Content [Original Ver-

sion: German]

1. General Information...............53

2. Safety Instructions................. 54

3. Use........................................54

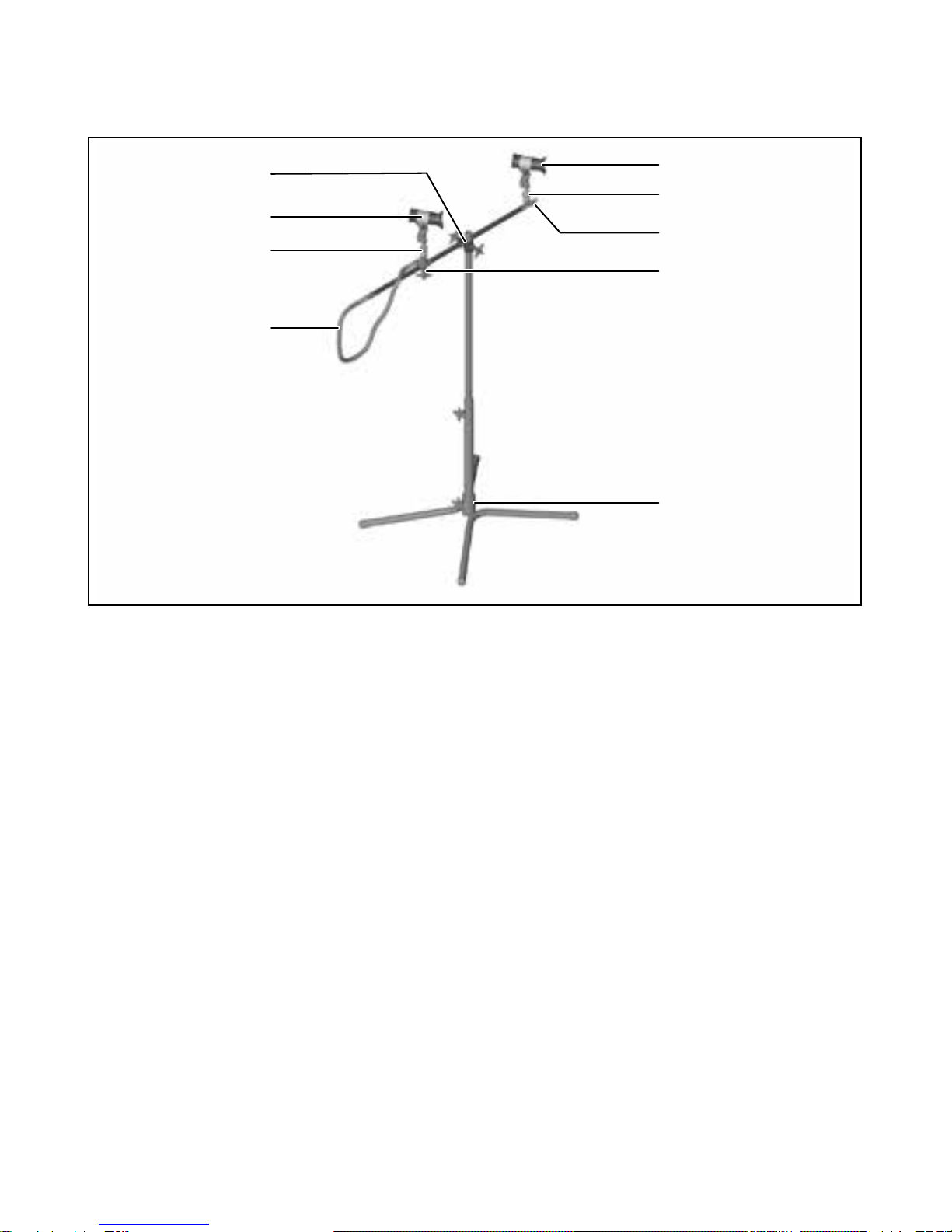

4. Description ............................54

5. Scope of Delivery ..................54

6. Technical Design ...................54

7. Technical Data....................... 55

8. First Use................................55

9. Normal Operation..................56

10. Maintenance and Care..........57

11. Malfunctions ..........................58

12. After Sale Service..................59

13. Spare Parts ...........................60

Read first!

Read these operating instructions

thoroughly and carefully before

use. Comply with the safety in-

Always make sure that these oper-

ating instructions are kept with the

product or keep them easily acces-

sible for everyone at any time!

1. General Information

These operating instructions con-

tain important information for oper-

ating the SATA dry jet 2, hereinafter

referred to as dry jet gun. They also

describe use, care, maintenance,

cleaning and troubleshooting.

1.1. Target group

This operating manual is intended

for

■Painting and varnishing profes-

sionals.

■Trained personnel for varnishing

work in industrial and craftman's

workshops.

1.2. Accident prevention

As a basic principle, the gen-

eral and specic national accident

prevention regulations must be

heeded, together with correspond-

ing workshop and industrial safety

instructions.

1.3. Replacement, accessory

and wear-and-tear parts

Always only use original SATA

spare parts, accessories and wear

parts. Accessories not supplied by

SATA have not been tested and ap-

proved. SATA assumes no liability

for damage caused by the use of

non-approved spare parts, acces-

sories and wear parts.

1.4. Warranty and

liability

The SATA General Conditions of

Sale and Delivery and further con-

tractual agreements apply, if ap-

plicable, as well as the valid legisla-

tion at the time.

SATA is not liable in case of

■non-adherence to the operating

manual.

■use of untrained personnel.

■improper use of the product.

[EN] Operating Instructions | english