFETY INSTRUCTIONS.........................................................................................................................................1

2. PRODUCT DESCRIPTION........................................................................................................................................1

2.1 OVERVIEW................................................................................................................................................................1

2.2 FUNCTION.................................................................................................................................................................1

MAIN MODULE (AR4DCT)...........................................................................................................................................1

2.3 TECHNICAL PARAMETER..........................................................................................................................................2

2.4 ENERGY METERING..................................................................................................................................................3

2.5 MAX./MIN.VALUE AND DEMAND...............................................................................................................................3

2.6 DIGITAL INPUT..........................................................................................................................................................3

2.7 RELAY OUTPUT.........................................................................................................................................................3

2.8 COMMUNICATION .....................................................................................................................................................4

3. INSTALLATION AND WIRING..................................................................................................................................4

3.1 DIMENSION...............................................................................................................................................................4

3.2 INSTALLATION ..........................................................................................................................................................4

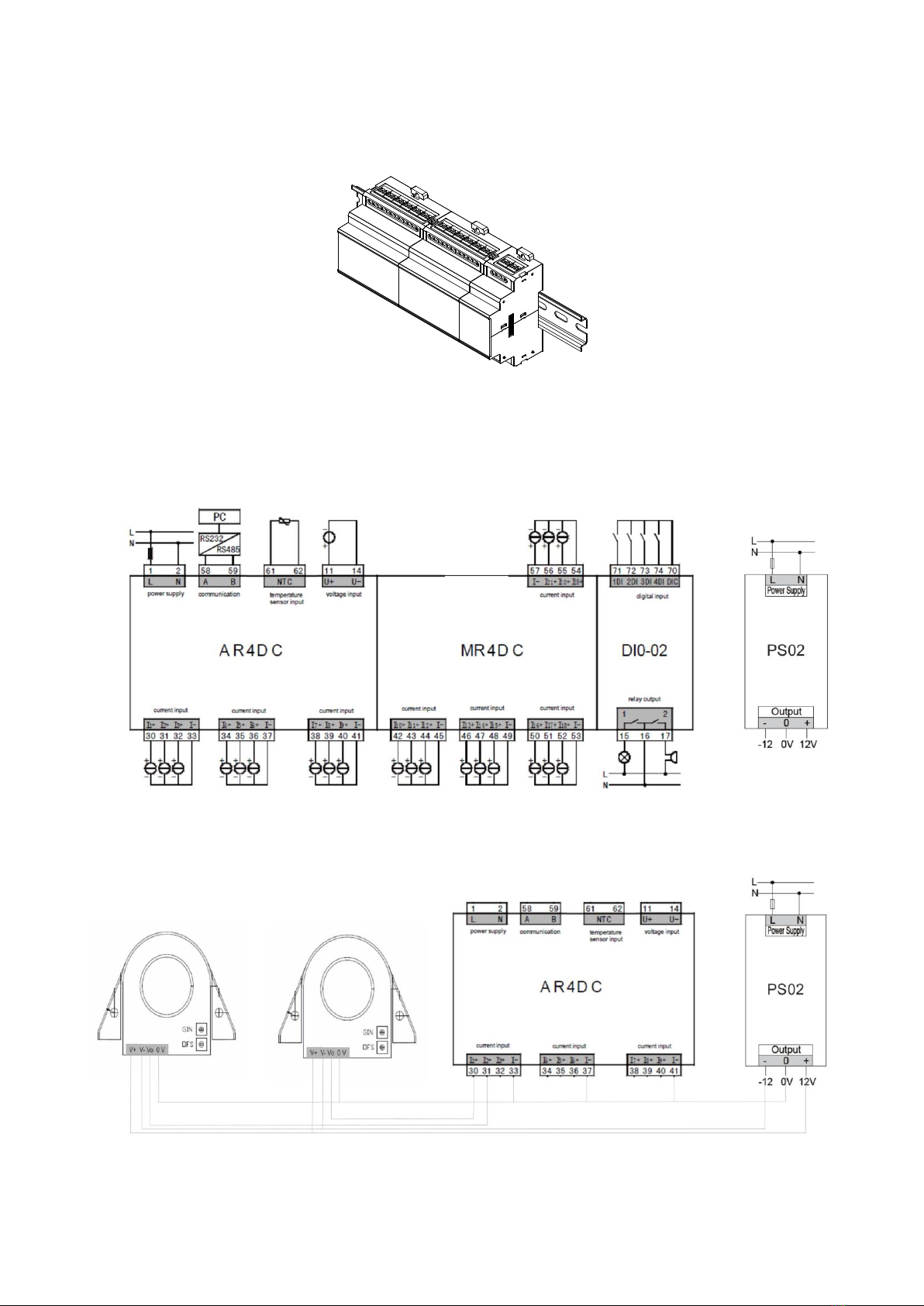

3.3 WIRING.....................................................................................................................................................................5

TYPICALWIRING..............................................................................................................................................................5

3.3.1AR4DCT +MR4DCT +DIO-02.........................................................................................................................5

4. OPERATION ................................................................................................................................................................8

4.1 PANEL DESCRIPTION................................................................................................................................................8

4.2 INSTRUCTION FOR OPERATION KEYS.......................................................................................................................8

4.3 INSTRUCTION FOR MEASUREMENT INTERFACE .......................................................................................................8

5. SETTING ......................................................................................................................................................................9

5.1 PROGRAMMING MODE..............................................................................................................................................9

6. COMMON PROBLEMS AND TROUBLESHOOTING.........................................................................................14

ABOUT COMMUNICATION ..............................................................................................................................................14

INCORRECT MEASUREMENTS.......................................................................................................................................14

ABOUT INCORRECT POWER RUNNING..........................................................................................................................15

THE METER DOES NOT RESPOND TOANY OPERATION .................................................................................................15

OTHER ABNORMAL PHENOMENA ..................................................................................................................................15