Sanyo M1990FE User manual

Other Sanyo Cassette Player manuals

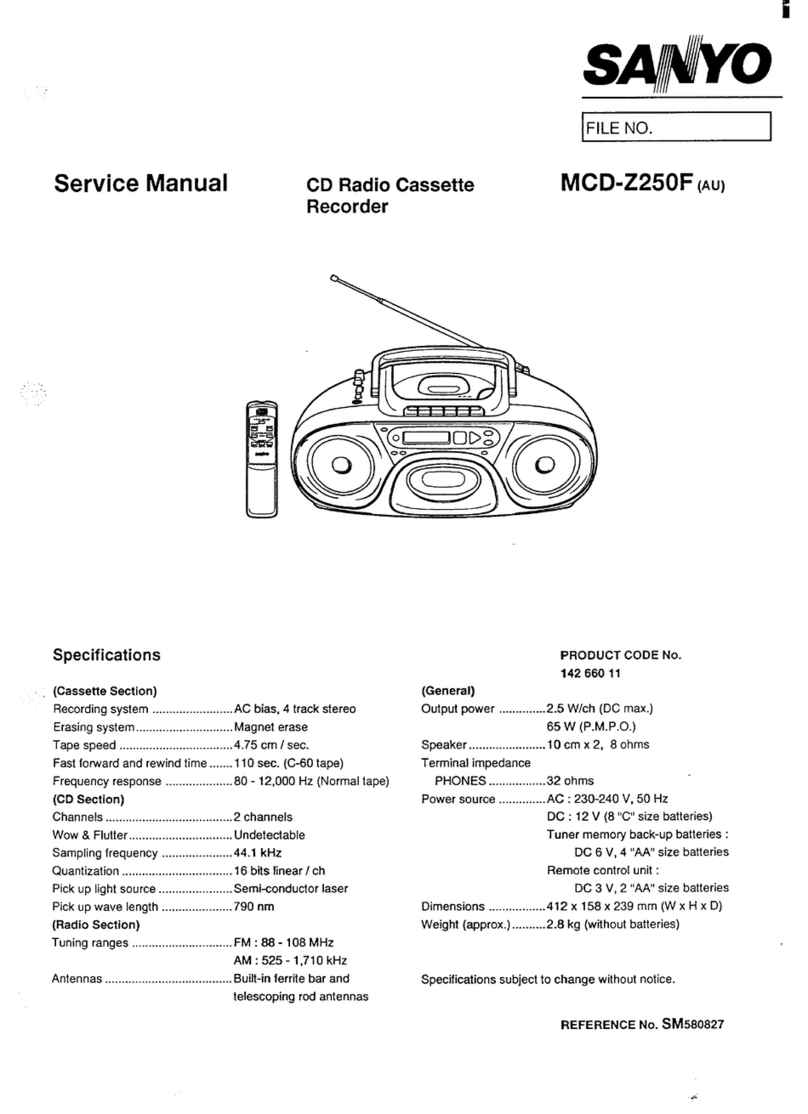

Sanyo

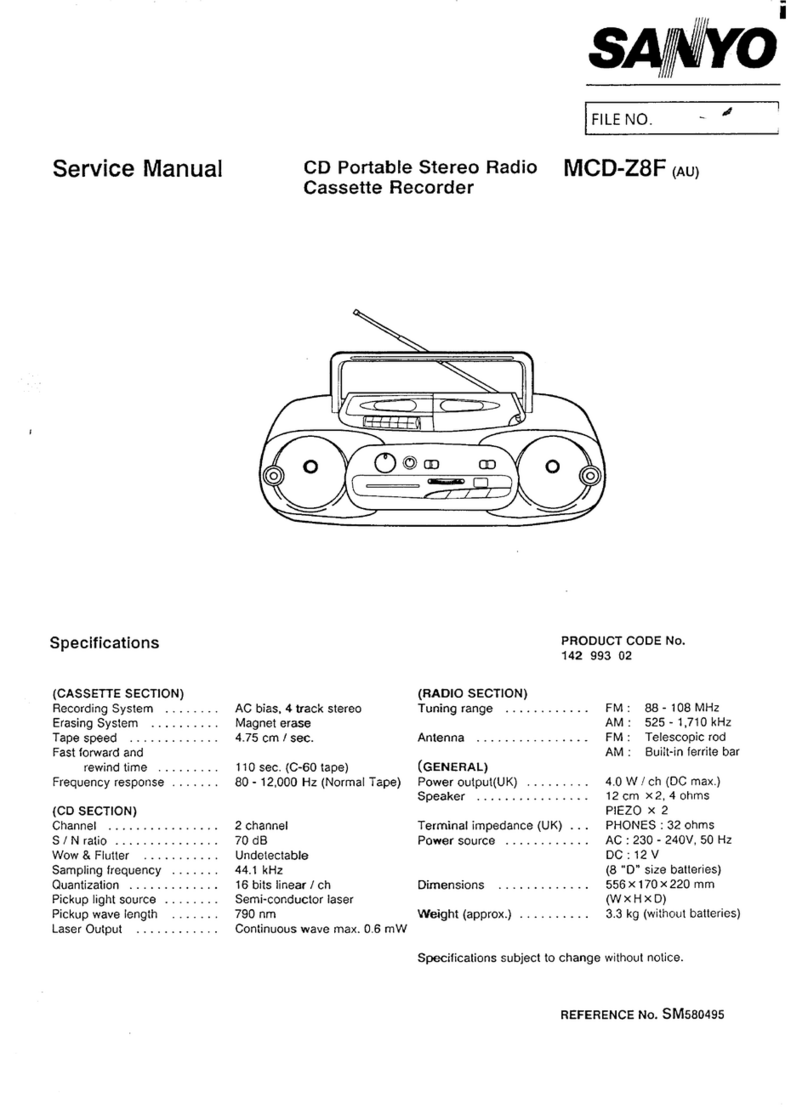

Sanyo MCD-Z8F (AU) User manual

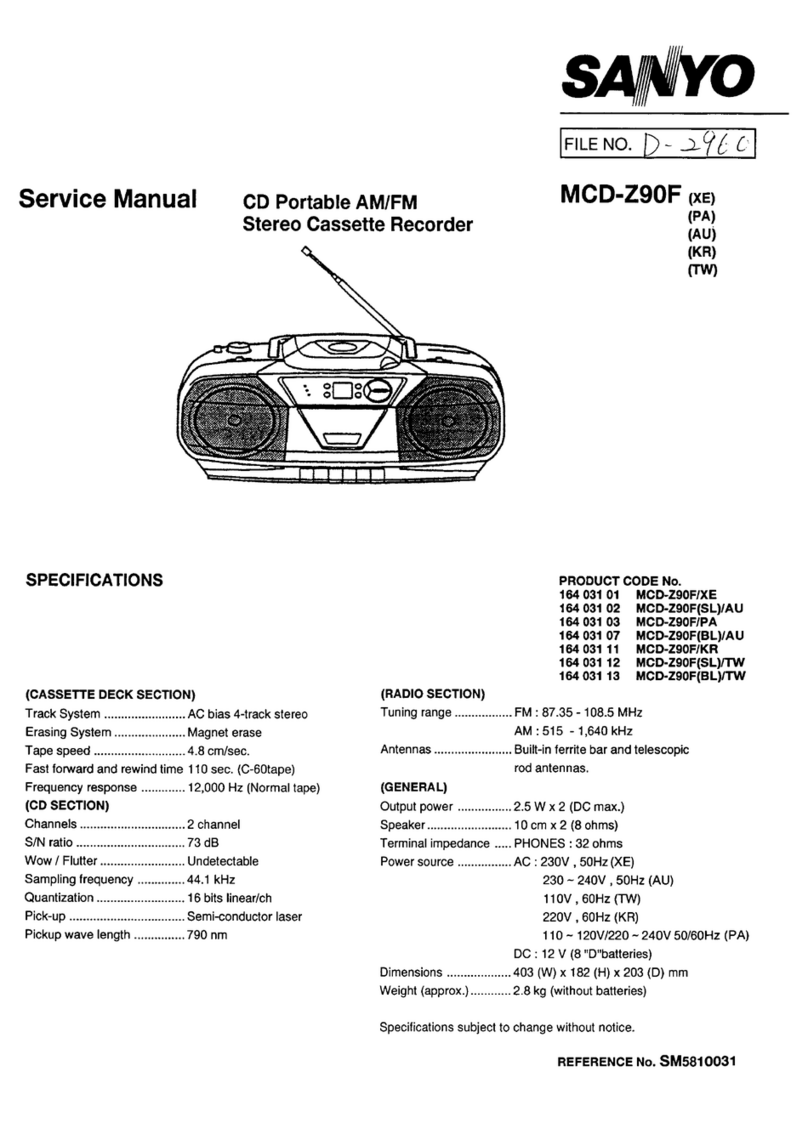

Sanyo

Sanyo M-X920LU User manual

Sanyo

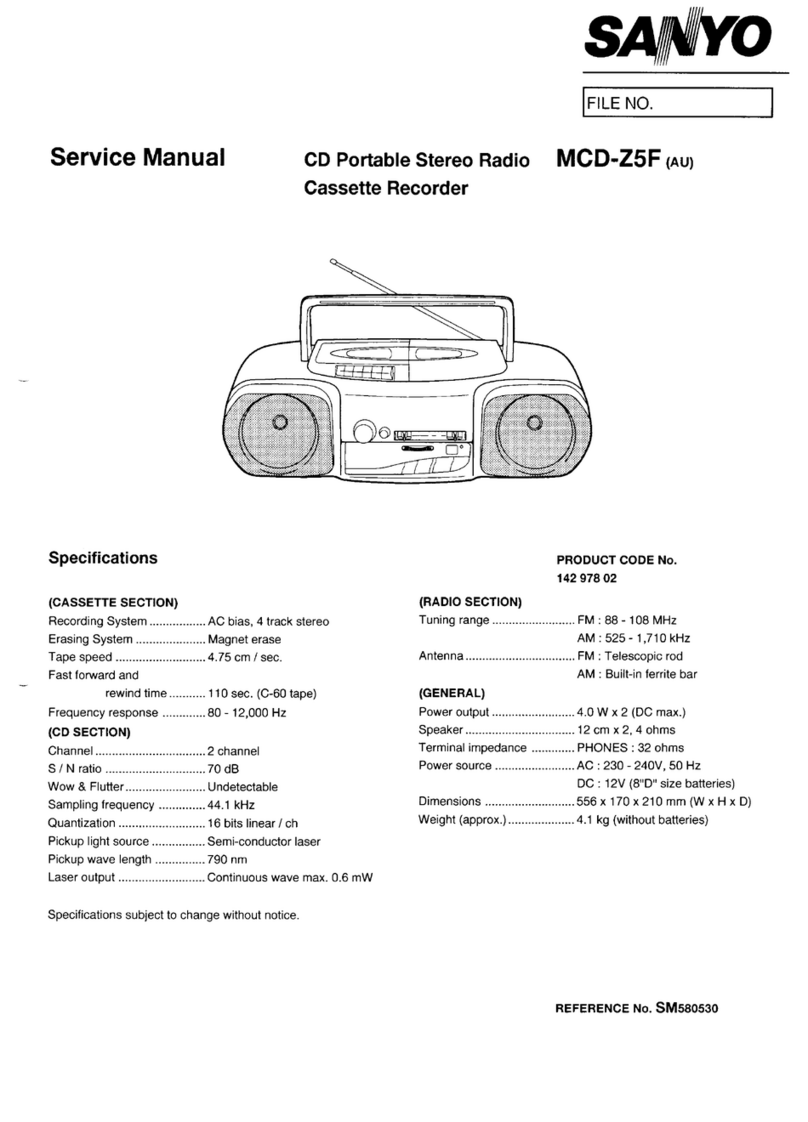

Sanyo MCD-Z5F User manual

Sanyo

Sanyo M-G12 User manual

Sanyo

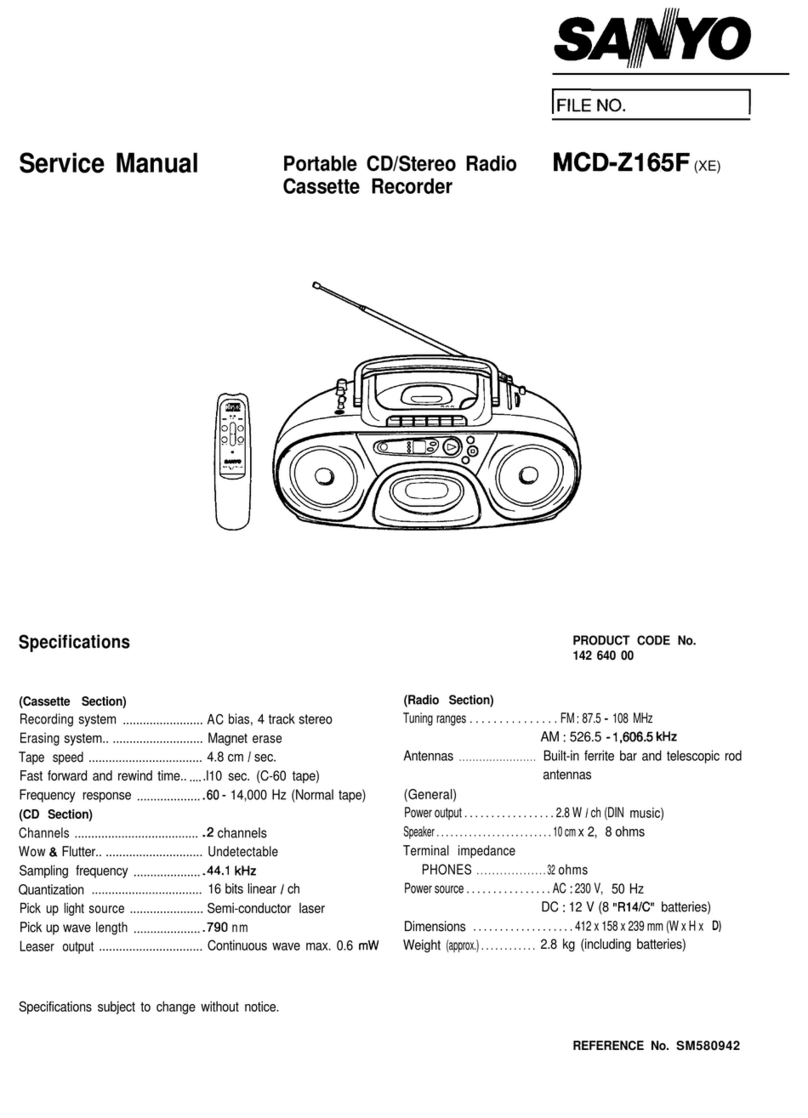

Sanyo MCD-Z165F User manual

Sanyo

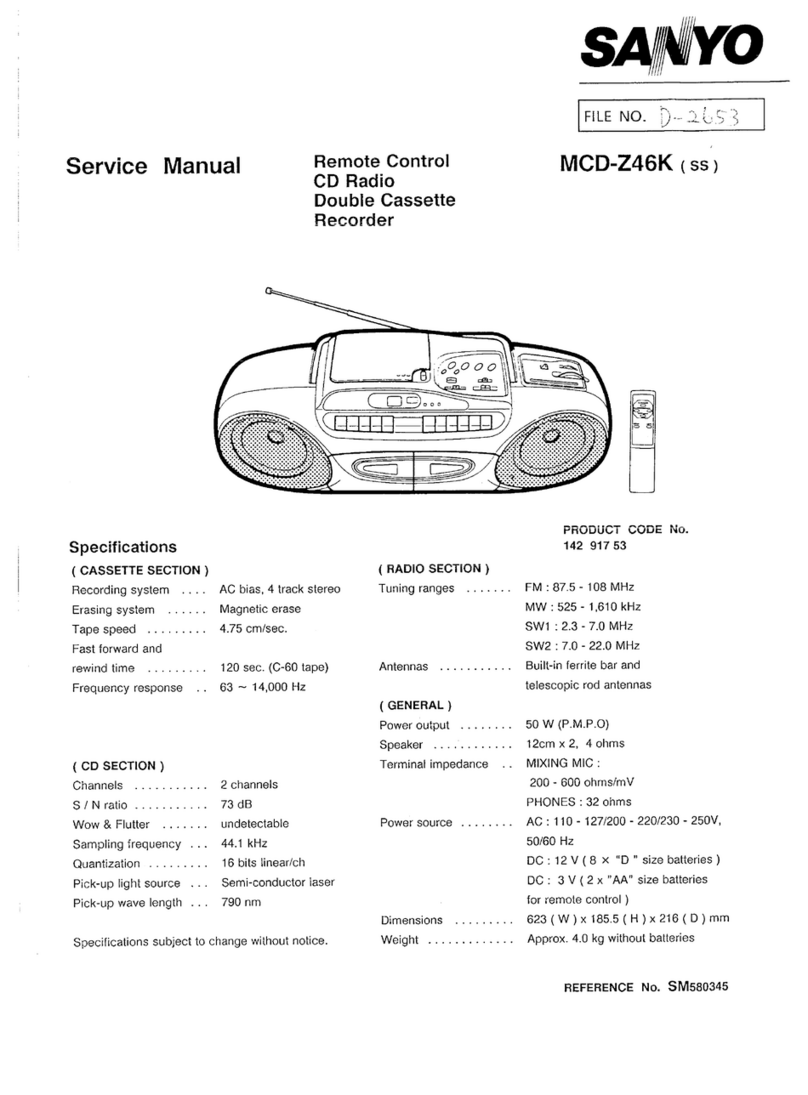

Sanyo MCD-Z46K User manual

Sanyo

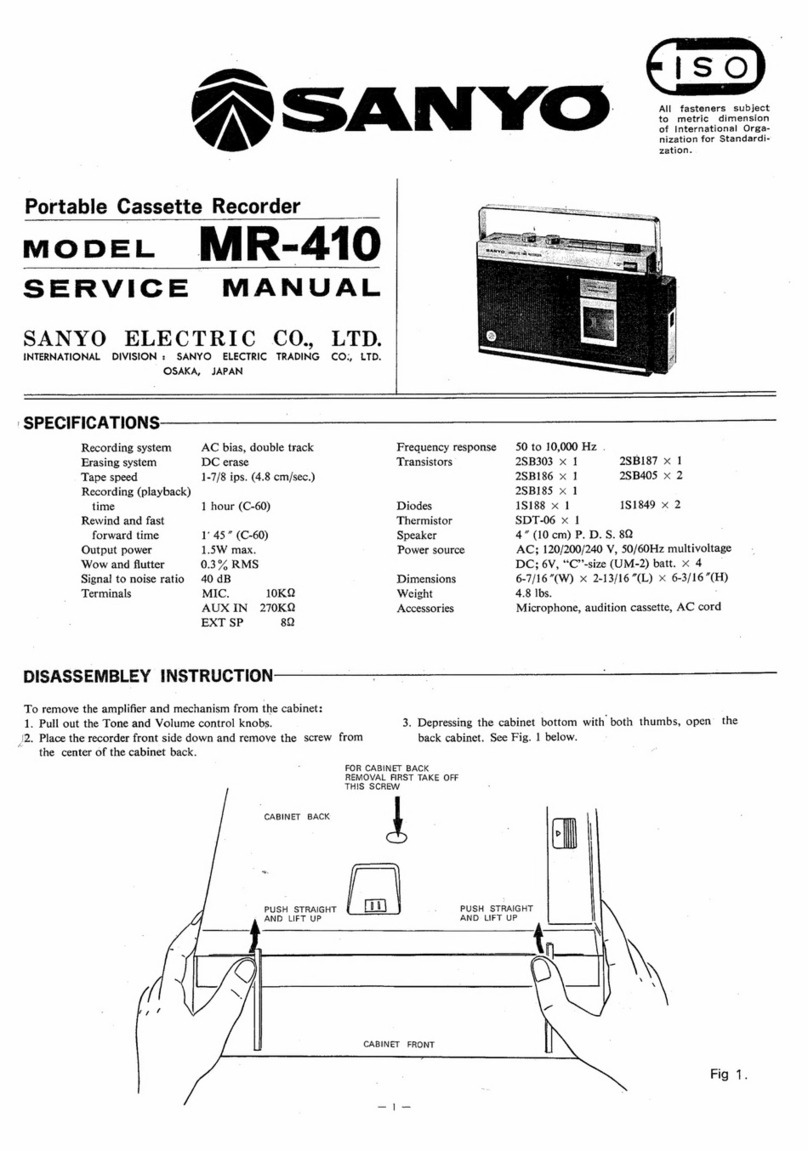

Sanyo MR-410 User manual

Sanyo

Sanyo MCD-s900F User manual

Sanyo

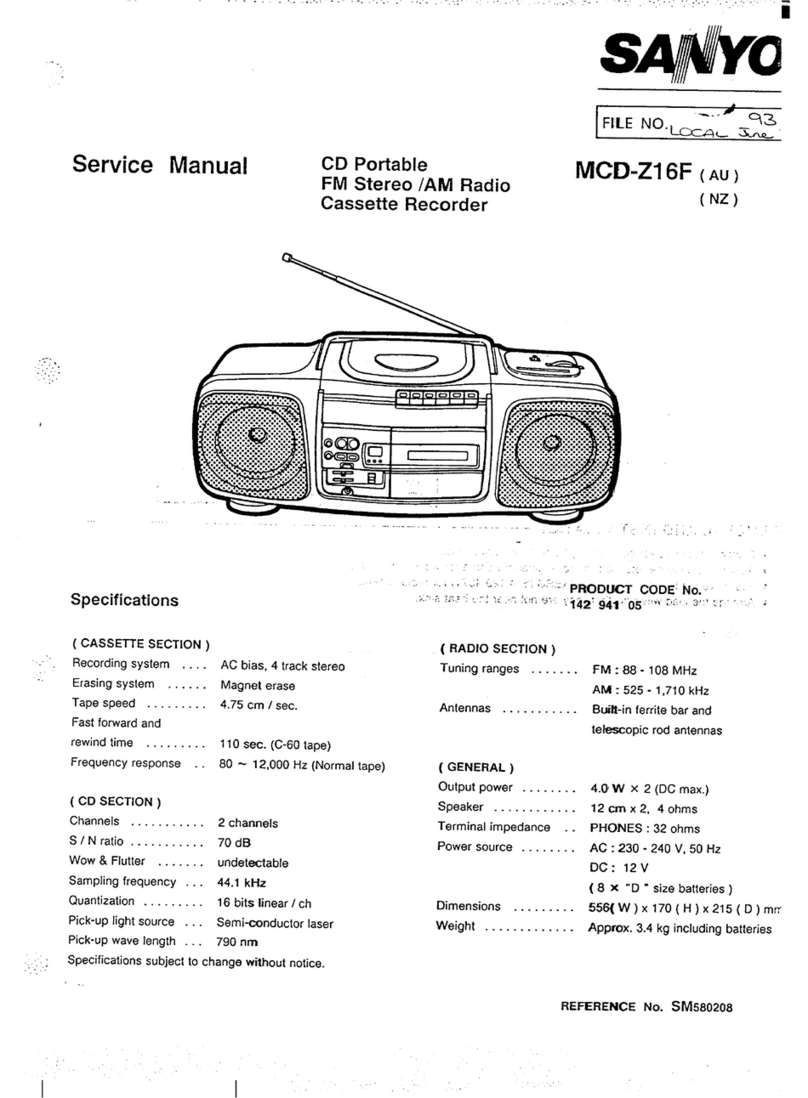

Sanyo MCD-Z16F User manual

Sanyo

Sanyo MGP17 User manual

Sanyo

Sanyo MCD-S730F User manual

Sanyo

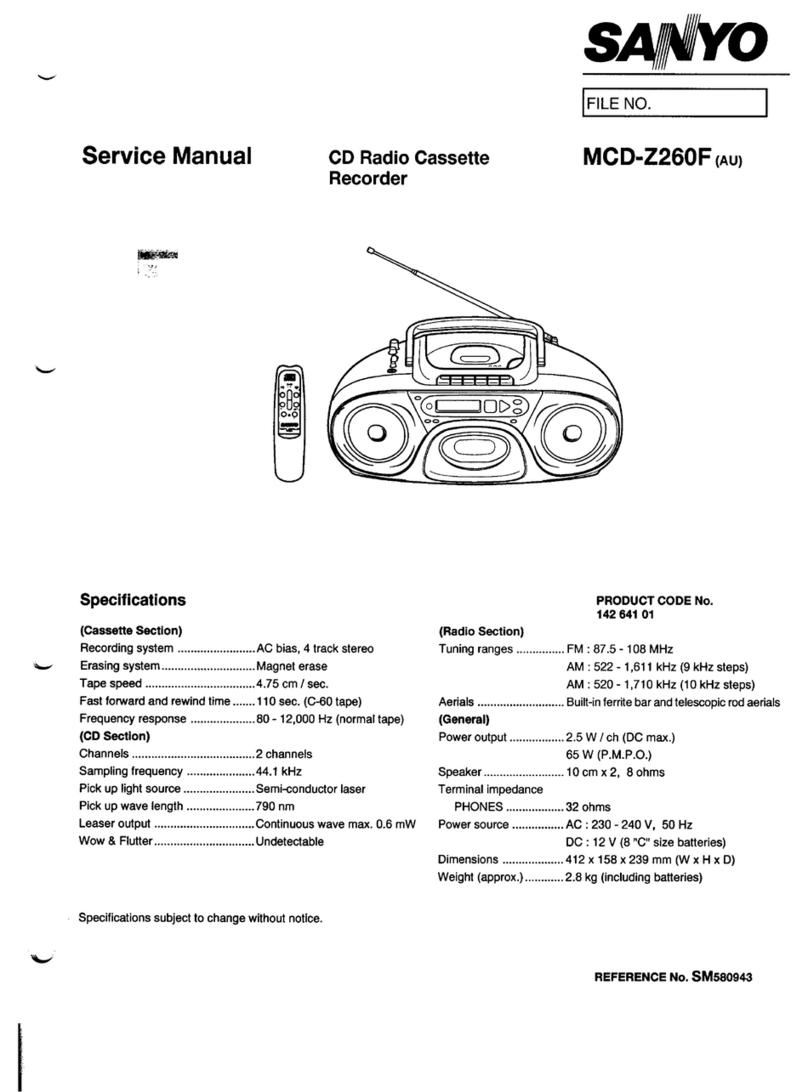

Sanyo MCD-Z260F User manual

Sanyo

Sanyo MCD-Z18F User manual

Sanyo

Sanyo MCD-S670F User manual

Sanyo

Sanyo M2541 User manual

Sanyo

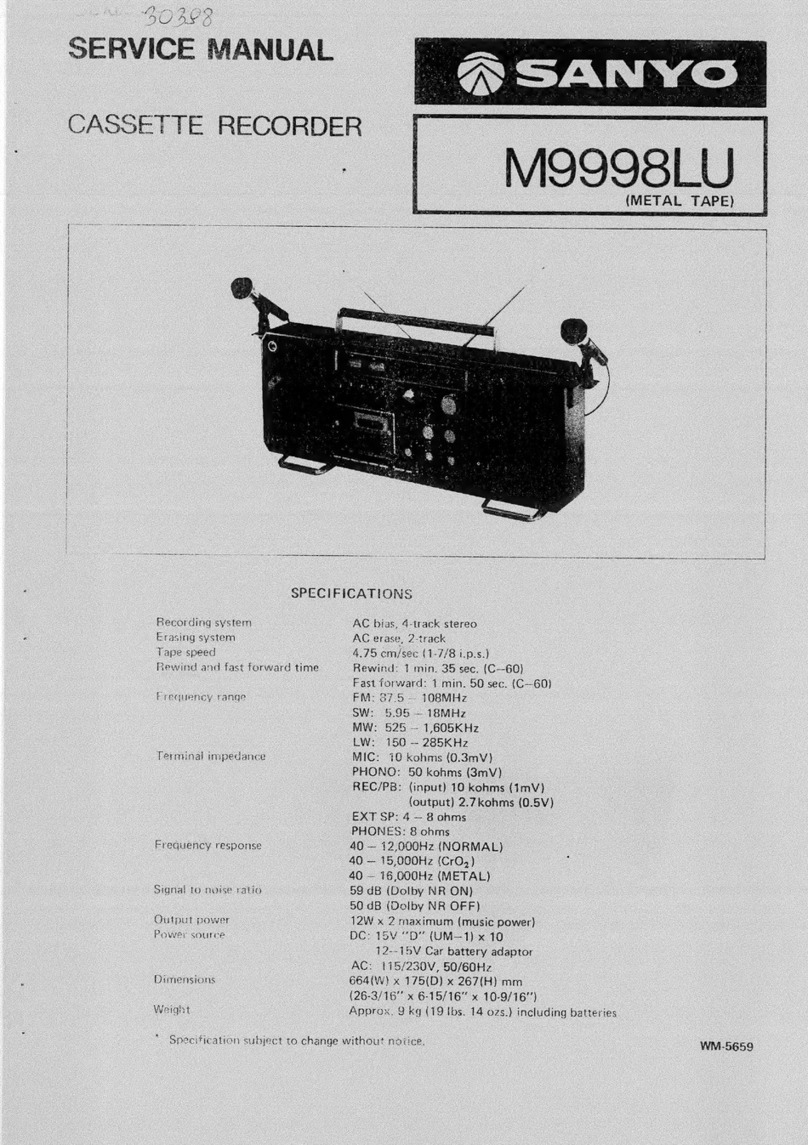

Sanyo M9998LU User manual

Sanyo

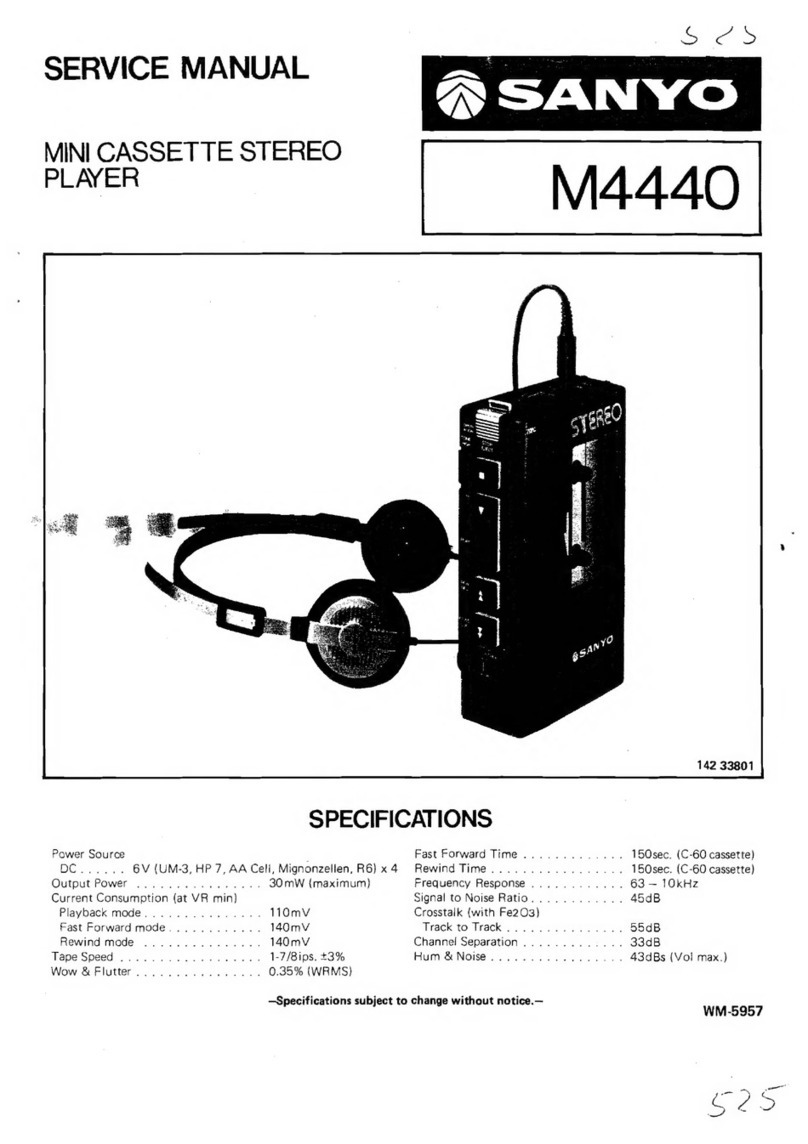

Sanyo M4440 User manual

Sanyo

Sanyo MCD-Z330F User manual

Sanyo

Sanyo TLS-S8000P User manual

Sanyo

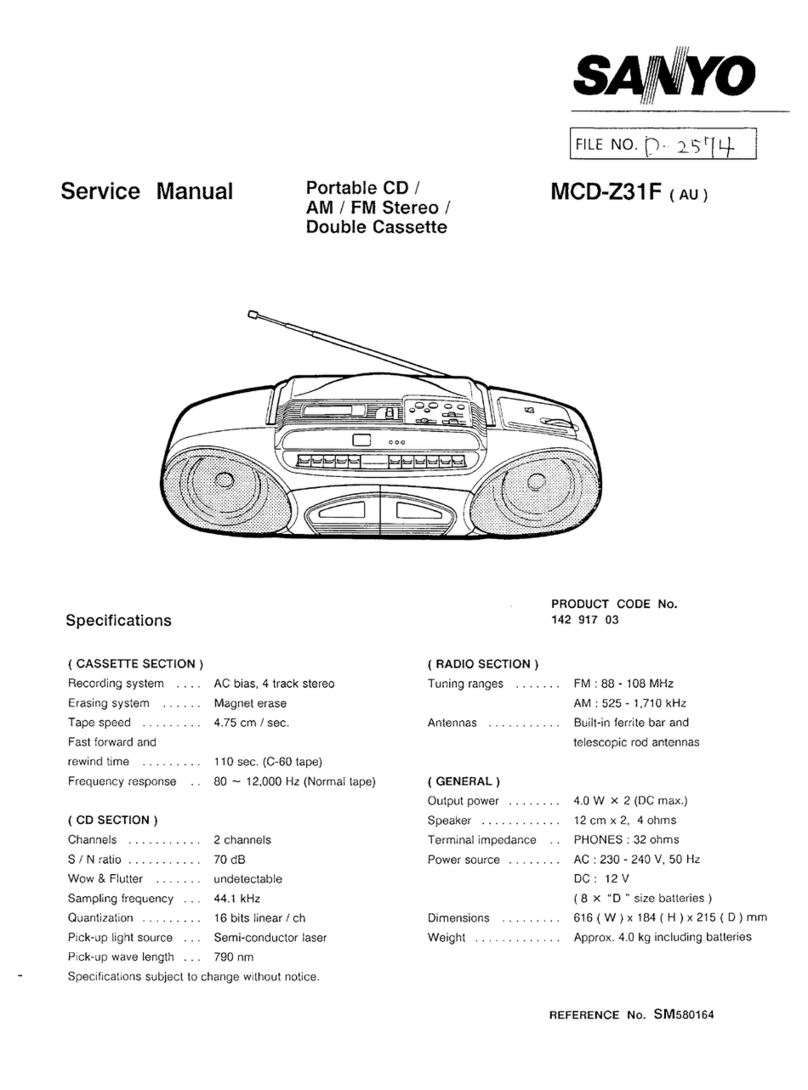

Sanyo MCD-Z31F User manual

Popular Cassette Player manuals by other brands

Sony

Sony CFS-B15 - Am/fm Stereo Cassette Recorder operating instructions

Sony

Sony WMFS220 - Portable Sports AM/FM Cassette... operating instructions

Aiwa

Aiwa HS-TA21 operating instructions

Aiwa

Aiwa CS-P77 Service manual

Sony

Sony Pressman TCM-465V operating instructions

Sony

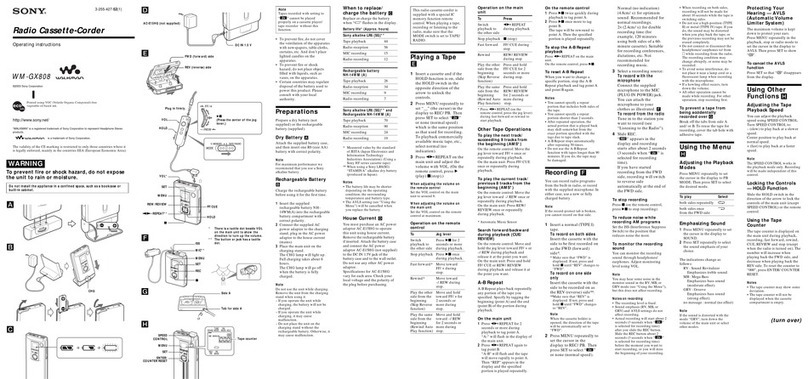

Sony WALKMAN WM-GX808 operating instructions