SAF Tehnika JSC 3

Contents

: OVERVIEW............................................................................................ 5

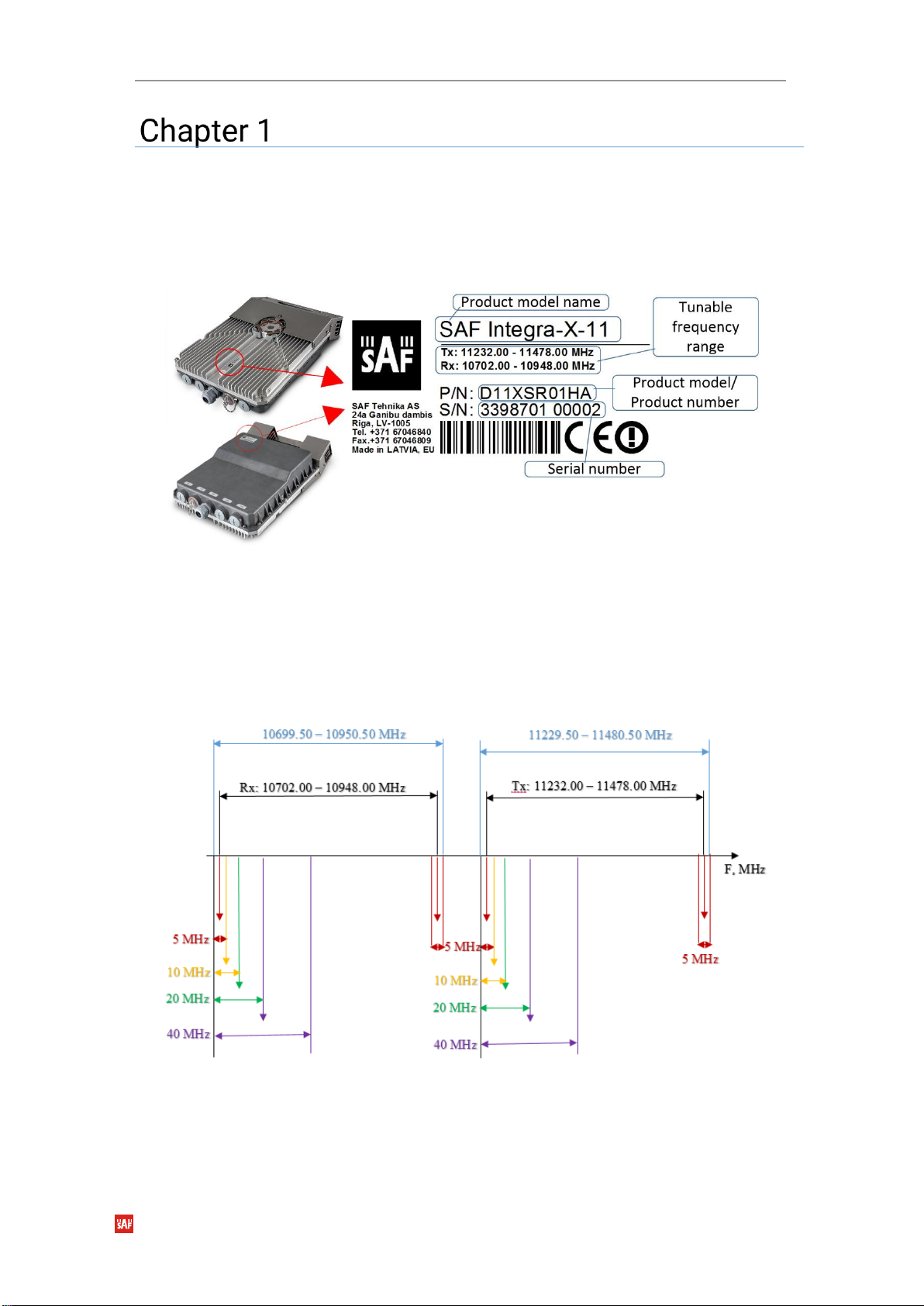

Labeling ............................................................................................................... 5

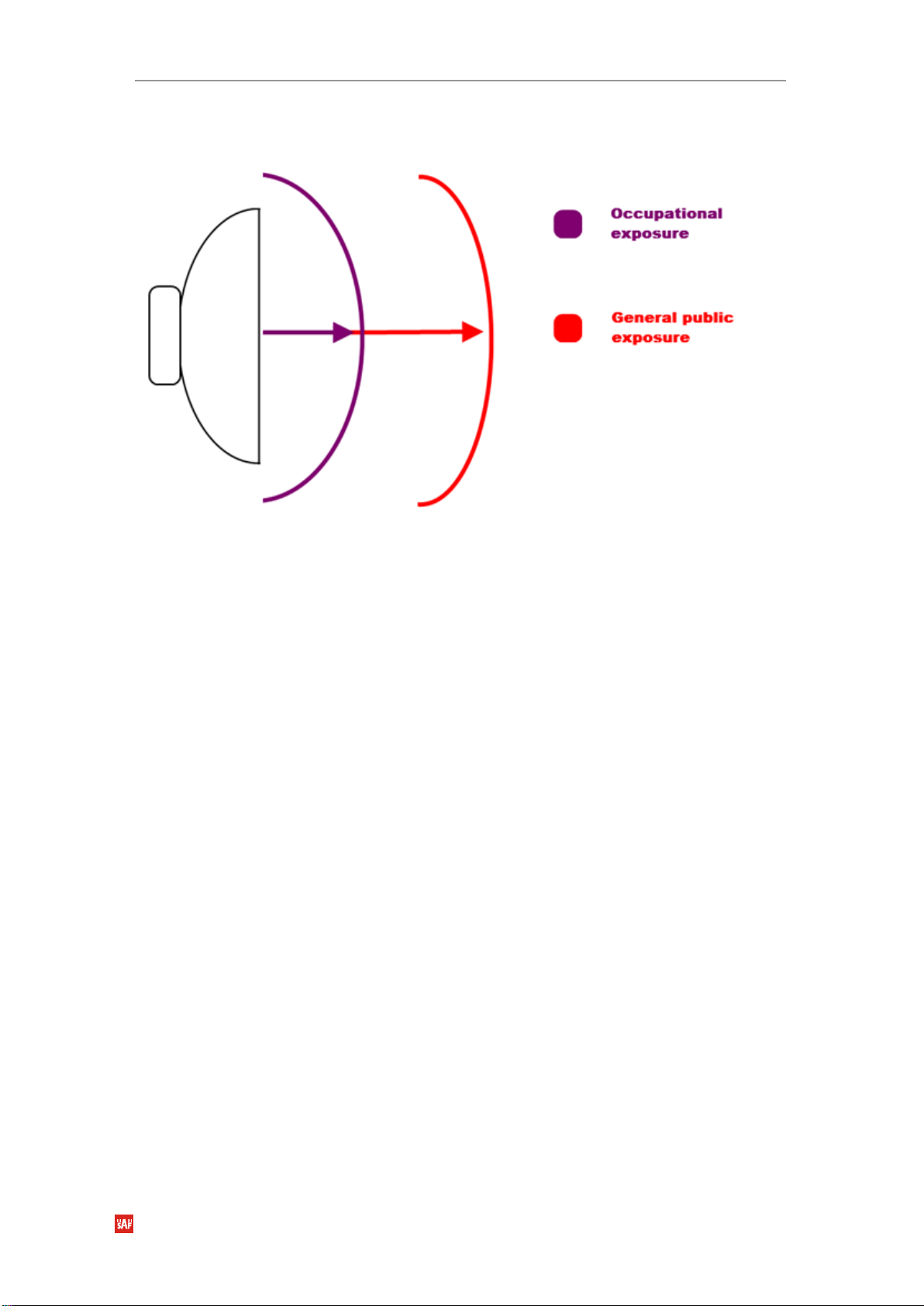

Microwave Radiation .......................................................................................... 7

: INSTALLATION .................................................................................... 8

Initial setup in indoor environment upon delivery (“bench test”).................... 9

Integra-X FODU: attaching to the antenna ...................................................... 11

Setting link polarization................................................................................ 12

Attaching FODU to the antenna ................................................................... 12

Grounding connection .................................................................................. 14

Power connections ....................................................................................... 14

Note on antenna and XPIC alignment ......................................................... 15

Connecting FO interface using a fiber conduit kit.......................................... 15

WEB GUI ............................................................................................... 17

Initial configuration........................................................................................... 17

Powering Integra-X FODU and connecting to PC ....................................... 17

Connecting Integra-X power supply ................................................................ 18

System requirements.................................................................................... 21

Ethernet management connection configuration ...................................... 22

Accessing Web GUI....................................................................................... 22

Main page.......................................................................................................... 24

Modifying basic system parameters........................................................... 25

Over The Air....................................................................................................... 33

Over The Air Radio Configuration....................................................... 33

Networking ........................................................................................................ 37

Networking Ethernet VLAN................................................................. 37

Networking Ethernet Port status and configuration......................... 39

Networking Ethernet Rate limit........................................................... 41

Networking Ethernet MAC address table .......................................... 43

Performance...................................................................................................... 45

Performance Alarm Alarm status ...................................................... 45

Performance Alarm Alarm event log.................................................. 46

Performance Alarm Sensor configuration......................................... 49

Performance Alarm Alarm threshold configuration ......................... 51

Performance Monitoring Performance graph................................... 53

Performance Monitoring Performance log ....................................... 55

Performance Ethernet Ethernet switch statistics............................. 56

Performance Ethernet Actual throughput ......................................... 61

Performance Ethernet QoS statistics ................................................ 62

Performance Over The Air Equalizer graph ....................................... 63

Performance Over The Air Constellation diagram............................ 64

Performance Over The Air Rx spectrum ............................................ 66

Performance Over The Air Modem performance ............................. 68

System ............................................................................................................... 69

System FW Firmware upgrade ........................................................... 69

System Configuration IP configuration ............................................. 72

System Configuration SNMP configuration ...................................... 74