7

Installation and Operation Manual

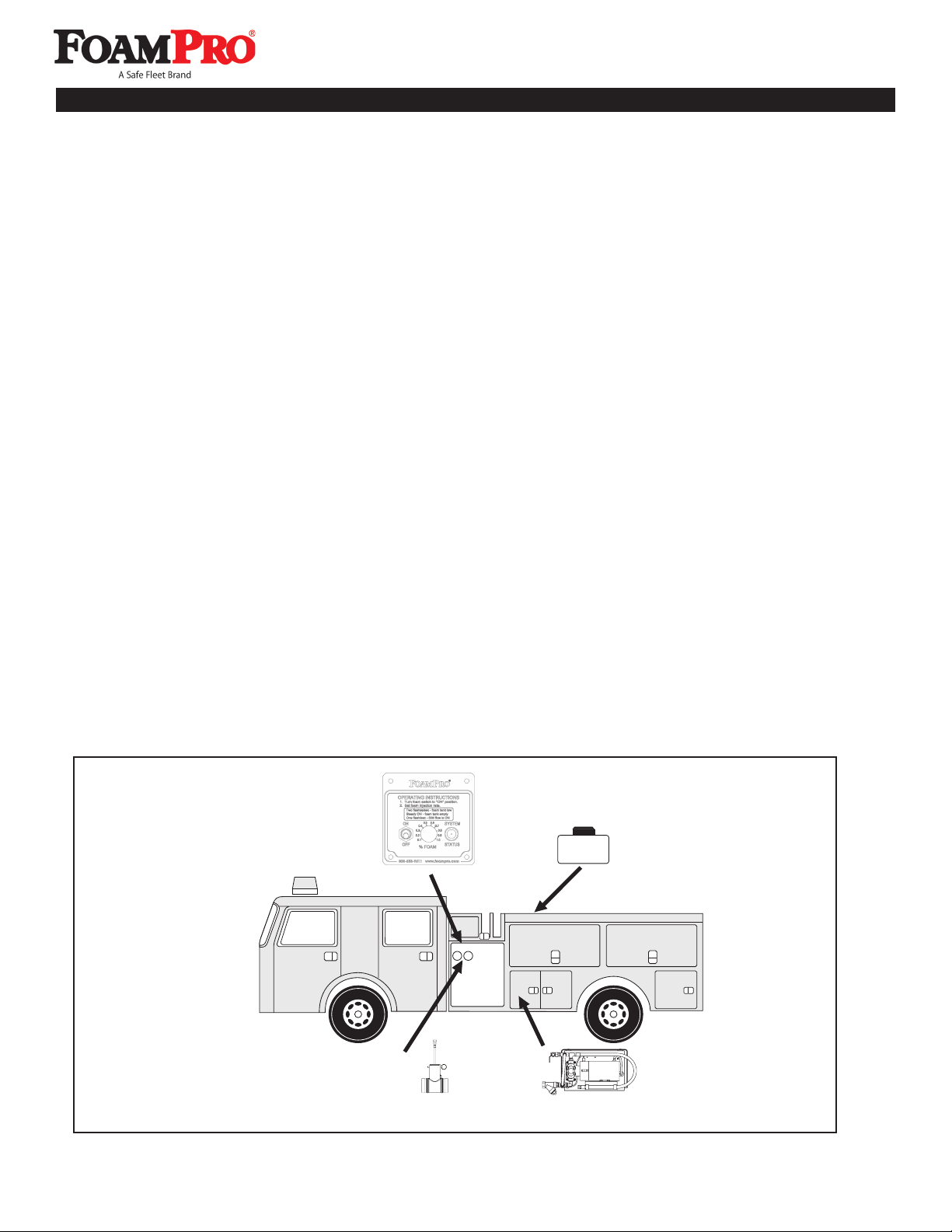

System 1600/1601

The FoamPro 1600/1601 system is provided with the major components and accessories required for installation.

Due to differences in chassis and apparatus configurations, the installer must provide pipe, hoses, tubing, wire

and fittings to satisfy installation requirements. The following paragraphs list the specifications for selection of

these components. Before beginning system installation, read this section thoroughly to make sure the proper

components are selected. For detailed system installation instructions, refer to Sections 5, 6 and 7.

FOAM CONCENTRATE SUCTION LINE

Corrosion-resistant fittings and hoses from the foam tank to

the inlet of the foam pump must be used. Use 3/4 inch [19

mm] minimum inside diameter or larger hose dependent

on the viscosity of the foam concentrate. Use components

that are rated for 23 in [584.2 mm] Hg vacuum and 50 psi

[3 BAR] pressure or greater. The components must be

compatible with all foam concentrates to be used. Fittings

used must be made of brass, 300 series stainless steel or

other corrosion resistant material. Before selection of hose

fittings, check for compatibility with foam concentrates to

be used. The use of clear suction hose is recommended

to allow viewing foam priming operations. The foam pump

must be positioned to allow no more than a 3 foot lift to a

positive suction head from the foam tank. A net positive

suction head (NPSH) is recommended.

FOAM CONCENTRATE DISCHARGE LINE

Fittings and hoses from the discharge of the foam pump

to the injector fitting must be supplied by the installer.

Hoses and fittings of 3/8-inch [9.5 mm] minimum INSIDE

diameter, rated at 400 psi [28 BAR] minimum working

pressure or maximum discharge pressure of the fire pump,

whichever is greater, must be supplied by the installer.

Fittings and hoses must be compatible with all foam

concentrates to be used. Use fittings of brass, 300 series

stainless steel or other corrosion resistant material that is

compatible with all foam concentrates to be used.

CHECK VALVES

NFPA requires installation of a check valve in the foam

concentrate injection line. To prevent foam concentrate

flow from the tank due to static head pressure, the foam

concentrate check valve shall have a 12 psi [0.6 BAR]

cracking pressure and shall be capable of withstanding the

pressures that will be generated in the foam injection line.

A check valve is also required in all water piping locations

where foam concentrate could drain back into pumps or

other components of the fire apparatus. As a minimum,

one check valve must be installed where the foam

solution water piping connects to the fire pump discharge

(FoamPro Main Waterway Check Valve is recommended).

Multiple drains that allow individual drain lines to

communicate may allow foam to short circuit past

the check valves; avoid this possibility. FoamPro

recommends separate drain valve(s) for the

discharge piping.

FOAM CONCENTRATE TANK

A foam concentrate tank must be supplied to

suit the capacity required for the apparatus

application. The tank should meet NFPA minimum

standards for the design capacity, including filler size,

venting and drain facility. A shut-off valve is recommended

to allow cleaning of the strainer.

ELECTRICAL REQUIREMENTS

Electrical wiring must be supplied from the main apparatus

electrical system to the foam pump base system. Power

must be supplied directly from the apparatus battery

without any connections to other high power devices, such

as primer pumps, hose reels, auxiliary starters, light bars,

etc. with its own disconnect switch, or a switch or contactor

actuated by the battery disconnect switch, PTO or other

device. Use proper wire size to be able to supply the foam

system with the proper voltage and amperage required.

The minimum service is as follows:

1600/1601 12VDC requires 32 amps

1600/1601 24VDC requires 16 amps

Braided flat ground straps are required for ground

connections. The flat straps limit the RFI/EMI interference

encountered with radios, computers or other sensitive

electronic equipment.

CAUTION: Always disconnect the ground straps

and control cables from the control module or

other FoamPro equipment before electric arc

welding at any point on the apparatus. Failure to

do so will result in a power surge through the

unit that could cause irreparable damage to the

electronic components.

4 Installer Supplied Parts