中文 EN DE RU KO PT JA ES

51325/05157

4

4) 将闲置不用的电动工具贮存在儿童所及范围之外,并且不要让不熟悉电动工具或对这些说明不了解的人操作电动

工具。电动工具在未经培训的用户手中是危险的。

5)保养电动工具。检查运动件是否调整到位或卡住,检查零件破损情况和影响电动工具运行的其他状况。如有损坏,

电动工具应在使用前修理好。许多事故由维护不良的电动工具引发。

6)保持切削刀具锋利和清洁。保养良好的有锋利切削刃的刀具不易卡住而且容易控制。

7)按照使用说明书,考虑作业条件和进行的作业来使用电动工具、附件和工具的刀头等。将电动工具用于那些与

其用途不符的操作可能会导致危险。

8)在一般作业场所,应使用 II 类工具;若使用 I 类工具时,还应在电气线路中采用额定剩余动作电流不大于 30mA

的剩余电流动作保护器、隔离变压器等保护措施。

9)在潮湿作业(已修订)场所或金属构架上等导电性能良好的作业场所,应使用 II 类或 III 类工具。

10)在锅炉、金属容器、管道内等作业场所,应使用 III 类工具或在电气线路中装设额定剩余电流不大于 30mA 的剩余

电流动作保护器的 II 类工具。

11 )III 类工具的安全隔离变压器,II 类工具的剩余电流动作保护器及 II、III 类工具的电源控制箱和电源耦合器等必须

放在作业(已修订)场所的外面。在狭窄作业 场所操作时,应有人在外监护。

12)在湿热、雨雪等作业环境,应使用具有相应防护等级的工具。

13)I类工具电源线中的绿 /黄双色线在任何情况下只能用作保护接地线(PE)。

14)工具的电源线不得任意接长或拆换。当电源离工具操作距离较远而电源线不够时,应采用耦合器进行联接。

15 )工具的插头、插座应按规定正确接线,插头、插座中的保护接地扱在任何情况下只能单独连接保护接地线(PE )。

严禁在插头、插座内用导线直接将保护接地扱与工作中性线连接起来。

16)工具的危险运动,零部件的防护装置(如防护罩、盖等)不得任意拆卸。

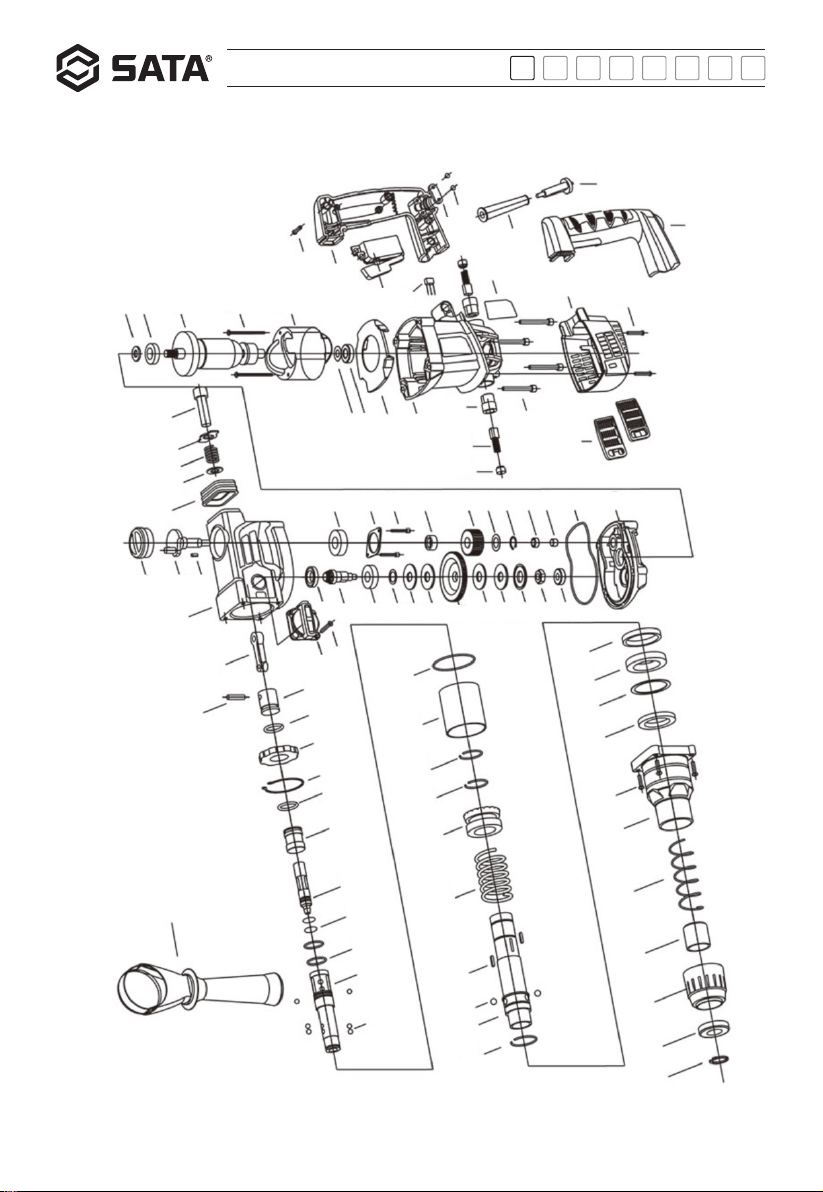

维修:

将你的电动工具送交专业维修人员,使用同样的备件进行修理。这样将确保所维修的电动工具的安全性。

电锤的补充安全规则:

1)戴(已修订)好耳罩,暴露在噪声中会引起听力损伤。

2)使用随工具提供的辅助手柄。操作失手会引起人身伤害。

3)当进行该切割工具可能与隐藏的电线或其自身的导线相接触的操作时请持握住工具的绝缘把手表面,与“火线”

相接触会导致本工具暴露的金属部件“带电”从而导致操作者触电。

4)请佩戴硬质头盔(安全帽)、护目镜和 /或防护面罩。普通眼镜或太阳镜的镜片玻璃不安全。我们也强烈建议

您佩带防尘面罩和厚垫手套。

5)操作前请务必确保刀头已经固定到位。

6)正常操作时工具会产生振动,使得工具上的螺丝容易出现松动,这样会造成机器故障或意外事故。因此请在操

作前仔细检査螺丝的紧固程度。

7)当遇到寒冷天气或长时间未使用本工具时,请通过空转操作使工具预热一段时间。此操作将解冻润滑油。若没

有进行适当的预热,则电镐难以顺畅运行。

8)请务必始终站稳。于高处使用工具时请确保下方无人。

9)请双手紧握工具。

10)请使您的双手远离工具的运动部件。

11)请勿使工具自行运行,仅当手持工具时才可进行操作。

12)操作时请勿将工具指向操作区域中的任何人。刀头可能会飞出从而严重损伤他人。

13)操作后请勿立即触摸刀头或刀头附近的部分,它们可能非常灼热而导致您的皮肤灼伤。

14)有些材料可能包含有毒的化学物质,请务必注意防止灰尘吸入和皮肤接触,请遵循材料供应商提供的安全数据。