3

Installation and Operation Manual

Power-Fill System

1. Always disconnect the power source before

servicing any part of the refill system.

2. Release all pressure within the system before

servicing any of its component parts.

3. Drain all liquids from the system before servicing

any of its component parts.

4. Check all hoses for weak or worn conditions

monthly. Make sure that all connections and

fittings are tight and secure.

5. Use inlet pipe, hose, and fittings - from the

panel to the refill pump inlet - that are rated for

23 inches Hg vacuum (584 mm Hg) and 50 psi

(3 BAR) pressure and are compatible with foam

agents.

6. Use discharge pipe, hose and fittings

from the pump outlet to the inlet of the foam tank

that are rated for a minimum of 50 psi (3 BAR)

and are compatible with foam/chemical agents.

7. Any electrical system has the potential to

cause sparks during service. Eliminate explosive

or hazardous environments during service/repair.

8. The components and fittings used in this system

must be compatible with the foam concentrates used

and pressures at which the pump system operates.

9. CAUTION: Do not operate the system at

or above a temperature of 1600F (710C).

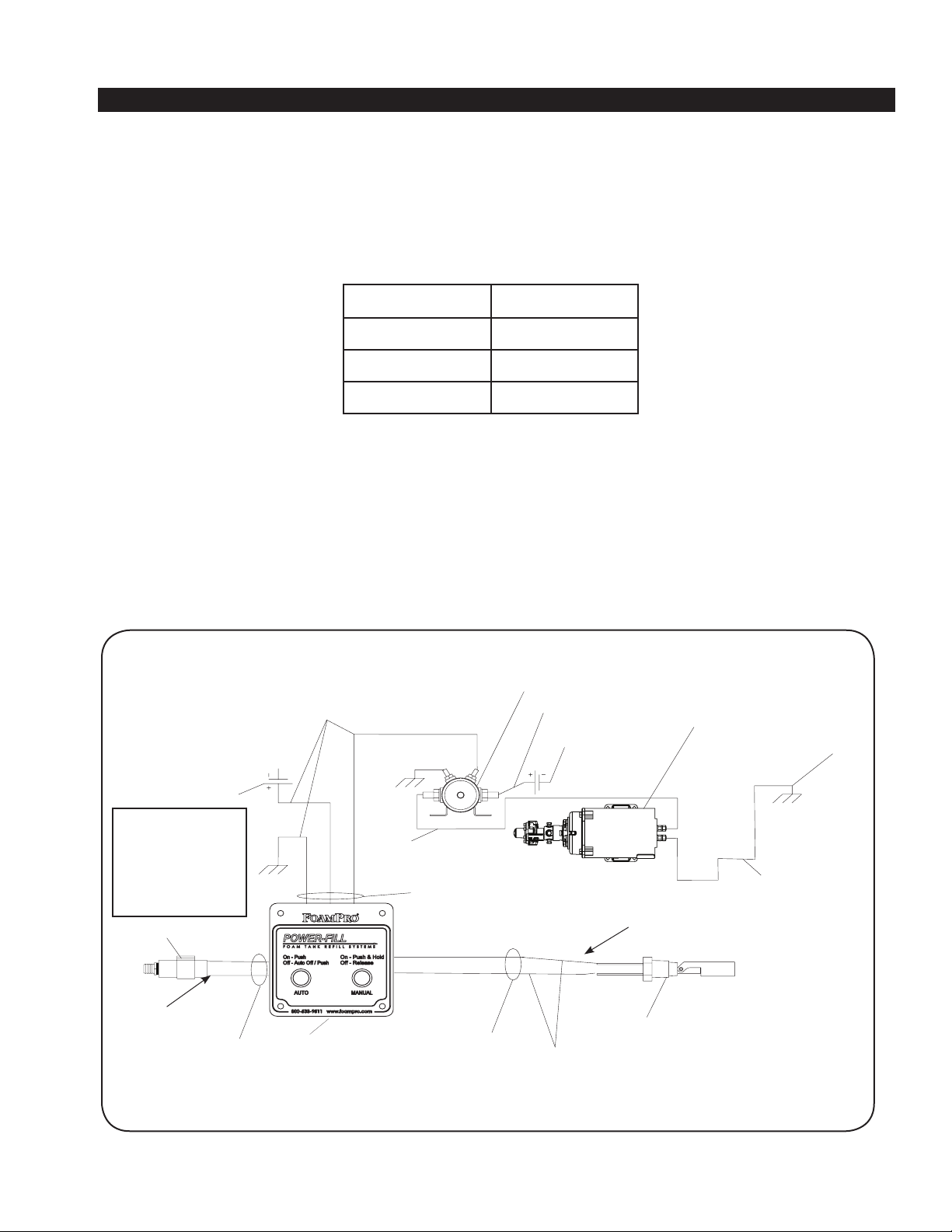

10. CAUTION: Make sure the electrical source of

power for the unit is a constant 12 or 24-volt

DC negative ground system for the 3435-

0134 and 3435-0135 truck-mounted systems,

capable of supplying 41 amps minimum. Make

sure the electrical source of power for the

3435-1020 portable unit is a 120 VAC grounded

circuit, capable of supplying 15 amps

minimum. Make sure the electrical source of

power for the 3435-1021 portable unit is a 240

VAC grounded circuit, capable of supplying 10

amps minimum.

11. CAUTION: Periodically inspect foam pump

and all system components. Perform routine

preventive maintenance as required.

12. Avoid spraying water on the pump/motor

assemblies as this could cause short circuits.

13. WARNING: Do not pump flammable or

explosive fluids such as gasoline, fuel

oil, kerosene, etc. Do not use in explosive

atmospheres. The refill system should be used

only with fluids compatible with its component

materials. Failure to follow this warning may

result in personal injury and/or property

damage.

14. Unplug the AC-driven system when not in use.

15. Never pull the cord to unplug the system from

the power source or to move the pump/motor

assembly, as cord, plug, or pump/motor damage

may occur.

16. Never operate unit without the GFI plug.

Please read all of the following safety precautions and

follow them carefully. They are important for personal injury

prevention or damage to the equipment.

1Safety