1GENERALINFORMATION...................................................................................................... 3

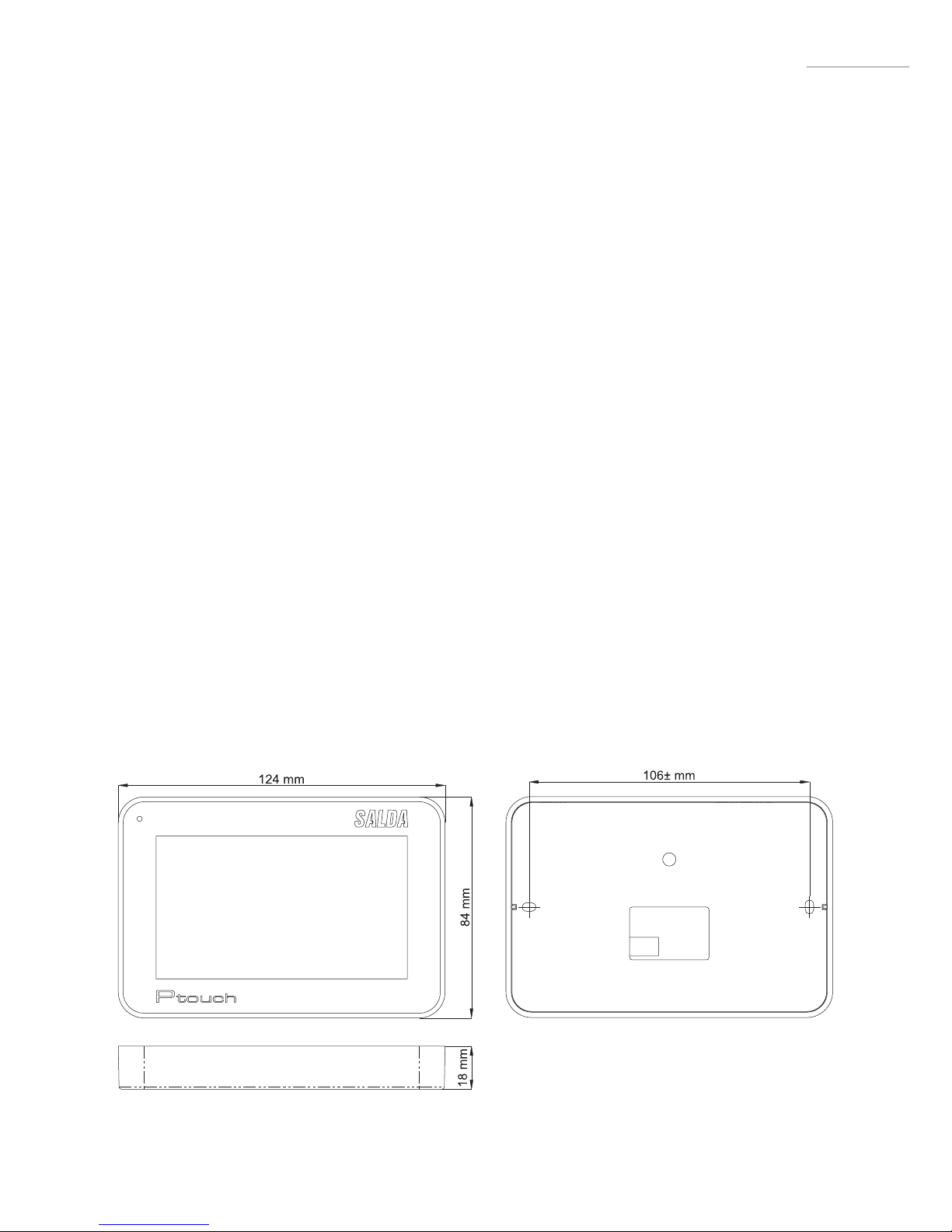

2DIMENSIONS............................................................................................................................. 3

3INSTALLATION.......................................................................................................................... 4

4SERVICE........................................................................................................................................ 5

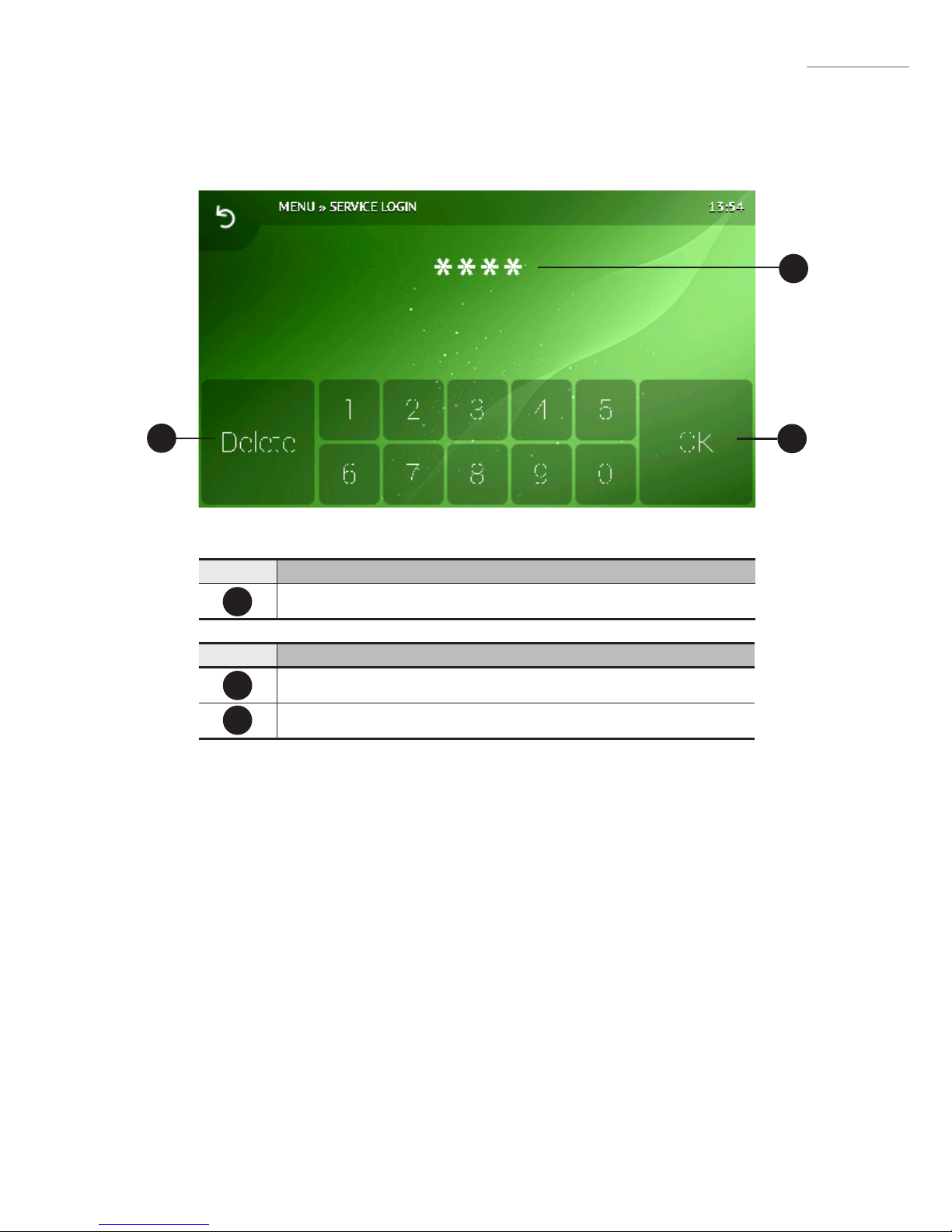

4.1 Service login ...................................................................................................................... 5

4.2 Service menu .................................................................................................................... 6

4.3 Ventilation mode settings ............................................................................................ 7

4.4 Cooling settings ............................................................................................................... 8

4.5 Fan settings menu ........................................................................................................... 8

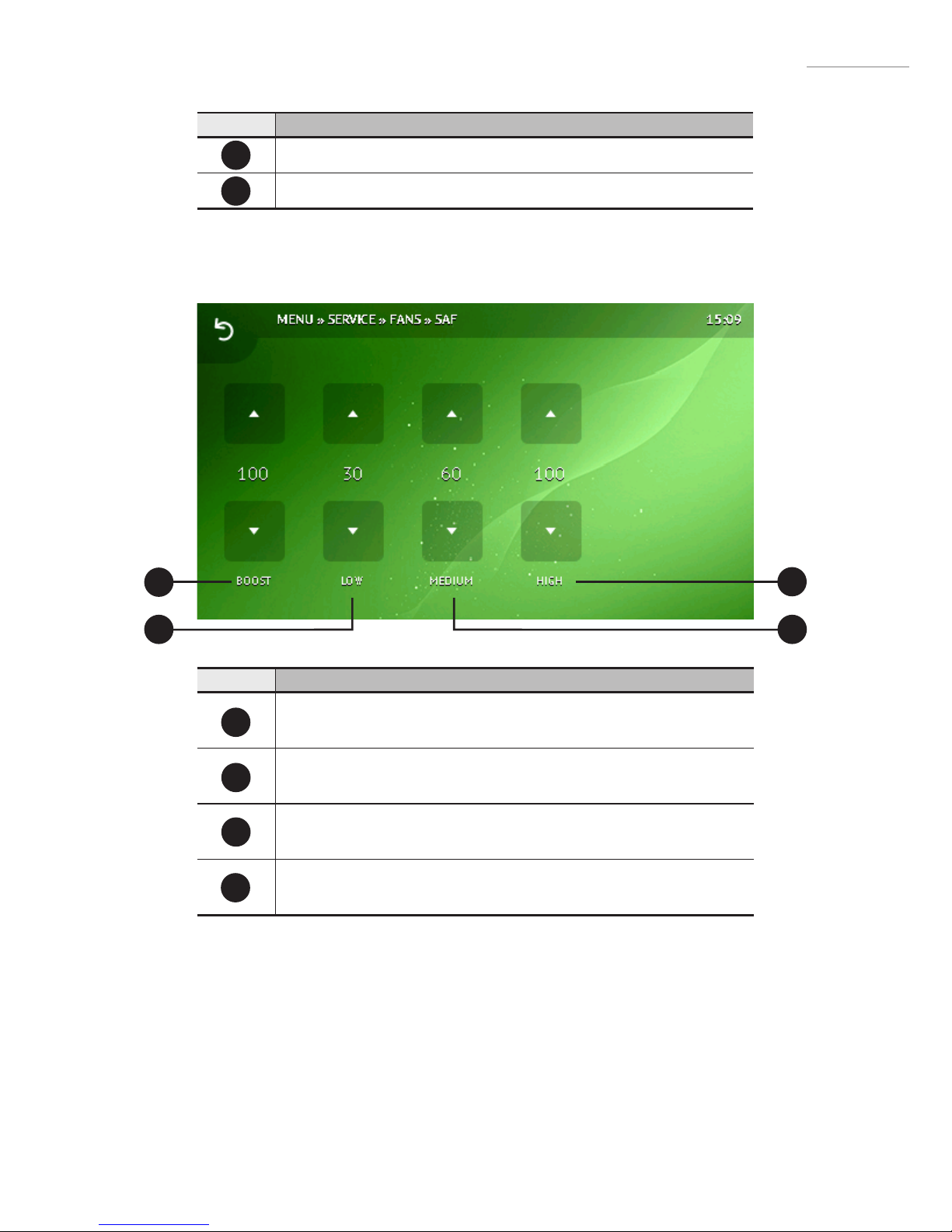

4.5.1 Air supply fan settings ......................................................................................... 9

4.5.2 Air extraction fan settings ................................................................................ 10

4.6 Modbus interface settings ......................................................................................... 11

4.7 System settings ...............................................................................................................12

4.8 Water heater settings ................................................................................................... 13

4.9 Ventilation settings ........................................................................................................14

4.10 PI controller settings................................................................................................... 15

4.10.1 PID adjustment screen ................................................................................... 16

4.11 Pressure sensor settings ............................................................................................17

4.12 CO2 sensor settings ....................................................................................................17

4.13 Anti-freezing settings .................................................................................................18

4.14 Air lter settings .......................................................................................................... 19

4.15 Factory settings ........................................................................................................... 19

TABLE OF

CONTENTS