S&S Northern Merlin CT1750 User manual

Merlin CT1750 User Guide

Rev: 07 05-19 1

Gas Safety Products

Merlin CT1750

Gas Proving & Interlock System

User Guide

Please read this guide carefully and retain for future use.

Merlin CT1750 User Guide

Rev: 07 05-19 2

Table of contents

1General Information..........................................................................................3

1.1 Panel Mounting.............................................................................................................3

2Circuit Board Terminals .....................................................................................4

2.1 POWER ...........................................................................................................................4

2.2 GAS VALVE ....................................................................................................................4

2.3 FAN 1 & 2 PD SW (Supply & Extract Fan PD Switches)..............................................4

2.4 BMS OUT .........................................................................................................................4

2.5 PRESSURE SENSOR .........................................................................................................4

2.6 FIRE PANEL .....................................................................................................................5

2.7 CO SENSOR....................................................................................................................5

2.8 CO2SENSOR ..................................................................................................................5

2.9 TEMP SENSOR.................................................................................................................5

2.10 EM REMOTE....................................................................................................................5

2.11 12vDC.............................................................................................................................6

2.12 0-10vDC Output ............................................................................................................6

3Installation & Operation ....................................................................................6

3.1System ON and OFF .....................................................................................................6

3.2 Using the Emergency Shut Off ....................................................................................6

3.3 BMS integration .............................................................................................................7

3.4 Fire alarm integration ...................................................................................................7

3.5 Gas Fill & Prove Time.....................................................................................................7

3.6 Gas Proving Enable/ Disable.......................................................................................7

3.7 Setting the minimum & maximum speed of fans......................................................8

3.8 Adjusting the fan speed during operation ................................................................8

4Panel LED Status.................................................................................................9

5CT1750 Wiring Spec.........................................................................................11

6Manufacturer’s Warranty ................................................................................12

Merlin CT1750 User Guide

Rev: 07 05-19 3

1General Information

The Merlin CT1750 is a ventilation interlock panel with gas pressure proving and features

analogue output signals to regulate the speed on the fans.

The system comprises of a control panel and a gas pressure sensor. The Merlin CT1750 can

receive connections from remote air pressure differential switches or external current monitors,

remote emergency shut-off buttons, gas detectors and a CO2 monitor. It can also be

integrated with a BMS and fire alarm.

It is recommended that the user reads this guide before using the system. Please do NOT

attempt to operate the unit until the contents of this document have been read and are

thoroughly understood.

1.1 Panel Mounting

The control panel is designed for surface mounting using 4 mounting screws. Removing the

cover on the panel gives access to the circuit board.

The PCB should be removed before drilling entry holes into the case.

Important Warning Statements

Never ignore your device when in alarm.

This device requires a continual supply of electrical power –it will not work without power.

This device should not be used to substitute proper installation, use and/or maintenance of fuel burning

appliances including appropriate ventilation and exhaust systems.

Your product should reach you in perfect condition, if you suspect it is damaged, contact your supplier.

Information on waste disposal for consumers of electrical & electronic equipment. (EEE)

When this product has reached the end of its life it must be treated as Waste Electrical & Electronics Equipment

(WEEE). Any WEEE marked products must not be mixed with general household waste, but kept separate for

the treatment, recovery and recycling of the materials used.

Please contact your supplier or local authority for details of recycling schemes in your area.

Merlin CT1750 User Guide

Rev: 07 05-19 4

2Circuit Board Terminals

2.1 POWER

A 100-240VAC electrical supply should be supplied to the panel.

This should be externally fused at 3A.

2.2 GAS VALVE

A 100-240VAC output connection for a gas solenoid valve.

2.3 FAN 1 & 2 PD SW (Supply & Extract Fan PD Switches)

These terminals are used to receive an input signal from external air

pressure switches or external current monitors.

These are linked out as a factory setting.

Wiring to the air PD switches & current monitors should be made using

two-core volt free connections. If only one fan is being used the

terminals not in use should be left linked out.

2.4 BMS OUT

Terminal connections are available on the circuit board for Building

Management systems.

Detailed on the circuit board as [BMS OUT - N/C, COM and N/O]

(Normally Closed / Common / Normally Open).

These are volt free connections and can be used to enable fan inverters.

This is a relay that changes state in alarm or when the gas is on/off and can be

used in conjunction with the 12vDC output and other external relays that affect other devices

and controls such as purge fans and audible alarms etc.

2.5 PRESSURE SENSOR

This terminal is connected to the gas pressure transducer as shown which is then screwed into

the downstream port on the gas solenoid valve.

Min Operating Pressure = 12mbar

Max Operating Pressure = 100mbar

ENSURE THIS IS SCREWED TO THE DOWNSTREAM PORT OF THE GAS SOLENOID VALVE.

Merlin CT1750 User Guide

Rev: 07 05-19 5

2.6 FIRE PANEL

The terminal for fire alarms is detailed on the circuit board as [FIRE PANEL].

These connections are linked out as a factory setting.

Fire alarms should be volt free and wired to the Merlin CT1750 using two-

core cable.

2.7 CO SENSOR

These can be wired to a Merlin carbon monoxide sensor as shown.

If no detector is being used leave the link in between the [ ]. Other

detector types are available.

2.8 CO2SENSOR

This terminal can be wired to CO2 monitor to shut off the system in the event

of CO2 being at alarm level.

If no CO2 monitor is supplied leave the terminal link in.

2.9 TEMP SENSOR

These connections are linked out as a factory setting.

Temperature sensors should be volt free and wired to the Merlin CT1750

using two-core cable.

2.10 EM REMOTE

The terminal for remote emergency shut-off buttons is detailed as [EM

REMOTE].

These connections are linked out as a factory setting.

Remote emergency shut-off buttons should be volt free and wired to the

Merlin CT1750 using two-core cable.

Merlin CT1750 User Guide

Rev: 07 05-19 6

2.11 12vDC

This is a permanent 12v DC output when there is power at the panel and

can be used to create a relay switch with the BMS relay output.

This is normally used to power a PM2 current monitor. (Supplied separately)

Contact your supplier for more information.

2.12 0-10vDC Output

0-10vDC outputs are detailed as [0-10vDC Fan 1] & [0-10vDC Fan 2].

These connections are used to regulate external fan speed

controllers which can accept this control signal.

3Installation & Operation

3.1 System ON and OFF

Turn off all open gas appliances.

Turn the Fans On.

Turn the key switch to on position.

To turn the system off, turn the key switch to off position.

3.2 Using the Emergency Shut Off

The Emergency shut off button is located on the front of the panel. There is also a facility for

remote shut off buttons to be wired in series.

The Emergency shut off button(s) will cut off the gas supply when

activated.

To reinstate the system, the Emergency shut off button(s) will need to be

reset and the panel restarted.

There are2 dip-switches located on the inside facia of the CT1750

labelled Fan 1 & Fan 2 [EM SEL].

They are both set in the OFF position which instructs the system to shut down the fans and gas

supply on activation of the Emergency shut off button(s).

Merlin CT1750 User Guide

Rev: 07 05-19 7

3.3 BMS integration

The Merlin CT1750 can be integrated with a BMS to make or break a circuit on gas on/gas off,

(valve open or valve closed). This will tell the BMS whether or not power is being sent to the

solenoid.

There is a dip-switch located on the inside facia of the Merlin CT1750

labelled [BMS SEL]. This is factory set to OFF which signals the BMS on gas

on/gas off.

When switched ON, the CT1750 will only signal the BMS on a fault, i.e. fan

fault, CO2 high level detected, gas detected, EM Stop pressed, etc.

3.4 Fire alarm integration

The Merlin CT1750 can be integrated with a fire alarm to close the gas supply automatically in

the event of a fire.

There are 2 dip-switches located on the inside facia of the CT1750

labelled Fan 1 & Fan 2 [FP SEL].

They are factory set to OFF which instructs the system to shut down the

fan/s and gas supply on detection of the fire.

On installation, these switches can be switched ON. This will instruct the

system to leave the relevant fan on and only shut off the gas supply

when fire detected.

3.5 Gas Fill & Prove Time

Gas fill and prove times are adjustable.

There are dip-switches located on the inside detailed [FILL TIME] and [PROVE TIME].

They are factory set in the OFF position.

Fill and prove time can be changed by turning the relevant dip switch to on position.

Fill time: OFF –5 seconds, ON –10 seconds

Prove time: OFF –30 seconds, ON –50 seconds

Once the settings have been changed please remove power from the

fuse spur for 10 seconds.

Fill time is the amount of time the gas valve is open to fill the gas line.

Prove time is the amount of time the system tests the gas line for any

leaks.

3.6 Gas Proving Enable/ Disable

The Merlin CT1750 has a built in gas pressure proving feature.

There is a switch located on the inside fascia detailed [PROVE DIS]. See switch picture above.

This is factory set to OFF (proving enabled). If you do not require gas pressure proving this can

be disabled by turning switch to ON.

Merlin CT1750 User Guide

Rev: 07 05-19 8

3.7 Setting the minimum & maximum speed of fans

The minimum and maximum fans speed can be customised Using the [MIN] and [MAX] buttons

located inside the facia of the CT1750. Upon pressing either the MIN or MAX speed button, the

speed display will flash with the current minimum or maximum fan speed.

Press the relevant button to cycle through the speeds until

the desired setting is displayed. After 5 seconds of no

activity, the flashing display will turn solid saving the setting

and showing current fan speed.

The default setting is 1 for minimum speed and 9 for

maximum speed.

The minimum, maximum and current speed values are saved in non-volatile memory and will

be retained even after power loss.

3.8 Adjusting the fan speed during operation

Located on the panel are up and down arrows increasing

or decreasing the fan speed. This range will be limited by

the maximum and minimum speeds setup as in section 3.7

Merlin CT1750 User Guide

Rev: 07 05-19 9

4Panel LED Status

When the system is connected to the mains supply, the red LED of the S&S logo located in the

bottom right corner of the panel will illuminate. When no power is present, this LED will not light.

Gas On

When the fans are operational and the key switch is turned on, the Merlin CT1750 will check the

installation for gas leaks. If gas proving is successful, the gas valve will open and the green ‘Gas

On’ LED will illuminate.

GREEN = Gas On

OFF = Gas Off

Testing

This LED will illuminate GREEN for approximately 30 seconds when the panel is checking the

integrity of the gas installation upon start up. GREEN = proving the gas line, do NOT operate any

appliances during the testing period.

Test Fail

Under normal working conditions this LED is off. When the panel detects a gas leak on start-up,

the LED will illuminate AMBER. Gas valve will remain closed.

OFF = OK

AMBER = gas proving test failed

Low Pressure

Under normal working conditions the LED is off. The LED will illuminate AMBER when the

incoming gas pressure drops below 12mBar for 10 seconds. The gas valve will close.

OFF = OK

AMBER = gas supply pressure low.

Fire Panel

If a fire alarm panel has been triggered, the LED will illuminate Amber and the gas will be

turned off. The Fire alarm panel must be re-set before restarting the system.

Off = OK

AMBER = Fire alarm panel pressed.

Merlin CT1750 User Guide

Rev: 07 05-19 10

CO Sensor

Under normal working conditions this LED is off. If the external Merlin detector connected

detects gas this will show RED. The Gas valve will close and the panel will send a signal to the

fan controller to increase the fan speed.

CO2Sensor

Under normal working conditions this LED is off. If the concentration of CO2 in the air is at

alarm level (relevant detector required) the LED will show RED. The Gas valve will close and

the panel will send a signal to the fan controller to increase the fan speed.

OFF = OK

RED = the concentration of CO2 is at alarm level.

Temp Sensor

Under normal working conditions this LED is off. If the temperature sensor senses temperatures

higher than the permitted set point this will send a fault signal pack to our panel and in turn

send the panel into alarm and the LED will show AMBER. The Gas valve will close and the panel

will send a signal to the fan controller to increase the fan speed.

Fan 1

Under normal working the LED will illuminate GREEN. If a fan fault is detected on fan 1, the LED

will be flashing. If the LED flashes for more than 20 seconds –the gas will shut off.

GREEN = OK

FLASHING = fan is not running.

Fan 2

Under normal working the LED will illuminate GREEN. If a fan fault is detected on fan 2, the LED

will be flashing. If the LED flashes for more than 20 seconds –the gas will shut off.

GREEN = OK

FLASHING = fan is not running

Fan Fault

Under normal working conditions this LED is off. If a fan fault is present for more than 20 seconds,

the LED will illuminate RED.

OFF = OK

RED = the gas supply has been shut off due to a ventilation fault.

EM Stop

If an emergency shut off button (either remote or on the panel) is pressed, the LED will

illuminate AMBER and the gas will be turned off. The EM Stop button must be re-set before

restarting the system.

OFF = OK

AMBER = EM Stop button pressed

Fan Control LED display

Under normal working conditions the LED display is showing fan speed number from 1 to 9.

The display will not show when fan control is turned off.

E= EM Stop activated

F= Fire detected

-= Fans speed override (when gas or high temperature detected)

Merlin CT1750 User Guide

Rev: 07 05-19 11

5CT1750 Wiring Spec

1. POWER: Mains Electrical Input 100-240VAC.

2. GAS VALVE: Gas Solenoid Valve Power Output, 100-240VAC.

3. FAN 1 PD SW: Fan 1 pressure differential switch or current switch. VOLT FREE INPUT

4. FAN 2 PD SW: Fan 2 pressure differential switch or current switch. VOLT FREE INPUT

5. BMS OUT: output contacts. Normally Open, Common and Normally Closed.

6. PRESSURE SENSOR: Gas pressure transducer input

7. FIRE PANEL (Supplied by others). VOLT FREE INPUT

8. CO SENSOR: power supply (purchased separately).

9. CO2 SENSOR: power supply (purchased separately).

10. TEMP SENSOR: Fusible Links (purchased separately). VOLT FREE INPUT

11. EM REMOTE: Remote emergency stop buttons and Fire Alarm input. VOLT FREE INPUT

12. 12VDC: Permanent output (Normally used to power a PM2 Current Monitor).

13. FAN 1 0-10VDC output.

14. FAN 2 0-10VDC output.

15. EM SEL: Emergency fan selection

16. FP SEL: Fire panel fan selection

17. BMS SEL: Enable / disable

18. Fan 1 & Fan 2 Speed Calibrator buttons.

19. Gas Pressure Proving Enable/Disable, Fill Time & Prove Time selection

Merlin CT1750 User Guide

Rev: 07 05-19 12

6Manufacturer’s Warranty

3 Year Limited Warranty

Warranty coverage: The manufacturer warrants to the original consumer purchaser, that this product will be free of

defects in material and workmanship for a period of three (3) years from date of purchase. The manufacturer’s liability

hereunder is limited to replacement of the product with repaired product at the discretion of the manufacture. This

warranty is void if the product has been damaged by accident, unreasonable use, neglect, tampering or other causes

not arising from defects in material or workmanship. This warranty extends to the original consumer purchaser of the

product only.

Warranty disclaimers: Any implied warranties arising out of this sale, including but not limited to the implied warranties of

description, merchantability and intended operational purpose, are limited in duration to the above warranty period. In

no event shall the manufacturer be liable for loss of use of this product or for any indirect, special, incidental or

consequential damages, or costs, or expenses incurred by the consumer or any other user of this product, whether due

to a breach of contract, negligence, strict liability in tort or otherwise. The manufacturer shall have no liability for any

personal injury, property damage or any special, incidental, contingent or consequential damage of any kind resulting

from gas leakage, fire or explosion. This warranty does not affect your statutory rights.

Warranty Performance: During the above warranty period, your product will be replaced with a comparable product if

the defective product is returned together with proof of purchase date. The replacement product will be in warranty for

the remainder of the original warranty period or for six months –whichever is the greatest.

CONTACT US:

S&S Northern Head Office

Tel: +44(0) 1257 470 983

Fax: +44(0) 1257 471 937

www.snsnorthern.com

info@snsnorthern.com

South East Division

Tel: +44(0) 1702 291 725

Fax: +44(0) 1702 299 148

south@snsnorthern.com

S&S Northern is the owner of this document and reserves all rights of modification without prior notice.

Table of contents

Other S&S Northern Control Panel manuals

Popular Control Panel manuals by other brands

Triad

Triad 8900 SH Series Operation and installation manual

AlphaVision

AlphaVision 16 user manual

Murphy

Murphy Selectronic Annunciator Series 1400 Specifications

D+H

D+H RZN 4304 Instructions for use

Maxim

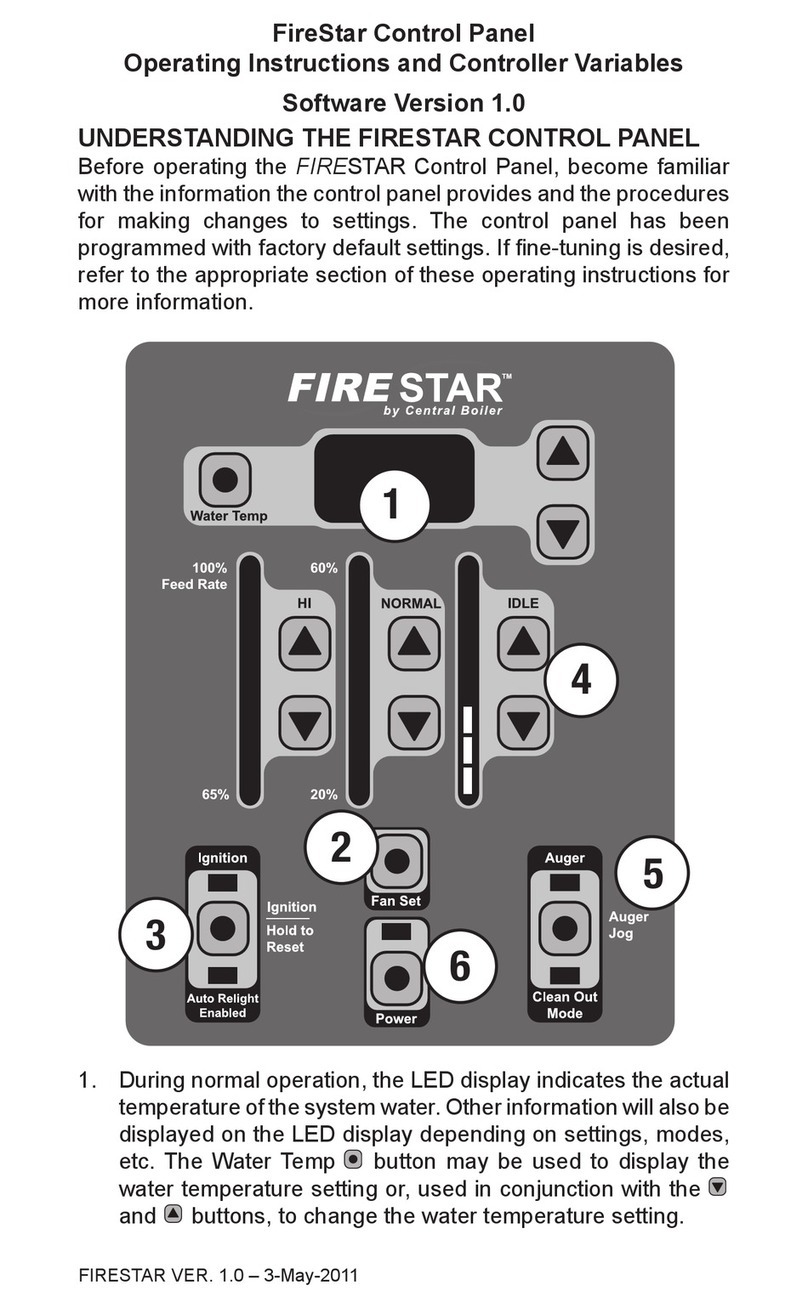

Maxim FireStar operating instructions

Digital Monitoring Products

Digital Monitoring Products XR500 Series Programming guide