4

Contents Warnings and

Safety Precautions

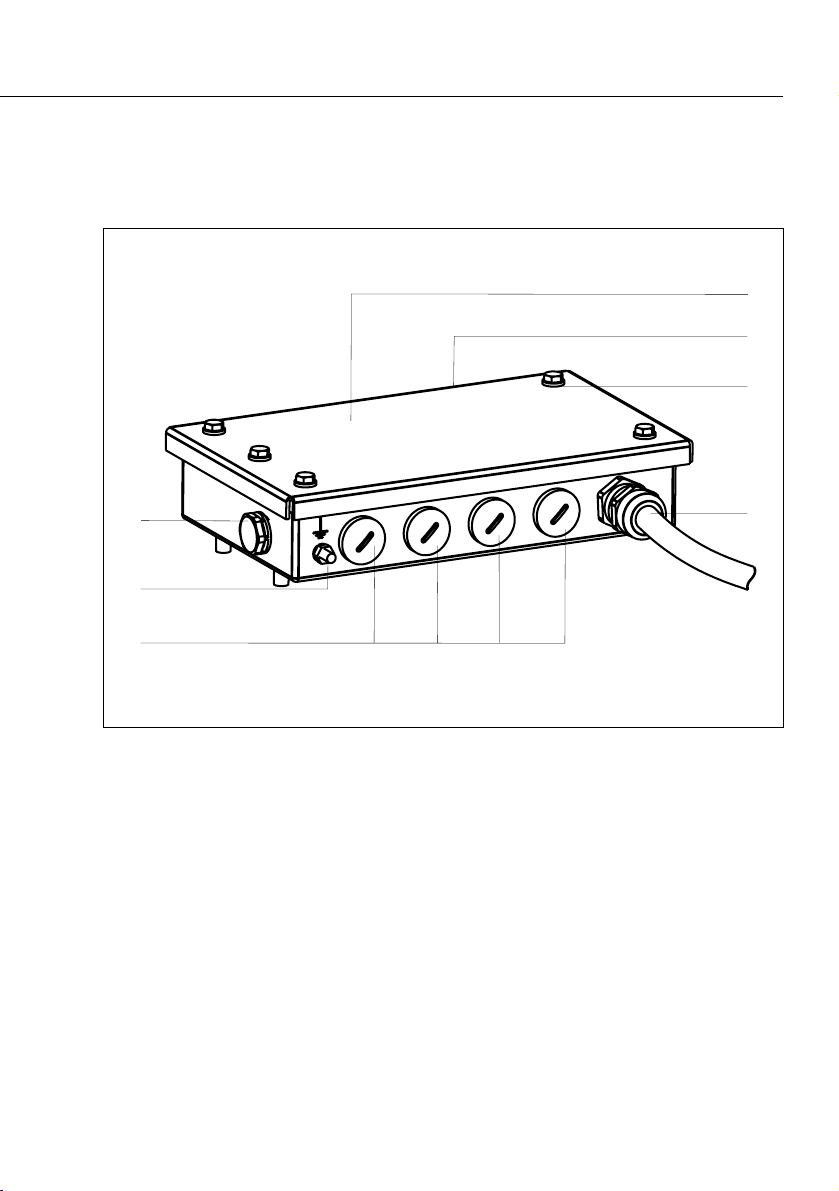

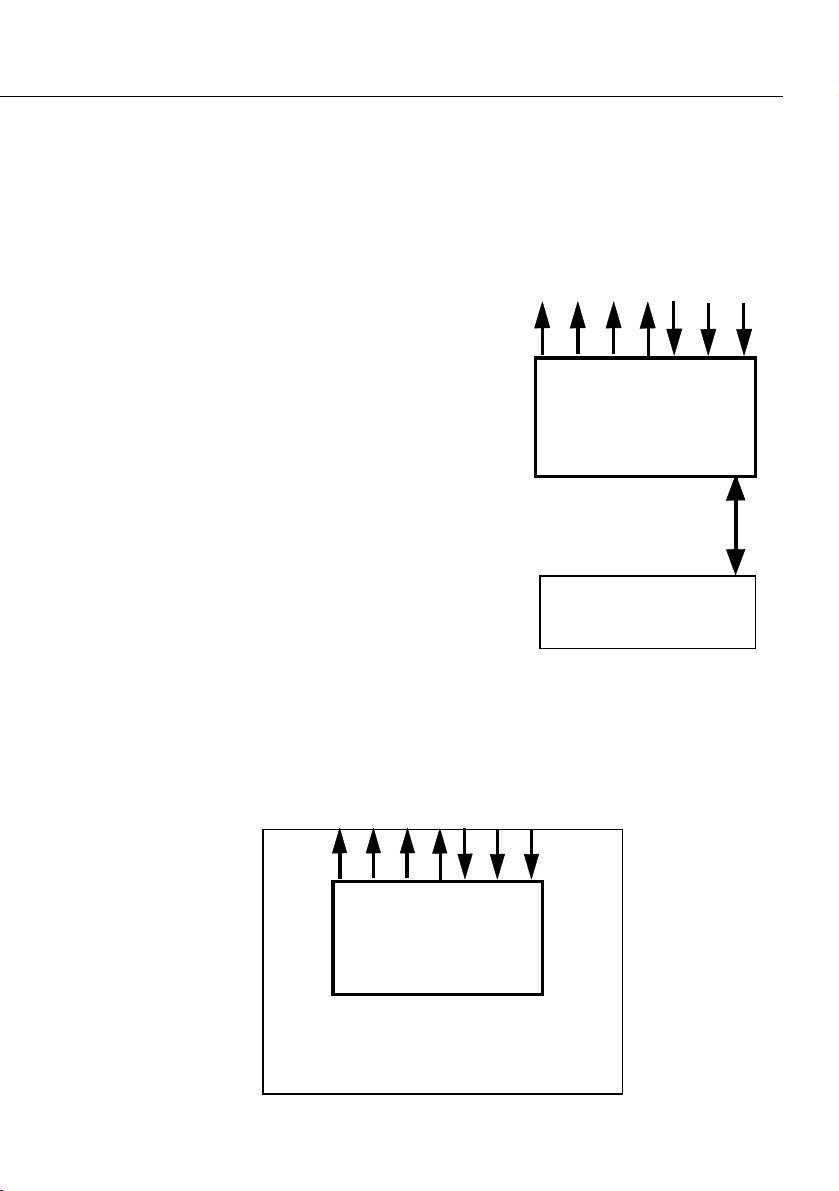

3General View of the Equipment

4Warnings and Safety Precautions

5Intended Use

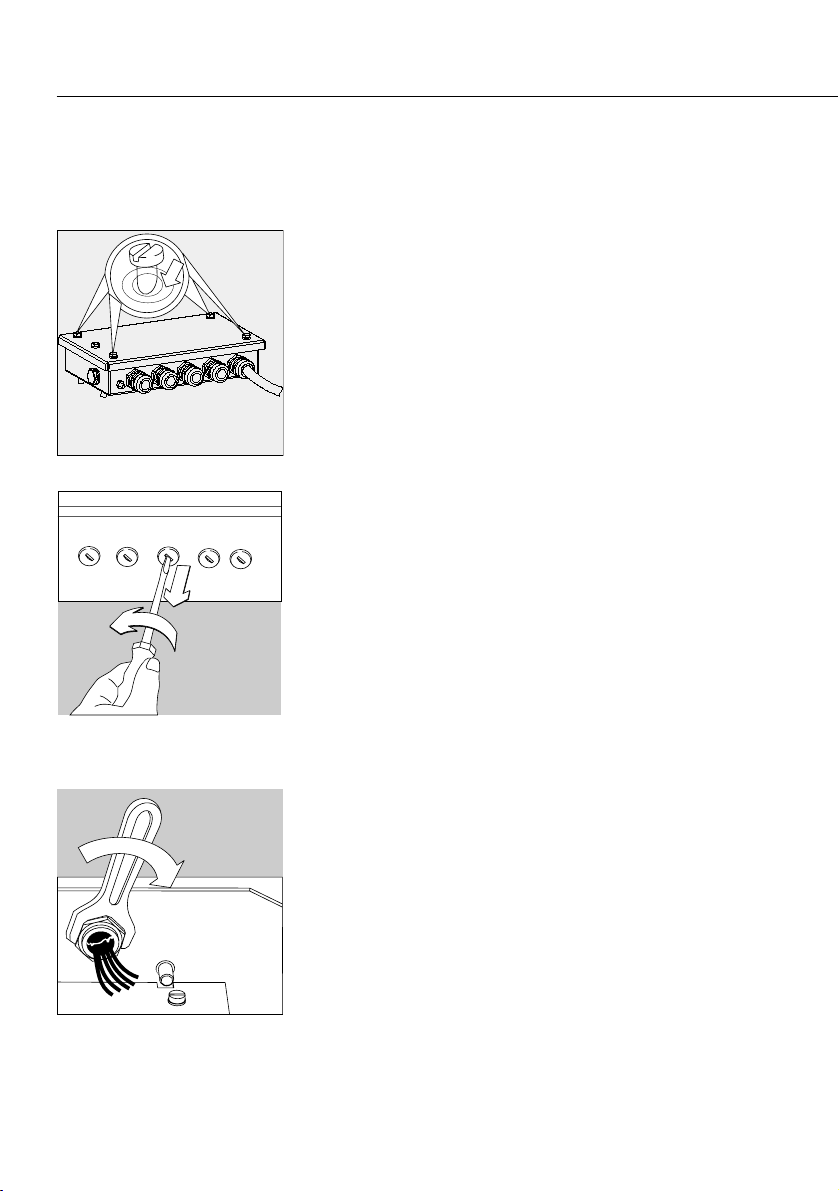

6Installation

6Installing the Filling Module

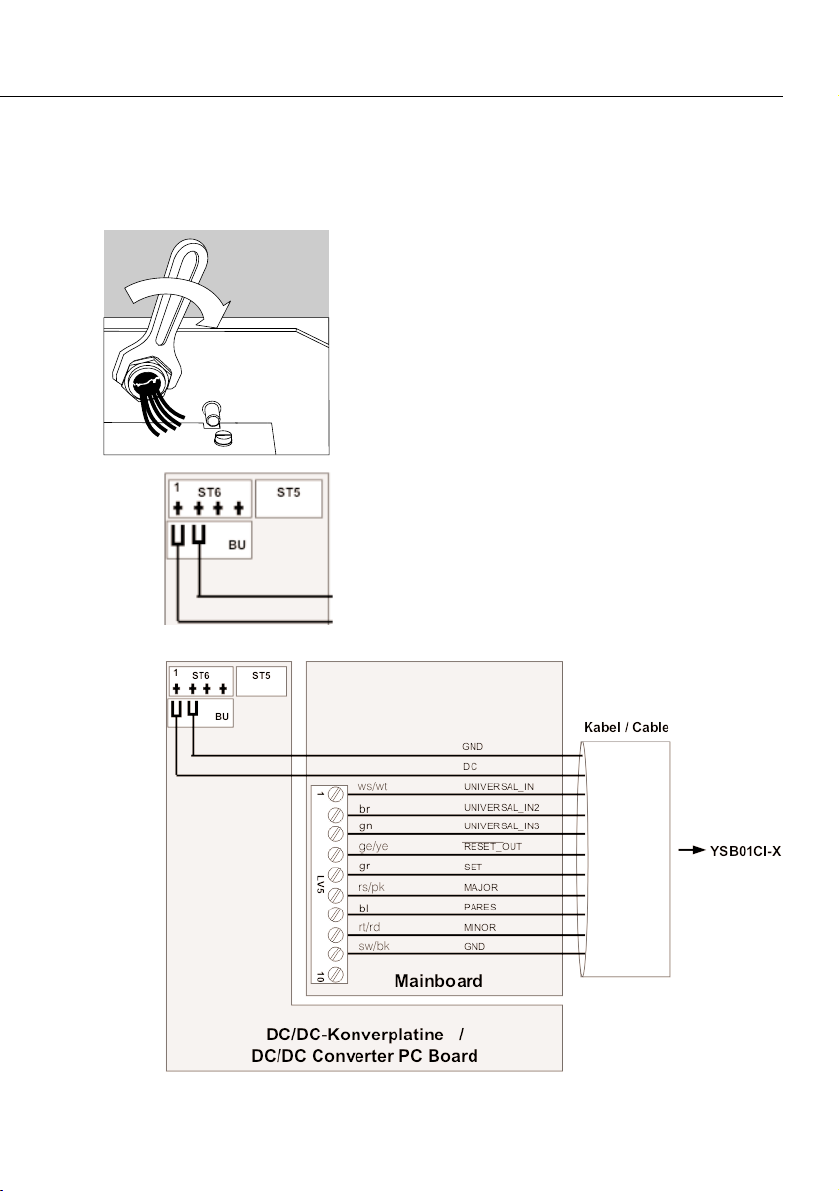

12 Installing the Filling PCB

15 Specifications

15 Accessories

16 Documents for Hazardous Areas

The following symbols are used in

these instructions:

§indicates required steps

$indicates steps required only under cer-

tain conditions

> describes what happens after you have

performed a particular step

– indicates an item in a list

!indicates a hazard

Equipment Supplied

– Filling module with filling PCB

or

– Filling PCB for CIXS3 indicator

– The equipment complies with Directive

94/9/EC for use in the following hazardous

areas: Zone 1 and 2 (gases) and Zone 20, 21

and 22 (dusts).

– When used in hazardous area in which com-

bustible dusts are present, the IP65 protection

of the equipment must be intact. For this

reason, it is essential that installation and

maintenance are performed with extreme care;

in particular:

– Make sure all seals are installed

– bserve all instructions carefully when

installing the cover

– Tighten all fastening screws

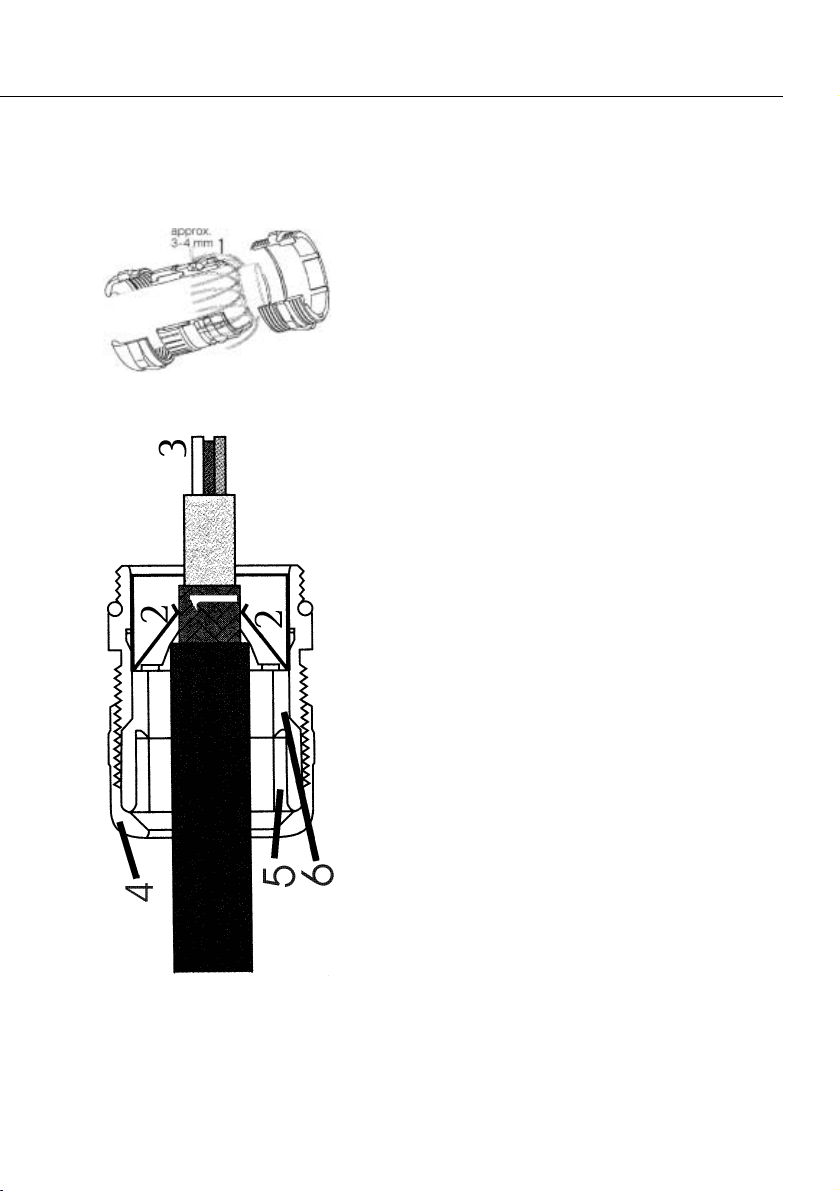

– Tighten all cable glands and make sure they

are installed in accordance with instructions

– The filling module must be disconnected from

power before the housing is opened. To do

this, unplug the power cord on the equipment

that powers the filling module (e.g., Combics

indicator).

Connect the filling module only to equipment

approved for this purpose by Sartorius.

– There is an M4 threaded rod on the filling

module for connecting a grounding conductor.

Make sure to ground (earth) the filling module.

– The filling module may be operated only within

an ambient temperature range of –20°C to

+40°C (–4°F to +104°F).

– When used in a hazardous area in which

combustible dusts are present, clean the filling

module regularly to prevent excessive build-up

of dust. In a Zone 20 hazardous area, the max-

imum permissible dust layer thickness is 5 mm.

– Installation, maintenance and repair work

should be performed only by service techni-

cians trained and authorized by Sartorius.

Any work that is not performed in accordance

with these instructions and acknowledged

technical standards will result in forfeiture of

the approval for use in hazardous areas, and of

all claims under the manufacturer’s warranty.

– Make sure to observe all national laws and

regulations governing the use of such equip-

ment. Ask your supplier for information on the

legal regulations applicable in your country.