PREFACE

1. Do not use the printer in any way other than described herein to avoid personal injury or

property damage.

2. Do not place the printer near flammables, explosives or heat sources. It is best to place it in a

well-ventilated, low-dust environment.

3. Do not expose the printer to violent vibration or any unstable environment. This will cause poor

printing quality.

4. The filaments recommended by the manufacturer are preferred as to avoid clogging in the hot

end and/or printer damage.

5. Do not use any other power cable than the one supplied. Use a grounded three-prong power

outlet.

6. Do not touch the nozzle or hot bed during printing. Keep hands away from machine while in use

to avoid burns or personal injury.

7. Do not wear gloves or loose clothing when operating the printer. Loose articles can be caught in

moving parts and cause personal injury or printer damage.

8. Clean off filament from the nozzle tip with the provided plier before the nozzle cools. Do not

touch the nozzle directly. It can cause personal injury due to high temperature.

9. Clean the printer frequently. Please power of the printer before cleaning. Clean the printer body

with a dry cloth to remove dust, adhered printing materials and other objects on guide rails. Use

glass cleaner or isopropyl alcohol to clean the print surface before every print for consistent

results.

10. Children under 10 years of age should not use the printer without supervision.

11. Software/hardware upgrade, model differences and new revisions may not be listed in this

manual.

Dear consumers,

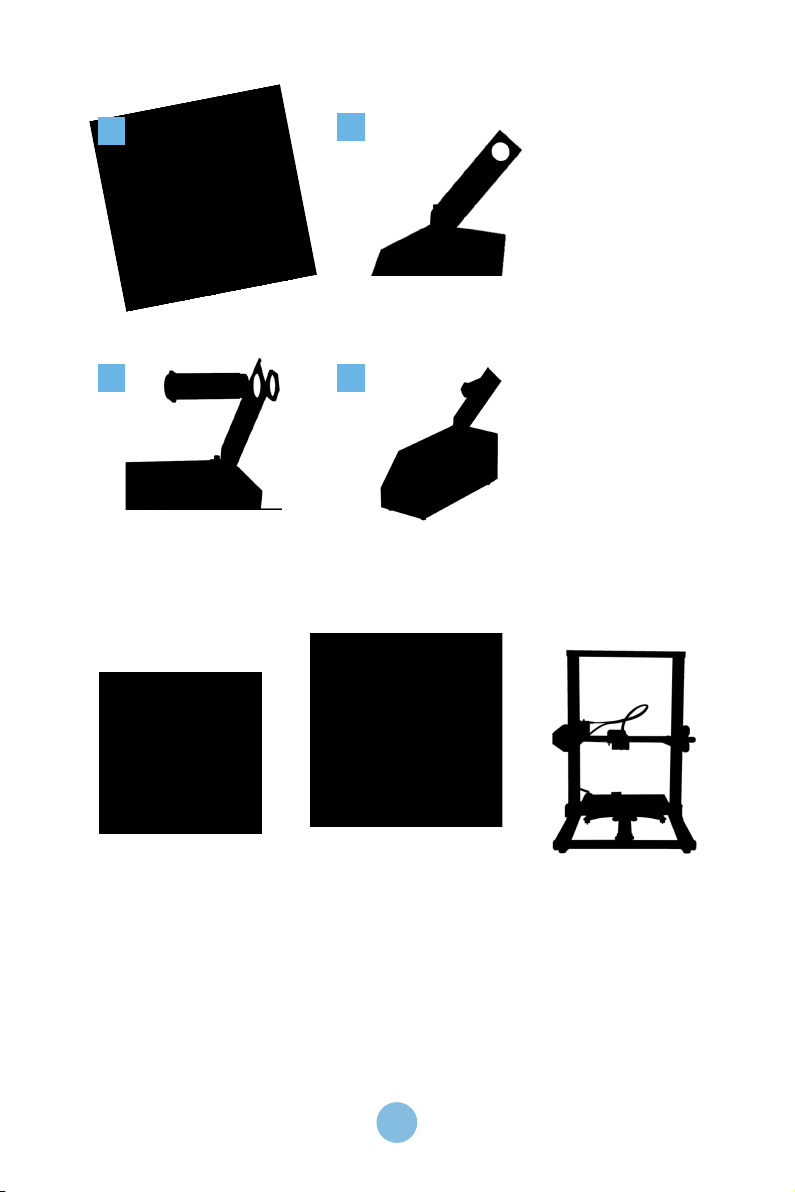

Thank you for choosing SainSmart CR-10 series 3D printers. For your best experience, please

read this instruction before operation. Our 3D team is always ready to provide you with assistance.

Please

contact

us

via

e-mail

(

[email protected] )

if

you

encounter

any

problem

with

the

printer.

For better 3D printing experience, you may learn how to use the printer in the following ways:

1. Read the attached instruction and watch videos on the SD card.

2. Visit sainsmart.com for relevant software/hardware information, operation and maintenance

instructions and contact details.

Sincerely,

SainSmart Team

NOTES