TABLE OF CONTENTS

Product Specications.........................................................................

Parts Inventory.....................................................................................

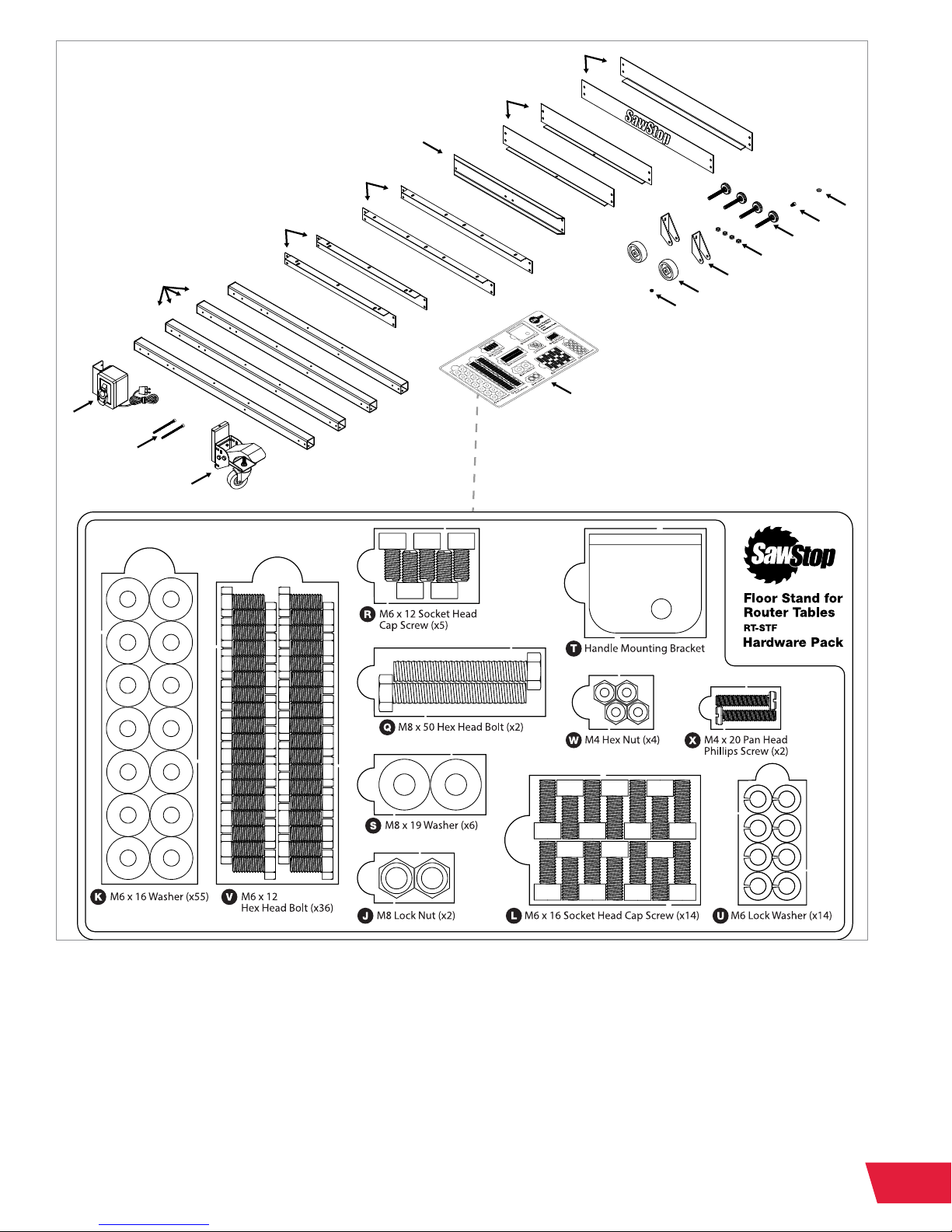

Floor Stand (RT-STF)......................................................................................................

32" x 24" Cast Iron Router Table (RT-C32).....................................................................

32" x 24" Phenolic Router Table (RT-PH32)....................................................................

32" Fence Assembly (RT-F32).........................................................................................

Assembly Options................................................................................

Assembly and Installation.....................................................................

Assembling the Floor Stand ..........................................................................................

Assembling the Cast Iron Table......................................................................................

Installing the Cast Iron Table..........................................................................................

Assembling the Phenolic Table......................................................................................

Installing the Phenolic Table...........................................................................................

Assembling the Fence....................................................................................................

Reference............................................................................................

Warranty.........................................................................................................................

Safety.............................................................................................................................

Warnings........................................................................................................................

Exploded View 1: Floor Stand for Router Tables (RT-STF) ..............................................

Parts List 1: Floor Stand for Router Tables (RT-STF) .....................................................

Exploded View 2: 32" x 24" Cast Iron Router Table (RT-C32) ...........................................

Parts List 2: 32" x 24" Cast Iron Router Table (RT-C32) ...................................................

Exploded View 3: 32" x 24" Phenolic Router Table (RT-PH32) ........................................

Parts List 3: 32" x 24" Phenolic Router Table (RT-PH32) .................................................

Exploded View 4: 32" Fence Assembly for Router Tables (RT-F32) ...............................

Parts List 4: 32" Fence Assembly for Router Tables (RT-F32) .......................................

Available Accessories..........................................................................

1

3

3

5

6

7

9

11

11

17

19

20

22

23

30

30

31

31

33

34

35

36

37

38

39

40

41