9

R. 03/12 855 819

Samson Corporation • One Samson Way • N.C. 28778 Swannanoa • Phone: 00 1 8286868511 • Fax: 00 1 8286868533

2012_03_06-17:30 ENGLISHESPAÑOL

Operation

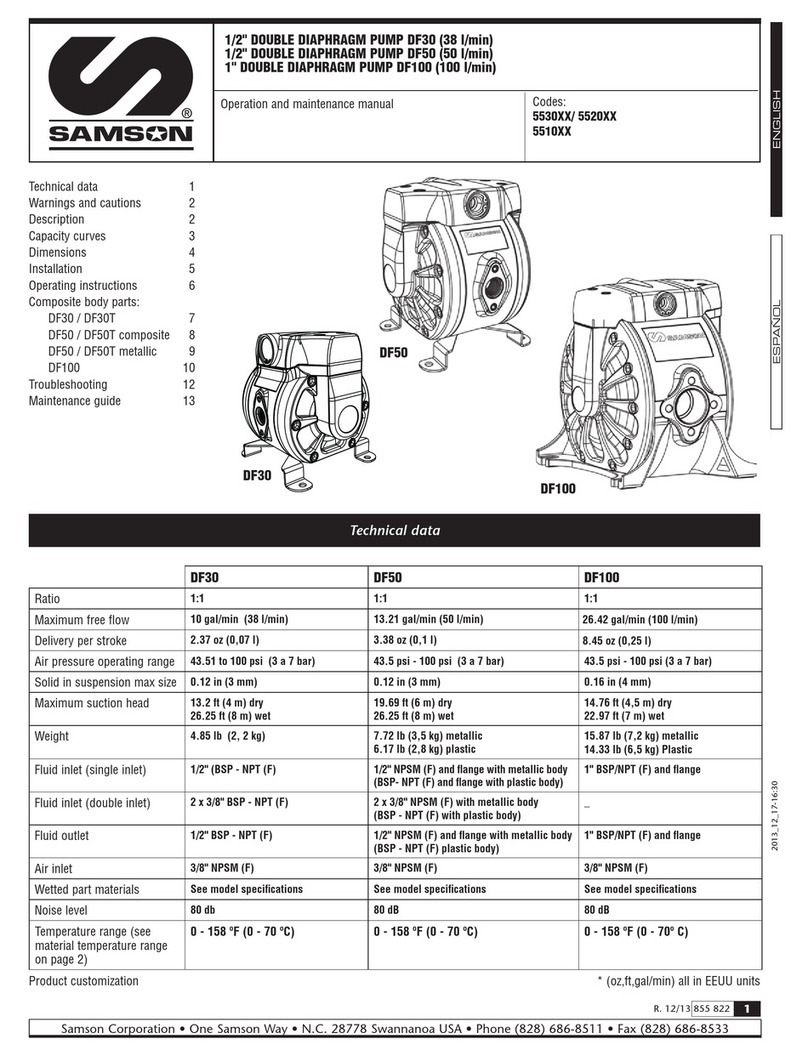

This pump is self-priming. To prime it the first time, you must connect the air pump supply to a low pressure using the pressure regulators

while keeping the outlet valve open.

When fluid begins to flow from the pump outlet, the pump is primed. For regulation of fluid pressure, the unit must be supplied with an air

pressure between 43.5 and 100 psi (3 and 7 bar). Adjust the discharge valve on the discharge side to control flow. For the performance

characteristics of the pump see the capacity curve shown on page 4.

Warning

• DF-100 pumps do not exceed a nominal noise level of 70 dB. It is recommended to use hearing protection when working near a

diaphragm pump. Noise can be significantly reduced using a remote exhaust using a hose attached to the appropriate port in the air

exhaust (optional connection not supplied with the pump).

• Never use the pump under any circumstances with nonconducting flammable fluids or explosives.

• Always wear appropriate protective clothing to handle the pump.

• Never place your face or body against the air exhaust while the pump is running.

• Cut off the air supply before any maintenance. Release all pressure in hoses and pipes before disconnecting the pump for maintenance.

• Make sure the air valve, pressure regulator valve and drain the discharge valve are closed. Also, make sure that the valve on the suction

side is open.

Caution

• Before starting the pump, always ensure that the discharge piping system is secure.

• Check the flow direction before starting.

• Never use compressed gases other than air.

• As you start to close the discharge valve the air supply pressure can increase. Make sure that the pressure stays within normal operating

range. (Main Specifications on page 1).

• The suction flow velocity of the fluid will vary depending on the viscosity and specific gravity of the fluid, the capacity for suction stroke

and other conditions, however, if the speed of the pump (the fluid flow rate) increases significantly, there will can be cavitation of the fluid

and it will reduce pump performance. Adjust air supply pressure and flow to prevent cavitation.

• If there is no flow of fluid after starting the pump, or you hear an unusual noise or notice any irregularities, immediately turn off the pump.

(Troubleshooting on page 15).

• You can stop the pump by closing the discharge valve while the air is on, but if this condition continues for several hours and the pump

is left unattended it can begin pumping automatically if a discharge pipe or connection starts to leak, spilling fluid and causing property

damage. When the dispense is complete, release the internal pressure close the discharge valve.

• When the pump stops while pumping liquids containing heavy loads of solids, the particles in the slurry precipitate in the outlet chamber.

If the pump is restarted without removing the contaminants, the diaphragm may be damaged or the pushing rod can be overloaded and

be damaged. Before restarting the pump, flush the remaining fluid and solids from the pump.

• Place a bucket under the relief valve to catch any waste that might be released.

• If the pump will remain out of use for a long period of time, purge and clean it.

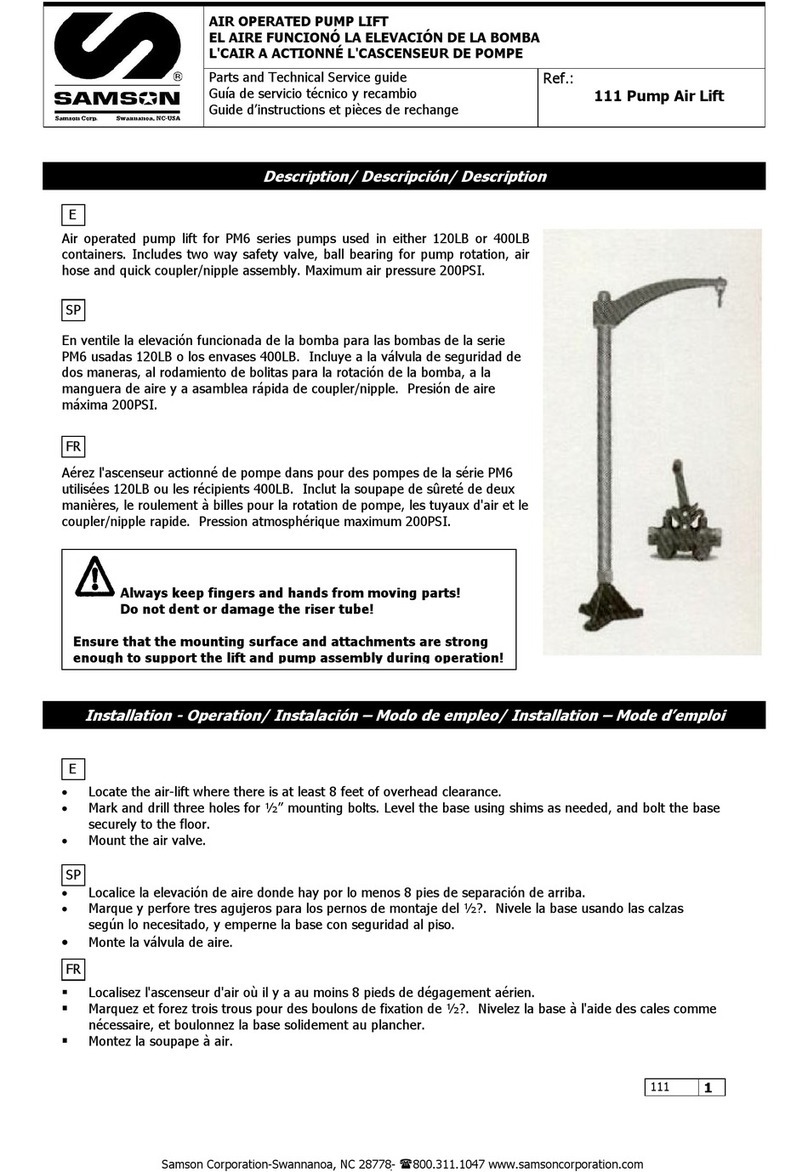

Installation

Warning

Air connection

To ensure that the air supply is sufficient to meet the demand of the pump, the diameter of the pipe must be equal to the diameter of the

supply port of the pump. Choose auxiliary air treatment equipment and fittings with sufficient airflow to exceed the air consumption of the

pump. In addition, peripheral air treatment equipment must be installed as close as possible to the pump unit.

The use of a coupler to connect the hoses aids future operation and maintenance tasks.