Safety Warnings

Read all Warnings and Cautions noted blow.

Failure to do so could result in serious or fa-

tal injury.

Prior to installation of this unit, carefully

read and adhere to all CAUTION,

ATTENTION, and ADVICE notices located

throughout this manual. Failure to comply

with these instructions can cause serious in-

jury, death, or damage to the unit.

RISK OF SUCTION ENTRAPMENT

HAZARD, WHICH, IF NOT AVOIDED CAN

RESULT IN SERIOUS INJURY OR DEATH.

Do not block pump suction at the pump or in

the pool as this can cause severe injury or

death.

Electrical wiring MUST be installed by a

trained professional and adhere to local

code and regulations.

Avoid electric shock. DO NOT USE pow-

er extension cords.

Connect ONLY to a Ground-Fault Circuit

Interrupter (GFCI) power outlet. Consult a

Qualified professional electrician for safe

and proper installation of a qualified electri-

cal outlet.

Incorrectly installed equipment may fail,

causing severe injuries or damage to the

pump-filter system.

Never submerge the filter and/or pump in

water.

Never place the pump or filter in your

pool.

Trapped air in the pump-filter system may

cause the TANK COVER to be blown off

which can result in death, serious injury, or

damage to the pump-filter system. Ensure

all air is out of system before operating.

NEVER change the 7 Position Multi-Port-

Valve while the system is operating.

ALWAYS unplug the system before

changing the control valve.

Install this product with a sufficient safety

margin from the pool to prevent children

from using the system to access the pool.

Never PLUG or UNPLUG this unit from

an electrical source while standing in water.

NEVER service this unit with the electrical

power cord connected.

Do NOT operate the system while the

pool is being used.

KEEP CHILDREN AWAY from all electri-

cal equipment.

NEVER ALLOW CHILDREN TO

OPERATE THIS EQUIPMENT.

The Pool Owner should always exercise

caution and common sense when utilizing

their swimming pool and operating equip-

ment.

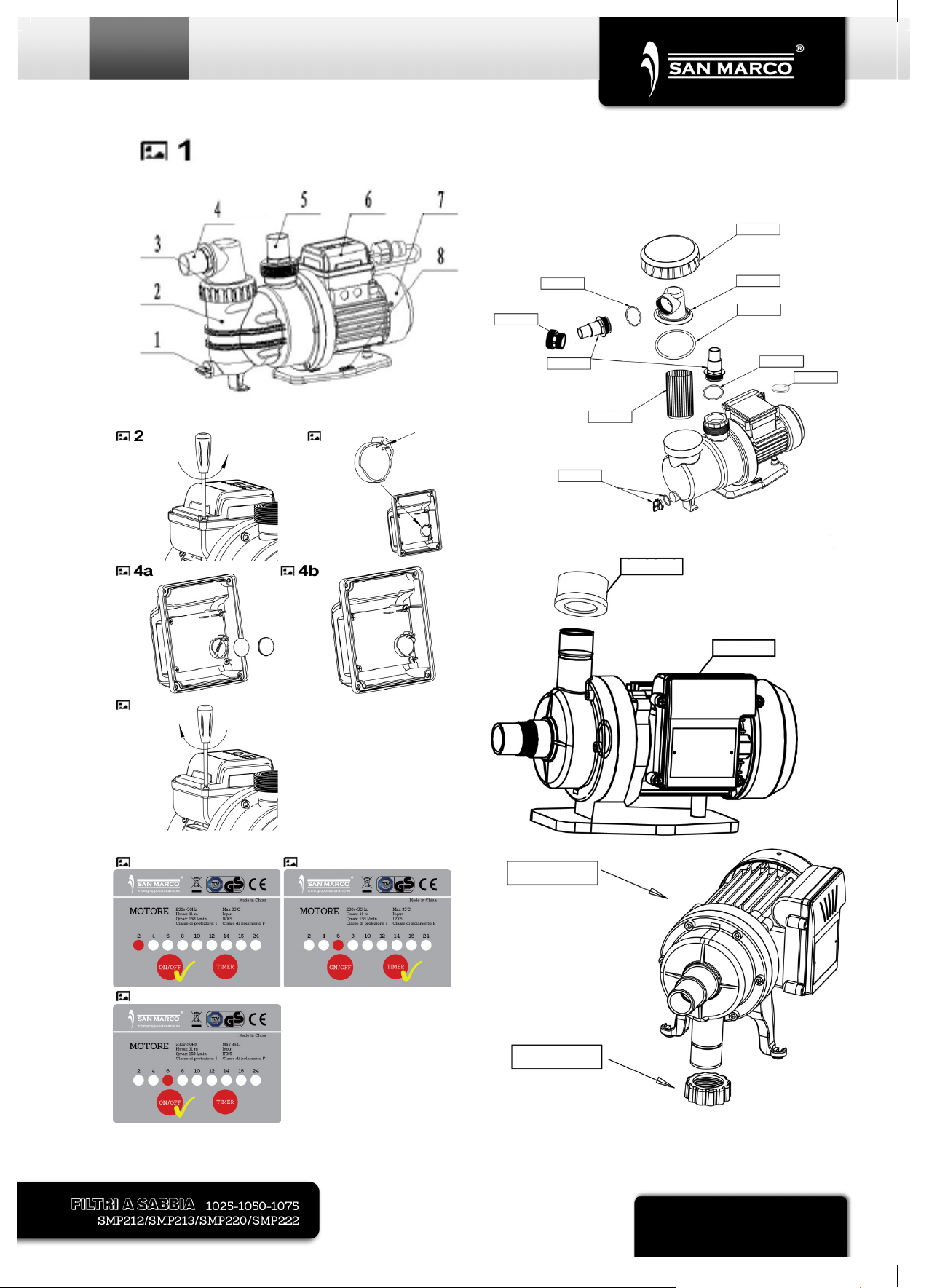

Generel Information

This manual provides information relating to the installation, utiliza-

tion and maintenance of our filtration system. We recommend that

you read this manual in its entirety and keep it for future reference.

The pump included with the filtration system is a horizontal, self-

priming centrifugal pump. For the pump to function correctly, the wa-

ter temperature must not exceed 35°C /95°F. The materials used in

the pump have undergone stringent hydraulic testing and electrical

inspections.

The filter included in the filtration system consists of high-grade pol-

ypropylene (PP). It is seamless and manufactured as a single unit

(absolutely corrosion resistant and resistant to commercially availa-

ble swimming pool chemicals). (Prerequisite: Compliance with the

standard recommended specifications for the pH- and chlorine-

value). It is equipped with a container drainage system, pressure

gauge, built-in container components, e.g.bottom strainer for even

water distribution and a stable PE separation wall between the filter

and the fresh water chamber. The filter container comes ready to

plug-in and is supplied with a user-friendly 7 Position Multi-Port

Valve integrated into the tank cover, an approved filter pump with

hair and lint basket, and a plastic base for ready on-site mounting.

Read this manual carefully before installation. The filtration system

and pump must be installed in accordance with the standards in ef-

fect.

We decline all responsibility for the consequences of failure to com-

ply with the installation instructions. We recommend that you comply

with the power source instructions to avoid overloading the pump

motor and/or electric shock.

This filtration system is not intended for use by persons with reduced

physical, sensory or mental capabilities, or lack of experience and

knowledge.

Safety notes and callout boxes should always be observed.

Safety Notes

Your filter pump was constructed and tested

and left the manufacturing plant in technically

operational condition. In order to maintain this

condition and ensure safe operation, the user

should observe the notes and product infor-

mation contained in this technical handbook.

If there is any indication that safe operation is

no longer possible, the device is to be dis-

connected from the power supply and se-

cured against accidental use.