Summary

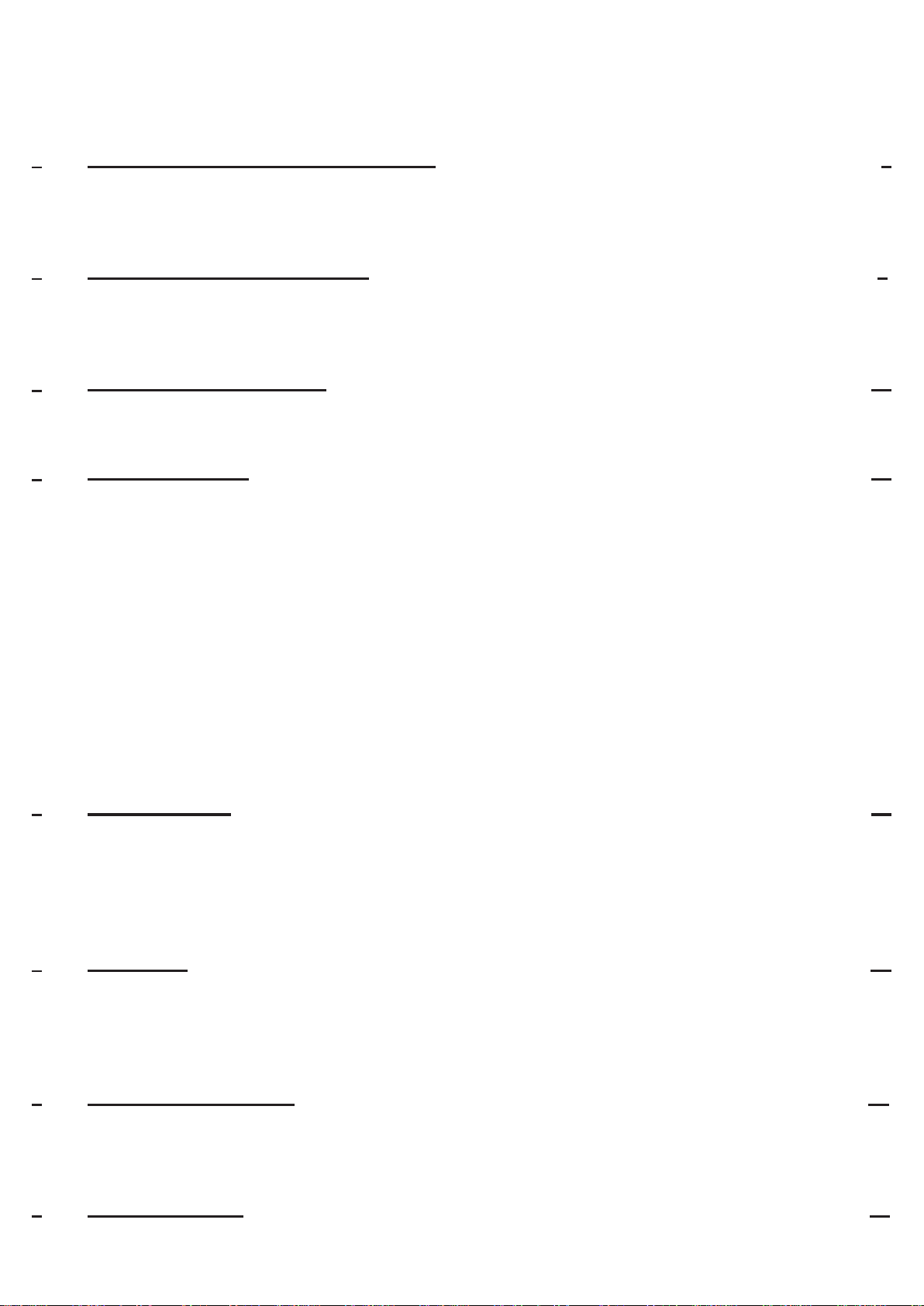

1 Safety instructions andwork technique......................................................................................7

1.1 General information, equipment, clothing..................................................................................7

1.2 Rules at work, hazard notes.........................................................................................................8

1.3 Maintenanceandrepair.................................................................................................................8

2 Technical data and accessories..................................................................................................9

2.1 Technical data of the machine.................................................................................................... 9

2.2 Accessories delivered with the machine. .................................................................................. 9

2.3 Optional accessories................................................................................................................... 9

3 Description ofthemachine.........................................................................................................10

3.1 Conception..................................................................................................................................10

3.2 Functional description. ..............................................................................................................11

4 Basic safety rules........................................................................................................................12

4.1 Use accordingto regulations.....................................................................................................12

4.2 Operating instructions................................................................................................................12

4.3 Measuresoforganization............................................................................................................13

4.4 Selectionofstaff..........................................................................................................................14

4.5 Safety instructions for certain phases of work. ...................................................................... 15

4.6 Maintenance and special work on the machine........................................................................16

4.7 Gas, dust, steam, smoke........................................................................................................... 17

4.8 Noise...........................................................................................................................................17

4.9 Lighting........................................................................................................................................17

4.10 Transport.........................................................................................................................................17

4.11 Storage. .......................................................................................................................................18

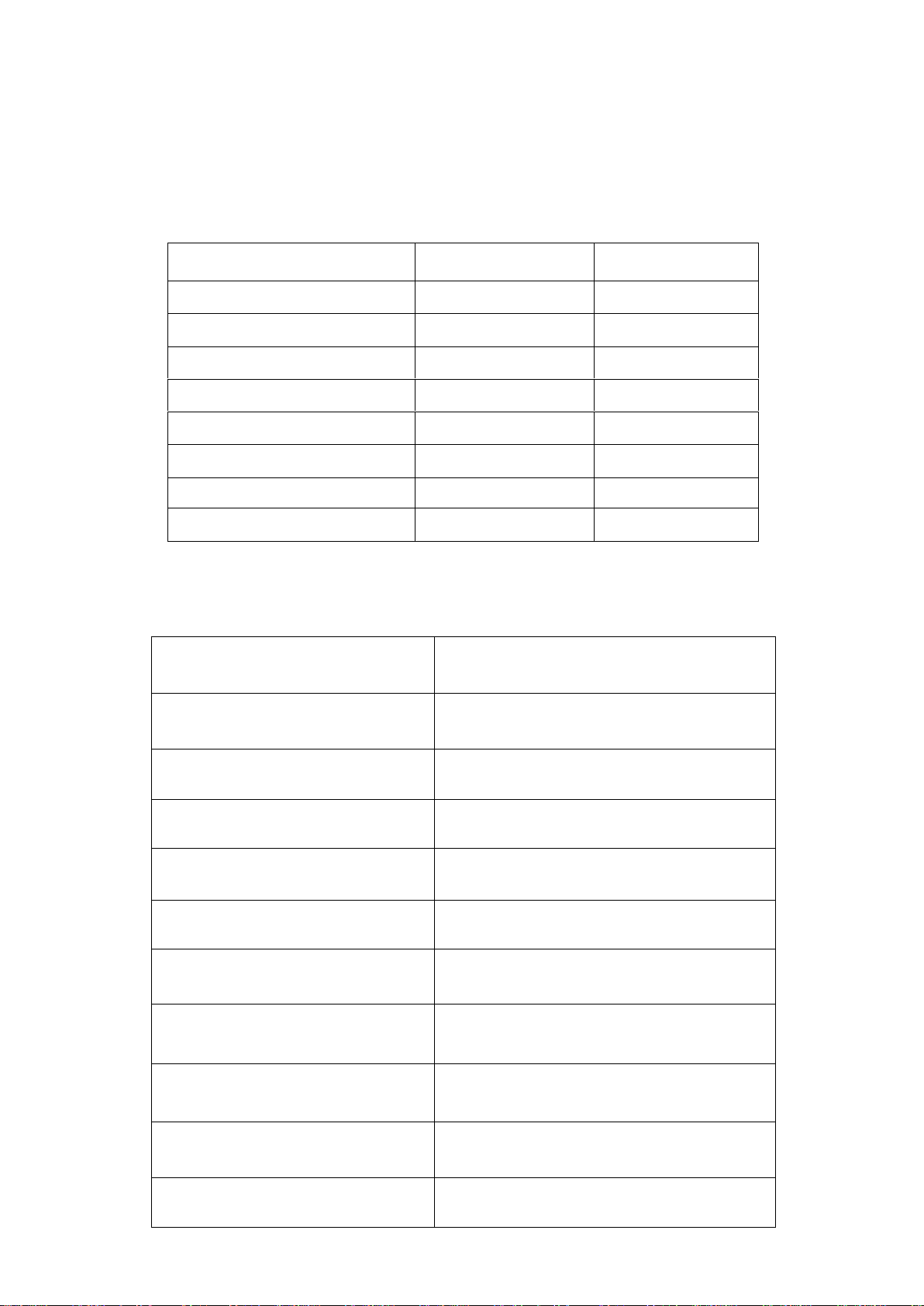

4.12 Statement regarding the vibration emission. .......................................................................... 18

4.13 Statement regarding noise emission. ......................................................................................19

5 Commissioning...........................................................................................................................20

5.1 Delivery checks.......................................................................................................................... 20

5.2 Fixation ofthe machine...............................................................................................................20

5.3 Water supply................................................................................................................................22

5.4 Angle adjustment....................................................................................................................... 23

5.5 Drill..............................................................................................................................................23

6 In function. ..................................................................................................................................25

6.1 Beforestarting.............................................................................................................................25

6.2 Start coring................................................................................................................................. 26

6.3 Stop coring.................................................................................................................................26

6.4 Change thediamonddrill............................................................................................................27

7 Maintenance and repair.............................................................................................................27

7.1 Drill core. ....................................................................................................................................27

7.2 Drill..............................................................................................................................................28

7.3 Slider…………………………………………………………………………………………………….....28

8 Search for errors........................................................................................................................ 29