- 1 -

Foreword

Thank you for using our company's inverter. Before using it, you must read this instruction

manual carefully. Please use it after you are familiar with the precautions of this product.

Installation Environment:

1. Installed indoors and in a well-ventilated place, generally should be installed vertically to

ensure the best cooling effect.

2. The ambient temperature is required to be in the range of -10~45℃.

3. The ambient humidity is required to be less than 90%, without water droplets condensing.

4. Install in a place with vibration less than 0.5G to prevent falling damage. The inverter is not

allowed to suffer sudden impact.

5. Install in an environment away from magnetic fields and free of flammable and explosive

substances.

6. Make sure to install the inverter on fireproof materials (such as metal) to prevent fire.

7. Make sure that no foreign objects enter the inverter to prevent circuit shortcuts from burning

down the inverter.

Safety Precautions

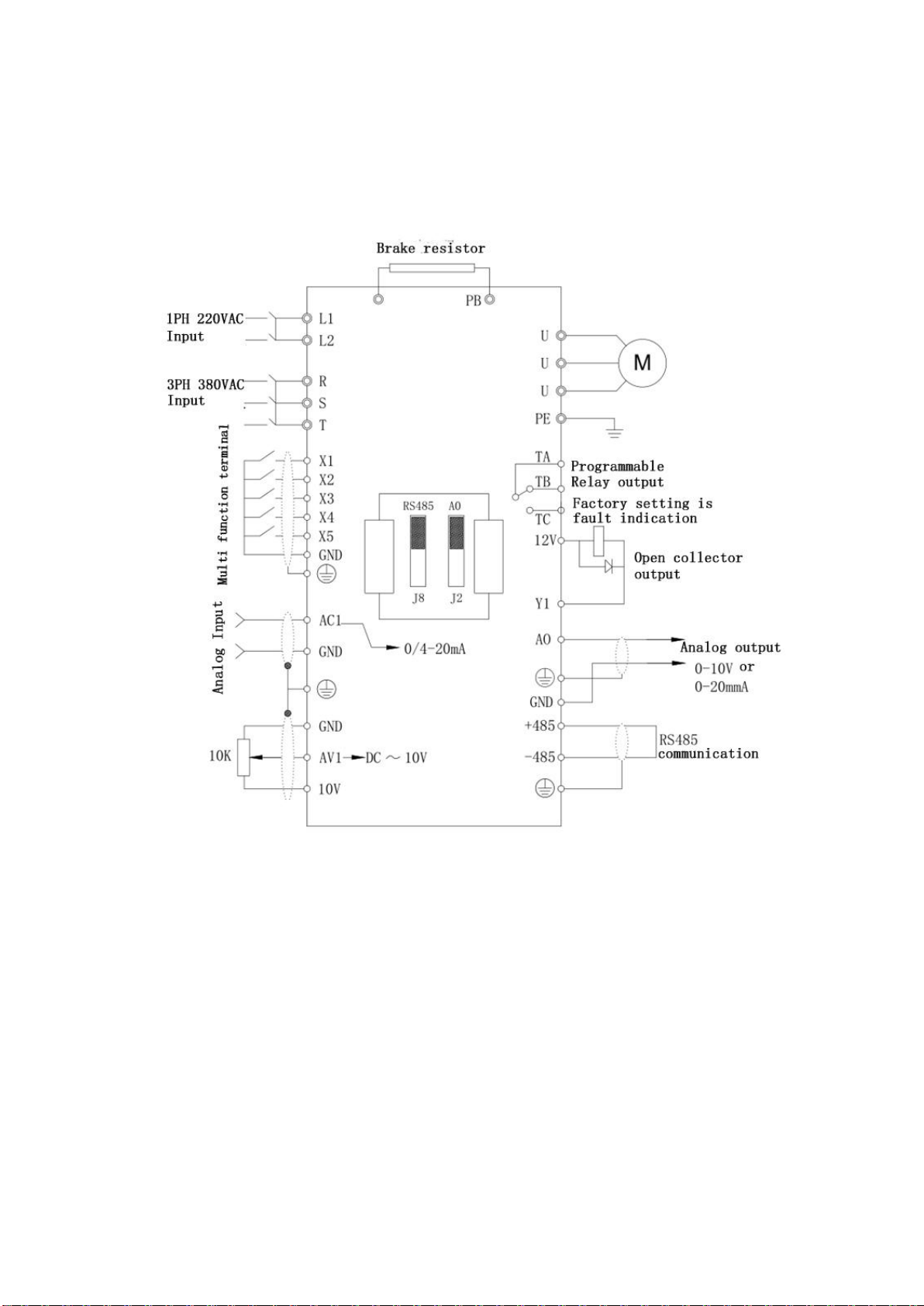

1. Before wiring, please confirm whether the input power is in the power off state.

2. It is strictly forbidden to operate with wet hands during wiring operation, and professional

electrical engineering personnel are required.

3. The main circuit terminal and the cable must be firmly connected, otherwise the inverter may

be damaged due to poor contact.

4. For safety reasons, the ground terminal of the inverter must be reliably grounded.

5. It is strictly forbidden to connect the AC 220V or 380V power supply to the terminals other

than TA and TC in the control terminal.

6. It is strictly forbidden to connect the AC power supply to the output U, V, W terminals of the

inverter.

7. On the input power supply side of the inverter, be sure to configure a fuseless circuit breaker

for circuit protection or a circuit breaker with leakage protection to prevent the accident

caused by the inverter from expanding.

8. Please confirm whether the voltage of the AC main circuit power supply is consistent with the

rated voltage of the inverter.

9. Do not intervene the contactor in the output circuit. If necessary, please consult our company

or relevant qualified personnel in advance.

10. When the inverter is powered on, do not open the cover or perform wiring work.

11. Do not touch the inside of the inverter after power-on, and do not put conductive rods or other