5

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

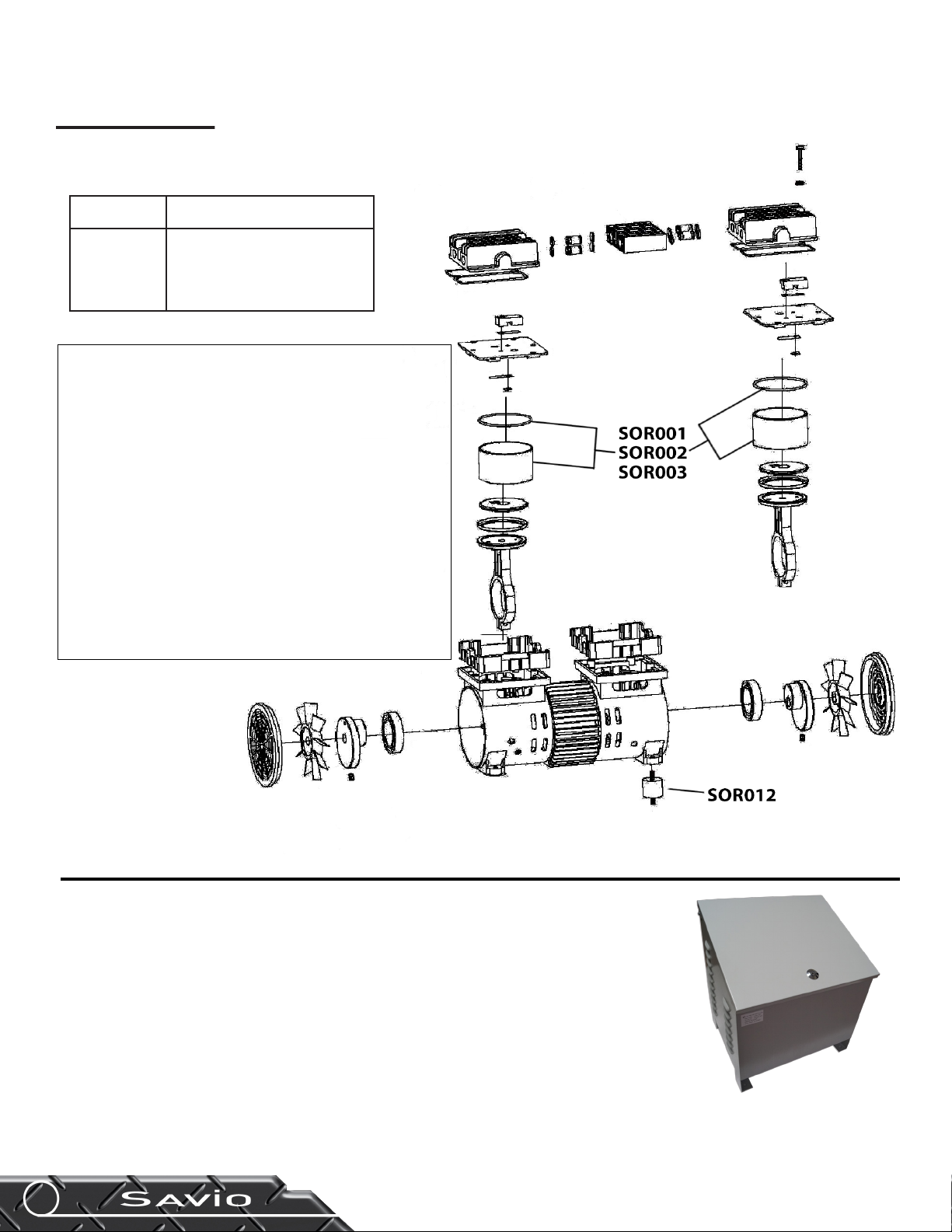

Maintenance Notes