- 2 -

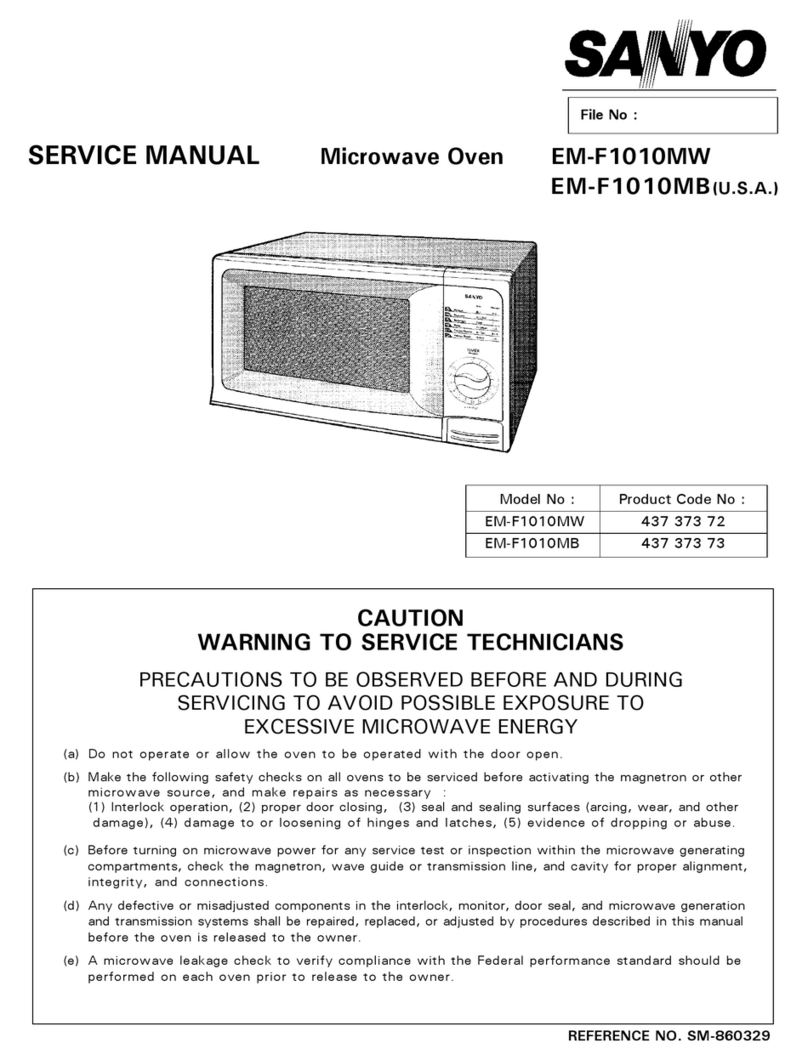

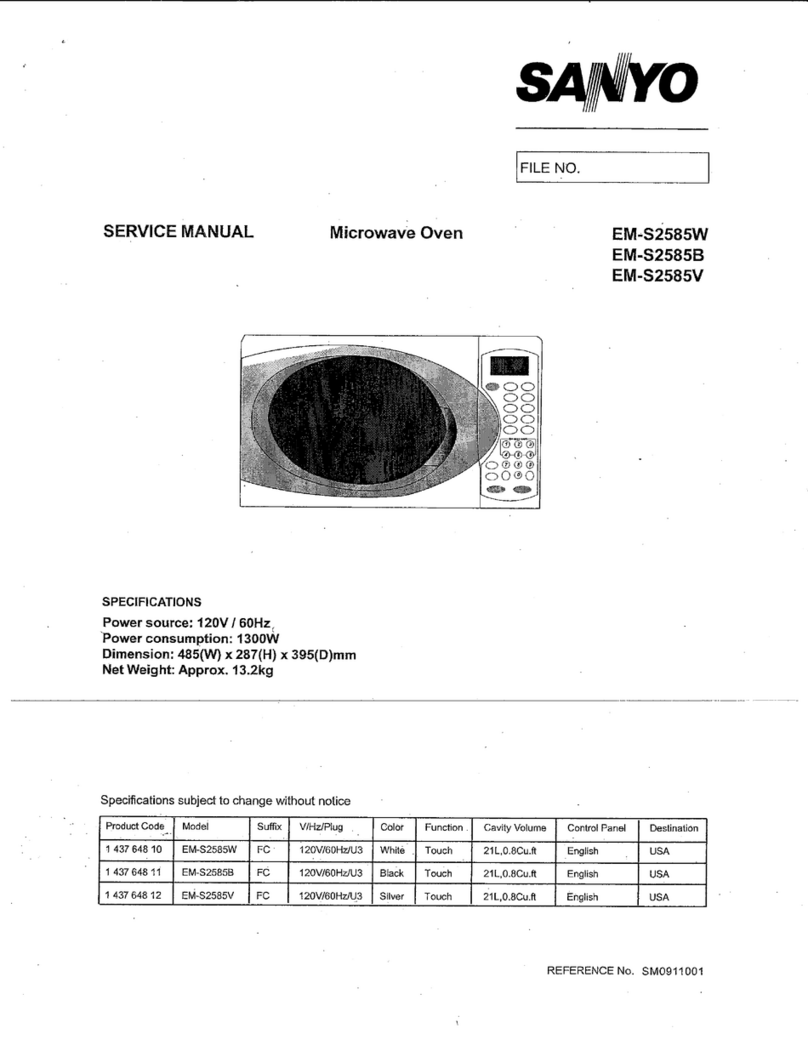

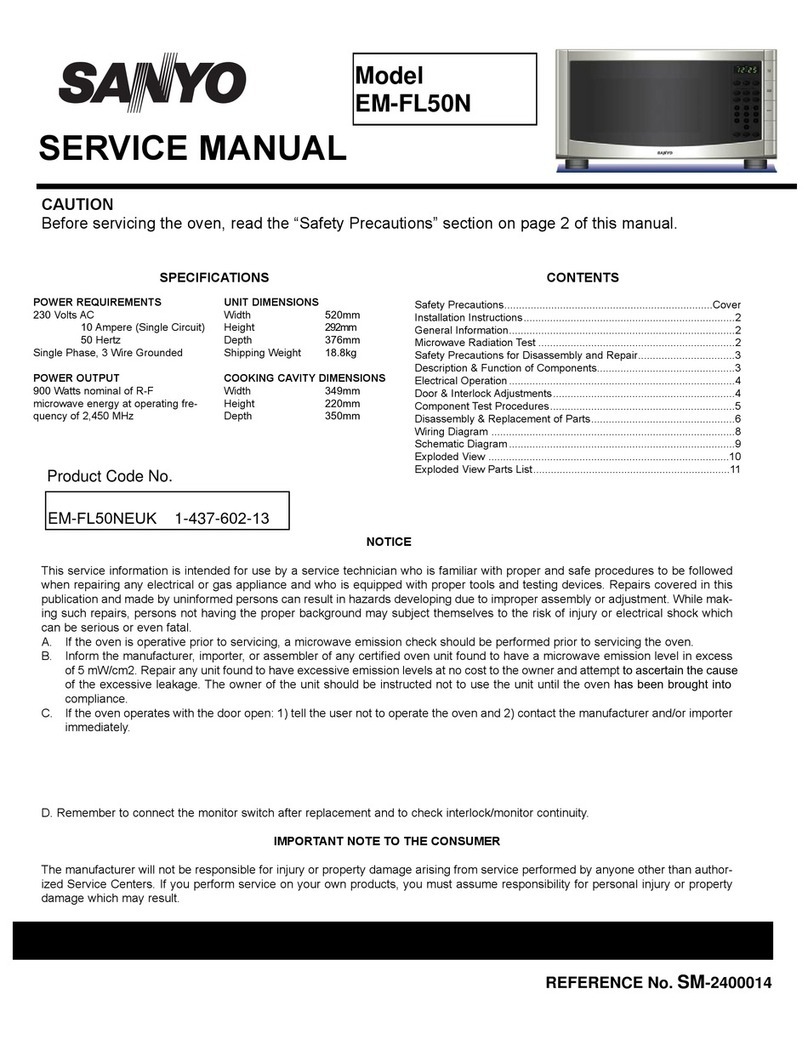

2.SPECIFICATIONS

Microwave output ................1,800W to 180W

Frequency ...........................2,450MHz

Power supply.......................230V, 50Hz

Rated current ......................13 Amp.

Safety Device ......................

Thermal limitter (Magnetron)

150 °C Open

80 °C Close

Thermistor (Magnetron) ..200 °C Open

108 °C Close

Thermistor(Duct).............120 °C Open

Fuse (Cartridge Type) .....250V 10A

Micro switch, Relay

Primary interlock Switch

Interlock monitor Switch

Door sensing Switch and

Relay RL-3 and 4

Max. input time....................Electronic Digital, up to

Manual

10min.

Memory 30min.

Overall Dimensions........422(W)x540(D)x335(H) mm

Oven cavity size ............330(W)x330(D)x230(H) mm

Effective Capacity of Oven Cavity ...............19.1

liters

Net weight ...........................32Kg

3. POWER OUTPUT MEASUREMENT

(1) Prepare 1000+5g tap water.

(2) Adjust water temperature to 10•}2 °C .

(3) Pour water into a container made of borosilicate

Glass, 190mm outer diameter cylinder, maximum

3mm thickness.

Note :Use the container kept on the room tem-

perature.

(4) place the container on the center of oven cavity.

(5) Set the heating time for 27 seconds and rating

full power and then start oven.

(6) Take the container out immediately when heat-

ing time is up.

(7) Stir water for making even water temperature in

the container.

(8) Measure water temperature.

Water temperature rise shall be 8 to 12 °C.

4. PRECATIONS AND REPAIR SERVICETIPS

PRELIMINARY

A. SINCE NEALY 4,000VOLTS EXISTS IN SOME

CIRCUITS OF THIS MICROWAVE OVEN, RE-

PAIRS SHOULD BE CARRIED OUT WITH

GREAT CARE.

B.TO AVOID POSSIBLE EXPOSURETO MICRO-

WAVE ENERGY LEAKAGE,THE FOLLOWING

PRECATIONS MUST BETAKEN BEFORE SER-

VICING.

(1) Before the power is applied.

(a) Open and close door several times to make

sure the door interlock switch and interlock

monitor switch operation properly.

(Listen for the clicking sound from switches.)

make sure the interlock monitor switch is

closed after the latch interlock switch is open

when the door is opened. (See pages 1 and 8)

(b) Make sure the perforated screen and the choke

dielectric of the door are correctly mounted.

(2) After the power is applied.

(a) Open and close the door to see if the interlock

mechanism operates properly.

(b) Check microwave energy leakage with a leak-

age detector and confirm the energy leakage

is below 5mW/c‡u.

(3) Do not operate the unit until it is completely

repaired if any of the following conditions exists.

(a) Door is not closed firmly against the

cavity front.

(b) The hinge is broken.

(c) The choke dielectric or the door seal is dam-

aged.

(d) The door is bent or warped, or there is any

other visible damage to the oven that may

cause microwave energy leakage.

Note: Always keep the seal clean.

(e) Make sure that there are no defective parts in

the interlock mechanism.

(f) Make sure that there are no defective parts in

the microwave generating and transmission as-

sembly.

(especially wave guide)

(4) Following items should be checked after the unit

is repaired.

(a) The interlock monitor switch is connected cor-

rectly and firmly.

(b) The magnetron gasket on the magnetron is

properly positioned.

(c) Waveguide and oven cavity are intact. (No

leakage of microwave energy).

(d)The door can be properly closed and the safety

switches work properly.

(e) The oven must be stopped when the door is

opened or the time is up.

The oven must not be operated with any of the above

components removed or bypassed.

HINT FOR LAMP-CHANGE

Before removing the cabinet, pull out the main-plug.

If you want to check the new lamp with the open

Cabinet, take care of the following safety-cautions:

Do not touch live parts.The lamp holder is not con-

nected to the earth protection lead by a metric

screws.