SAFETY

Read the instructions before use

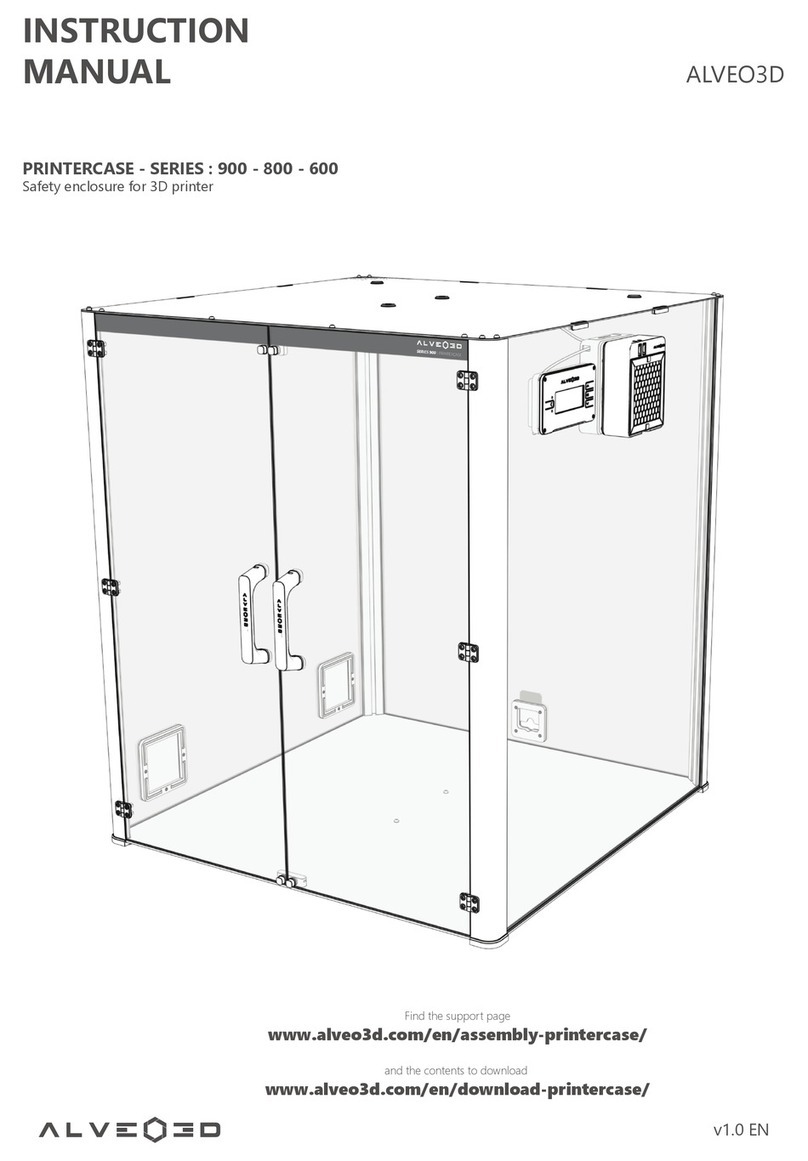

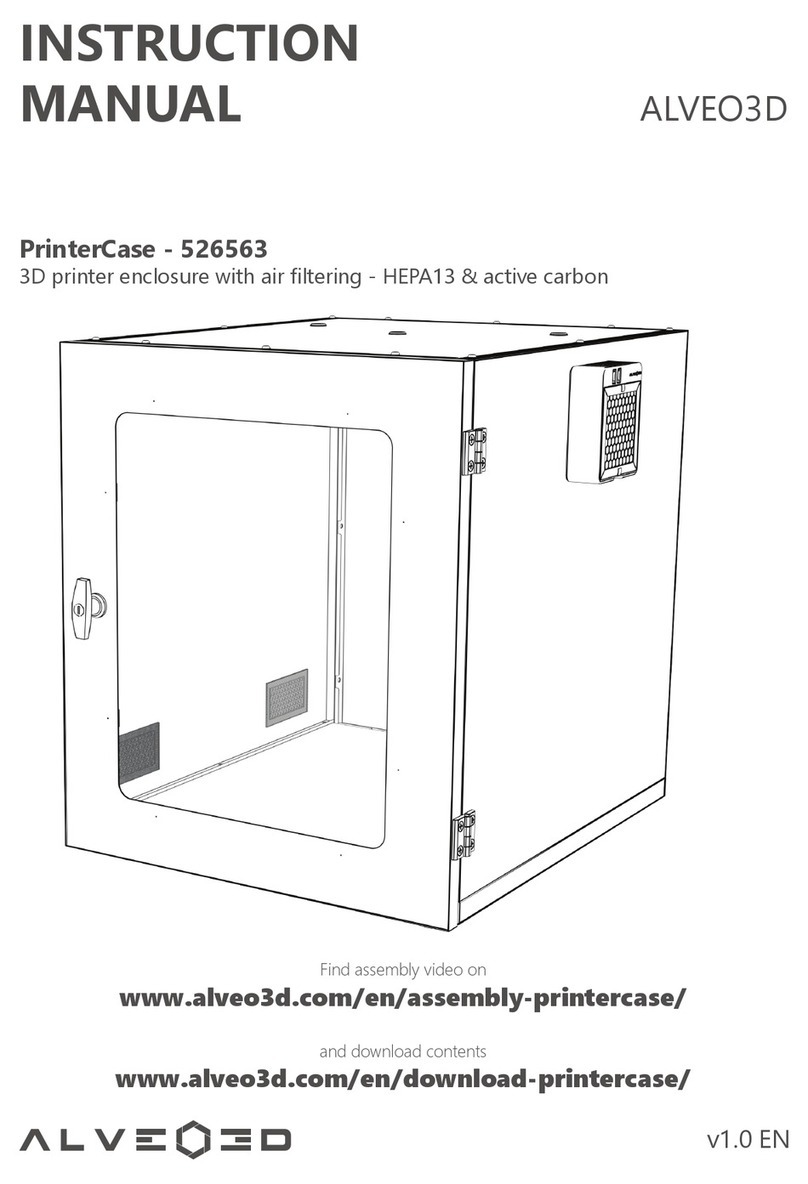

The use of an enclosure helps to contain the pollutant emissions

associated with the use of 3D printers. It is recommended to

always use ventilation during the printing process.

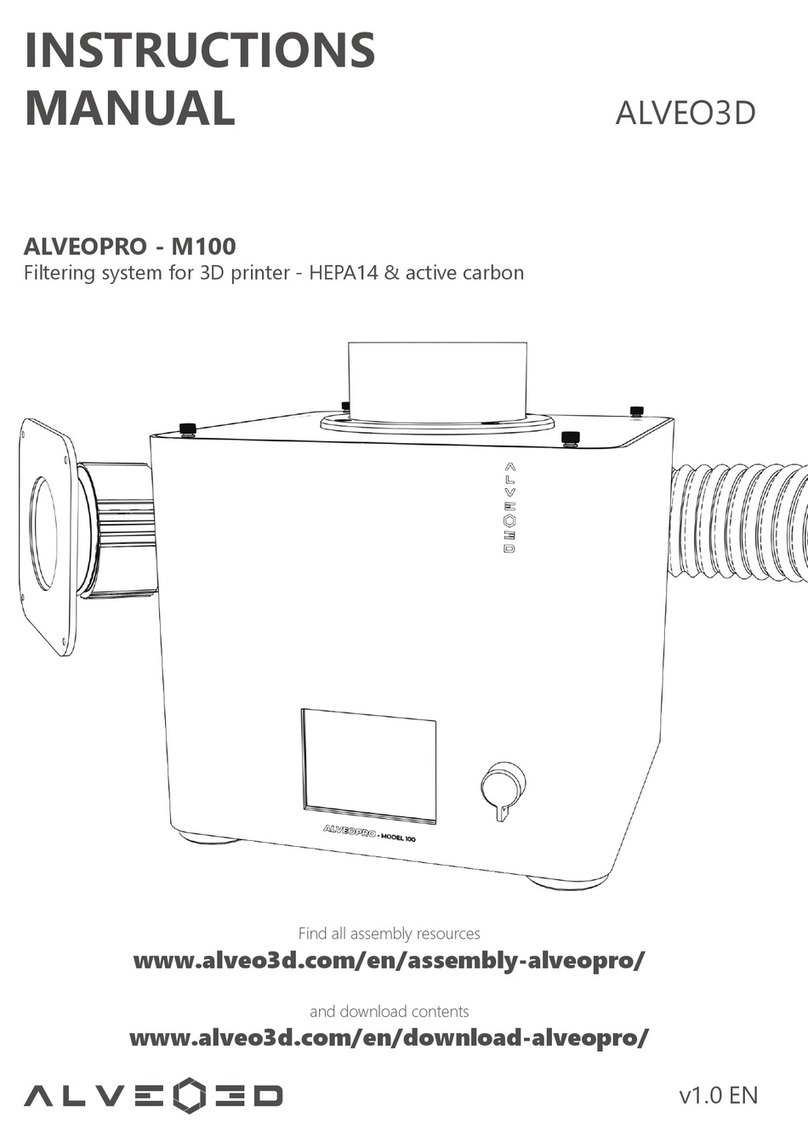

The filtration system uses a powerful fan. You should only turn it

on after the device is completely assembled with the protective

screw-on cover and filter. Failure to do so may result in injury.

Please use the electrical voltages recommended during the

assembly instructions to power the unit to avoid damage to the

electronic components.

Avoid contact with the electronic board during operation.

Before each print, make sure the filter is well positioned in its

casing.

Operating range of the filter 0-60°C max

The PrintBOX enclosure does not, under any circumstances,

dispense to operate the resin 3D printer with its original cover

safety.

The PrintBOX enclosure must be placed on the flat surface.

02