Symptom Possible Causes Solution

Air Pressure. Check air lines.Lift does not raise.

Defective seals. Check and replace.

Lift does not lower. Broken valve.

Valve installed backwards.

Valve mechanism clogged open.

Check and replace if needed.

Reverse ports.

Remove screen and clean valve.

Síntomas Posibles causas Soluciones

Presión De Aire. Compruebe las líneas de aire.La elevación no levanta.

Sellos defectuosos. Compruebe y substituya.

La elevación no baja. Válvula quebrada.

Válvula instalada al revés.

El mecanismo de la válvula está abierta

debido a suciedad.

Compruebe y substituya si está necesitado.

Cambiar los puertos.

Quitar la pantalla y limpiar la válvula.

Symptômes Causes possibles Solutions

Pression atmosphérique. Vérifiez les compagnies aériennes.L'ascenseur n'augmente pas.

Joints défectueux. Vérifiez et remplacez.

L'ascenseur ne s'abaisse pas. Valve cassée.

Valve installée vers l'arrière.

Ouvert obstrué par mécanisme de valve..

Vérifiez et remplacez si nécessaire.

Ports renversés.

Enlevez l'écran et nettoyez la valve.

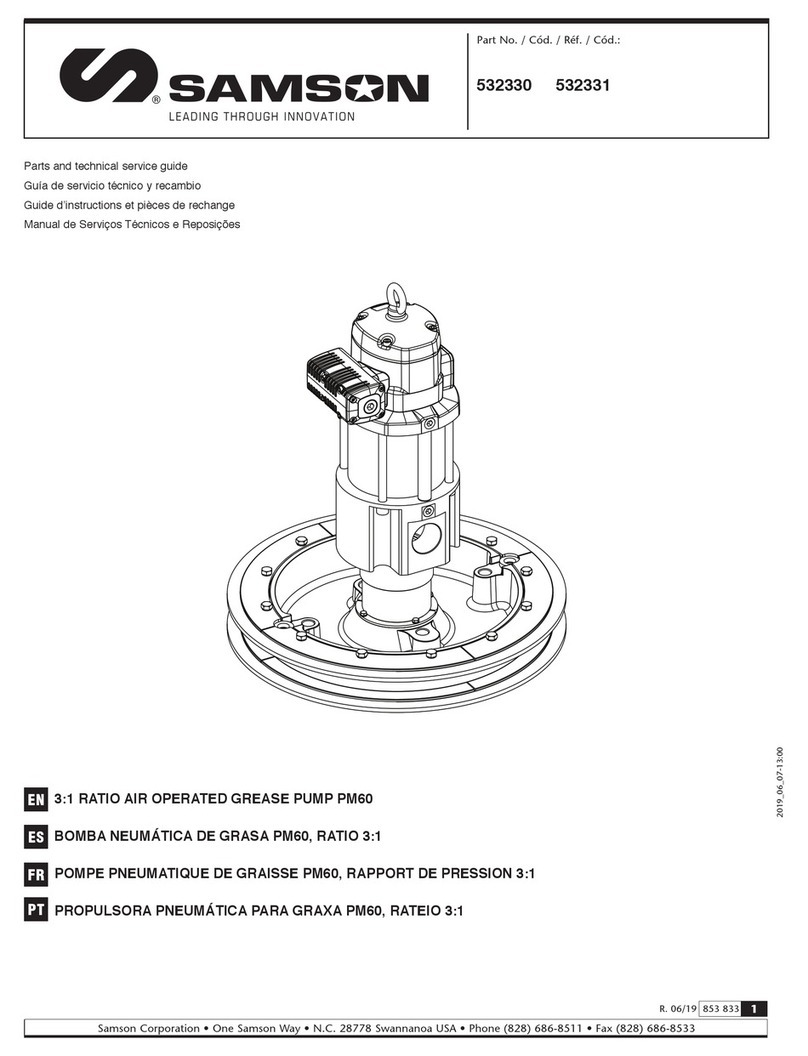

Lift Capacity Levante La Capacidad Soulevez La Capacité 136KG ¤ 300LB

Maximum working pressure Presión máxima de trabajo Pression max. de travail 20 bar ¤ 200 PSI

Inlet thread Entrada de air Raccordement entrée air 1/4” (F)/ H 1/4” G

Item Part No. Description Qty.

1 812573 Cap 1

2 800361 O-Ring 1

3 812479 Piston 1

4 805810 1/4" Ball 20

5 812750 V-Packing 1

6 812746 Piston Tube 1

7 812571 Clamp Suppt 1

8 850252 Bolt 7/16-20 4

9 825011 Lock Washer 4

10 850168 Nut 7/16-20 4

11 813263 Arm 1

12 805939 Nut 3/8-16 1

13 805756 Washer 3/8 1

14 808672 Eye Bolt 1

15 813273 S-Hook 1

16 812748 Stop Tube 1

17 814355 Outer Cyl. 1

18 812747 Guide Nut 1

19 4451-001 Air Valve 1

20 813 Air Hose 1

21 930 Air Coupler 1

22 931 Air Nipple 1

23 812187 Regulator 1

24 805941 Elbow 1

25 812744 Base 1

111 2

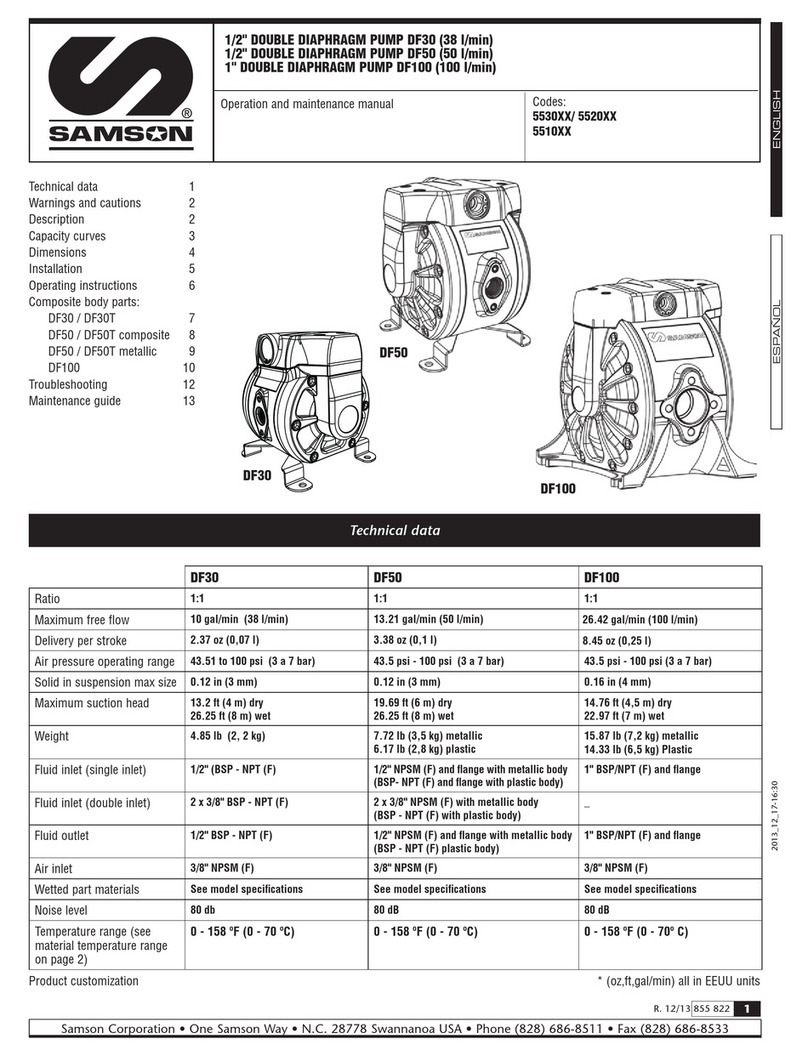

Technical data