5

Description of the Equipment

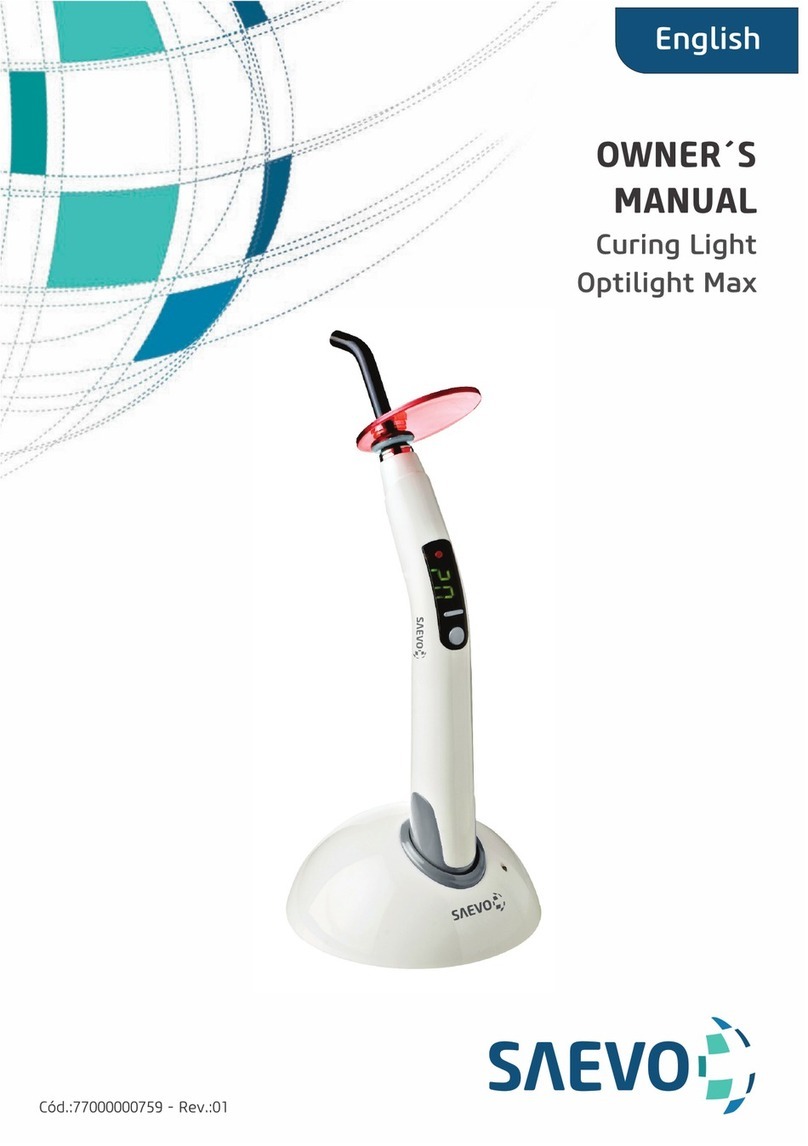

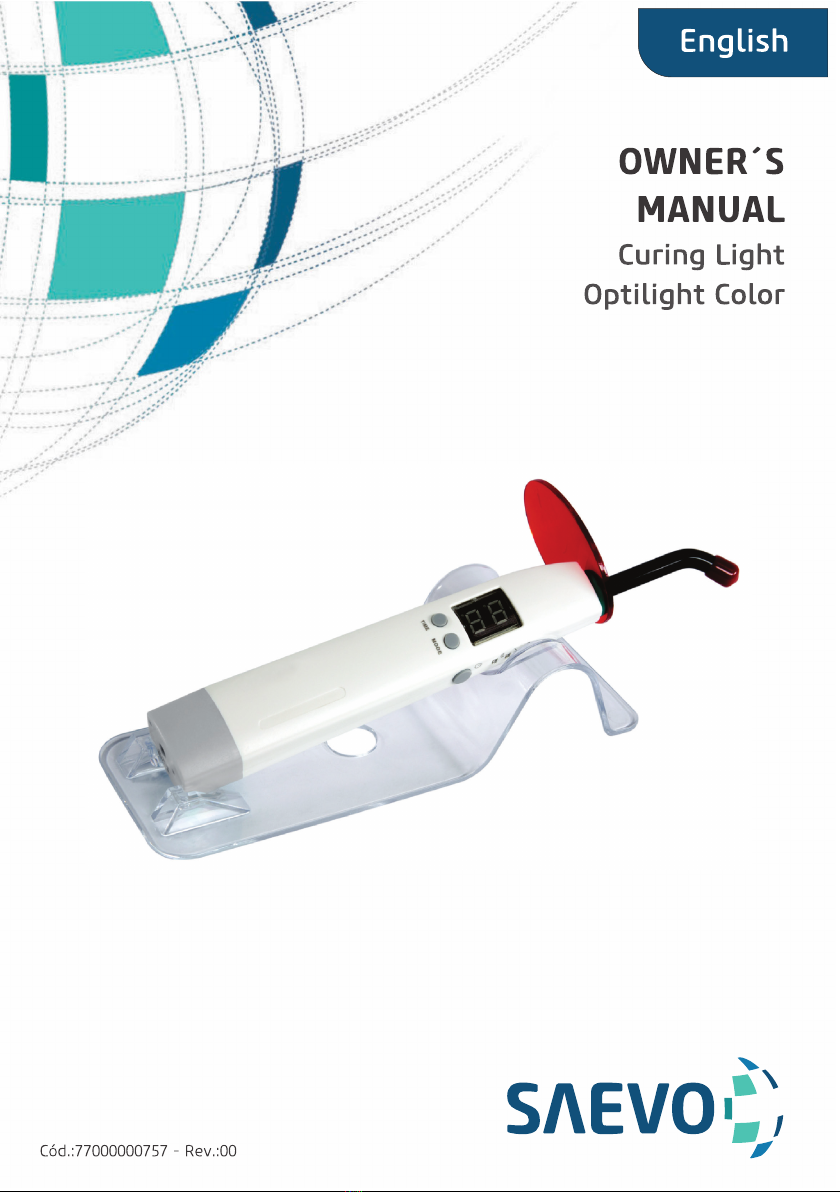

Optilight Color is the latest generation of LED photo activation devices.

This abbreviation is the acronym for Light Emitting Diode, a totally dierent way of emitting light,

in comparison to the halogen conventional devices. Unlike traditional equipments, which generate

light in wide wave spectrum and a lot of heat, this technology allows the emission of cold light in

a precise wavelength for the activation of several dental products apply.

LED technology, recently introduced in odontology, has brought several advantages to

photopolymerizers on direct restoration in composed resin. Besides innitely more durable, LEDs

have become the most compact, ergonomic and easy-to-install and transport equipments. The

cold light emission and in precise wavelengths assure a safe polymerization of activated composite

by the camphorquinone, without the risk of tooth warming, pulp injuries or discomfort for both

operator and patients.

The safety and eciency of the LEDs, now with high energy emission, are available to all the clinical

procedures that require light power for photo activation.

The wavelength from 450nm to 470nm associated with the high energy emitted by Optilight Color

enables the multi functionality of this device:

• Direct restoring processes: composite resins, ionomers and adhesives.

• Indirect restoring: laminated adhesive cementation, inlays, aesthetic pins and metalfree diadems.

• Activation of material photo active as sealants, surgical cements and the basis of a foraging.

Designed and built within the most advanced technology in order to provide results within the

specications set by the highest world odontology authorities.

Equipped with a power supply with an automatic bi-volt key that allows to use the equipment in

any supply voltage between 100 to 240V ~ - 50/60Hz.

Digital control on the display in the handpiece itself.

Variation of choosing the operation time (5,10,15 and 20 seconds).

It has 3 application modes: Continuous, Ramp and Pulse:

• Continuous: Maximum mode and continuous light intensity (same luminosity from the beginning

to the end of the polymerization).

• Ramp: Gradual light intensity mode, increases gradually.

• Pulse: Pulse mode has cycles that oscillate at a xed frequency.

Physical Principle used by the Equipment

The physical principle is the emission of a light for polymerizing photo sensible substances, since

the equipment is featured with a cold light emitter (LED) with the wavelength comprised within

450nm a 470nm (blue light), which has the ideal intensity for integrating with camphorquinone.

Indication of Equipment

This equipment is for dental use only and must be used and handled by a qualied person

(professional properly regulated in compliance with the Country’s local legislation) observing the

instructions contained in this manual.

It is the user’s obligation to only use the equipment in perfect conditions and protect himself,

patients and third parties against potential hazard.

Purpose of the equipment

This equipment is for dental use only aiming to photo polymerize photo sensible substances through

the emission of a blue light.

It was designed for being used in several dental processes such as: Restorative procedures, bracket

bonding and activation of material photo activated as sealant, liner bases.

IDENTIFICATION OF EQUIPMENT