Samsung SVR-433 User manual

Other Samsung VCR System manuals

Samsung

Samsung SV-415X User manual

Samsung

Samsung SVR-639 User manual

Samsung

Samsung SV-7000W User manual

Samsung

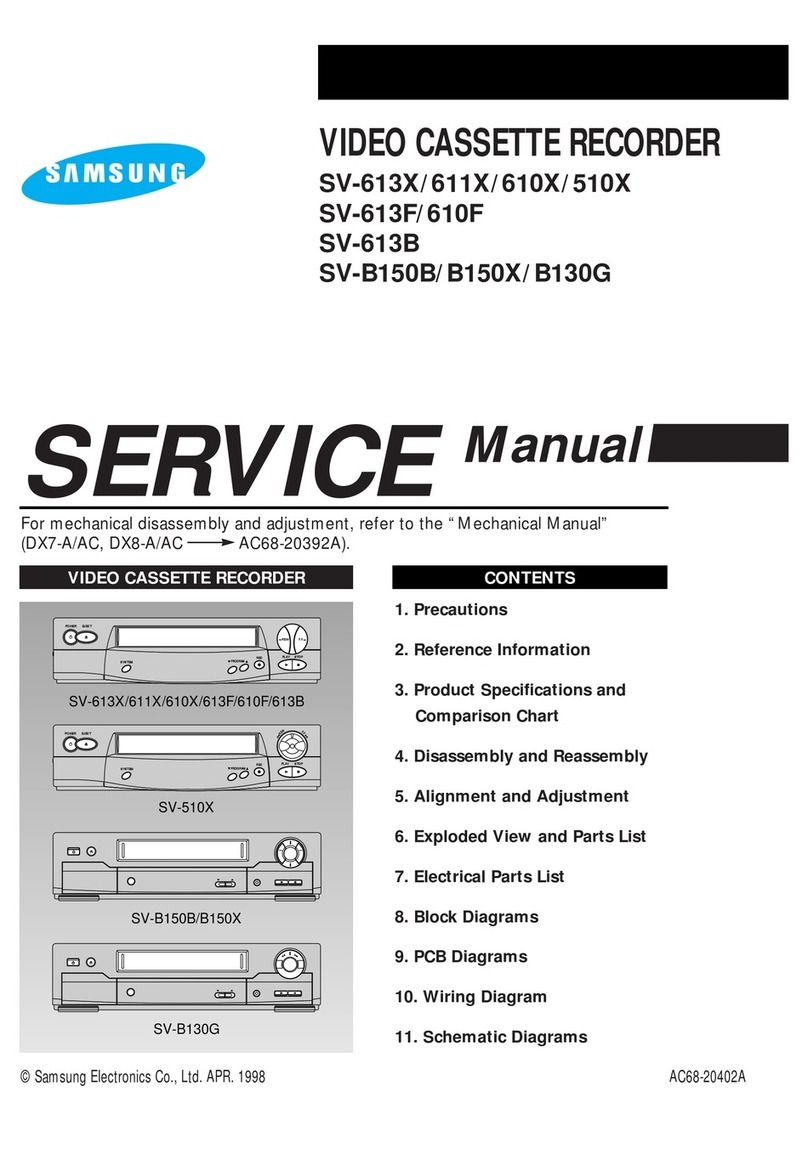

Samsung SV-613X User manual

Samsung

Samsung SV-610X User manual

Samsung

Samsung SV-C15P User manual

Samsung

Samsung SV-5M User manual

Samsung

Samsung SV-660GS User manual

Samsung

Samsung SV-M30K User manual

Samsung

Samsung VR5260C User manual

Samsung

Samsung SV-261GX User manual

Samsung

Samsung SV-H620K User manual

Samsung

Samsung SV-271B User manual

Samsung

Samsung SV-251B User manual

Samsung

Samsung SV-232B User manual

Samsung

Samsung SV-160GS User manual

Samsung

Samsung VR8809 User manual

Samsung

Samsung SV-434F User manual

Samsung

Samsung SV-613X User manual

Samsung

Samsung SV-261I User manual