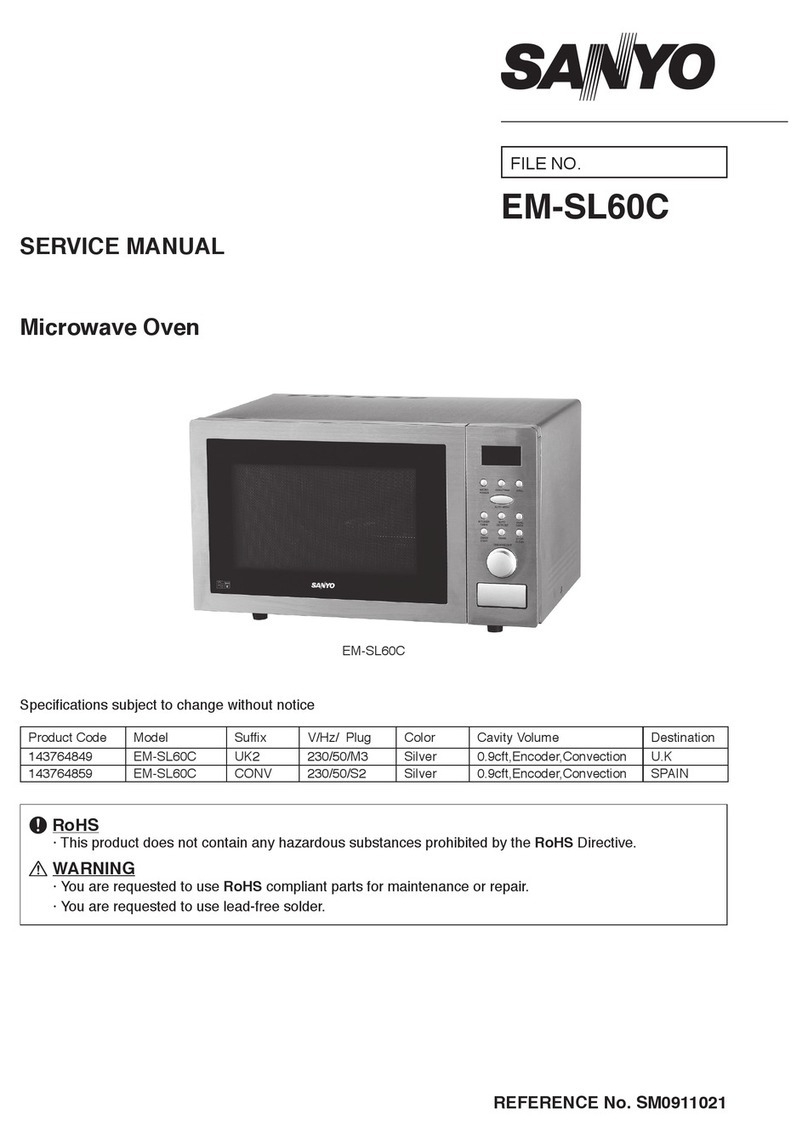

2. SPECIFICATIONS

Rated Power Consumption...l 400W

Rated power Supply ..,,,..,,,.. 220- 230 V/50Hz

Microwave output ................ 900/450/150/80W

/Defrost

Frequency ............................ 2,450 MHz+50MHz

Saftey Device ...................... Thermal Protector for

Cavity, open at 135*C

Themal Protector for

Magnetron, open at 135°C

Fuse (Carloridge Type 8A)

Primary interlock switch

Secondary interlock switch

Interlock monitor switch

Relay RL-2 on Control

circuit board

Timer ...................at................6 OMin. at 900/450/150 W

90Min. at 80 Won Defrost

Overall dimensions ............... 520wx413d x350 hmm

Oven cavity size .................... 330wx348dx 173 h mm

Effective Capacity of Oven .....2O liter

Net Weight ............23K!l............23K!l

3. POWER OUTPUT MEASUREMENT

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

Prepare 1000*5g tap water.

Adjust water temperature to 10°t20C.

Pour water into acontainer made of borosilicate

glass, 190mm outer diameter cylinder, maximum

3mm thickness.

Note. Use the container kept on the room temper-

ature.

Place the container in the center of oven cavity.

Set the heating time for 47 seconds and rating full

power and then ftart oven.

Take the container out immediately when heating

time is up,

Stir water for making even water temperature in the

container.

Measure water temperature.

Water temperature rise shall be 8° to 12°C.

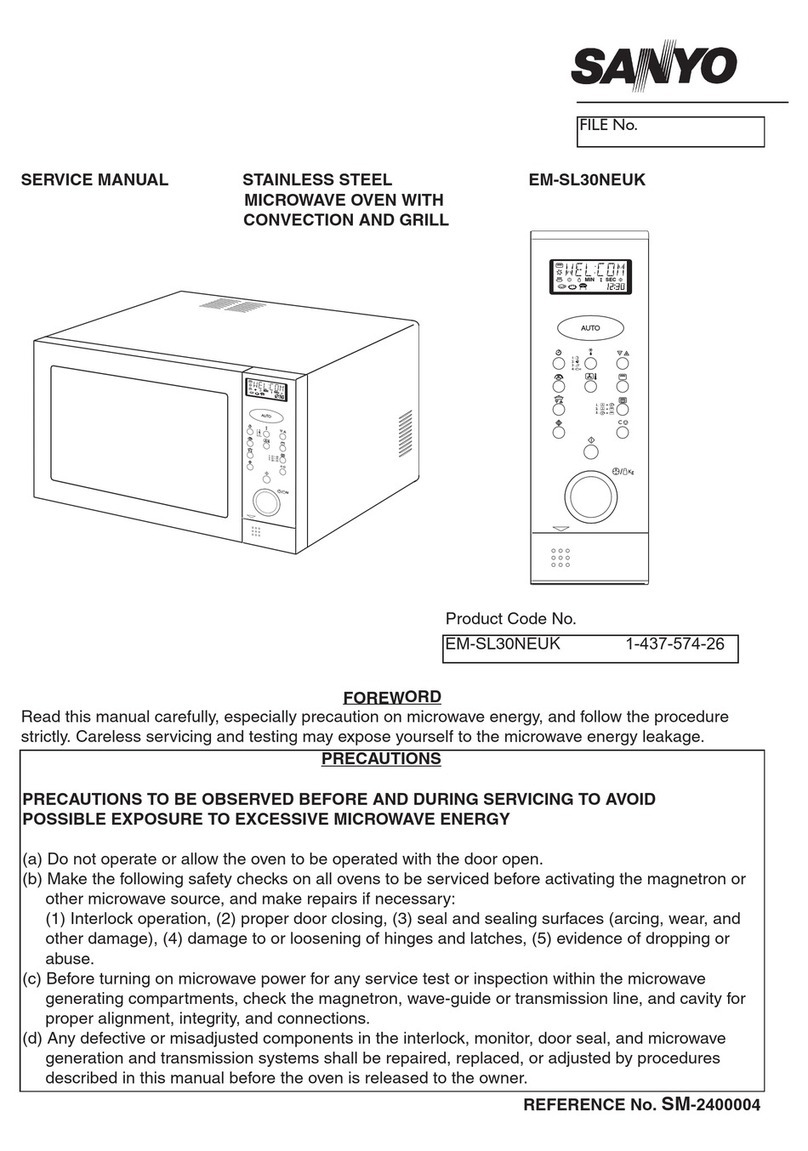

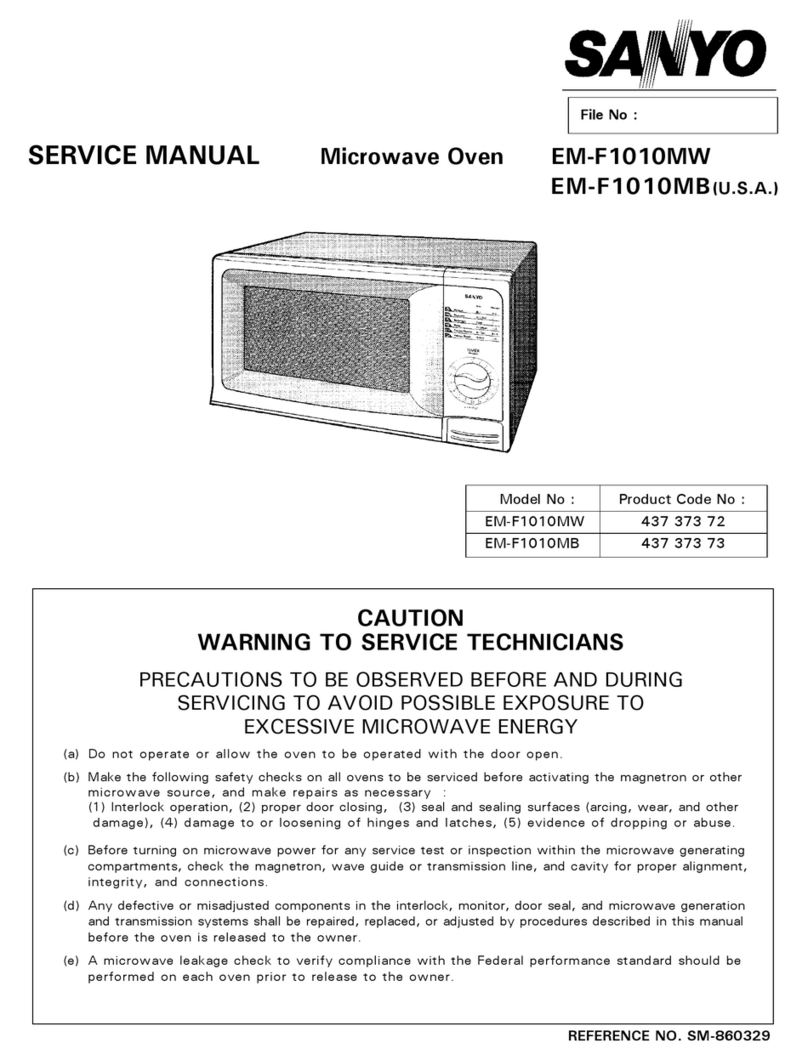

4. PRECAUTIONS AND REPAIR SERVICE TIPS

PRELIMINARY

A. SINCE NEALY 4,000 VOLTS EXIST IN SOME

CIRCUITS OF THE MICROWAVEOVENS,

REPAIRS SHOULD BE CARRIED OUT WITH

GREAT CARE.

B.TO AVOID POSSIBLE EXPOSURE TO MICRO-

WAVE ENERGY LEAKAGE, THE FOLLOWING

PRECAUTIONS MUST BE TAKEN BEFORE

SERVICING.

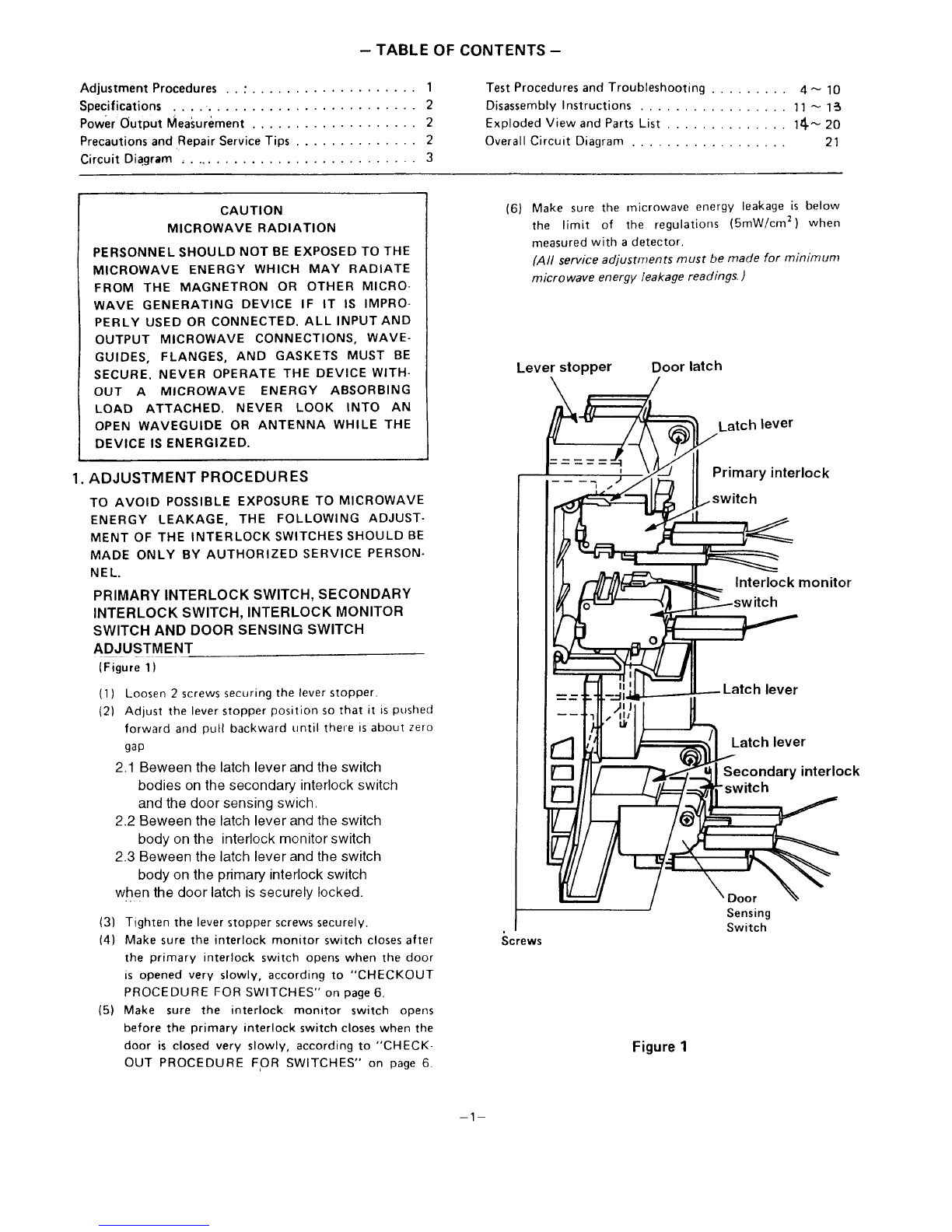

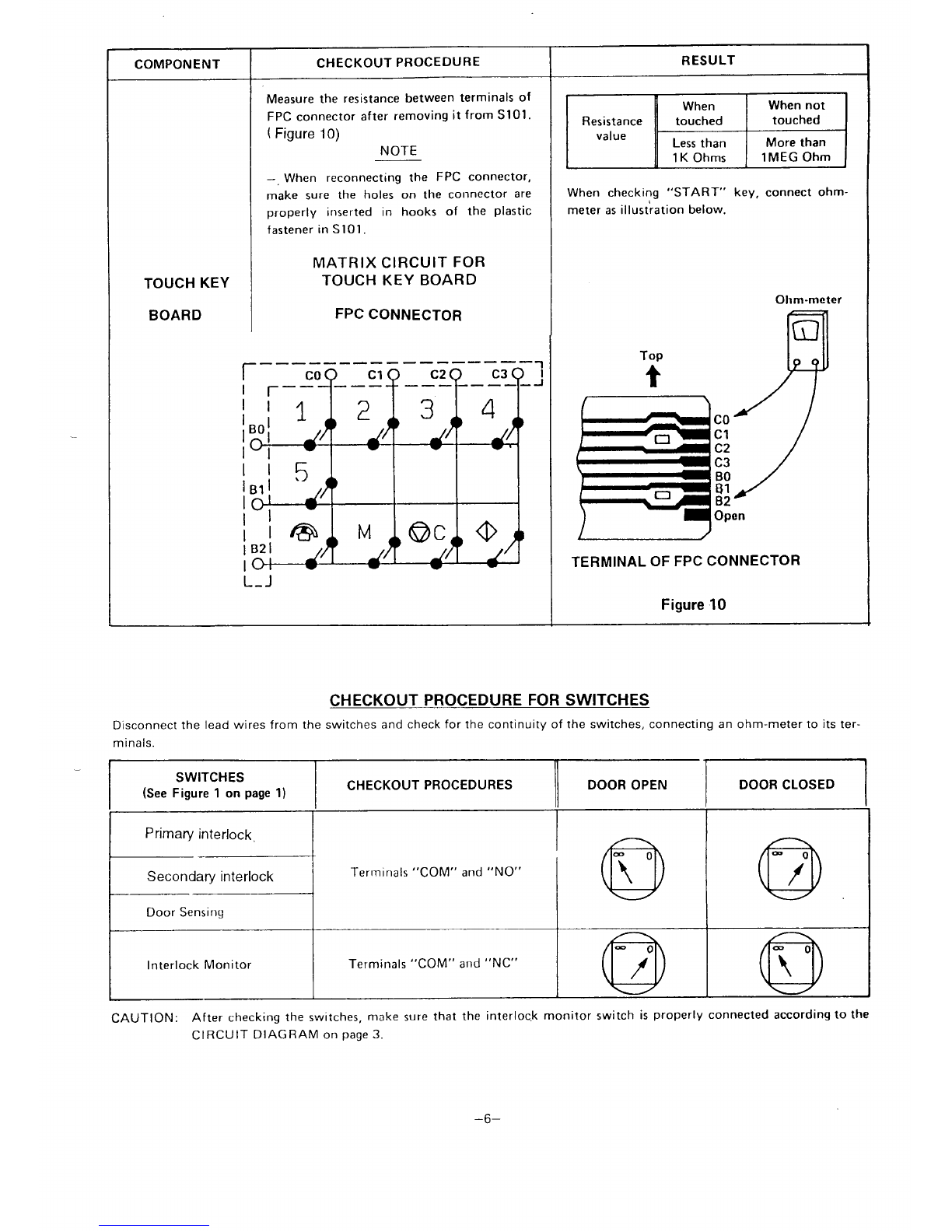

(1) Before the power is applied:

(a) Open and close the door several times to make

sure the primary interlock switch, the secondary

interlock switch, the interlock monitor switch

and the door sensing switch operate properly.

listen for the cliking sound from the switches.

Make sure the interlock monitor switch is

closed after the primary interlock switch is

opened when the door is opened.

(See pages 1 and 6)

(b) Make sure the perforated screen and the choke di-

electric of the door are correctly mounted.

(2) After the power is applied:

(a) Open and close the door to see If the interlock

mechanism operates properly.

(b) Check microwave energy leakage with aleakage

detector and confirm the energy leakage is below 5

mW/cm2 ).

(3) Do not operate the unit until it is completely repair-

ed, if any of the following conditions exists.

(a) Door does not close firmly against the cavity front.

(b) The hinge is broken.

(c) The choke dielectric or the door seal is damaged.

(d) The door is bent or warped, or there is any other

visible damage to the oven that may cause micro-

wave energy leakage.

(e) Make sure that there are no defective parts in the

interlock mechanism.

(f) Make sure there are no defective parts in the micro-

wave generating and transmission assembly. (espe-

cially waveguide).

(4) Following items should be checked after the unit is

repaired.

(a) The interlock monitor switch is connected correctly

and firmly.

(b) The magnetron gasket on the magnetron IS properly

positioned.

(c) Waveguide and oven cavity are intact (no leakage of

microwave energy).

(d) The door can be Properly closed and the safety

switches work Properly.

(e) The oven must be stopped when the door is opened

or the time is up

The oven must not be operated with any of the above

components removed or bypassed.

HINT FOR LAMP CHANGE

Before removing the cabinet, pull out the main plug.

If you want to check the new lamp with the oen

cabinet, take care of the following safety cautions.:

Do not touch live parts, The lamp holder is not connected

to the earth wotecton lead bv ametric screw.

–2–