2

arnings

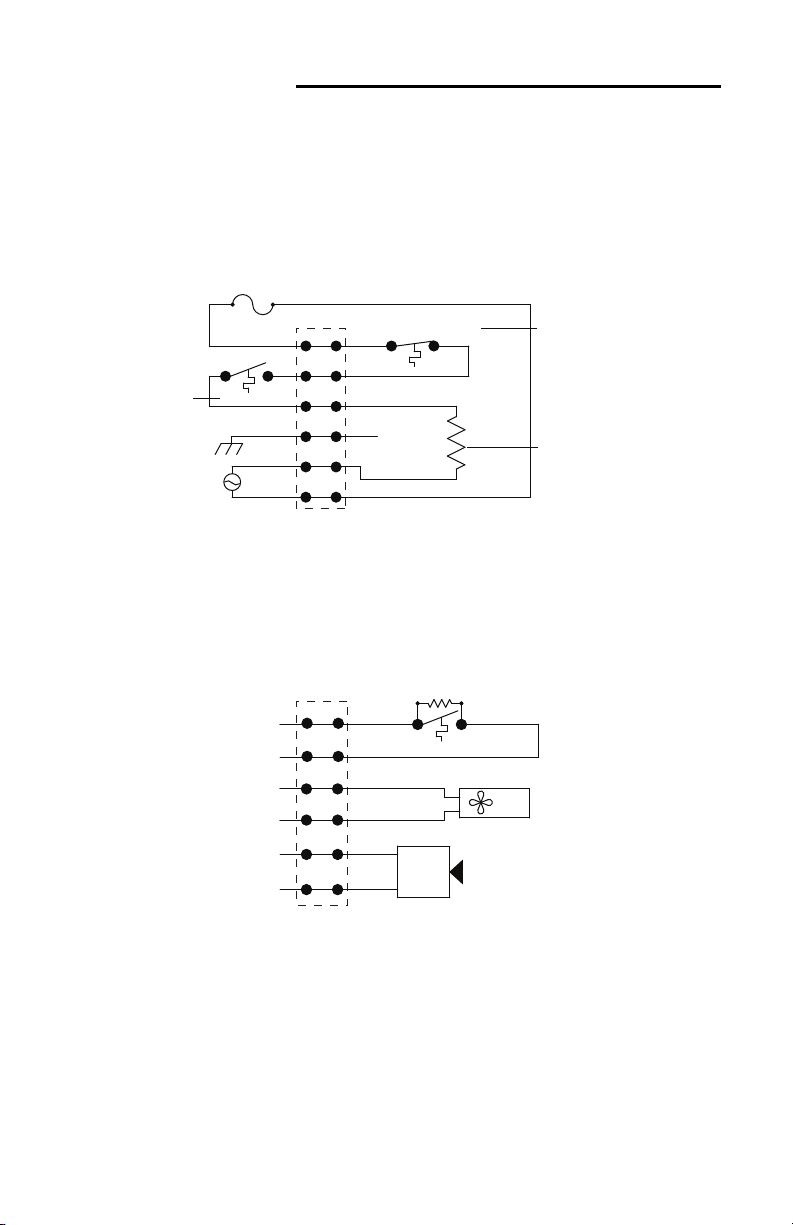

The enclosure is used to protect UL/cUL listed 1638 and 1971 visual

notification appliances at temperatures down to -70˚F (-57˚C). It is the

installer’s responsibility to comply with NEC 70 Articles 502 and 503, NFPA72,

and other applicable fire and electrical codes. Conduit or raceway paths need

to be sealed as near to the enclosure as possible. Installer should have

maintained supervision over the low temperature thermostat. The low

temperature monitoring thermostat makes the circuit at +32°F (0°C) and

clears the circuit at +50°F (+10°C). This listing requires that the fire alarm

supervisory control module be only of the latching type. On the appliance

mounting plate is a label where you should record the installation date. Also

include below the serial number and installation date on the instruction sheet

for quick reference.

Serial Number ____________________________________

Installation Date __________________________________

!

Installation Notes

1. The enclosure is rated to protect signaling appliances indoors and

outdoors and in areas of direct weather exposure.

2. When covering fire-signaling appliances with the enclosure, some light

loss occurs. Please follow the guidelines listed during installation.

3. Strobe light loss values for respective manufacturers are shown on page

3. To determine the new composite candela value of the use with the

guard refer to the sample calculation shown on page 3 for a

manufacturer’s strobe.

4. Record the manufacturer’s candela value as “A” and the light loss value

as “B” and the assembly value as “C”. Example: A 60 candela strobe with

a 30% light loss transmission value. Value “A” is now 60. Value “B” is

(60 times 30% or 0.30) in this case 18.

5. Now value “C” is value “A” minus value “B” or 60-18 = 42 candela light

source. Now refer to NFPA tables for proper room size that newly

established value “C” will work in. Then submittal installation drawings

must show the composite candela value in this example 42.

6. On a multiple candela value strobe such as 15/30/75 a calculation must

be done for each value and the drawing notation composite value for

each number on the strobe.

7. All field wiring within this enclosure must be rated for a minimum

operating range of 0ºC - 110ºC.