S&S Northern Merlin 2000X User manual

Installation & Operation Manual Merlin 2000X

Rev: 1 1

Merlin 2000X

Installation & Operation Manual

Please read this manual carefully and retain for future use.

The Merlin 2000X is a gas proving and gas detection controller with ventilation interlocking and current

monitoring.

Information contained within this manual should be referenced for typical installation and operation only.

For specific requirements that may deviate from the information in this guide –contact your supplier.

Installation & Operation Manual Merlin 2000X

Rev: 1 2

Contents

IMPORTANT WARNING STATEMENTS ....................................................3

INSTALLATION..........................................................................................4

Planning ............................................................................................................................... 4

Mounting.............................................................................................................................. 4

Board Connections Diagram............................................................................................. 5

Board Connections Overview ........................................................................................... 6

Access Configuration Settings ......................................................................................... 8

Configuration Settings Explained ..................................................................................... 8

Factory Set Condition ........................................................................................................ 9

Fan Calibration.................................................................................................................... 9

Fan Dropout Threshold Values ....................................................................................... 10

Specification......................................................................................................................11

OPERATION.............................................................................................12

First Power Up ..................................................................................................................12

LED Indication Status....................................................................................................... 12

Utility Touch Buttons / LED Indication Status ...............................................................13

System Diagnostics..........................................................................................................14

General Maintenance.......................................................................................................14

Installation Details.............................................................................................................16

Installation & Operation Manual Merlin 2000X

Rev: 1 3

IMPORTANT WARNING STATEMENTS

Please take the time to thoroughly read this user’s guide which should be retained for future reference.

It is recommended that this device be commissioned upon installation.

Do not apply lighter gas or other aerosols to external gas detectors or monitors –this can cause extreme damage to

the gas sensing elements.

High concentrations of alcohol found in many products may damage, deteriorate or affect the gas sensing elements

of the detectors –Avoid exposure near your devices.

Never ignore your devices when in alarm. Actuation of your alarm indicates the presence of an error or issue that

requires immediate attention.

This device requires a continual supply of electrical power –it will not work without power.

This device should not be used to substitute proper installation, use and/or maintenance of fuel burning appliances

including appropriate ventilation and exhaust systems.

Your product should reach you in perfect condition, if you suspect it is damaged, contact your supplier.

Manufacturer’s Warranty

Warranty coverage:

The manufacturer warrants to the original consumer purchaser, that this product will be free of defects in material

and workmanship for a period of three (3) years from date of purchase. The manufacturer’s liability hereunder is

limited to replacement of the product with repaired product at the discretion of the manufacture. This warranty is

void if the product has been damaged by accident, unreasonable use, neglect, tampering or other causes not arising

from defects in material or workmanship. This warranty extends to the original consumer purchaser of the product

only.

Warranty disclaimers:

Any implied warranties arising out of this sale, including but not limited to the implied warranties of description,

merchantability and intended operational purpose, are limited in duration to the above warranty period. In no event

shall the manufacturer be liable for loss of use of this product or for any indirect, special, incidental or consequential

damages, or costs, or expenses incurred by the consumer or any other user of this product, whether due to a breach

of contract, negligence, strict liability in tort or otherwise. The manufacturer shall have no liability for any personal

injury, property damage or any special, incidental, contingent or consequential damage of any kind resulting from gas

leakage, fire or explosion. This warranty does not affect your statutory rights.

Warranty Performance:

During the above warranty period, your product will be replaced with a comparable product if the defective product

is returned together with proof of purchase date. The replacement product will be in warranty for the remainder of the

original warranty period or for six months –whichever is the greatest.

Information on waste disposal for consumers of electrical & electronic equipment.

When this product has reached the end of its life it must be treated as Waste Electrical & Electronics Equipment (WEEE).

Any WEEE marked products must not be mixed with general household waste, but kept separate for the treatment, recovery and

recycling of the materials used. Please contact your supplier or local authority for details of recycling schemes in your area.

Installation & Operation Manual Merlin 2000X

Rev: 1 4

INSTALLATION

Planning

This panel can be used to carry out gas proving testing on pipe work to check if there is a gas

appliance left open or potential gas leak. The Merlin 2000X is designed to give the user full control

over incoming gas supply with the lockable main key-switch and touch sensors. The panel can monitor

gas levels in the air by connecting carbon dioxide, natural gas, carbon monoxide and LPG sensors.

This model features a digital settings and diagnostic screen.

Selectable panel features include;

Gas proving fill and prove time upon start up;

Two optional pressure levels for failure of the proving test.

Dual fan current monitoring from 0.1 to 18A;

Automatic timeout;

Connections to remote emergency shut off;

Selectable utility emergency shut off;

Fire Panel connection configuration;

Building Management System integration;

Fan calibration and current monitoring including diagnostics.

Please refer to your detector manual for important information regarding coverage, location and

positioning including areas and conditions to avoid!

Mounting

Unpack all the parts!

Placing the panel at eye level allows for optimum monitoring of LED Indicators.

1. Carefully remove the front cover from the unit by

unscrewing the four bolts located at each corner.

To do this –use the socket wrench provided.

2. Remove the power board from enclosure.

3. Mark the four screw holes located on the back of the

enclosure to the wall. Ensure the wall surface is flat to

prevent base distortion.

4. After executing the mounting and the connections –replace the front cover and insert the security

caps over the four bolts.

Be careful when creating access for cables –Damage to boards will void any warranty!

Any damage attempting to remove the circuit board parts may void any warranty!

Installation & Operation Manual Merlin 2000X

Rev: 1 5

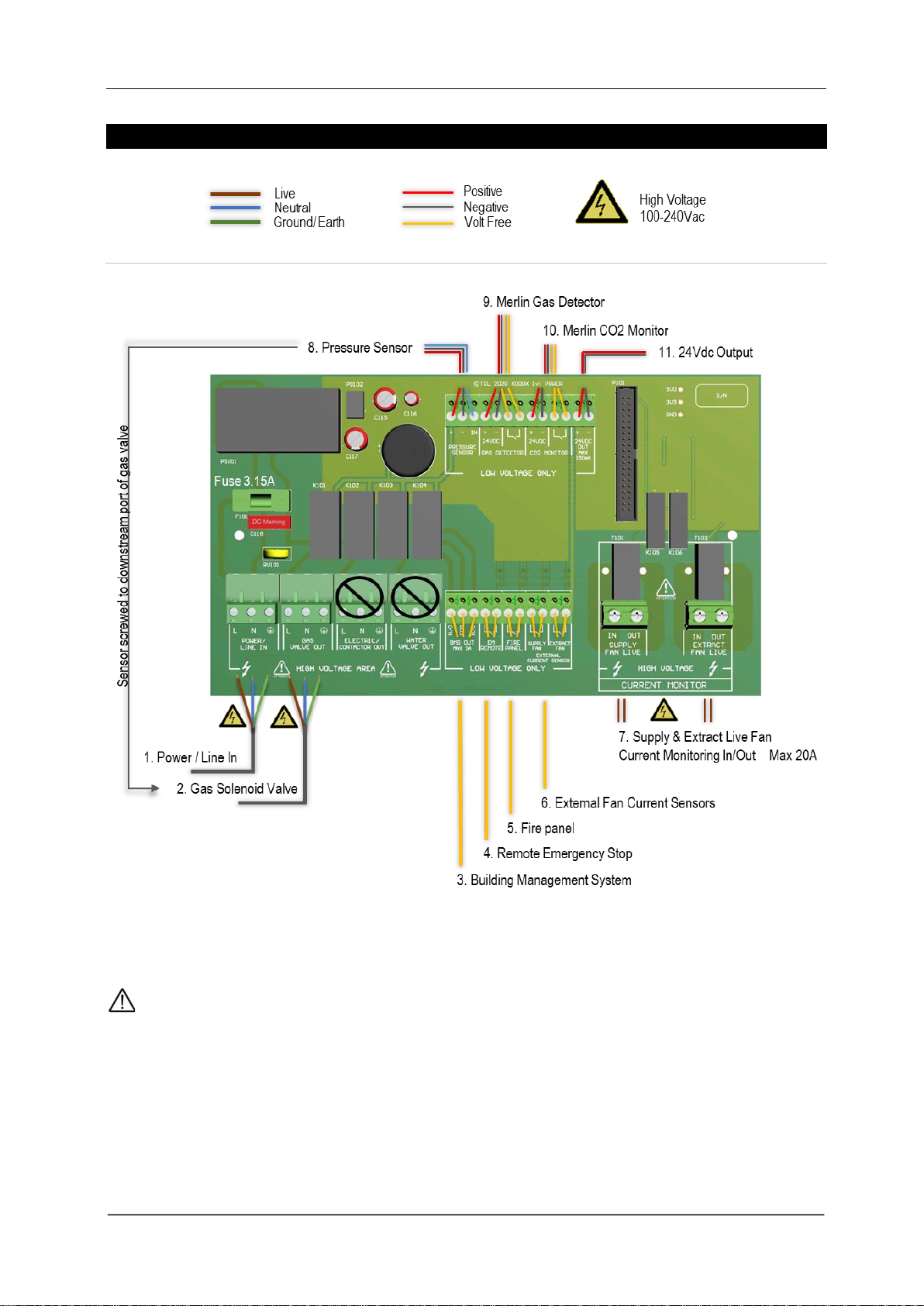

Board Connections Diagram

WARNING!

To avoid electrical shock you must always isolate the mains supply before opening the panel!

Take care when making connections to high voltage connectors!

Avoid running mains wiring across the circuit board!

Any damage attempting to remove the circuit board may void any warranty!

Separate different circuits from each other by means of routing, clamping or barrier!

To avoid electrical interference, avoid installation near fan speed controllers!

Installation & Operation Manual Merlin 2000X

Rev: 1 6

Board Connections Overview

1. POWER / LINE IN.

100-240Vac electrical power should be supplied to the [POWER / LINE IN] terminal and fused at 3A.

On connecting the mains supply to the panel the power LED indicator will light up –this is located

on the front cover (red dot of logo).

2. GAS VALVE OUT.

100-240Vac electrical power output is supplied from the [GAS VALVE OUT] terminal using a 3 core

cable can be connected to a gas solenoid valve and isolate gas supply on alarm status. Pressure

sensors should be screwed to the downstream port of the solenoid valve.

Refer to your valve manual for more information.

3. BMS OUTPUT.

Connections are available on the board for Building Management Systems. This is a relay that

changes state in alarm or when the gas is on/off. It can be used in conjunction with the 24Vdc

output and other external relays that affect other devices and controls such as purge fans and

audible alarms etc.

See section: SETTINGS- for BMS options.

4. EM REMOTE.

Open/Close circuit connections for external devices is marked as [EM STOP] and can shut off utility

supply when activated.

This is fitted with a factory link to represent a closed circuit.

5. FIRE PANEL

The terminal for fire alarms is detailed on the circuit board as [FIRE PANEL] and can shut off utility

supply when activated.

This is fitted with a factory link to represent a closed circuit.

6. EXTERNAL FAN CURRENT SENSORS

These terminals are used to receive an input signal from external air pressure switches or external

current monitors. These are linked out as a factory setting to represent a closed circuit.

If only one fan is being used, the terminal not in use should be left closed!

Installation & Operation Manual Merlin 2000X

Rev: 1 7

7. CURRENT MONITOR

There are two terminals on the circuit board, one detailed as

pictured [SUPPLY FAN LIVE] the other detailed [EXTRACT

FAN LIVE].

The live feed from the fan controller should be connected to

either the supply or extract side depending on which fan/s are

being monitored.

Each will monitor its own independent fan.

From a fan controller the live feed should be taken to the [IN]

terminal and the [OUT] terminal should wire to the fan motor controller.

Max 18A.

8. PRESSURE SENSOR.

The sensor will monitor the gas supply pressure and if pressure

drops below 12mbar –the gas valve will close as this could mean a gas leak is

present.

Operating pressure: 0-100mbar.

Screw the sensor into the downstream port of the gas solenoid valve.

9. GAS DETECTOR.

24Vdc power can be supplied to a Merlin gas detector to shut off the system in the event of

dangerous gas concentrations being detected. If no detector is being used leave the factory fitted

link in.

Refer to your gas detector manual for further information.

10. CO2 MONITOR.

24Vdc power can be supplied to a Merlin CO2monitor to shut off the system if high concentrations

of CO2is detected.

Refer to your CO2monitor manual for further information.

11. 24V DC.

This is a permanent power output for external auxiliary devices when there is power supplied to the

panel and can be used to create a relay switch with the BMS relay output.

Max output: 150mA

Installation & Operation Manual Merlin 2000X

Rev: 1 8

Access Configuration Settings

On the front fascia circuit board you’ll find a [SETTINGS] dip-switch –when switched ON (before turning

the panel on) via the key switch, the screen will display the settings menu –you can now configure your

panel. To view, change and save settings, you must provide mains power.

There are four buttons, press to navigate through the settings and

configure the system. To select functions and change options;

navigate functions by pressing [UP] or [DOWN];

press [OK] to select options;

press [UP] or [DOWN] to change option setting;

press [OK]to save option or [BACK] to return to function.

When changes have been made –turn the SETTINGS switch OFF and restart the key switch!

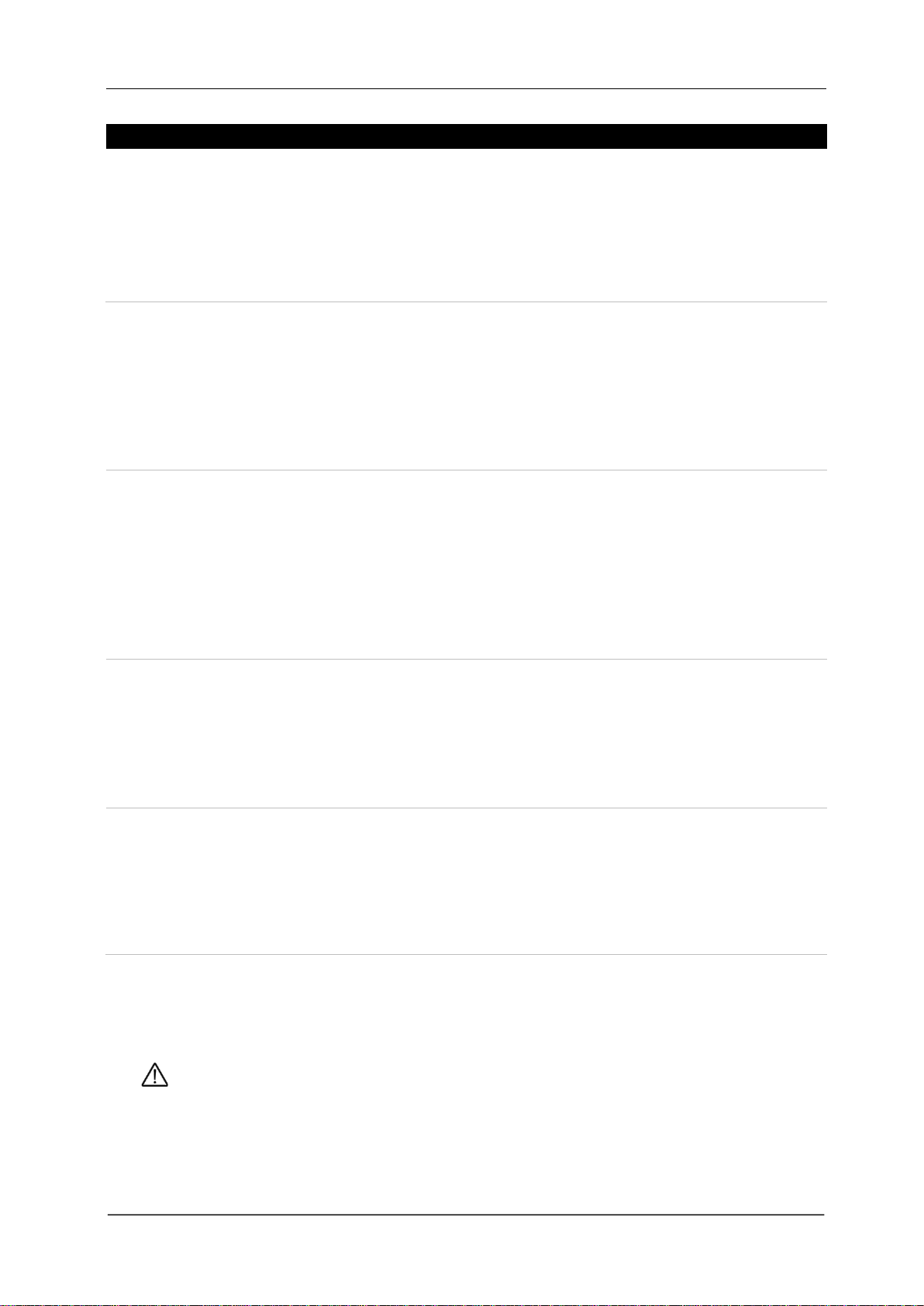

Configuration Settings Explained

Page 1 Page 2 Page 3 Page 4 Page 5

FUNCTION

OPTION

Explanation

PROVING

- OFF

- ON

Enable/disable gas pressure proving upon system start up/reset to check the

gas line for leaks. See section: LED status.

FILL TIME (S)

- 5

- 10

Time (seconds) the gas valve is open to fill gas line for proving.

Proving must be switched on.

PROVE TIME (S)

- 30

- 50

Time (seconds) the panel tests the gas line for leaks.

Proving must be switched ON.

TOLERANCE (%)

- 10

- 15

Percentage drop in pressure for failure of the gas proving test.

(10% or <12mbar). Proving must be switched ON.

TIMEOUT (H)

- OFF

- 1-12

Time (hours) that the system will automatically shut down all utility supply.

Select OFF or from 1 to 12 hours.

BMS SEL.

- GAS ON

- ERROR

- KEY SW.

GAS ON signals the BMS when gas is supplied or not only.

ERROR signals the BMS on an error condition i.e. gas levels, etc.

KEY SW. BMS follow by key switch ON/OFF status only.

GEW BUTTONS (S)

- 10

- ON

Gas (G) touch buttons on the panel will be active for 10 seconds to enable

supply when key switch is turned ON or be set permanently ON and active

anytime. See section: First Power Up.

FACTORY RESET

- NO

- YES

Return to factory set condition.

See Section: Factory Set Condition

FANS CM.

- OFF

- ON

- SUP ONLY

- EXT ONLY

Combination of fan current monitoring.

Select either current monitoring OFF, current monitoring for both Supply and

Extract (ON) or either Supply or Extract only.

Installation & Operation Manual Merlin 2000X

Rev: 1 9

FANS CALIB.

-

- OK

If fans are calibrated, this will be set as ‘OK’.

See section: Fan Calibration to calibrate fans.

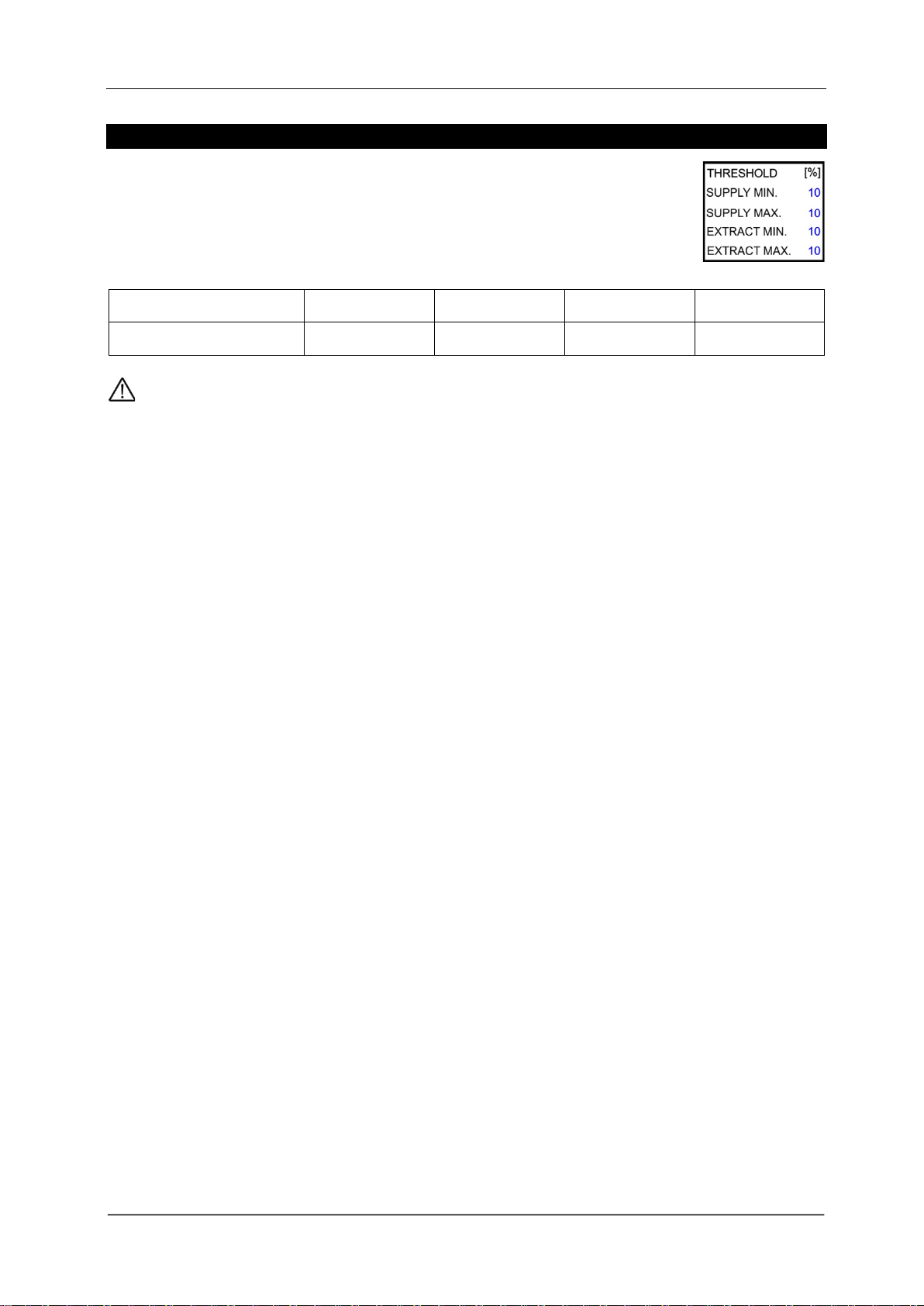

FANS THRESHOLD

%

- 10

- 20

- 30

- 40

Dropout threshold for Min and Max current values of both supply and

extraction fans. It is possible to select between a 10% to a 40% dropout

threshold if required. You will need to recalibrate fans after changing dropout

thresholds. See section: Fan Dropout Threshold Values.

FANS CALIB. RESET

- NO

- YES

Remove and reset any saved fan calibration settings.

See Section: Factory Set Condition

Factory Set Condition

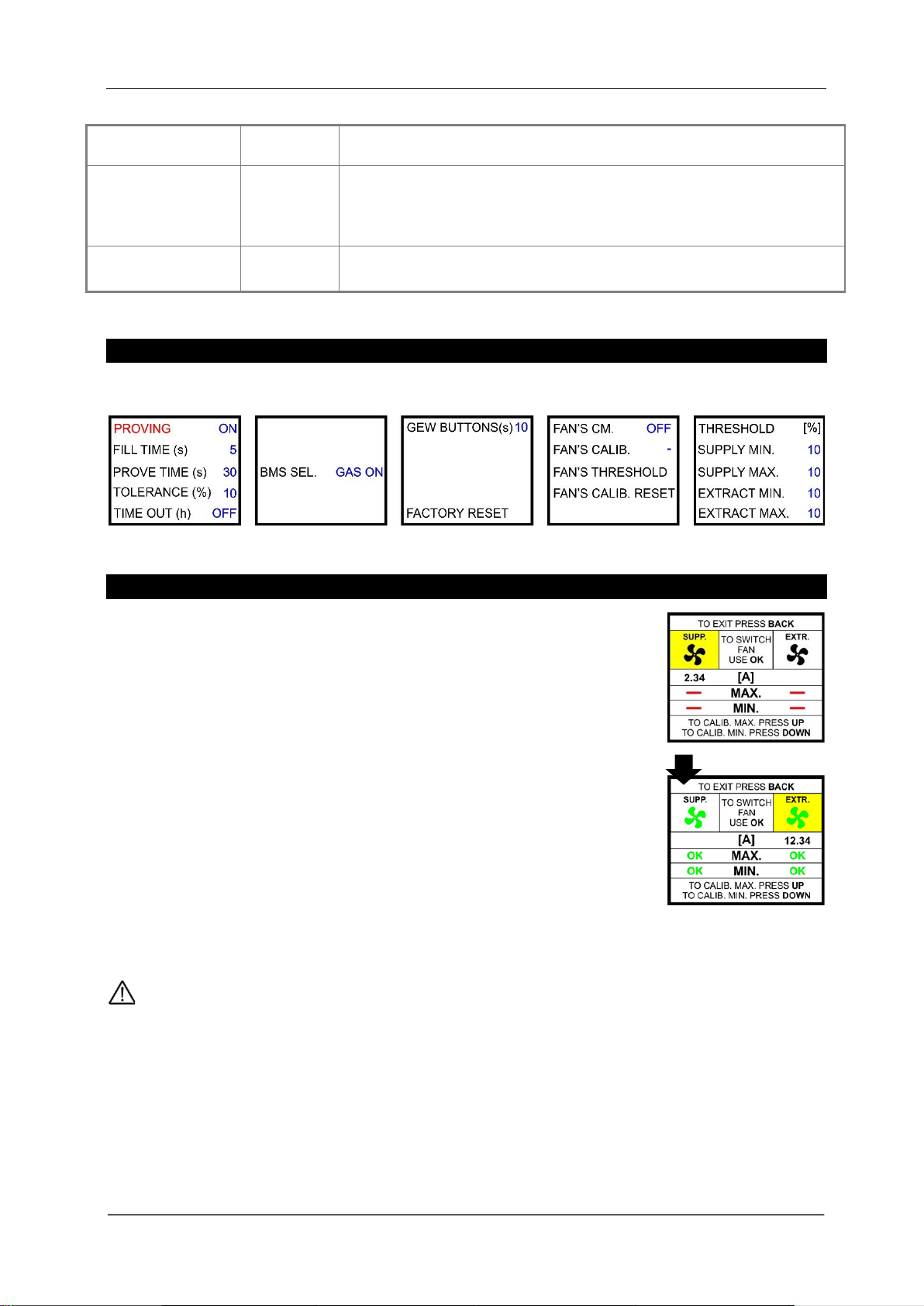

Fan Calibration

Select [FANS CALIB.] In the settings menu.

1. Press [OK] to switch to supply (SUPP.) or extraction (EXTR.) fan.

Fan selection highlighted yellow.

2. Wait for the current value to appear (A).

3. Press [UP] button to calibrate highest fan current.

If successful, ‘OK’appears on screen (MAX.)

4. Press [DOWN] button to calibrate low fan current.

If successful, ‘OK’appears on screen (MIN.)

Fan icons switch from black to green.

If calibration is unsuccessful then alter fan dropout thresholds in the settings menu and repeat.

Installation & Operation Manual Merlin 2000X

Rev: 1 10

Fan Dropout Threshold Values

When [FANS THRESHOLD]is selected in the settings menu, the user can adjust the

minimum and maximum current values by 10, 20, 30 or 40%.

Fans with a current between 0.1 to 0.2A we recommend a dropout threshold ≥30%.

Threshold value (%)

10

20

30

40

Running current (Max.)

18A

16.5A

15A

14A

If calibration is successful it is possible to change the fan threshold without recalibration.

Fans new threshold automatically recalculates min and max current fan fault values.

The 2000X can display fan currents (amp) and gas pressure (mbar) in the diagnostic screen.

See section: Diagnostics

Installation & Operation Manual Merlin 2000X

Rev: 1 11

Specification

Model:

2000X

Display

1.8” Screen TFT (located inside)

Power Input Voltage

100-240Vac

Gas Valve Output Voltage

100-240Vac

BMS Max Output

3A

Single phase AC current monitor calibration range

0.1 –18 Amps

Single phase AC current monitor display

0 - 22Amps

Power Consumption

4.7 W (Panel), 20W max (fully loaded)

Internal Fuse

3.15A

Operating Temperature

0 –50°C (32 –122°F) 30-85%RH Non-Condensing

Audible Alarm Buzzer dB

65 dB (300mm distance in quiet conditions)

Pressure Sensor Operating Pressure

0 - 100mbar

O/All Dimensions (H x W x D) mm

180 x 255 x 77mm

Installation & Operation Manual Merlin 2000X

Rev: 1 12

OPERATION

First Power Up

1. Supply mains power, the red LED on the front of the panel will illuminate (dot on logo).

2. Turn fans on.

3. Turn the key switch to on position.

4. **Gas service LED will flash for 10 seconds.

5. **Press Gas service button to turn gas valve on.

6. **The panel will check the integrity of the gas line for leaks.

**Factory set condition.

Gas service can be turned on or off within 10 seconds of the key switch being on and panel powered up.

After 10 seconds, gas utility button will be disabled. The user must turn the key off and back on to adjust

services. (This can be changed to permanently available in settings).

LED Indication Status

Testing

This LED will illuminate for approximately 30 seconds when the panel is checking the integrity of the

gas installation upon start up. Do not operate appliances while this is on.

Test Fail

Under normal working conditions this LED is off. If the panel detects an issue with the gas supply

upon start-up this LED will illuminate and the gas valve will remain closed.

Pressure Low

Under normal working conditions this LED is off. The LED will illuminate when pressure of the gas

supply drops below 12mbar for 10 secs or more and the gas valve will close.

Timeout

This LED will illuminate if automatic shut-down has occurred following defined timer.

EM Stop

If an emergency shut off button (either remote or on the panel) is pressed, the LED will illuminate

and the gas supply will be isolated. Any shut-off buttons must be reset before restarting the system.

Gas Detected

If an external Merlin detector connected detects dangerous gas levels this LED will illuminate and

the gas supply is isolated.

Installation & Operation Manual Merlin 2000X

Rev: 1 13

CO2High

If the concentration of CO2 in the air is at alarm level (relevant detector required), the LED will

illuminate and the gas supply is isolated.

Fire Alarm

If the fire panel connected detects a fire the LED will illuminate and the gas is isolated.

Supply Fan - Under normal working conditions this LED is on.

If a supply fan external current sensor fault is detected, the LED will flash.

After ~20 seconds: the LED will remain on and Fan Fault LED will illuminate.

If a supply fan internal current monitor fault is detected, the LED will flash.

After ~20 seconds the LED will flash twice a second and Fan Fault LED will illuminate.

Extract Fan - Under normal working conditions this LED is on.

If an extract fan external current sensor fault is detected, the LED will flash.

After ~20 seconds: the LED will remain on and Fan Fault LED will illuminate.

If an extract fan internal current monitor fault is detected, the LED will flash.

After ~20 seconds the LED will flash twice a second and Fan Fault LED will illuminate.

Fan Fault

If a fan fault occurs for longer than 20 seconds, the LED will illuminate RED.

Utility Touch Buttons / LED Indication Status

Gas - When the key switch is turned on, the system will check the installation for gas leaks.

**If gas proving is successful, the Testing LED will turn off and this Gas LED will remain ON.

**Factory Set Condition.

Gas LED will flash when checking external current sensors, current monitor or gas proving.

Installation & Operation Manual Merlin 2000X

Rev: 1 14

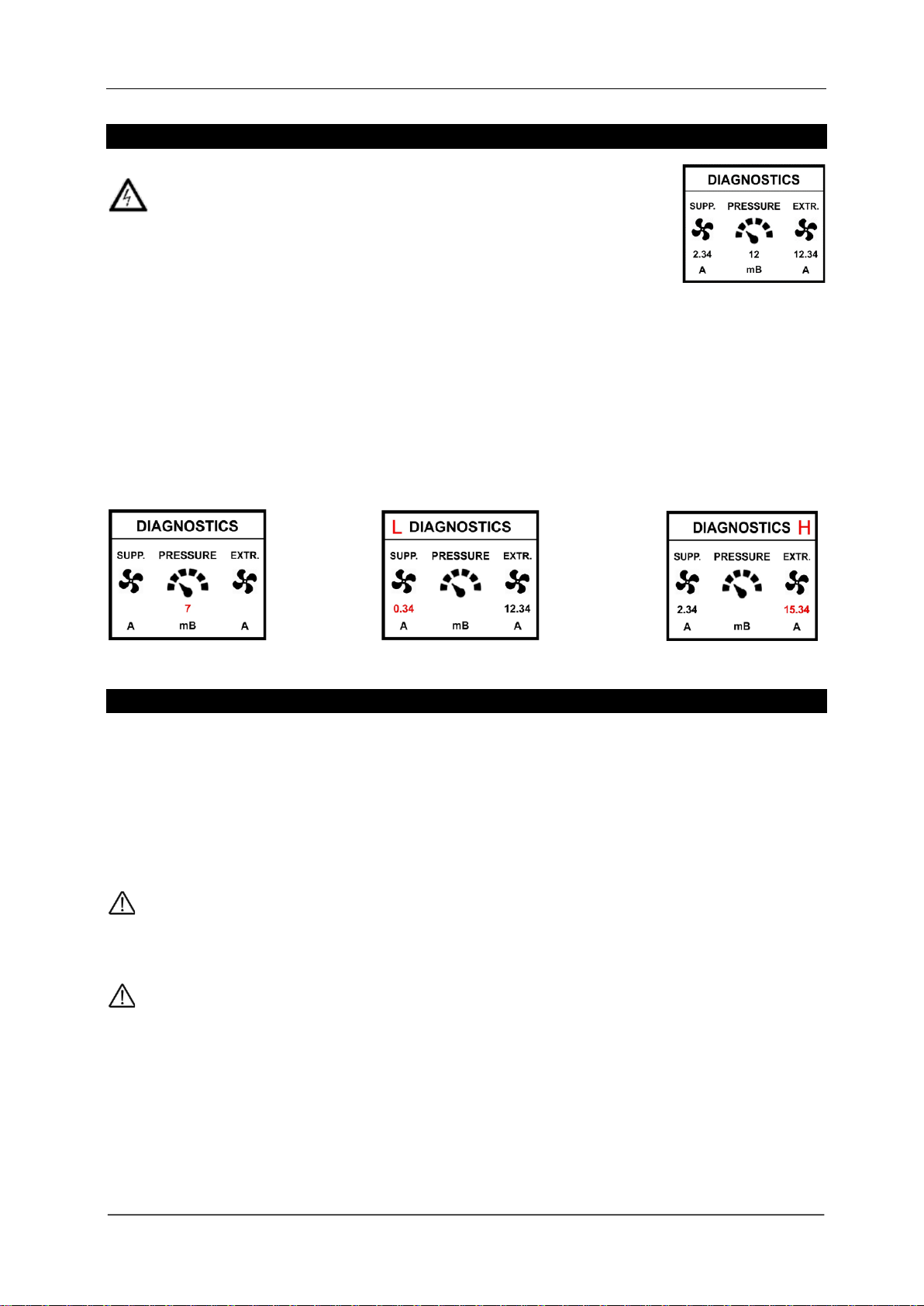

System Diagnostics

WARNING! Contact with mains electrical power can be fatal!

The panel can display fan current (Amps) and gas pressure (mbar).

To view these diagnostics, carefully remove the front fascia of the panel, to activate screen diagnostics,

press either the [OK], [UP] or [DOWN] button. The diagnostic screen is available during; proving status;

normal operation; fan fault and pressure low status. The screen will automatically enter sleep mode after

10 minutes of inactivity or when the [BACK] button pressed.

L= fan current is less than the minimum calibrated value.

H= fan current is greater than the maximum calibrated value.

Gas pressure is low Current higher than calibrated value.

Current less than calibrated value.

General Maintenance

Keep your system in good working order follow these basic principles;

Remove any dust/debris from the outer enclosure regularly using a slightly damp cloth.

Never use detergents or solvents to clean your gas detection devices.

Never spray air fresheners, hair spray, paint or other aerosols near devices.

Never paint devices. Paint will seal vents and interfere with the device.

It is recommended that detectors are inspected and serviced at least annually from the date of

installation for optimum performance and protection due to sensitivity drifts!

High concentrations of alcohol found in many products may damage, deteriorate or affect the gas sensor

such as; wine; deodorants; stain removers; thinners etc. Other gases and substances to avoid are;

Corrosives (i.e. chlorine & hydrogen chloride); Alkali metals; Basic or acidic compounds; Silicones;

Tetraethyl lead; Halogens and halogenated compounds!

Installation & Operation Manual Merlin 2000X

Rev: 1 15

ENGINEERING NOTES - Blank

Installation & Operation Manual Merlin 2000X

Rev: 1 16

Installation Details

Please pass this manual to the system owner or system user.

Date of Installation:

Installation Location:

Organisation:

Stamp/ Signature of the installer:

S&S Northern Head Office

Tel: +44(0) 1257 470 983

Fax: +44(0) 1257 471 937

www.snsnorthern.com

info@snsnorthern.com

South East Division

Tel: +44(0) 1702 291 725

Fax: +44(0) 1702 299 148

S&S Northern is the owner of this document and reserves all rights of modification without prior notice.

Table of contents

Other S&S Northern Control Panel manuals

Popular Control Panel manuals by other brands

Plum

Plum eSTER x80 Installation and operating manual

TUYA

TUYA S9E manual

Genie

Genie Series II installation instructions

Menvier Security

Menvier Security TS700 Installation & programming instructions

Schenck process

Schenck process Intecont Tersus Beltweigher instruction manual

Aritech

Aritech 1X-E4 Series installation manual