Section 40 00-02-0994

2016-06-28 - v -

Table of Contents

Introduction.................................................................................................................................7

Mounting the Unit .........................................................................................................7

Wiring...........................................................................................................................9

Murphy PowerCore®20 (MPC-20) .............................................................................11

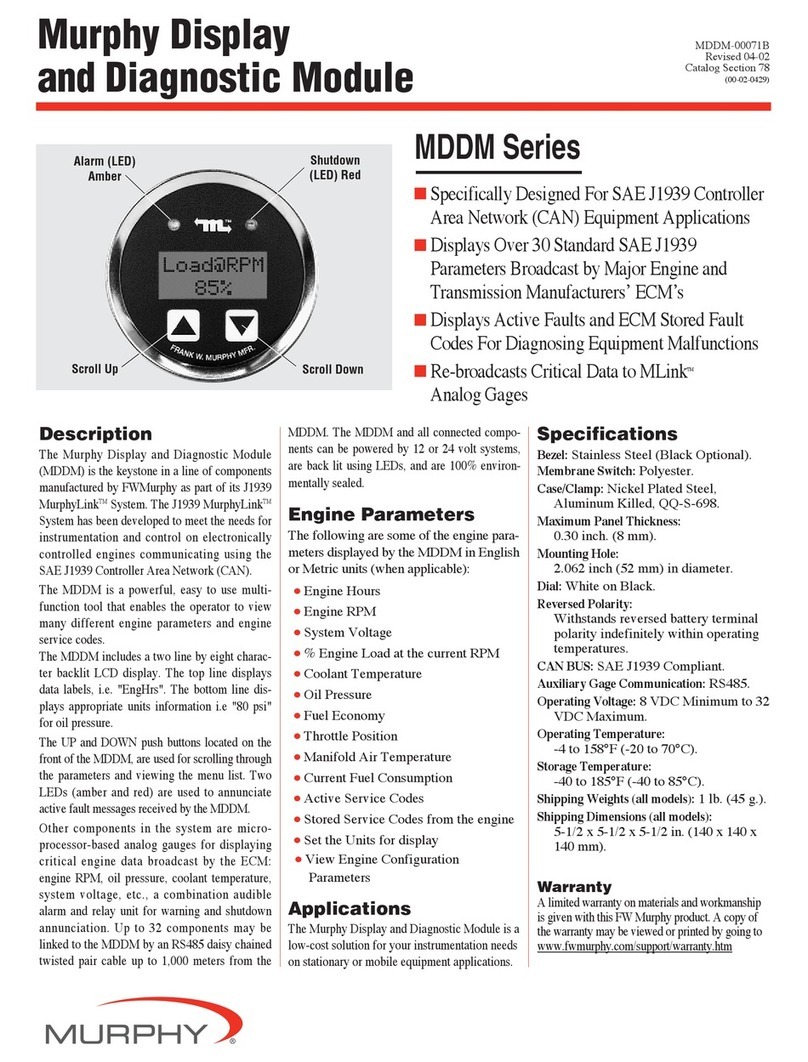

User Interface.............................................................................................................13

Accessing the Menu ................................................................................................................14

Main Menu .................................................................................................................................15

Start/Stop Settings...................................................................................................................19

Single Contact Start/Stop...........................................................................................19

Two Contact Maintained Start/Stop (commonly known as Floats) .............................19

Two Contact Momentary Start/Stop ...........................................................................19

(Level, Pressure, Temperature or Flow) Transducer Start/Stop.................................19

Local Start Key Start/Stop..........................................................................................19

Quick-Start Setup Guide .........................................................................................................20

Adjusting the Contrast................................................................................................20

Setting MPC-20 to Auto Start on a Single Contact Input............................................20

Setting MPC-20 to Auto Start on Local Key ...............................................................20

Setting MPC-20 to Auto Start on Float Inputs ............................................................20

Setting MPC-20 to Auto Start on Pressure.................................................................21

Setting MPC-20 to Auto Start on Level ......................................................................21

Setting MPC-20 to Auto Start on Flow .......................................................................21

Setting MPC-20 to Auto Start on Clock ......................................................................21

Setting MPC-20 to Auto Start on Temperature...........................................................21

Setting MPC-20 to Stop the Engine from Utilizing the Countdown Timer...................22

Screen Examples .....................................................................................................................22

MPC-20 Screens In Order..........................................................................................23

Warning and Shut-Down Icons...................................................................................27

Icon Troubleshooting..................................................................................................27

Menu Glossary .........................................................................................................................28