4

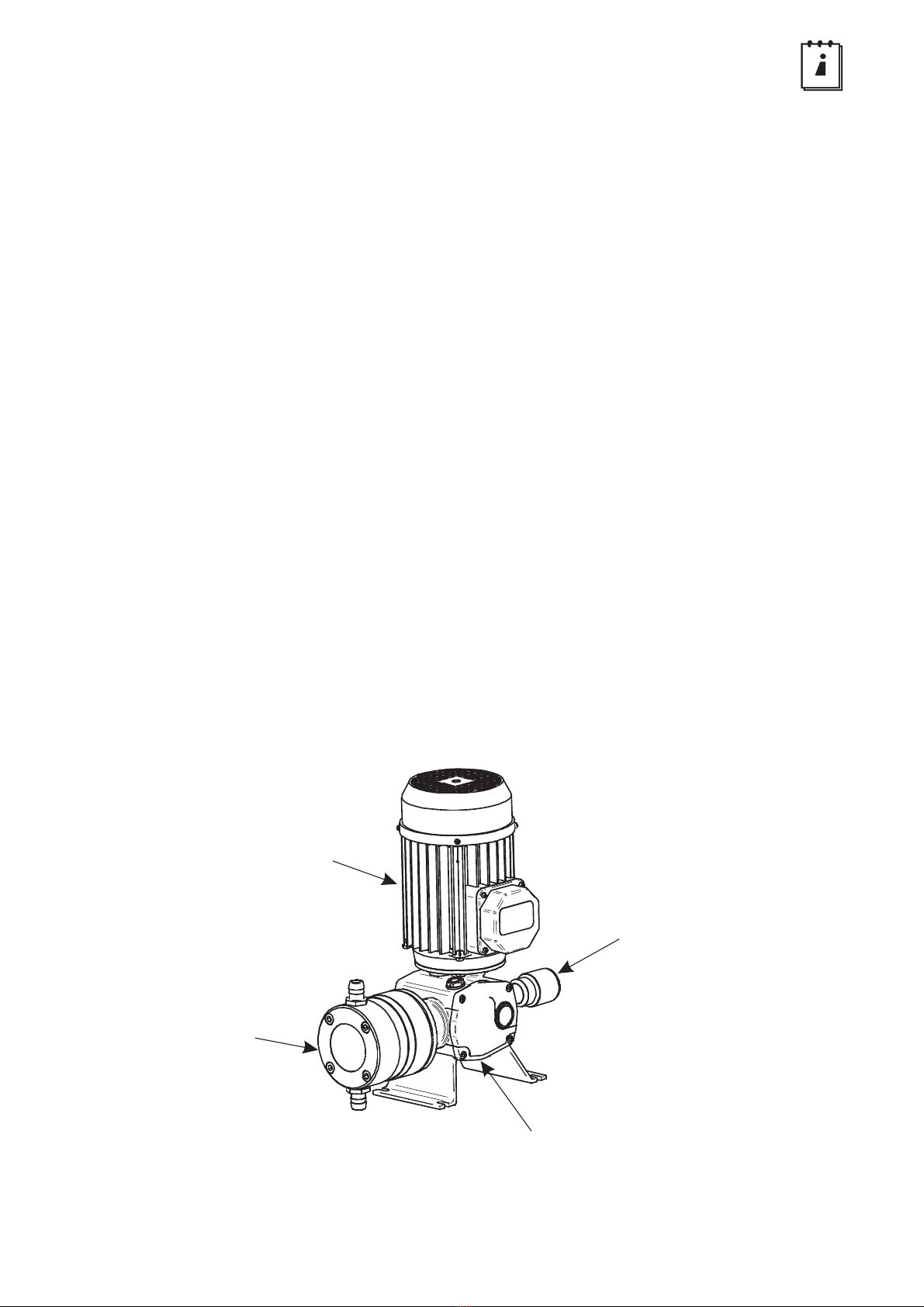

1.- GENERAL DESCRIPTION

DOSTEC-40 dosing pumps are heavy duty, high precission, electric diaphragm

pumps for dosing liquid products.

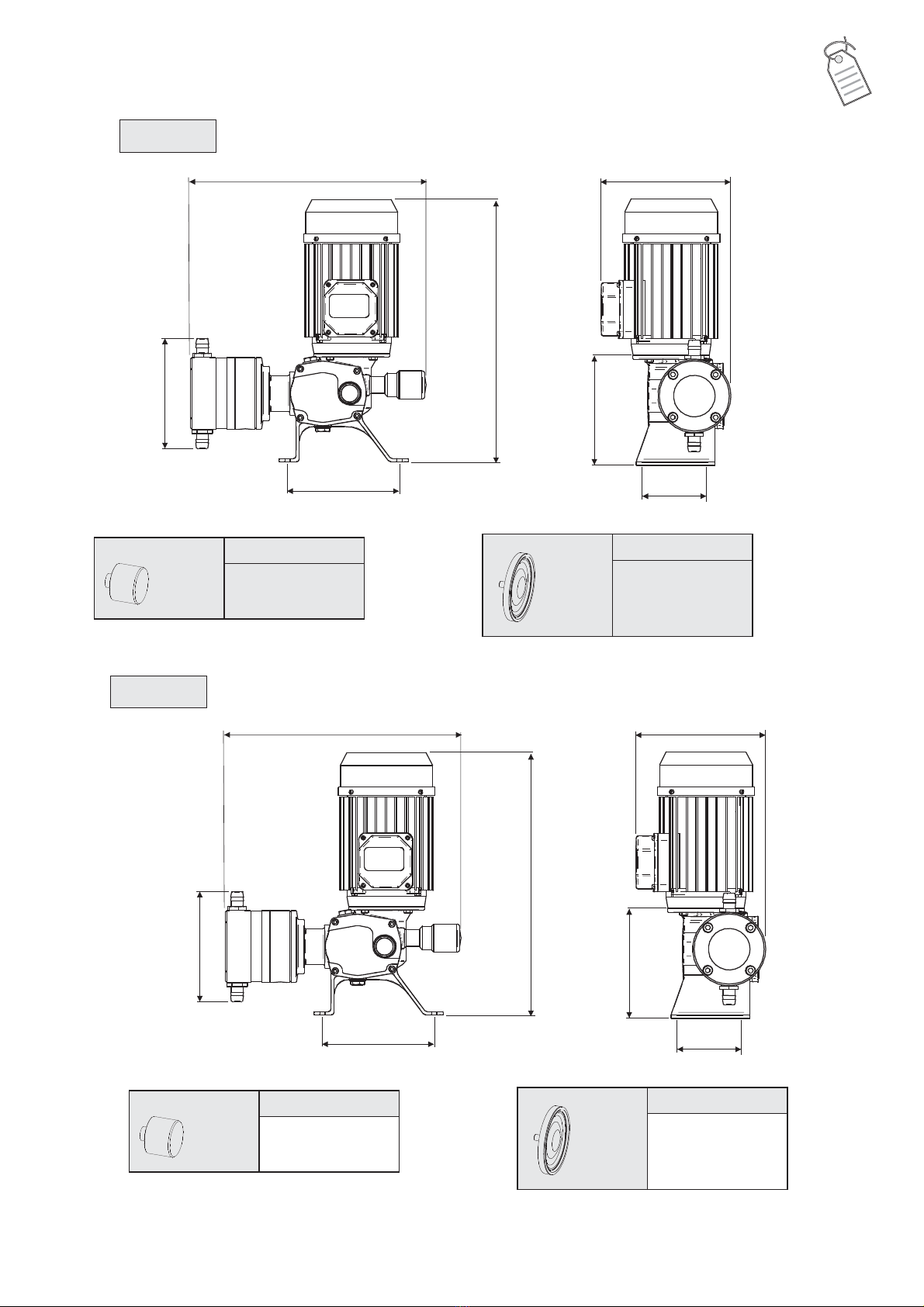

This series allows many injection possibilities depending on the head being

chosen. The available heads are: 25, 50, 100, 200, 300, 500 l/hr for the piston

series, and 25, 50, 100, 200, 300 l/hr for the diafragme series.

DOSTEC-40 dosing pumps are manufactured with materials that can resist

most chemicals products, even acids. They are designed for all sorts of

processes where it is necessary to dose a product into a hydraulic network,

such as: food, textile, chemical industry, water treatments, etc. (See materials

in Technical Features). In case there is any doubt about compatibility of

materials with the products to be used please contact ITC S.L. Technical

Service.

Dosing flow of each module is adjustable independently with no need to stop

the pump from 0% to 100% of its capacity.

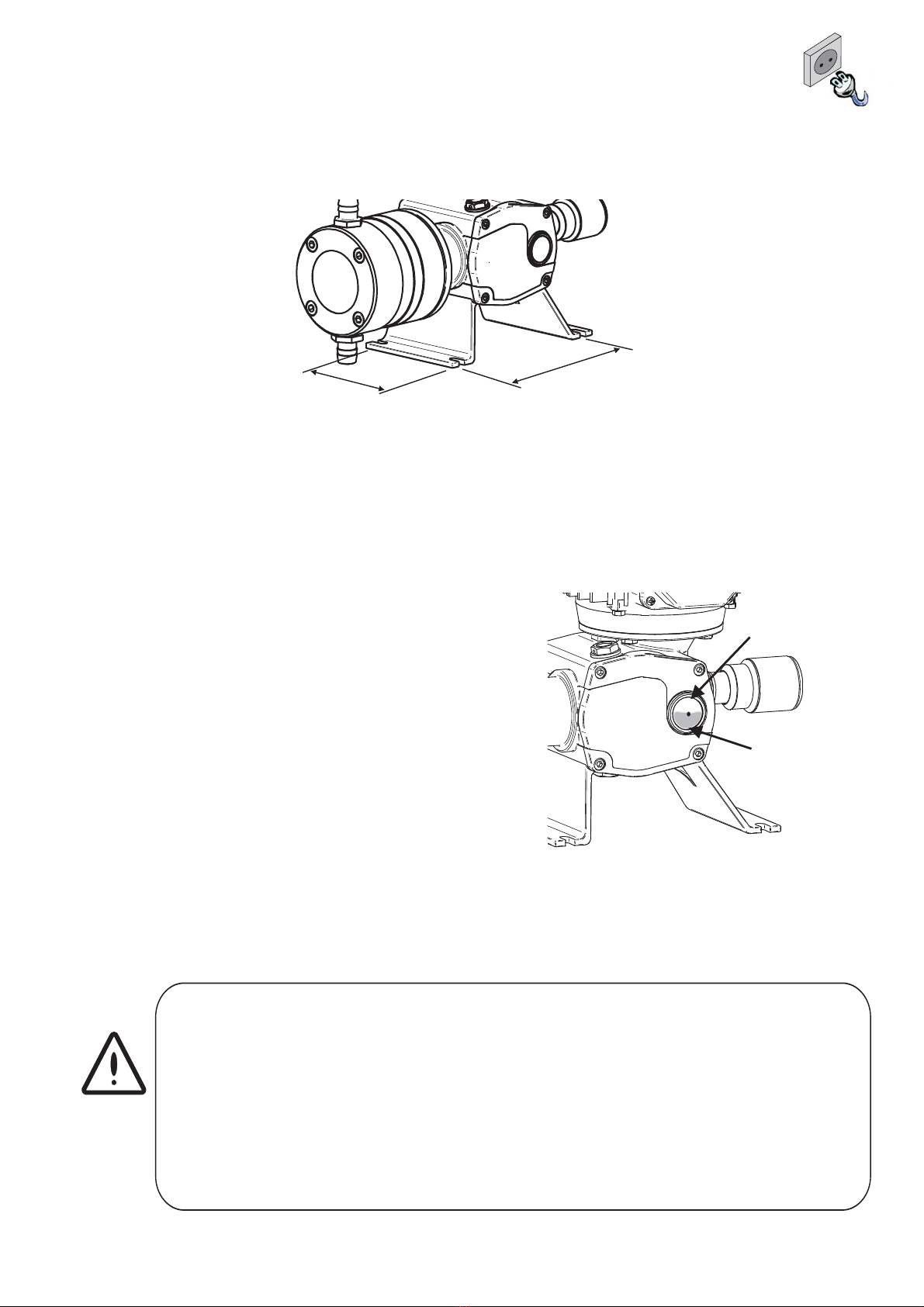

Motor

Cylinder

Block

Regulator