After

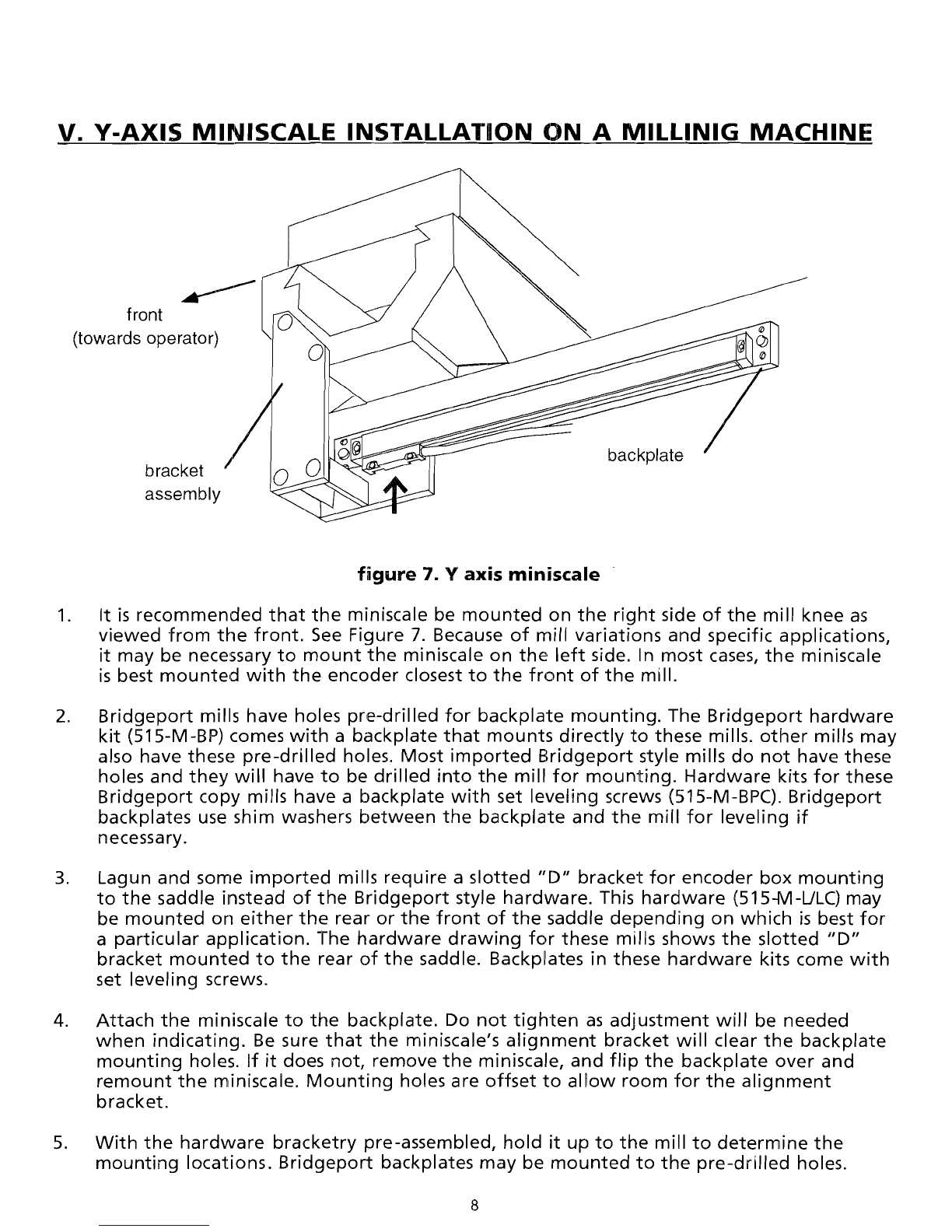

locating

the

mounting

area,

mark

both

ends using

the

ways as a reference

with

a

precision

instrument,

such as calipers.

Drill/tap

for

5/16-18 x 1-7/8 socket cap bolts.

Mount

the

backplate

(with

the

miniscale

attached)

to

the

mill.

Verify

that

the

encoder

box

bracket

and

the

rest

of

the

bracketry

will

mount

to

the

encoder

box.

Adjust

the

backplate

for

parallelism using

the

leveling screws

(or

washer/shim

for

Bridgeport

hardware)

as necessary.

SETSCREWS

MUST

BE

PROPERLY

ADJUSTED. IMPROPER ADJUSTMENT

MAY

CAUSE

WARPING OR TWISTING OF THE BACKPLATE.

6.

Indicate

the

spar surface

(top)

with

respect

to

the

ways using a

depth

micrometer,

dial

indicator

or

calipers.

Adjust

the

two

miniscale ends so

that

the

spar surface is parallel

to

the

table

travel

within

0.005 inch (0.13 mm)

over

its

entire

travel.

Use

the

ways as a

reference.

Indicate

the

miniscale face housing surface

from

end

to

end

to

within

0.005

inch (0.13 mm)

over

its

entire

travel.

Adjust

the

backplate

and/or

miniscale using

the

leveling

screws

(or

washer/shim

for

Bridgeport

hardware)

as necessary.

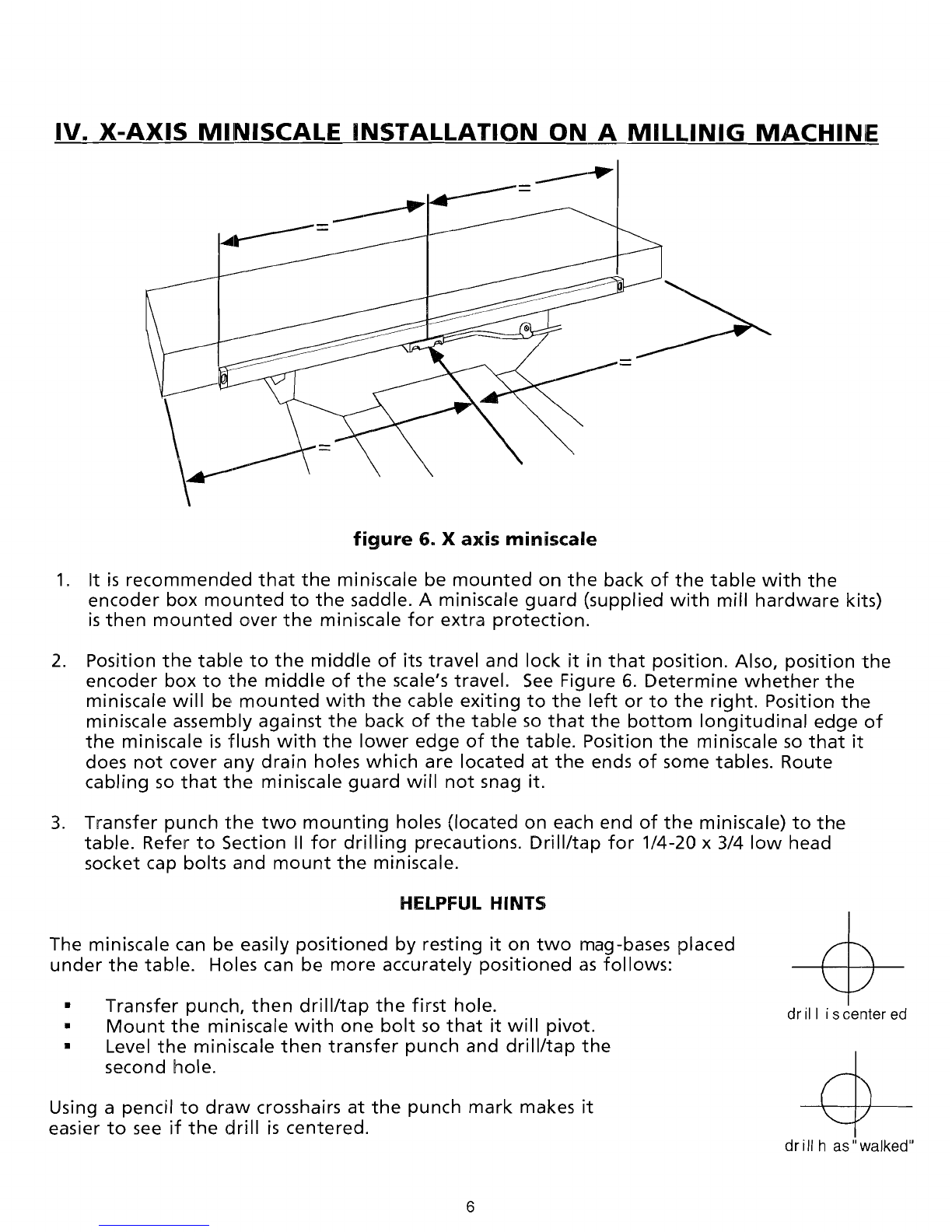

7. Position

the

table

fully

to

its end

of

travel

closest

to

the

operator

(standing

in

front

of

the

machine) and lock

it

into

position.

Position

the

encoder

box

to

the

end

of

its

travel

(towards

the

front

or

operator

side).

Mark

the

saddle

location

and

drill/tap

for

1/4-20 x

3/4 socket cap bolts.

Mount

the

bracket

assembly.

8. Encoder Box

Mounting:

a. Transfer punch

the

two

encoder

box

mounting

holes

to

the

bracket.

Drill/tap

for

8-32 x 3/4 socket cap screws.

b. Insert and

adjust

the

4

encoder

box

set screws (5-40)

until

they

just

touch

the

rnountinq

surface

Improper

adjustment

can

force

the

encoder

box

out

of

its

calibrated

position

and

cause

erratic

miniscale

performance

and

damage.

c.

Mount

the

encoder

box

with

the

two

8-32 x 3/4 socket cap screws. Do

not

overtighten

the

encoder

box

mounting

screws.

f. Release

the

table

lock

and move

the

Y axis

table

to

its

two

extreme

positions

while

monitoring

the

encoder

box

travel.

VERIFY THAT TBE MINISCALE CANNOT

BE

OVERTRAVELED. See Figure 5.

9. No miniscale

guard

is

provided

for

the

mill

Y axis since

the

miniscale is

mounted

underneath

the

saddle. However, an

optional

rniniscale

guard

may be

obtained

by

contacting

your

dealer

or

the

factory.

10. Route

and

secure

the

cables

to

the

display. Ensure

that

the

cables are

not

hanging

loose

to

be

caught

on any

part

of

the

machine

during

operation.

NOTE

Do

not

run miniscale cables parallel

with

power

wires. Induced noise

may

cause

the

display

to

miscount.

Maintain

a

minimum

of

6 inches

between

cables

and

cross

at

right

angles.

9