UN Test Data (Model:3LUNA-1-T0636)

1.Test Item: Vib ation (T3) P.5/10

2.Test Purpose: This test simulates vib ation du ing t anspo t.

3.Test Procedure:

Cells and batte ies a e fi mly secu ed to the platfo m of the vib ation machine without disto ting the cells in such a

manne as to faithfully t ansmit the vib ation. The vib ation shall be a sinusoidal wavefo m with a loga ithmic sweep

between 7 Hz and 200 Hz and back to 7 Hz t ave sed in 15 minutes.This cycle shall be epeated 12 times fo a

total of 3 hou s fo each of th ee mutually pe pendicula mounting positions of the cell. One of the di ections of

vib ation must be pe pendicula to the te minal face.

The loga ithmic f equency sweep is as follows: f om 7 Hz a peak accele ation of 1gn is maintained until 18 Hz is

eached. The amplitude is then maintained at 0.8 mm(1.6 mm total excu sion) and thef equency inc eased until a

peak accele ation of 8gn occu s (app oximately 50Hz).A peak accele ation of 8 gn is then maintained until the

f equency is inc eased to 200Hz.

SANYO Internal Procedure:

As above.

4.Test Requirements:

No mass loss(less than 0.1%),no leakage,no venting,no disassembly,no uptu e and no fi e,and the voltage

etention is not less than 90%.

The equi ement elating to voltage is not applicable to test batte ies at fully discha ged states.

.Test Date: 2010/2/2

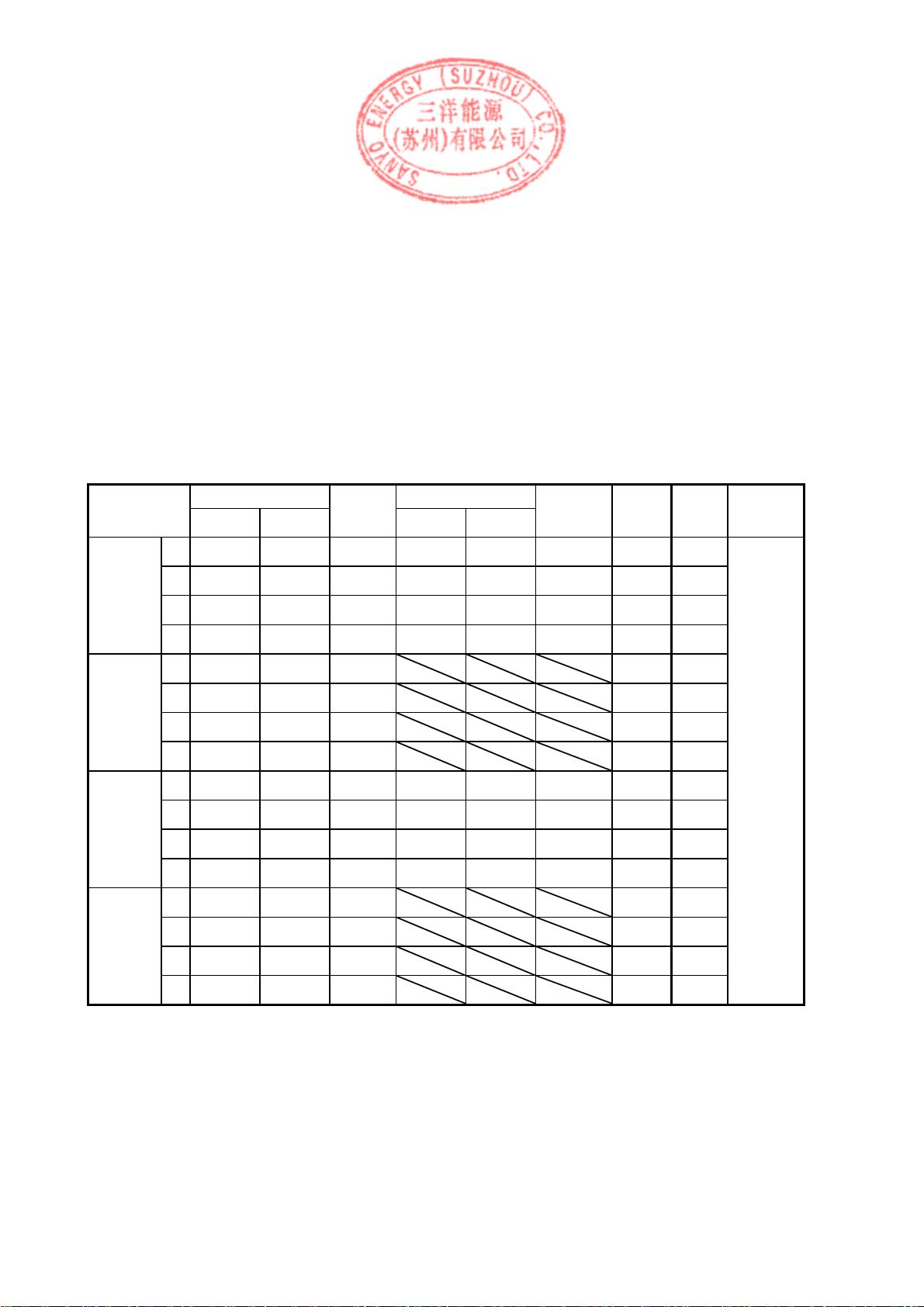

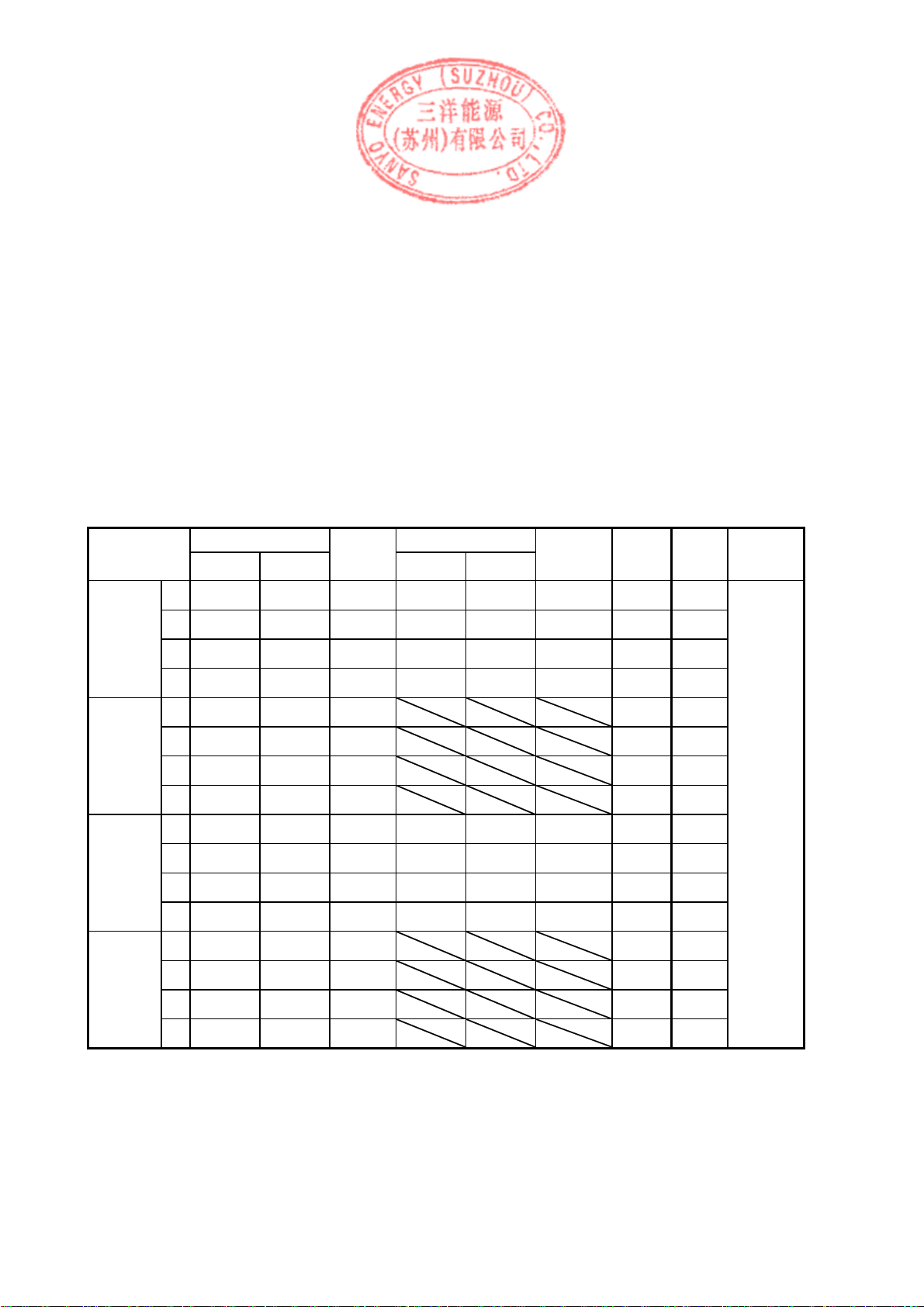

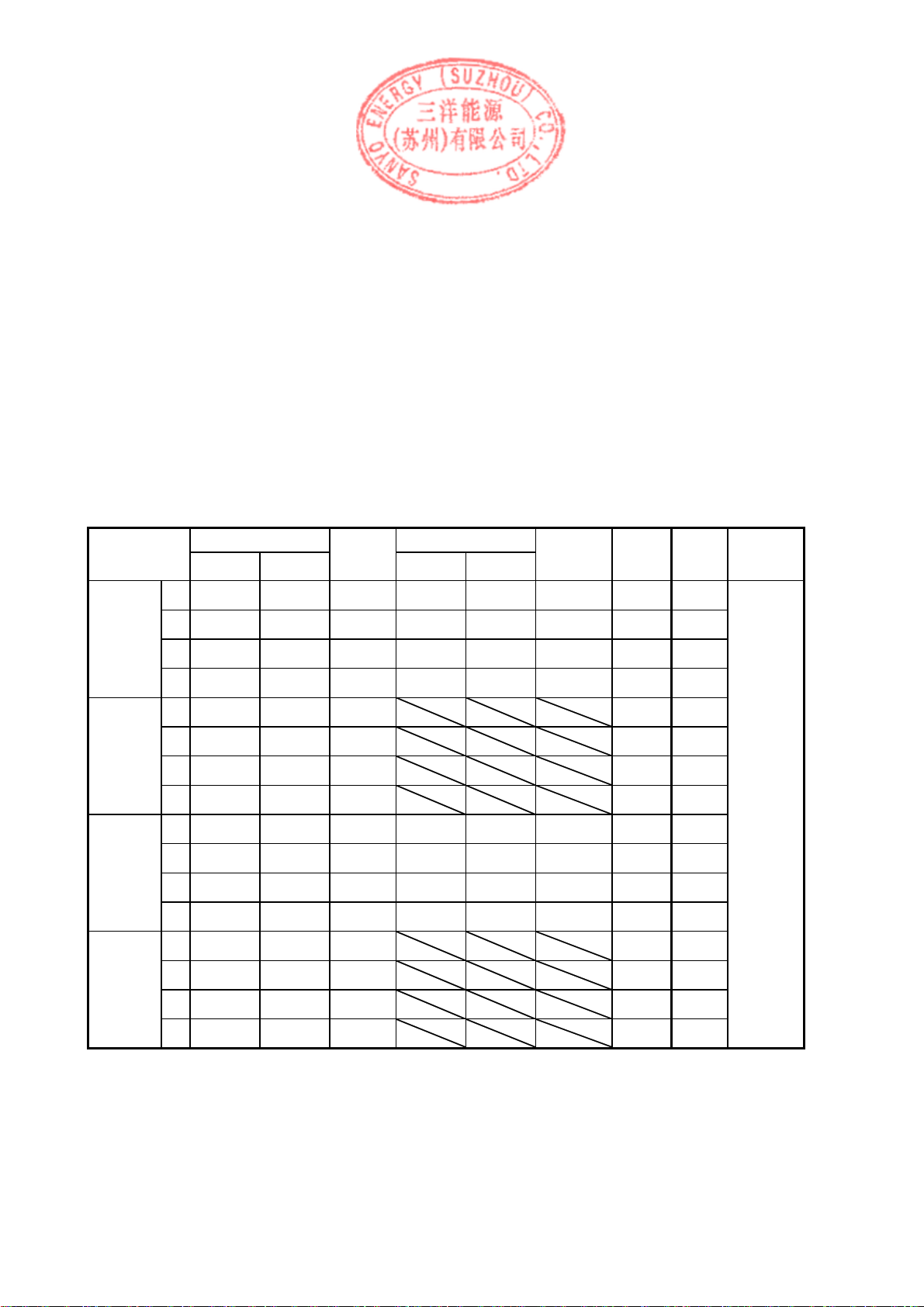

6.Test Data

After test

After test

1 161.95 161.96 0.006 12.62 12.62 100.0 0 PASS

2 161.92 161.95 0.019 12.61 12.60 99.9 0 PASS

3 161.77 161.78 0.006 12.60 12.60 100.0 0 PASS

4 162.25 162.25 0.000 12.62 12.62 100.0 0 PASS

5 161.95 161.95 0.000 0 PASS

6 161.96 161.97 0.006 0 PASS

7 161.94 161.98 0.025 0 PASS

8 161.89 161.91 0.012 0 PASS

9 161.96 161.97 0.006 12.64 12.64 100.0 0 PASS

10 161.76 161.76 0.000 12.66 12.65 99.9 0 PASS

11 161.95 161.95 0.000 12.65 12.65 100.0 0 PASS

12 161.83 161.86 0.019 12.63 12.63 100.0 0 PASS

13 161.96 161.98 0.012 0 PASS

14 162.03 162.04 0.006 0 PASS

15 161.69 161.71 0.012 0 PASS

16 161.91 161.92 0.006 0 PASS

Notes: L-Leakage, V-Venting, D-Disassembly, R-Ruptu e, F-Fi e,

0-No leakage, no venting, no disassembly, no uptu e & no fi e

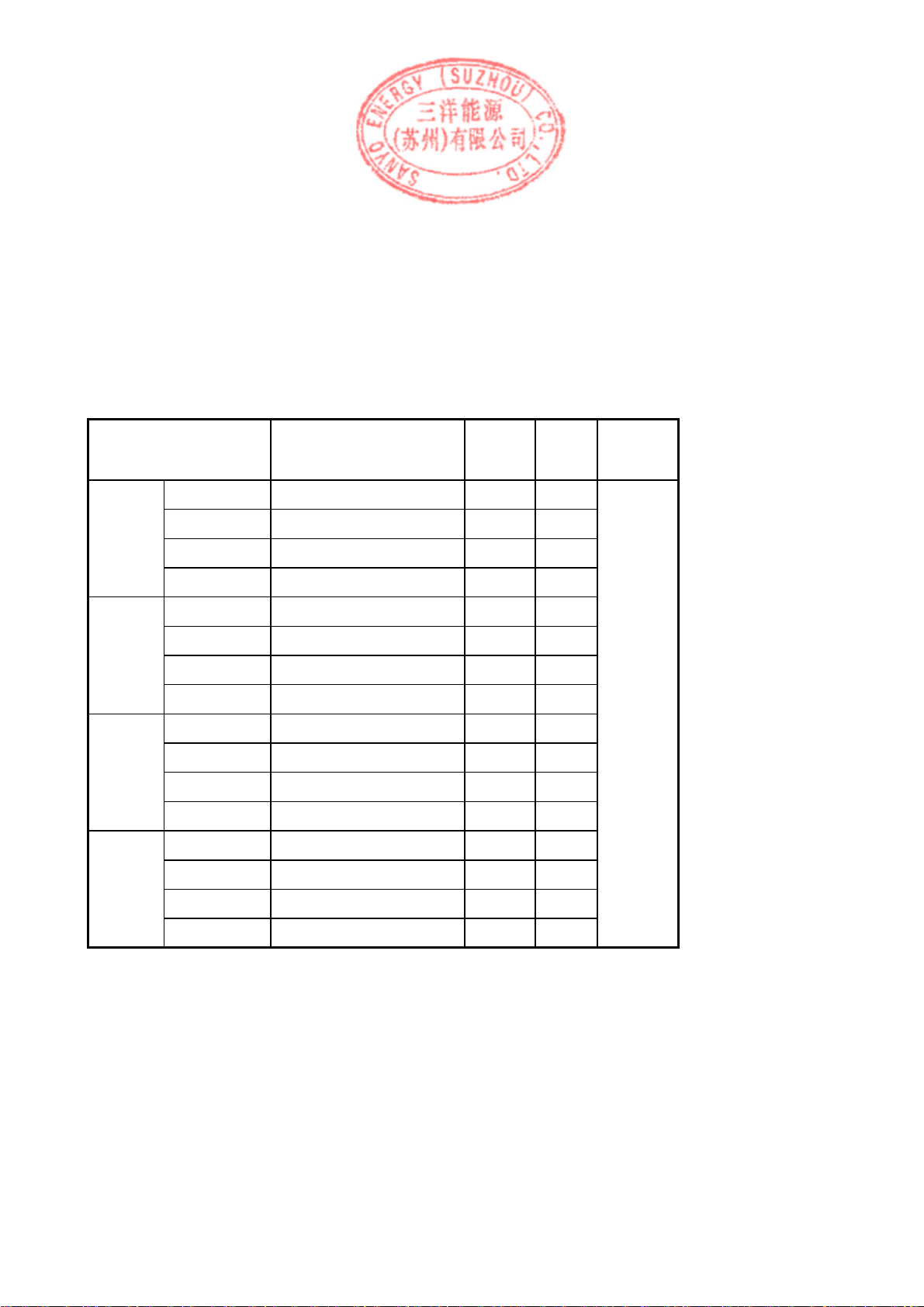

Other

event Result Judgement

At fi st

cycle,in

fully

cha ged

states

PASS

At fi st

cycle,in

fully

discha ged

states

Afte 50

cycles

ending in

fully

cha ged

states

Afte 50

cycles

ending in

fully

discha ged

states

Battery No.

Mass(g) Mass loss

(%)

Voltage(V) Voltage

Retention(

%)(=>90%)