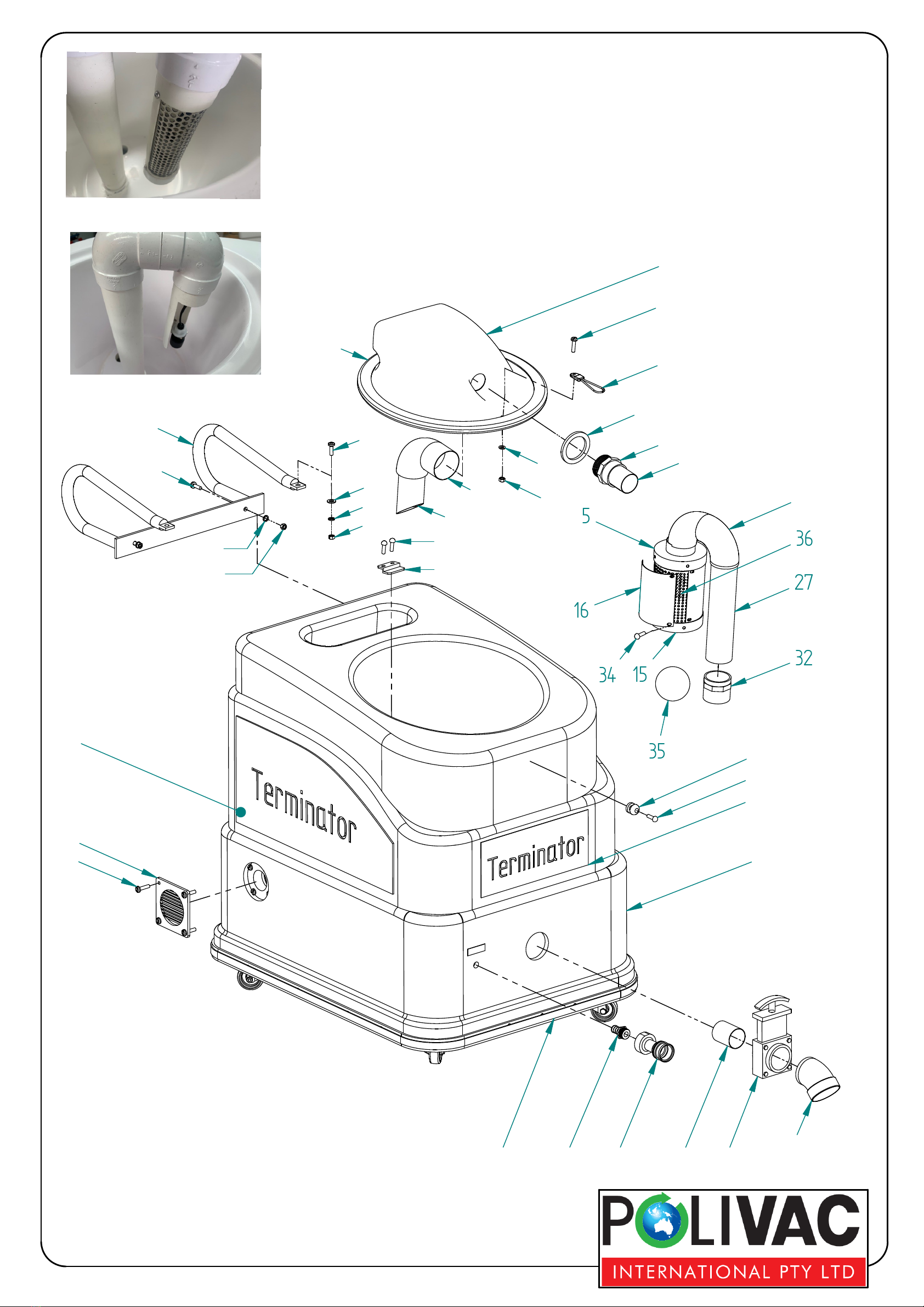

Polivac Terminator User manual

Other Polivac Floor Machine manuals

Polivac

Polivac Stealth Series User manual

Polivac

Polivac Predator MK II User manual

Polivac

Polivac Predator MK I User manual

Polivac

Polivac Predator MK II User manual

Polivac

Polivac Predator MK III User manual

Polivac

Polivac GAZ20 User manual

Polivac

Polivac ST2100 User manual

Polivac

Polivac GAZ24 User manual

Polivac

Polivac GAZ20 User manual

Polivac

Polivac GASS38KOH User manual