24

7.4 Safety information for the operator /

operating personnel

Any risks from electric power must be eliminated. The

cooking induction unit shall only be used if the installati-

on of the electricity is fitted by an approved installation

contractor in accordance with specific national and local

regulations.

- The heating area is warmed up from the heat of the

pan. To avoid injuries (burning) do not touch the

heating area.

- To avoid overheating of pans by means of evaporating

the contents, don’t heat up pans unattended.

- Switch the control knob off if you take the pan away for

a while. This will avoid having the heating process

continue automatically when a pan is placed back on

the heating area. So, if any person starts to use the

cooker, he/she will have to start the heating process by

turning the control knob in the ON-position.

- Do not insert any piece of paper, cardboard, cloth, etc.

between the pan and the heating area, as this might

initiate a fire.

- As metallic objects are heated up very quickly when

placed on the operating heating area, do not place any

other objects (closed cans, aluminium foil, cutlery,

jewelry, watches etc.) on the induction cooker. Persons

with a pacemaker should consult their doctor whether

they are safe near an induction cooker or not.

- Do not place credit cards, phone cards, cassette tapes,

or other objects that are sensitive to magnetism on the

Ceran plate or in the ceramic bowl.

- The induction cooker has an internal air-cooling

system. Do not obstruct the air inlet- and air outlet-slots

with objects (cloth). This would cause overheating and

therefore the cooker would switch off.

- Avoid liquid entering into the cooker. Do not let water or

food overflow the pan. Do not clean the cooker with a

jet of water.

- If the heating area (Ceran plate) is cracked or broken,

the induction cooker must be switched off and

disconnected from the electric connection. Don’t touch

any parts inside the cooker.

7.5 Inappropriated operating methods

The operating reliability of the cookers can only be

guaranteed with proper use.

The limit values must be observed as per technical data.

7.6 Unauthorized reconstruction and use

of spare parts

Reconstruction of the cooker or changes to the cooker

are not allowed. Contact the manufacturer if you intend

to make any changes on the cooker. To guarantee the

safety, just use genuine spare parts and accessories

authorized by the manufacturer. The use of other

components voids all warranties.

7.7 Pan detection

Pans having a diameter smaller than 12cm are not

detected. During pan detection, the indicator operation

flashes. No power is transferred and the indicator lamp

flashes if no pan is detected.

7.8 Control of the heating area

The heating area is controlled with a temperature

sensor. Overheated pans (hot oil, empty pans) can be

detected. Energy transfer will be stopped. The induction

unit must be re-started after it has cooled down.

8. Out of operation

If the cooker is out of operation make sure that the

control knob is in the OFF position. If you don’t use the

cooker for a longer period (several days) unplug the unit.

Make sure that no liquid can enter into the cooker.

Don’t clean the cooker with a jet of water.

9. Fault finding / Rectification

CAUTION: Do not open the cooker,

dangerous electric voltage inside.

The cookers may only be opened by authorized service

personnel.

Stop any actions if the heating area (Ceran plate) is

cracked or broken, the induction cooker must be swit-

ched off and disconnected from the electric supply. Don’t

touch any parts inside the cooker.

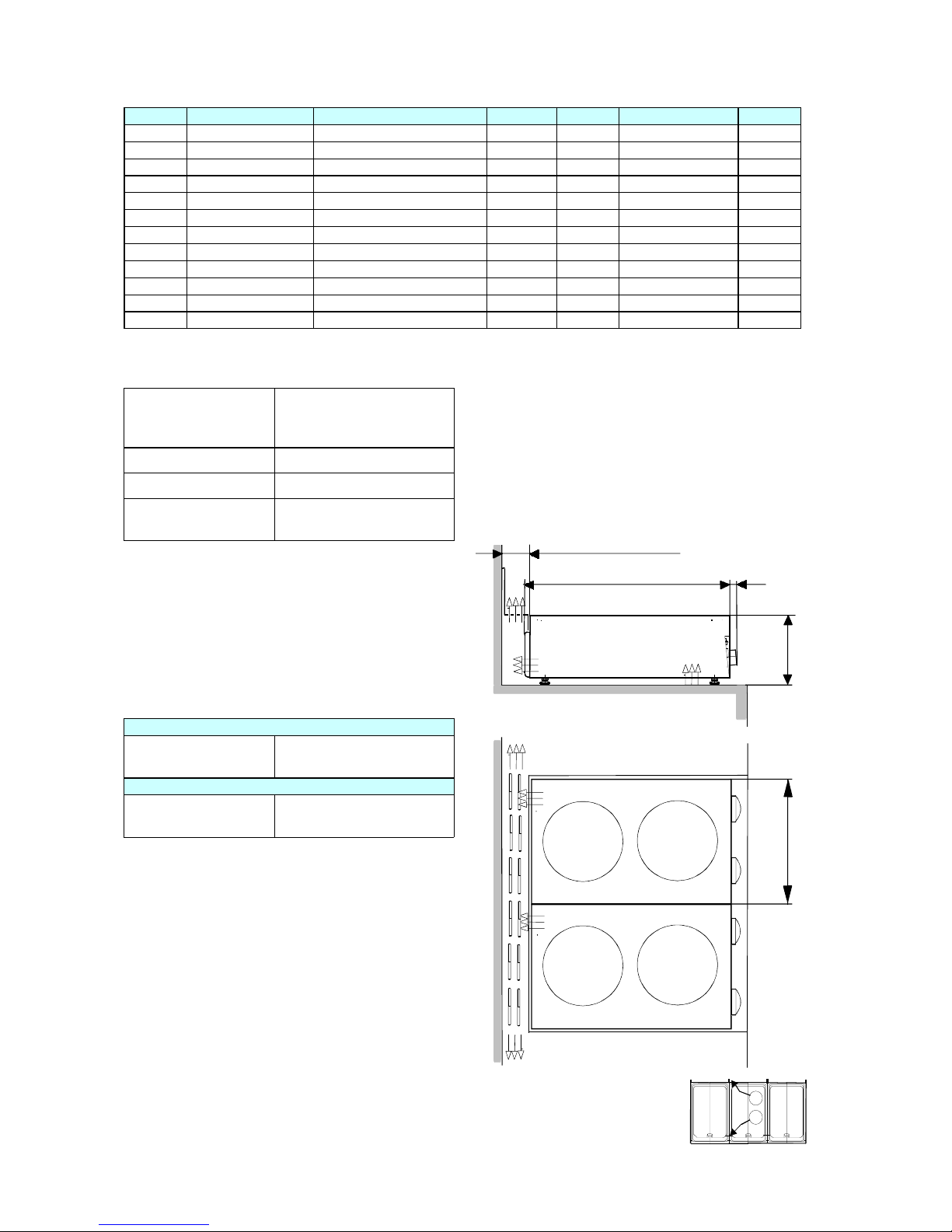

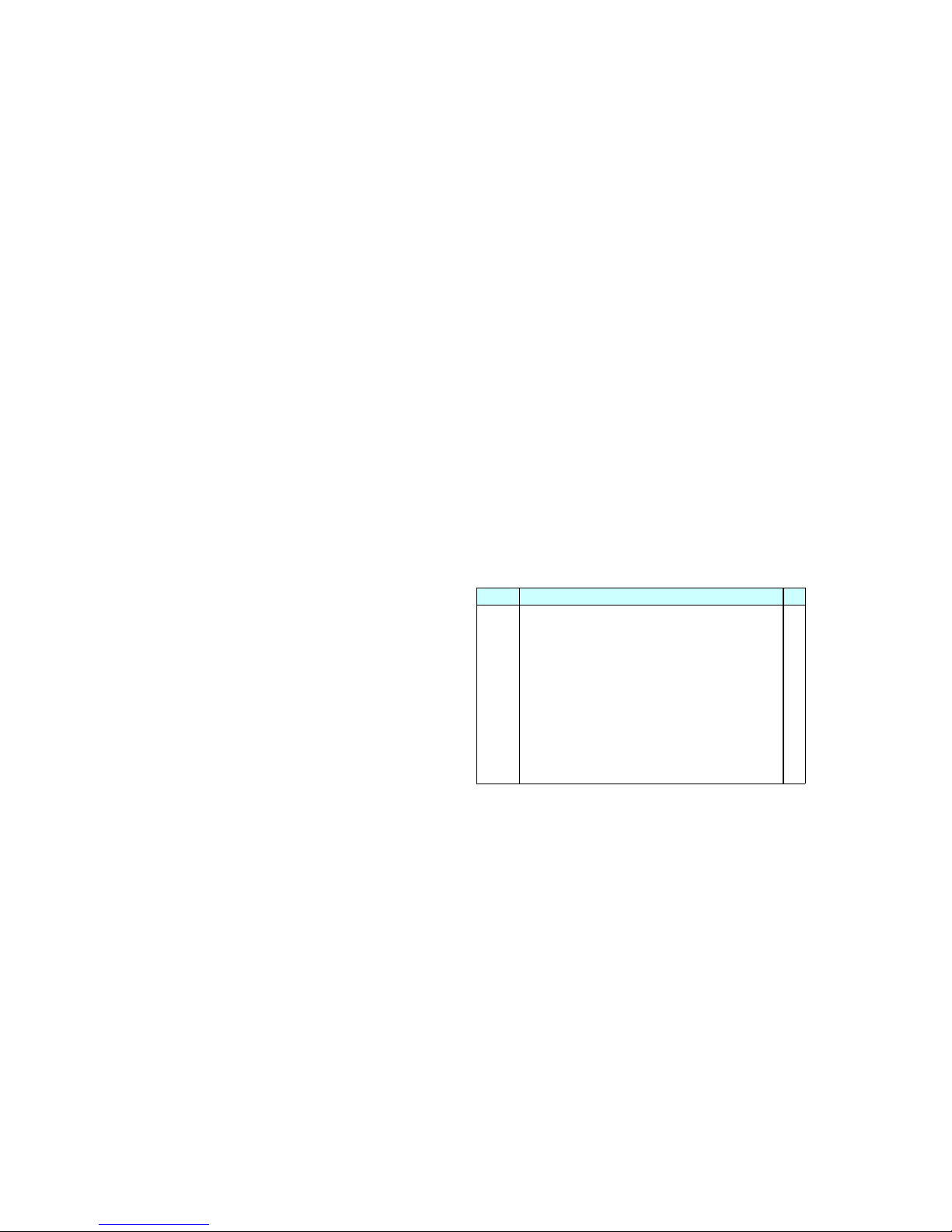

Error messages

Number of flashing signals

1) Wrong pan material

2) The appliance can only be switched on, after resetting

the switch to 0 and the cooking zone is cooled down.

3) The induction unit continues working but the

temperature of the cooking platform is not controlled

anymore

Order of error message: The indicator lamp flashes for

an interval of 0,6 sec. The number of the following short

flashes has to be counted and informs about the kind of

error corresponding to the above mentioned code

system. Additionally the red ERROR indicating lamp is

on.

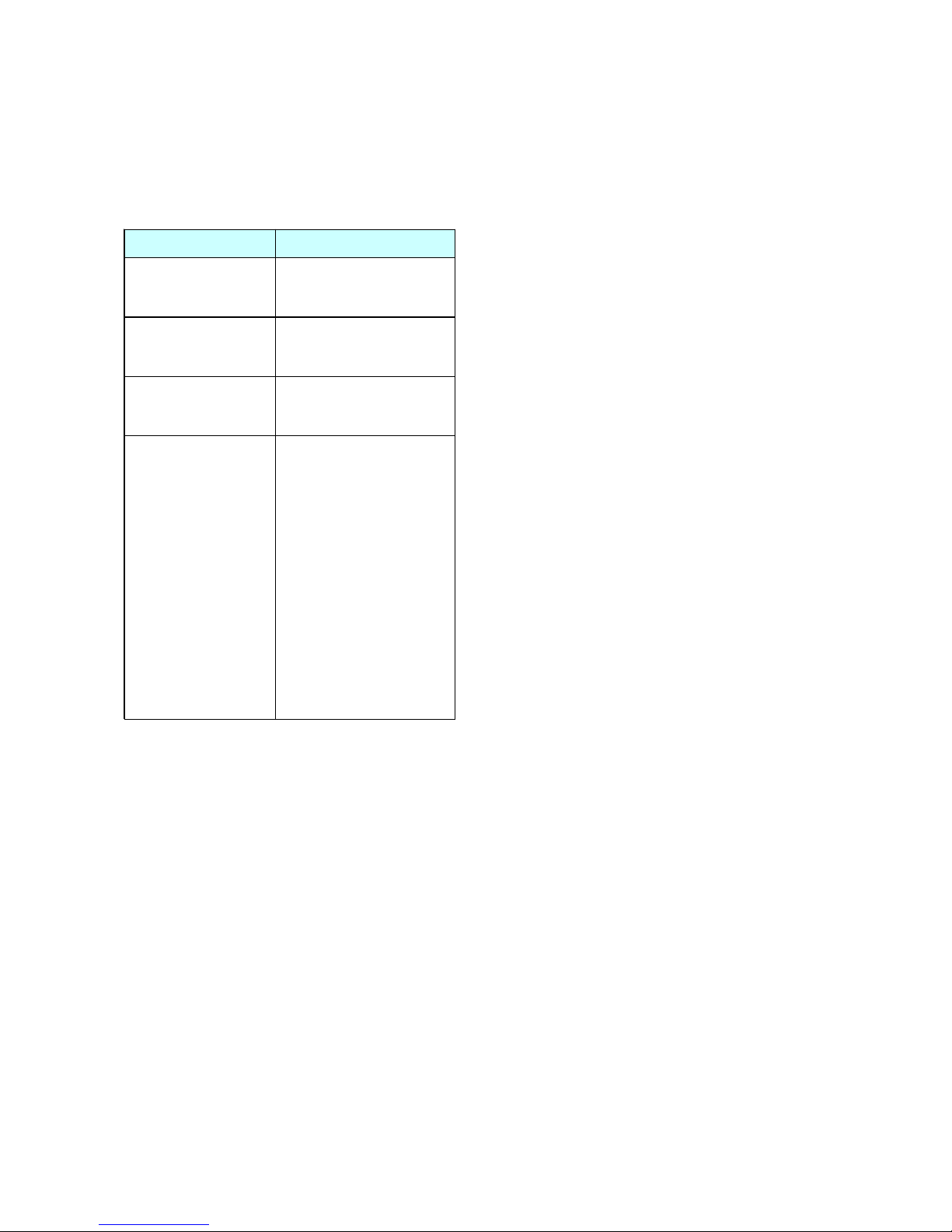

Code Signification

-- No fault, normal operation

01 No coil current, Hardware overcurrent

02 High coil current, Software overcurrent 1)

03 Temperature cooling plage

04 Temperature cooking platform,

overheating

2)

05 Power rotary switch line break

06 Raised inside temperature

07 Sensing element of cooking platform,

short circuit

3)