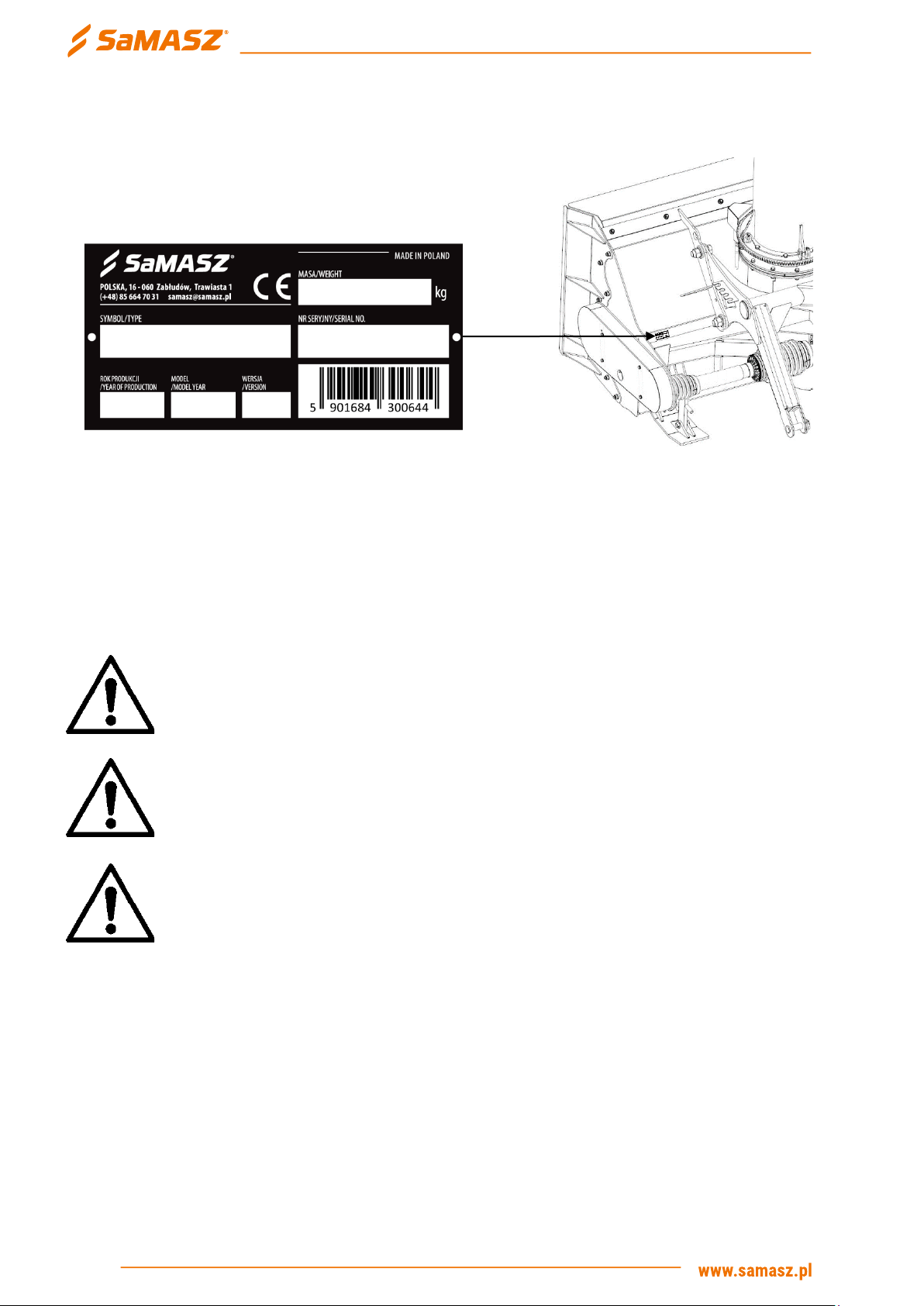

1. IDENTIFYING THE MACHINE ...........................................................................................4

2. INTENDED USE .............................................................................................................4

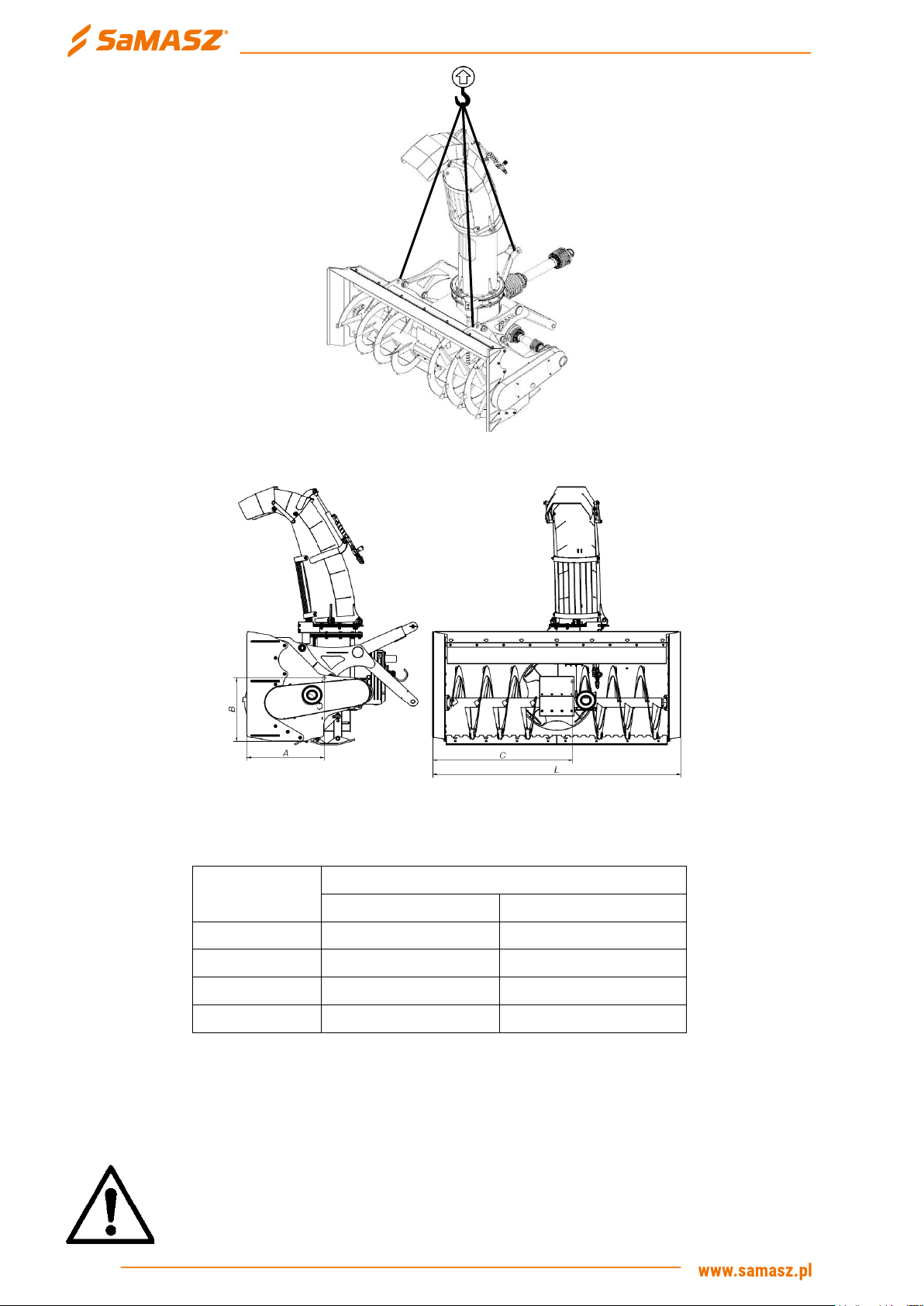

2.1. Technical characteristics ......................................................................................................5

2.2. General design......................................................................................................................6

2.3. Equipment and spare parts....................................................................................................6

3. SAFETY CONDITIONS ....................................................................................................7

3.1. Safety principles ...................................................................................................................7

3.2. Relocating machine onto another vehicle for transport...........................................................9

3.3. Operating parts...................................................................................................................10

3.4. PTO shaft ...........................................................................................................................11

3.5. Hydraulic assembly.............................................................................................................11

3.6. Residual risk .......................................................................................................................11

3.7. Safety decals......................................................................................................................12

4. OPERATING ROTARY SNOW BLOWER.............................................................................14

4.1. Mounting blower to tractor ..................................................................................................14

4.2. Mounting telescopic articulated shaft..................................................................................16

4.3. Transport and standstill position .........................................................................................18

4.4. Controlling rotary snow blower ............................................................................................18

4.5. Preparing rotary snow blower for operation..........................................................................19

4.6. Operation............................................................................................................................19

4.7. Dismounting blower from the tractor ...................................................................................20

5. MAINTENANCE...........................................................................................................20

5.1. Operating service................................................................................................................20

5.2. Maintenance and storing.....................................................................................................21

5.3. Lubrication .........................................................................................................................22

5.3.1. Risks present when lubricating.................................................................................22

5.3.2. Gearbox ..................................................................................................................22

5.3.3. Chain gear...............................................................................................................22

5.3.4. Lubrication points....................................................................................................23

6. DEFINING THE TOTAL WEIGHT, AXIS LOAD, TYRE LOAD CAPACITY AND MINIMUM LOAD......24

7. DISMOUNTING AND WITHDRAWAL FROM USE.................................................................26

7.1. Repair.................................................................................................................................26

7.2. Disassembly and withdrawal from use.................................................................................26

7.3. Withdrawal from use ...........................................................................................................26

7.4. Environment .......................................................................................................................26

8. WARRANTY................................................................................................................27

8.1. Warranty card .....................................................................................................................27

8.2. Warranty terms ...................................................................................................................27

8.3. Warranty repairs record.......................................................................................................29