Doc.-ID: 220518-PT20BAU-SS-Ex Installation Manual rev.01.docx, Page 2 of 24

Table of contents

1Introduction ..............................................................................................................4

2Technical data ..........................................................................................................4

2.1 Characteristic values for explosion protection.....................................................4

2.1.1 Optional marking........................................................................................................................4

2.1.2 Standard basis and certificate ...................................................................................................5

2.2 Electrical parameters...........................................................................................6

2.2.1 Voltage supply: ..........................................................................................................................6

2.2.2 Performance, temperatures and temperature classes ..............................................................6

3General safety instructions and special conditions..............................................8

4Area of application...................................................................................................9

5Transportation and storage...................................................................................10

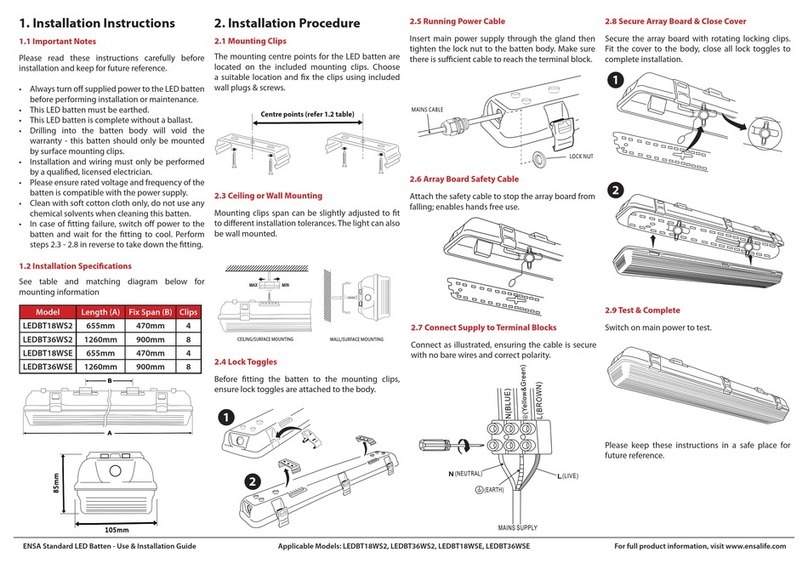

6Commissioning ......................................................................................................11

6.1 Installation.........................................................................................................11

6.1.1 Types from T20-VA1.1 to VA2.2..............................................................................................11

6.1.2 Type T20-VA2.3.......................................................................................................................12

6.1.3 Type T20-VA4.x.......................................................................................................................13

6.2 Opening and closing the housing......................................................................13

6.2.1 Type T20-VAx.x.x.x .................................................................................................................13

6.3 Electrical connection and commissioning..........................................................16

6.4 Supplementary elements (suitable cables & cable glands)...............................17

7Troubleshooting.....................................................................................................18

8Maintenance/ Modification.....................................................................................19

9Repair......................................................................................................................19

10 Disposal/ Recycling............................................................................................19

11 Drawings..............................................................................................................19

12 Certificates ..........................................................................................................20

12.1 EU - Declaration of Conformity..........................................................................20

12.2 EU Type Examination Certificate (ATEX)..........................................................21

12.3 IECEx Certificate of Conformity:........................................................................21

12.4 Other certificates...............................................................................................21