— 2 —

SAFETY PRECAUTIONS

WARNING: The chassis of this receiver has a floating

ground with the potential of one half the AC line voltage in

respect to earth ground. Service should not be attempted by

anyone not familiar with the precautions necessary when

working on this type of equipment.

The following precautions must be observed:

1. An isolation transformer must be connected in the power

line between the receiver and the AC line before any ser-

vice is performed on the receiver.

2. Comply with all caution and safety-related notes provid-

ed on the side of the cabinet, inside the cabinet, on the

chassis, and the picture tube.

3. When replacing a chassis in the cabinet, always be certain

that all the protective devices are installed properly, such

as control knobs, adjustment covers, shields and barriers.

DO NOT OPERATE THIS TELEVISION RECEIVER

WITHOUT THE PROTECTIVE SHIELD IN POSITION AND

PROPERLY SECURED.

4. Before replacing the back cover of the set, thoroughly

inspect the inside of the cabinet to see that no stray parts

or tools have been left inside.

Before returning any television to the customer, the

service technician must perform the following safety

checks to be sure that the unit is completely safe to

operate without danger of electrical shock.

ANTENNA COLD CHECK

Remove AC plug from the 120 VAC outlet and place a

jumper across the two blades. Connect one lead of an ohm-

meter to the jumpered AC plug, and touch the other lead to

each exposed antenna terminal (UHF and VHF antenna ter-

minals). The resistance must measure between 1M ohm and

5.2M ohm. Any resistance value below or above this range

indicates an abnormality which requires corrective action.

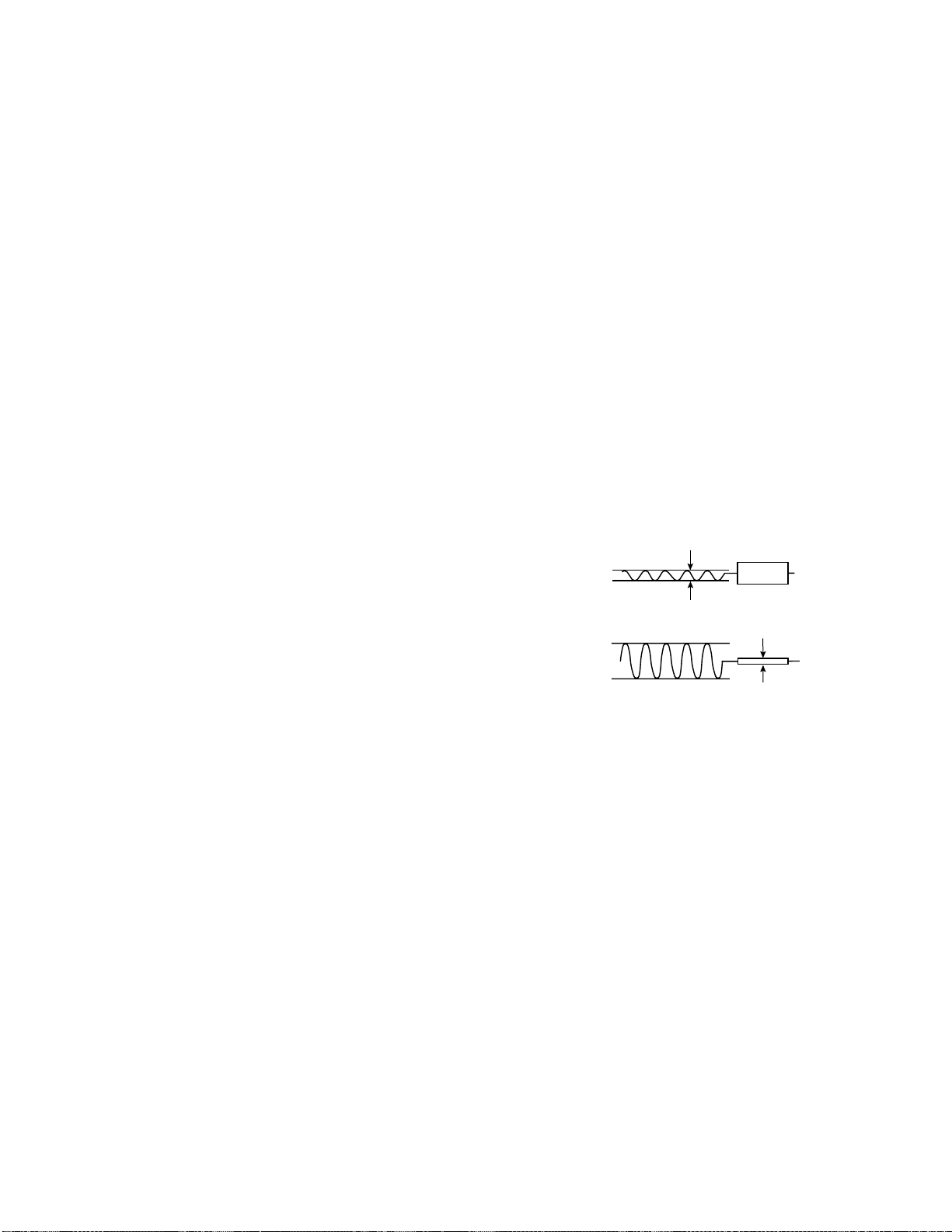

LEAKAGE CURRENT CHECK

Plug the AC line cord directly into a 120 VAC outlet. (Do not

use an isolation transformer for this check.) Use an AC volt-

meter, that has 5000 ohms per volt or more sensitivity.

Connect a 1500 ohm 10 watt resistor, paralleled by a 0.15 µF

150 VAC capacitor, between a known good earth ground

(water pipe, conduit, etc.) and all exposed metal parts of the

cabinet (antennas, handle bracket, metal cabinet, screw

heads, metal overlays, control shafts, etc.). Measure the AC

voltage across the 1500 ohm resistor. The AC voltage

should not exceed 750 mV. A reading exceeding 750 mV

indicates that a dangerous potential exists. The fault must

be located and corrected. Repeat the above test with the

receiver power plug reversed.

NEVER RETURN A RECEIVER TO THE CUSTOMER

WITHOUT TAKING THE NECESSARY CORRECTIVE ACTION.

X-RADIATION PRECAUTION

The primary source of X-RADIATION in solid-state receivers is

the picture tube. The picture tube is specially constructed to

limit X-Ray emission. For continued X-RADIATION protection,

the replacement tube must be the same type as the original

(including the suffix letter in the part numbers). Excessive high

voltage may produce potentially hazardous X-RADIATION. To

avoid such hazards, the high voltage must be maintained within

specific limits. Refer to the X-RADIATION WARNING NOTE on

the CHASSIS SCHEMATIC in this service manual for specific

high voltage limits. If the high voltage exceeds specified limits,

check the components specified on the chassis schematic

diagram and take the necessary corrective action. Carefully

follow the instructions for the +B Voltage Check and the High

Voltage Check to maintain the high voltage within the specified

limits.

HIGHVOLTAGE HOLD-DOWNTEST

To prevent X-RADIATION from the picture tube due to

excessive high voltage, a HOLD-DOWN circuit is provided in

the high voltage circuit. Every time the receiver is serviced,

the high voltage HOLD-DOWN circuit must be tested for

proper operation. Refer to the HIGH VOLTAGE HOLD-

DOWN TEST in service adjustments.

PRODUCT SAFETY NOTICE

When replacing components in a receiver, always keep in

mind the necessary product safety precautions. Pay special

attention to the replacement of components marked with a

star (★) in the parts list and in the schematic diagrams. To

ensure safe product operation, it is necessary to replace

those components with the exact same PARTS.

SAFETY INSTRUCTIONS