Models SB1-A & SB25A Type 4 Page 4 520-146-000 7/03

inspection or replacement. First remove the air distribution valve body and the pilot

valve body from the pump. The plungers can be located by looking into the

intermediate. It may be necessary to use a fine piece of wire to pull them out. The

bushing can be turned out through the inner chamber by removing the outer

chamber assembly. Replace the bushings if pins have bent.

SERVICE INSTRUCTIONS: TROUBLE SHOOTING

1. Pump will not cycle

A. Check to make sure the unit has enough pressure to operate and that the air inlet

valve is open.

B. Check the discharge line to insure that the discharge line is neither closed nor

blocked.

C. It the spool in the air distribution valve is not shifting, check the main spool. It must

slide freely.

D. Excessive air leakage in the pump can prevent cycling. This condition will be

evident. Air leakage into the discharge line indicates a ruptured diaphragm. Air

leakage from the exhaust port indicates leakage in the air distribution valve. See

further service instructions.

E. Blockage in the liquid chamber can impede movement of diaphragm.

2. Pump cycles but will not pump

A. Suction side of pump pulling in air. Check the suction line for air leaks and be sure

that the end of the suction line is submerged. Check flange bolting. Check valve

flanges and manifold to chamber flange joints.

B. Make certain the suction line or strainer is not plugged. Restriction at the suction

is indicated by a high vacuum reading when a vacuum gauge is installed in the

suction line.

C. Check valves may not be seating properly. To check, remove the suction line and

cover the suction port with your hand. If the unit does not pull a good suction

(vacuum), the check valves should be inspected for proper seating.

D. Static suction lift may be too high. Priming can be improved by elevating the

suction and discharge lines higher than the check valves and pouring liquid into

the unit through the suction inlet. When priming at high suction lifts or with long

suction lines operate the pump at maximum cycle rate.

3. Low performance

A. Capacity is reduced as the discharge pressure increases, as indicated on the

performance curve. Performance capability varies with available inlet air supply.

Check air pressure at the pump inlet when the pump is operating to make certain

that adequate air supply is maintained.

B. Check vacuum at the pump suction. Capacity is reduced as vacuum increases.

Reduced flow rate due to starved suction will be evident when cycle rate can be

varied without change in capacity. This condition will be more prevalent when

pumping viscous liquids. When pumping thick, heavy materials the suction line

must be kept as large in diameter and as short as possible, to keep suction loss

minimal.

C. Low flow rate and slow cycling rate indicate restricted flow through the discharge

line. Low flow rate and fast cycling rate indicate restriction in the suction line or air

leakage into suction.

D. Unstable cycling indicates improper check valve seating on one chamber. This

condition is confirmed when unstable cycling repeats consistently on alternate

exhausts. Cycling that is not consistently unstable may indicate partial exhaust

restriction due to freezing and thawing of exhaust air. Use of an air dryer should

solve this problem.

For additional information, see the Warren Rupp Troubleshooting Guide.

WARRANTY

This pump is warranted for a period of five years against defective material and

workmanship. Failure to comply with the recommendations stated in this manual

voids all factory warranty.

IMPORTANT

This pump is pressurized internally with

air pressure during operation. Always

make certain that all bolting is in good

condition and that all of the correct

bolting is reinstalled during assembly.

CAUTION

In the event of diaphragm rupture,

pumped material may enter the air end

of the pump, and be discharged into the

atmosphere. If pumping a product which

is hazardous or toxic, the air exhaust

must be piped to an appropriate area for

safe disposition.

CAUTION

Before maintenance or repair, shut off

the compressed air line, bleed the

pressure, and disconnect the air line

from the pump. The discharge line may

be pressurized and must be bled of its

pressure. When used for toxic or

aggressive fluids, the pump should

always be flushed clean prior to

disassembly.

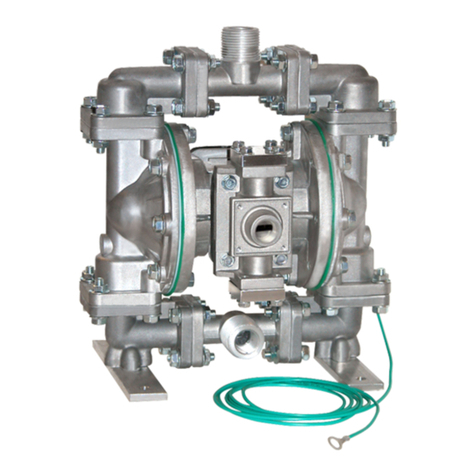

WARNING

Take action to prevent static sparking.

Fire or explosion can result, especially

when handling flammable liquids. The

pump, piping, valves, containers or

other miscellaneous equipment must

be grounded. (See page 5)

WARNING

The weight of the air supply line and of

the filter must be supported by some

means other than the air valve cap.

Failure to provide support may result in

damage to the pump.

RECOMMENDED WARREN

RUPP ACCESSORIES TO

MAXIMIZE PUMP

PERFORMANCE:

• Tranquilizer®Surge Suppressor.

For nearly pulse-free flow.

• Warren Rupp Filter/Regulator. For

modular installation and service

convenience.

• Warren Rupp Speed Control. For

manual or programmable process

control. Manual adjustment or

4-20mA reception.

For more detailed information on

these accessories, contact your local

Warren Rupp Factory-Authorized

Distributor, or Warren Rupp

corporate headquarters.