4

WATER HEATER INSTALLATION

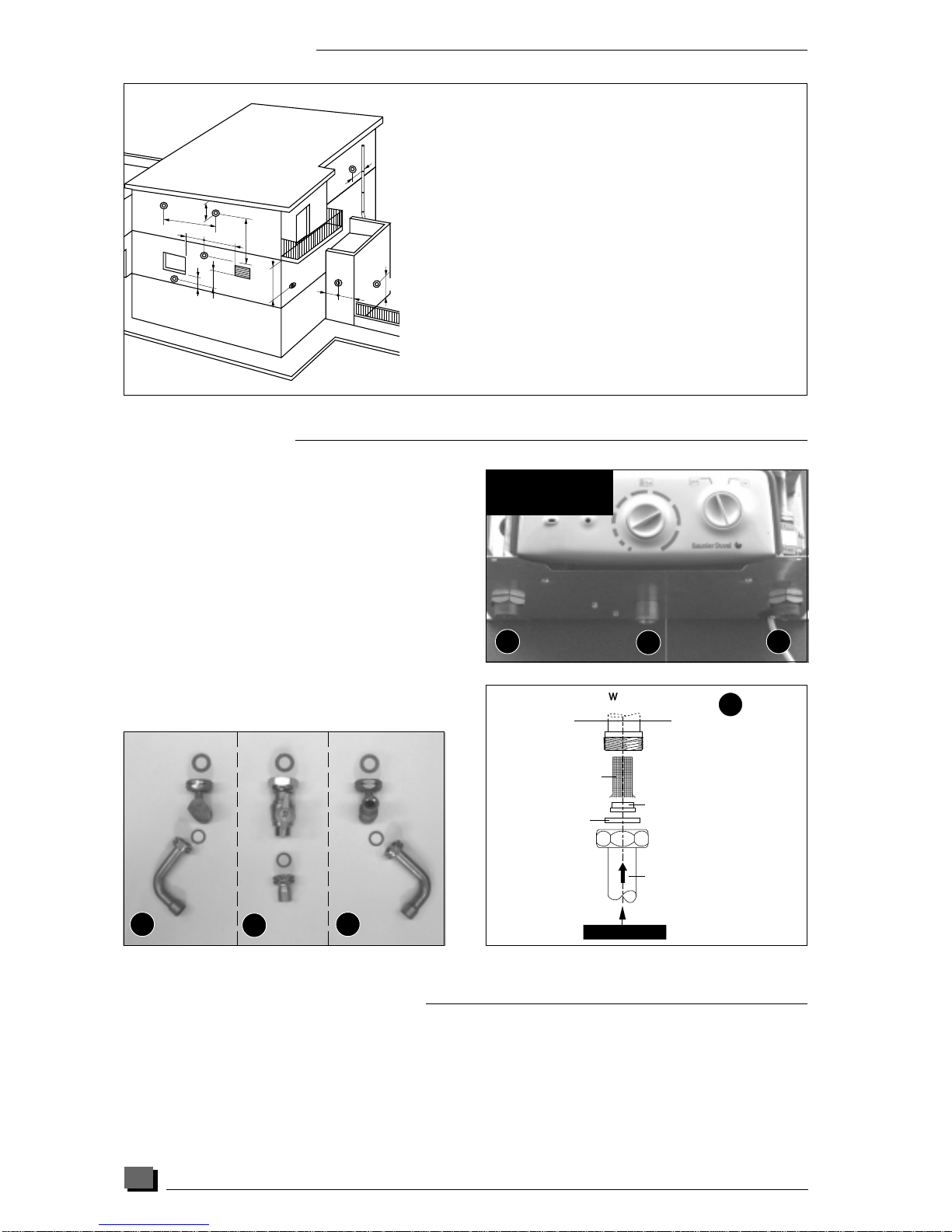

LOCATION

When determining the siting of the water heater,

make sure you keep an approx. distance of 50 mm

between the sides of the appliance to ensure total

accessibility for servicing.

The jig will enable you to determine the position of

the flue system hole at the top outlet. All informa-

tion regarding the installation of the flue system is

provided in the flue system package.

If the water-heater is not fitted straight away, the

water and gas fittings must be protected from

contaminents E.G. plaster, paint.

PIPE FITTINGS : Gas Manual gas cock 3/4" F - 1/2" M

Cold water inlet : stop cock 3/4" F - 1/2 " M with

angled tail

DHW outlet : 3/4" F - 1/2 " M angled tail

This appliance must be installed in accordance with

the current issue of :

●The gas safety (installation and use) regulations

●The building regulations

●The local water company byelaws

●The building standards regulations (Scotland)

●The health and safety at work act.

The gas safety (installation and use) regulations : it is

the law that all gas appliances are installed by

competent persons in accordance with the above

regulations. Failure to install appliances correctly

could lead to prosecution. It is in your own interest,

and that of safety, to ensure the law is complied

with.

TECHNICAL DATA

Refer to the data badge for exact type of appliance

and the gases it is suitable for.

Variable output of 8,7 kW (29665 Btu/h)

to 22,7 kW (77403 Btu/h)

Efficiency 78,4 %

Minimum flow rate, hot water temperature to :

maxi. position 2,7 l/min (0,60 g/min)

mini. position 4,2 l/min (0,92 g/min)

Maximum flow rate (by flow limiter) 3 l/min (2,86 g/min)

Specific flow rate (∆t 30 °C) 11 l/min (2,42 g/min)

Minimum water pressure [pw] 0,3 bar (4,50 Ib/in2)

Maximum water pressure*[pw] 10 bar (150 Ib/in2)

Max hot water temperature 60 °C

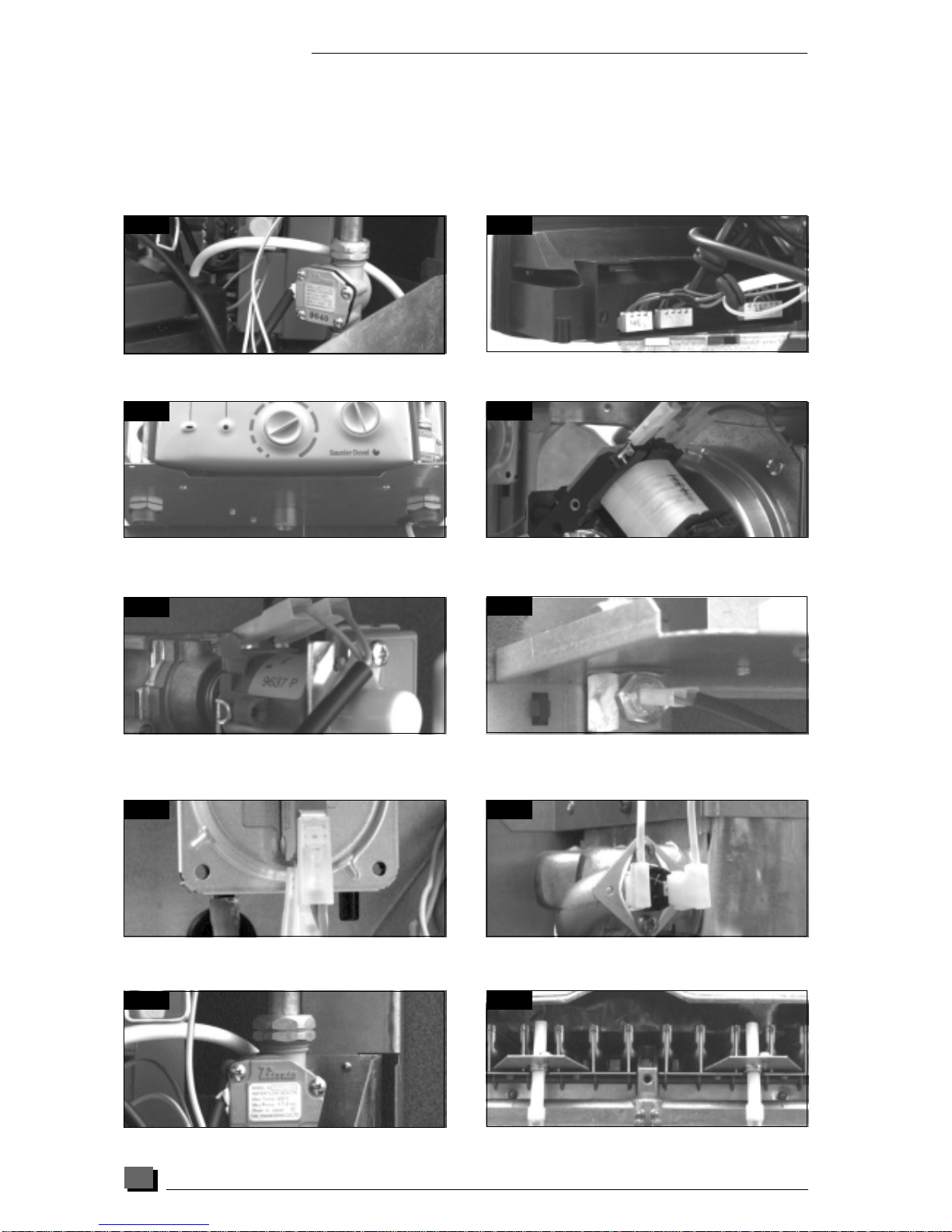

Venting of flue gases via flue system Ø 60 mm

Incoming fresh air via flue system Ø 100 mm

Supply voltage 230 V

Current 0,31 A

Power 55 W

Electrical protection IP 44

* These maximum water pressure values take into account

the dilation of the water.

Only a qualified technician is authorized to intervene on

sealed mechanisms.

Gas Category : II

2H3+

.

Ø buner injector 1,20 mm

Appliance Inlet pressure 20 mbar

Max. gas flow rate output 2,75 m3/h

Min. gas flow rate 1,13 m3/h

Natural (G 20) (ref. 15

°

C and 1013 mbar)

Ø buner injector 0,80 mm

Appliance Inlet pressure 28 - 30 mbar

Max. gas flow rate output 2,04 kg/h

Min. gas flow rate 0,83 kg/h

Butane (G 30)

Ø buner injector 0,80 mm

Appliance Inlet pressure 37mbar

Max. gas flow rate output 2,02 m3/h

Min. gas flow rate 0,82 m3/h

Propane (G 31)

Car 019

100 100

141 141

445,2 316,4

61,6

17

17

19,5

EFEC GAZ

86

103

AC GAS AF

134

50

mini

245 mini

100 100

141 141

445,2 316,4

61,6

1717

19,5

EFEC GAZ

100 mm 100 mm

316,4 mm

3%