Signal name

(abbreviation)Pin number

(CN1A)Function

PMDSA1S3P01

Pulse input

(CW)1

2Inputs the drive pulse for the rotation in the CW direction.

Pulse input

(CCW)3

4Inputs the drive pulse for the rotation in the CCW direction.

Power down input

(PD)5

6

Inputting the PD signal turns off the current that flows through the stepping motor.

Photo coupler input method : Internal photo coupler ON…… PD function enabled

Rotation monitor output

(MON)MON

(collector)7

MON

(collector)8

Indicates ON when the exciting phase is at the origin position.

In the full-step, outputs once for every 6 pulses.

●The CW direction of the rotation of the stepping motor is the clockwise direction when viewing the stepping motor from the output axis side(flange side).

The CCW direction is the counterclockwise direction when viewing the stepping motor from the output axis side

(flange side)

.

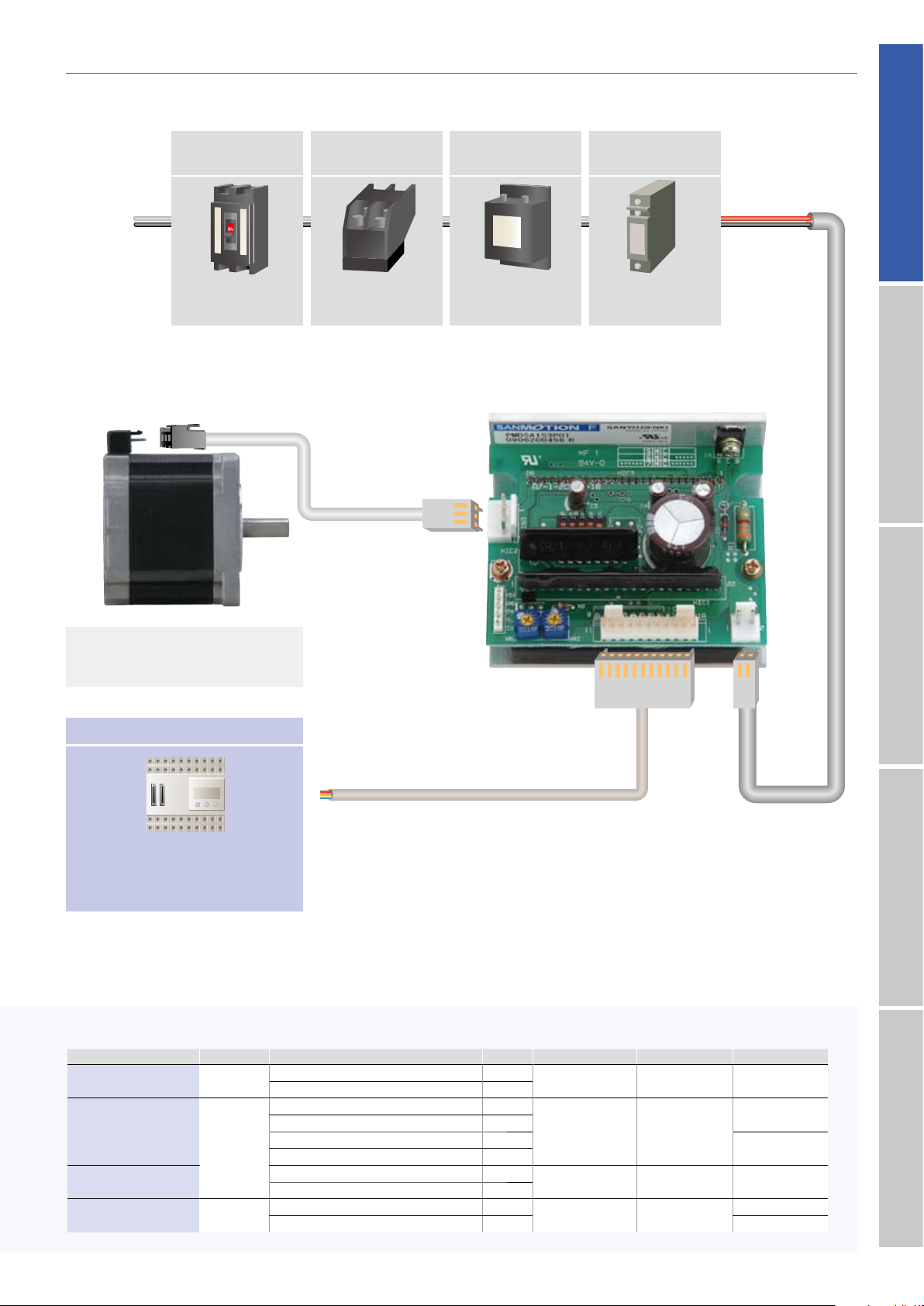

DC input

Each section name of the driver

1DC source connector

(CN2)

………Connect the DC source.

2Stepping motor output connector

(CN3)

………Connect the stepping motor drive line.

3I/O signal connector

(CN1A)

………Connect the I/O signal.

4Function selection DIP switchpack

(SL, F/R, A, B, C)

………Select the function depending on your specification.

Function selection DIP switchpack

Operation, connection, and function

SL Automatic current reduction

ON 100 % of current rating when stopped

OFF

Approx. 50 % of current rating when stopped

・The factory settings are shown in the

figure above.

・Before changing the settings of the

function selection DIP switches, turn off

the source of the PM driver.

Note 1)The temperature increase in the

motor driver can be controlled

by setting SL to OFF

(approx. 50 %

of the rated current)

.

Note 2)

The output torque when SL is OFF

(approx. 50 % of the rated current)

is approx. 50 % of that when SL is

ON

(100 % of the rated current)

.

1SL

(auto current down selection)

Select the auto current down function.

2F/R selection

(Note)

This switch is not used.

Do not set it to OFF.

DIP switch Step angle Number of drive pulses per one period

of phase current

A B C

ON ON

OFF

Basic step angle 1/1

(1.2°

pulse)6

ON OFF Basic step angle 1/2

(0.6°

pulse)12

OFF ON Basic step angle 1/4

(0.3°

pulse)24

OFF OFF Basic step angle 1/8

(0.15°

pulse)48

OFF OFF ON Basic step angle 1/16

(0.075°

pulse)48

・When the DIP switch “C”=“ON”(1/16 division)

, the internal circuit

(stepping motor)

operates at the rising edge and falling edge of the drive pulse. If the duty ratio of the

drive pulse moves out of the adjustment significantly by 50 %, operation becomes

unstable.

3・4・5A, B, C

(step angle setting)

Set the step angle

System configuration

I/O signal function

3

4

1 2 3 4 5