Operation

Startup

After installing, connecting ductwork and condensate lines and

wiring, unit is ready for startup. Check all internal wire

connections and connections to external control devices.

A disconnector with appropriate value should be mounted to

the wiring circuit.

6

Please do wiring according to the attached wire diagram. A

ticking sound can be heard when the unit is electrified. And then

you may please debug the unit in accordance with the manual of

thermostat.

1. Turn the thermostat fan switch to the “ON” position. Unit

blower should start.

Note: Unit may not start for 3 minutes due to anti-short

cycle relays.

2. Check the airflow and make sure no supply grilles or

duct dampers are closed to restrict airflow.

3. Set the thermostat temperature setting to low and turn the

systems switch to the heating mode.

4. Gradually increase the temperature to approximate room

temperature until unit starts.

5. After operating the unit for 10 minutes, check the air

temperature rise between supply and return airstreams. The

rise should be at least 10℃.

6. Using asurface pyrometer or other device, check entering

and leaving water temperatures. The recommended

temperature drop between entering and leaving water may

range from 3-5℃at 7℃EWT (Entering Water Temperature)

or from 3-8℃ at 21℃EWT(At heating mode in winter).

Note: If any of the above conditions do not exist, one or

more of the following problems exist: low airflow, low

water flow or unit not performing properly.

7. Set the thermostat system switch to cooling mode and

reduce temperature setting gradually until unit starts.

After operating the unit for afew minutes, check if it is

functioning properly and providing satisfactory cooling.

Note: Minimum dry bulb temperature drop between

supply and return airstreams should be about 9℃A

water temperature rise of 7℃-14℃could be anticipated

at relatively low water flow rates.

Maintenance

Air

Filters

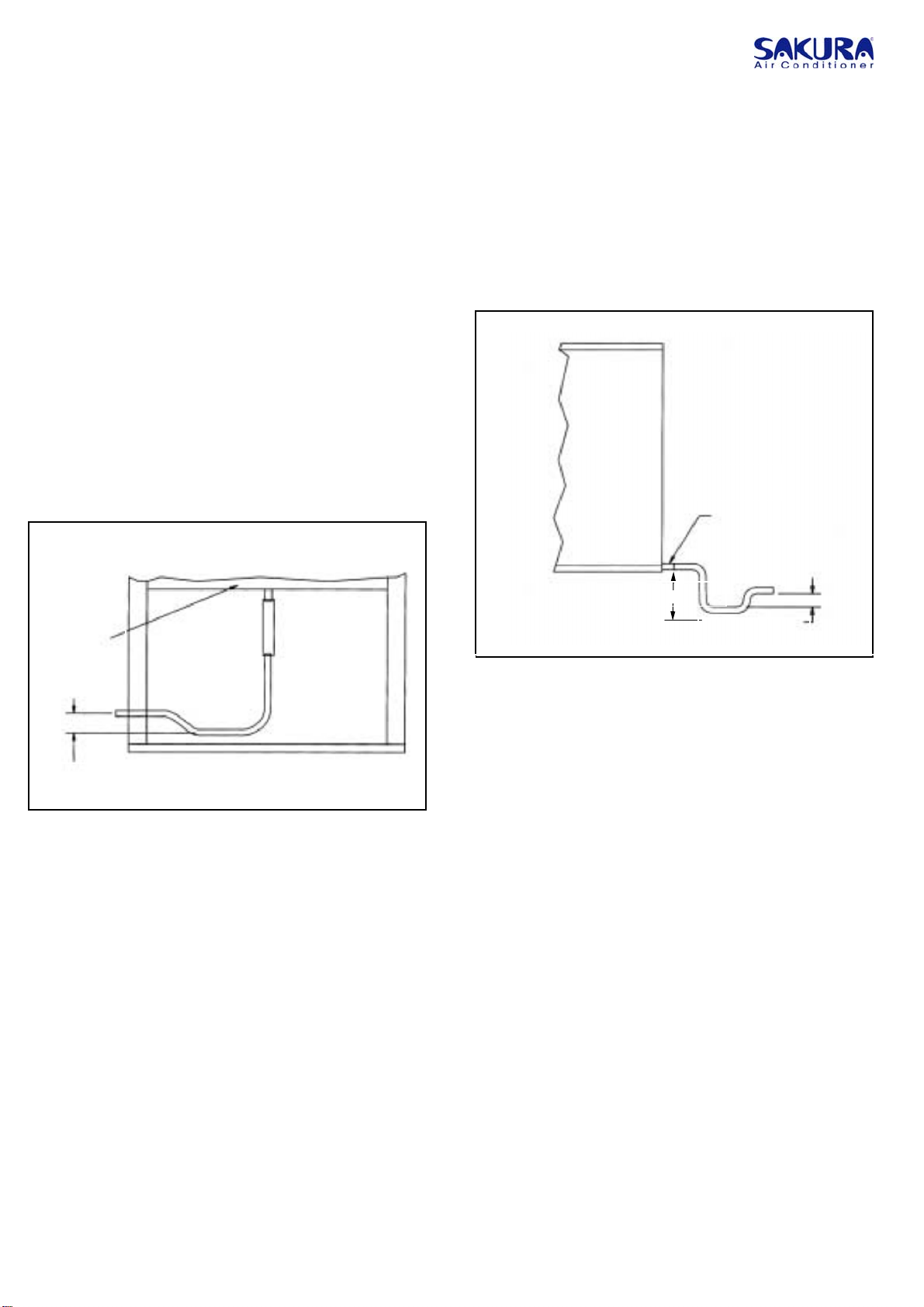

Do not operate the heat pump without an air filter. Clean

the filters at least once every three months and more

frequently in dusty or unclean environments. Dirty filters will

cause inefficient heat pump performance.

Air Coil and Blower Wheel

Check the air coil and blower wheel at least once each

year and clean as necessary.

Compresso

Sakura heat pumps have been designed with switches that

protect the unit’s refrigerant system. They will automatically

shut down the compressor if refrigerant pressure rises too

high or drops too low.

General Service

Any repair or service on the unit must be performed by

qualified service personnel.

Factory-mounted Options

Cooling-only

Units are available for those applications requiring no

heating from the unit .

Extended range

Allows the unit to operate at lower entering water

temperature, includes insulated piping and insulated

coaxial heat exchanger.

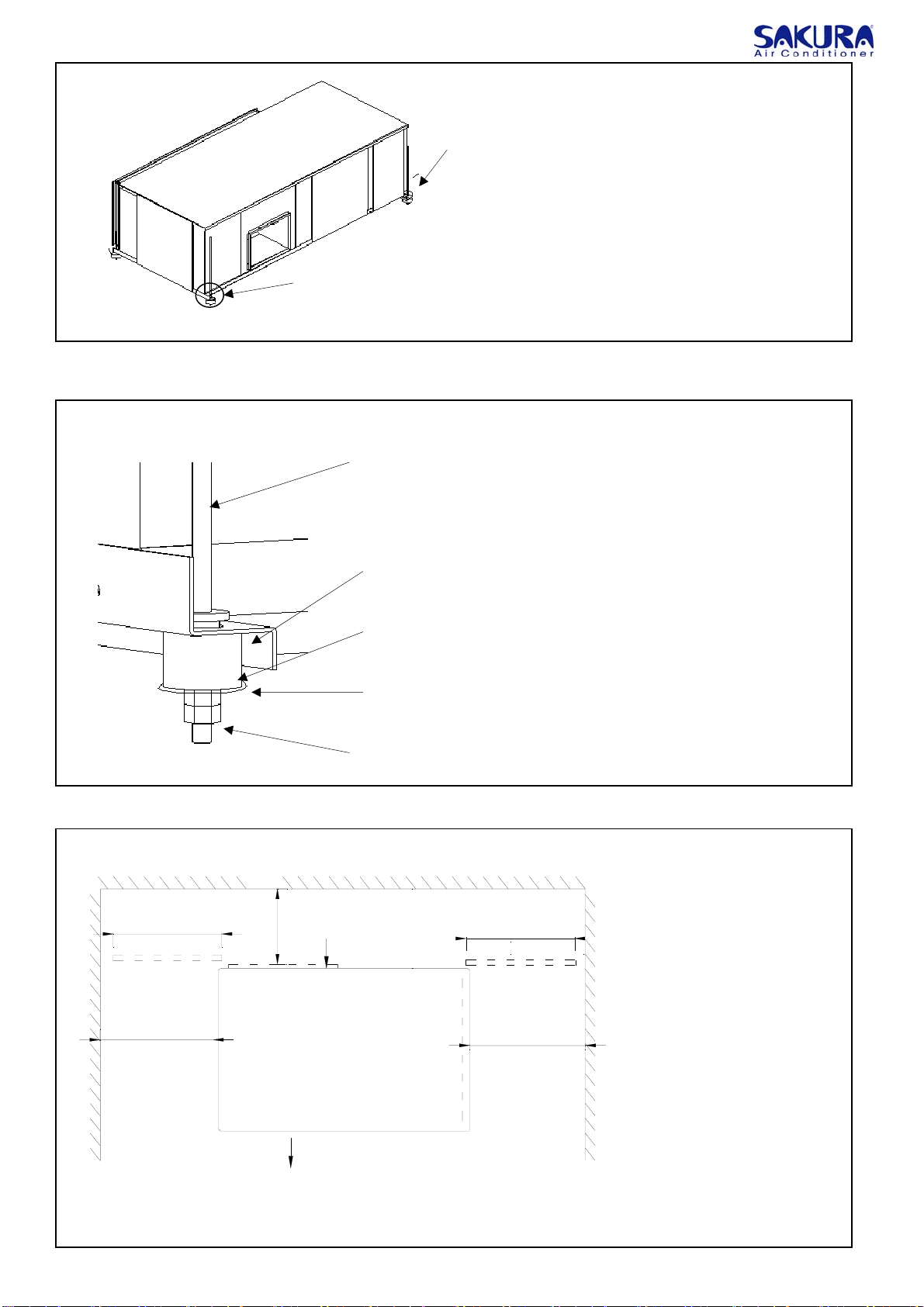

25/50 mm filter

25 and 50 mm filter rack replaces the 10mm rack to allow for

more efficient and lasting 25 or 50mm filters

Field-mounted Options

Water Flow Switch

The Water Flow Switch will shut off the unit when the water

flow is smaller than limit value to protect the system

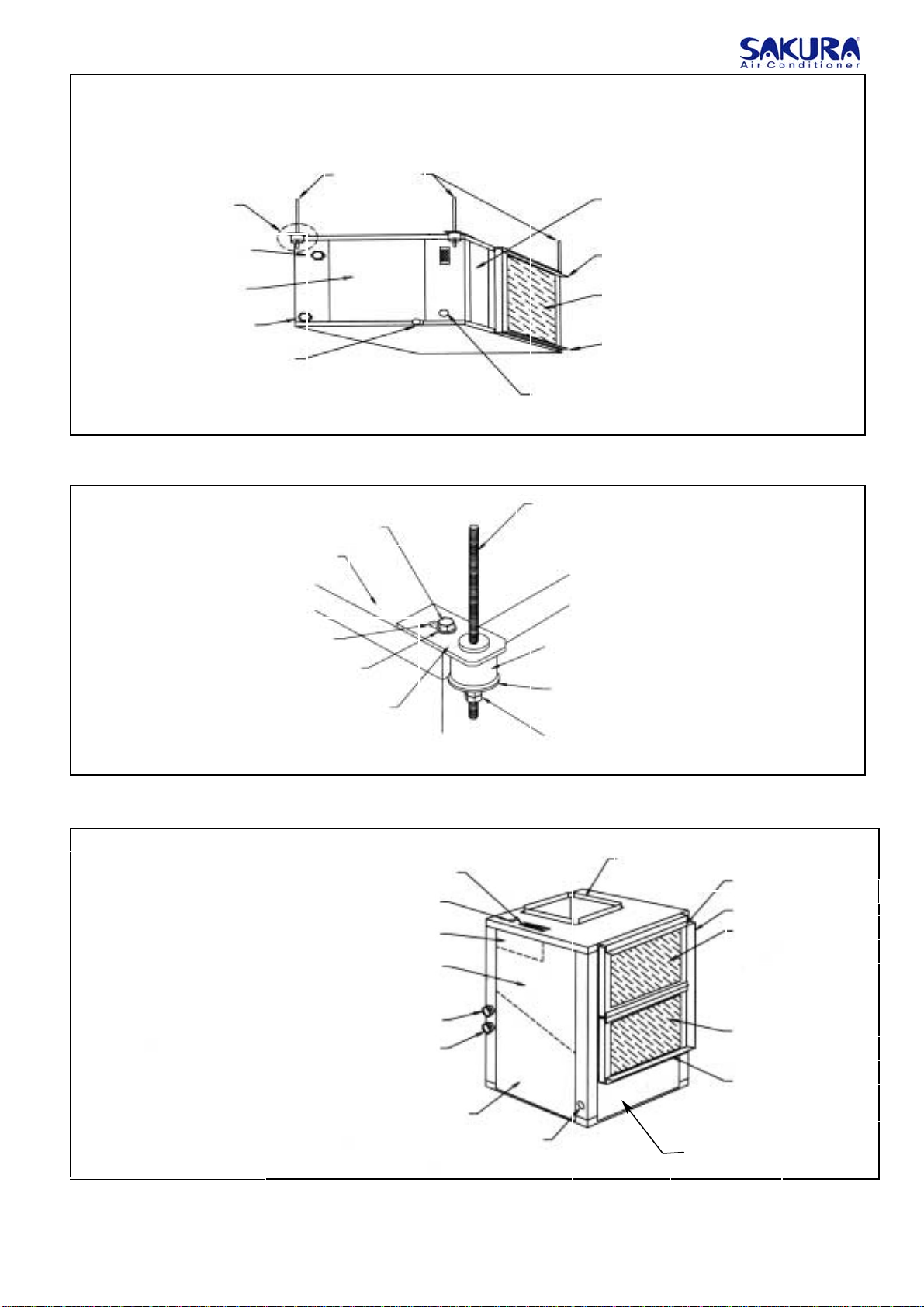

Flexible hose kits

Flexible hose kits are available in, 3/4-inch and 1-inch

diameters, 600mm and 900mm long. Each hose is

constructed of braided stainless steel and has steel fittings

with a swivel at one end. Hoses are rated at minimum 1000

kPa.