Installation guide

The stove must be installed in compliance with the provisions of relevant local binding

regulations.

PN-EN 13229:2002 Norm “Inserts and Open Fireplaces for Solid Fuels. Requirements and

Testing”, PN-EN 13240:2002 Norm “Heaters for Solid Fuels. Requirements and Testing”

is saying:

The stove must be located away from combustible products. It may, therefore, be required

to protect the wall and fireplace surrounding materials. The stoves must rest on a solid,

fireproof base. Make sure that the chimney is free from soot and other impurities. The

chimney must be air-tight and equipped with a cleanout door. The stove must be installed

with a direct flue connection and a flue liner made from non combustible and oxidation

resistant materials. If the chimney draft is weak, a new flue liner may be required. Where

the draft inside the chimney is excessive, a chimney adapter should be installed.

Alternatively, draft control devices may be mounted on the chimney top.

Flue systems should be inspected by authorised person, and any adaptations should be

carried out by professionals.

It is essential to provide fresh air into the room where the appliance is located. Fresh air

should be delivered from outside by means of a patent pipe, and the air intake should be

located near the ground level. A flue adaptor should also be installed to help cut off the air

when the fireplace is not in use. To fully enjoy the fireplace, leave installation work with a

professional company.

The air vent, which operates in the same room as the fireplace or in the room which it

ventilates, may cause problems. The room where the stove is located should have at least

12m² of floor area. The wall against which the stove is installed and the floor in front of the

stove must be made from non-flammable materials (at least 50cm).

The stove must not be dragged along the floor to ensure that its legs are not broken.

We shall not be held liable for any installations that have not been carried out in

compliance with the binding building regulations.

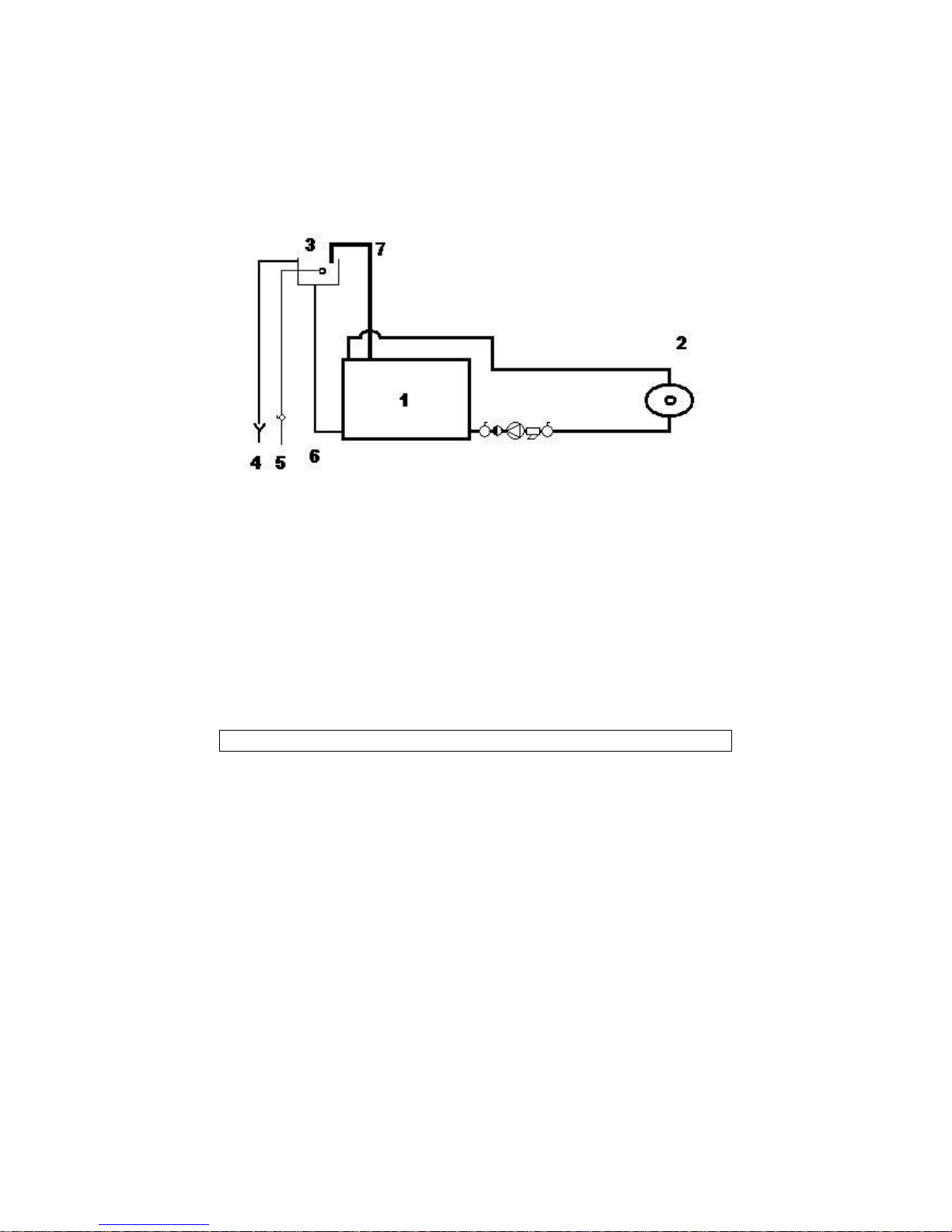

Installing a stove with a water jacket

A fireplace may be installed on the premises of not less than 12 square meters of floor area.

The wall and the floor adjacent to the stove should be made of non-combustible materials.

The floor in front of the fireplace (at least 50 cm) must be protected against accidental fire.

The installation of the water jacket elements in the open system must be carried out by

authorised professionals with due consideration for local safety regulations.

The water jacket of the stove is not designed to function in a closed pressure system.

Installing the water elements of the stove in a pressure system will void the guarantee. The

manufacturer shall not be held liable for any damage and/or defects caused as a result of such

installation.

Where the device is installed in the system which, during the heating season, is not used on a

continuous basis, it is recommended to use an anti-freezing agent specially designated for

central heating systems. The water jacket should be connected to the central heating system

by means of threaded connectors. Only steel or copper pipes can be used to connect the water

jacket with the stove. It is inadmissible to use plastic pipes because the heating agent can

exceed 95°C, which may damage the hating installation system. Steel pipe 1” or copper