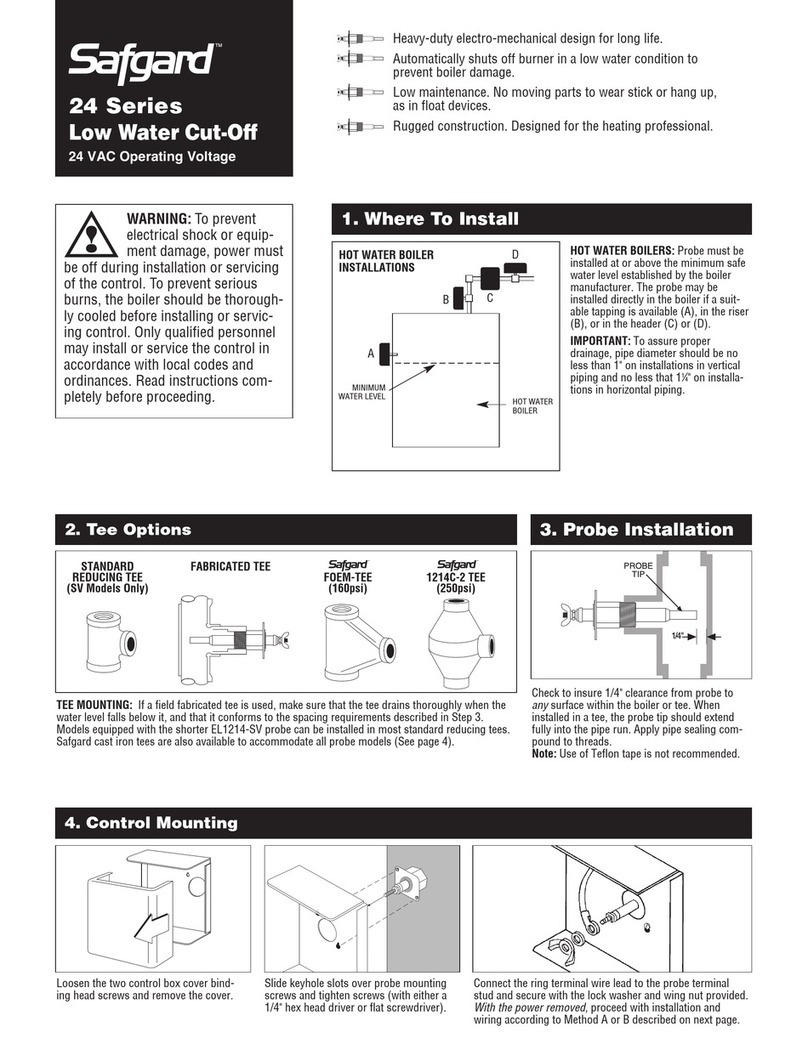

SERVICE / MAINTENANCE

The 711 Series Control requires regular

maintenance to ensure continue , safe oper-

ation. During normal boiler function, se i-

ment may accumulate in the low water cut-

off's probe housing. If left unchecke , this

se iment can buil up, trap water in the

probe housing, an prevent the control from

etecting a low water con ition in the boiler.

A regular blow own of the control is

require for proper operation.

To flush the se iment from the chamber, the

control must be blown own throughout the

heating season in accor ance with the fol-

lowing sche ule:

• Daily for first week following control

installation

• Prior to heating season startup in the fall

• Once per week uring the heating season

I structio s: Confirm water is visible in the

gauge glass. If not visible, shut the burner

off, allow the boiler to fully cool, then a

water until visible in the gauge glass. Once

water is visible, bring your boiler back up to

temperature. With the boiler running, place a

heat resistant pail irectly beneath the con-

trol casting blow own valve. Open the valve

an allow the se iment an water to rain

into the pail. Continue to rain the water

until it runs clean (One to two gallons is gen-

erally sufficient). Close the valve when com-

plete . Replenish the water in the boiler if

nee e .

OPERATING INSTRUCTIONS

TROUBLESHOOTING

1If the burner oes not shut own upon

water falling below the lower probe:

Remove power to the burner an check

installation. Check wiring an make sure

that burner is connecte to the fourth ter-

minal from left on terminal (P2). If wiring

is correct, check to make sure the probes

are not falsely groun e . Voltage between

the probes an chassis groun shoul be

120-140 VAC with water beneath both

probes. A lower rea ing may in icate a

shorte probe. Remove probes an check

for contamination.

2If the burner will not fire with water at the

top probe: With a voltmeter an power

applie at terminals G an H: Check the

voltage between the upper probe an

chassis groun . Rea ing shoul be 0-10

VAC with water at the upper probe. A

higher rea ing may be the result of poorly

con uctive water or probe contamination.

Remove probes an check for contamina-

tion. If the burner will still not fire after

cleaning probes, contact factory for assis-

tance.

5

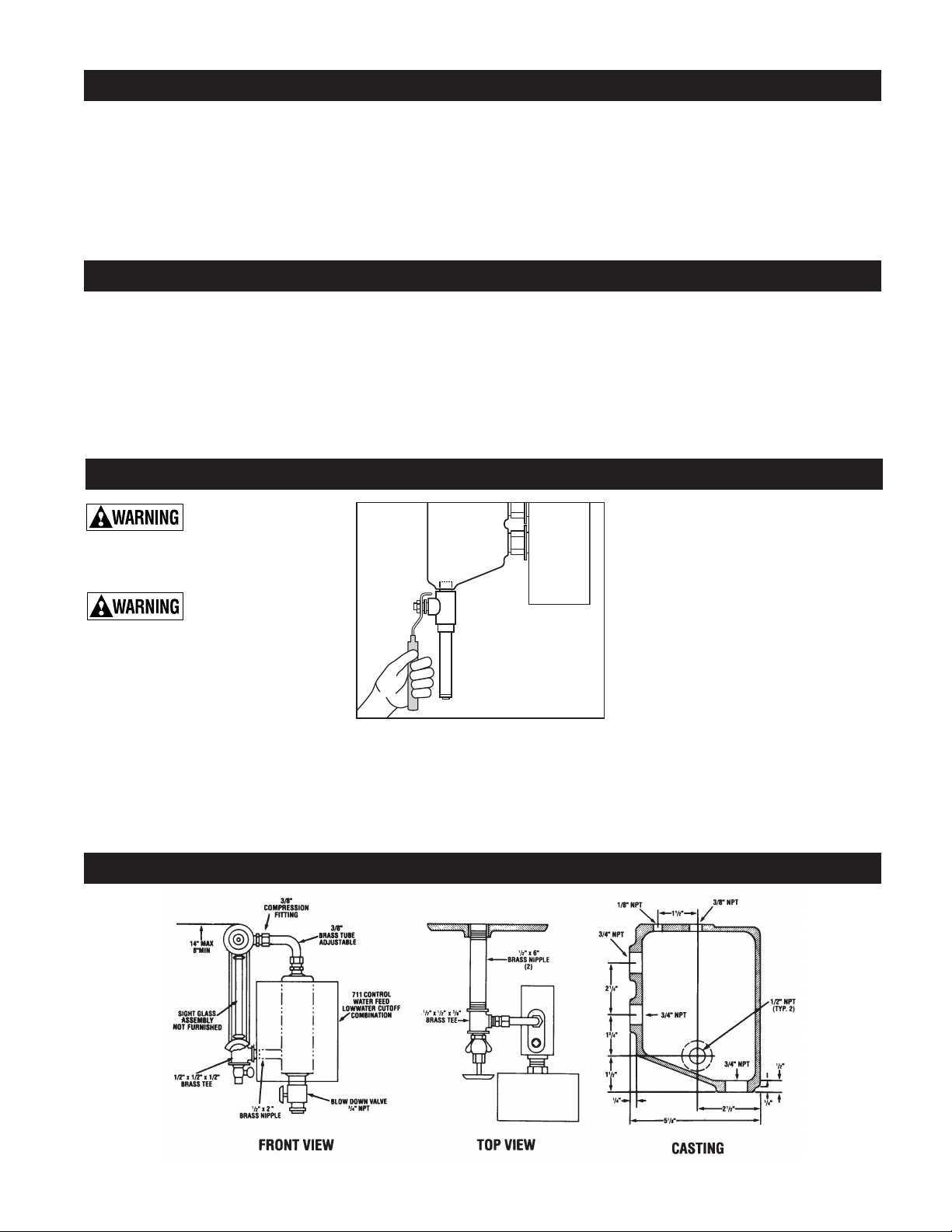

DIMENSIONS

NOTE: Hy rolevel recommen s that the boil-

er manufacturer’s proce ures for skimming

the boiler be performe prior to placing the

control into operation.

1After installation, raise the boiler water

level until water is in contact with the

upper probe. Turn on power an set the

thermostat to call for heat. The burner

shoul fire imme iately.

2Using the boiler rain, slowly lower the

water level to a point below the lower

probe. The burner shoul shut own

imme iately upon a low water con ition.

NOTE: The water shoul not be lowere

beyon a visible point on the gauge glass.

IMPORTANT: If the burner oes not shut

own in a low water con ition, turn off

power imme iately an refer to trou-

bleshooting instructions below.

REGULAR MAINTENANCE

REQUIRED. Failure to

properly maintain the control can lea to

severe amage to the boiler, other property,

personal injury, or eath.

To prevent serious person-

al injury from steam an

hot water, make sure there is a ischarge line

from the blow own valve to a proper place of

isposal. Failure to follow this caution coul

result in personal injury.