12037 N Highwa

9

Seminole, OK 7486

Phone (405) 382-0731

www.enviro-ok.co

www.safran‐

passenger

‐solutions.co

Copyright©2020 OriginalRelease ATA21‐00‐60

Page|4

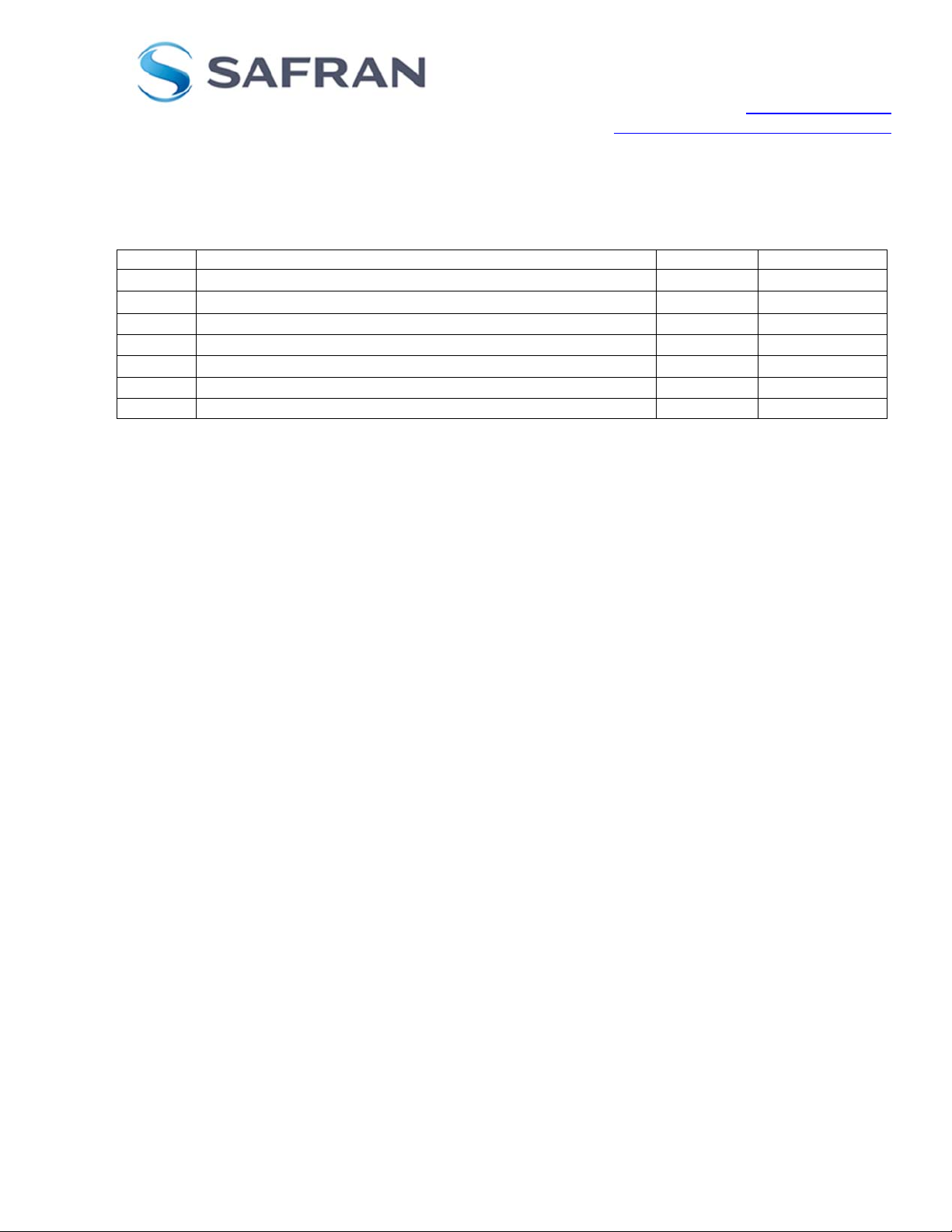

TABLE OF CONTENTS

1. MANUALINTRODUCTION................................................................................................................................7

1.1. Generalintroduction(HowtoUse):.........................................................................................................7

1.2. Acronyms,Abbreviations,and

Symbols:

..................................................................................................8

1.3. StandardTorque

Values:

..........................................................................................................................9

1.4. Documentsrequired:...............................................................................................................................9

2. SYSTEMDESCRIPTIONANDOPERATION........................................................................................................10

2.1. General:..................................................................................................................................................10

2.2. SystemDescriptionandOperation:.......................................................................................................11

2.3. SystemComponentDescriptionandOperation:...................................................................................12

3. TESTINGANDFAULTISOLATION....................................................................................................................15

3.1. General:..................................................................................................................................................15

3.2. SystemLeakCheckTesting

Procedure:

..................................................................................................15

3.3. FaultIsolation(Trouble‐

Shooting):

........................................................................................................17

4. SYSTEMPLUMBINGDIAGRAM.......................................................................................................................20

4.1. R‐134ARefrigerantFlowSchematic:......................................................................................................20

5. DISASSEMBLY.................................................................................................................................................21

5.1. General:..................................................................................................................................................21

5.2. CondenserModuleDisassemblyProcedures.........................................................................................22

5.3. EvaporatorModuleAssemblyDisassembly

Procedures

........................................................................23

6. CLEANINGPROCEDURES................................................................................................................................24

6.1. General:..................................................................................................................................................24

6.2. CondenserModuleCleaningProcedures:..............................................................................................25

6.3. EvaporatorModuleAssemblyCleaningProcedures:.............................................................................26

7. INSPECTIONSCHEDULE..................................................................................................................................27

7.1. CondenserModuleAssemblyInspection

Schedule:

..............................................................................27

7.2. EvaporatorModuleAssemblyInspectionSchedule:..............................................................................28

8. REPAIRPROCEDURES.....................................................................................................................................30