SCANGAZER

OTG SAFETY GLASSES

You have chosen Scandia Gear personal protective

equipment (PPE). Please read these instructions

prior to use and prior to any maintenance.

European EN 166:2001 standard

EN 166:2001 : European standard for personal eye

protection

These CE-certified safety spectacles belong to

Category II and are approved in accordance with

Regulation (EU) 2016/425 and the requirements of

the European harmonized standard EN166:2001.

This product has been subjected to a EU-type

examination performed by:

Alienor Certification N.B.2754

Z.A. du Sanital, 21 Rue Albert Einstein

86100 Chatellerault, France

This PPE is designed to provide the user with

adequate protection. The rating of the PPE is

indicated by markings and related indexes on the

frames and lenses. This rating is obtained from

tests in which the prototypes were submitted.

The EU Declaration of Conformity (DOC) for this

product can be obtained through following link:

www.scandiagear.com

Application and limitations

Please ensure that this eyewear always fits well.

The main purpose of this safety eyewear is to

provide the wearer with limited impact resistance.

The eyewear may not be suitable for certain

environments, such as those with low light

surroundings or liquid splash hazards. These

spectacles are intended for the following:

A) use in factories, on construction sites, in mining

operations, and on other worksites where

basic eye protection (i.e., particle impact speed

under 45 m/s) is required.

B) preventing impact hazards associated with

chipping, grinding, machining, masonry work,

riveting, and sanding.

Model

The name of the model is always indicated on the

barcode of the packaging.

Storage

Store in a dry place at room temperature and

protect from direct sunlight. The eyewear must be

transported and stored in the original package, at a

temperature between 5°C and 40°C (41°F and 104°F)

and a relative humidity of <90%.

Maintenance

The lenses must be cleaned or disinfected regularly.

This must be done using a mild detergent, optical

cleaning solution, or a solution very low in alcohol

at room temperature (20°C/68°F ± 5°C/ 41°F). The

eyewear should provide adequate protection for a

period exceeding six (6) months and up to two (2)

years. Regularly check the status. Scratched or

damaged lenses must be replaced or disposed

of immediately. The markings found on the lens and

on the frames represent the ratings of the prod-

uct. Scandia Gear is not be liable for damages aris-

ing from misuse, and improper maintenance and

preservation of this PPE.

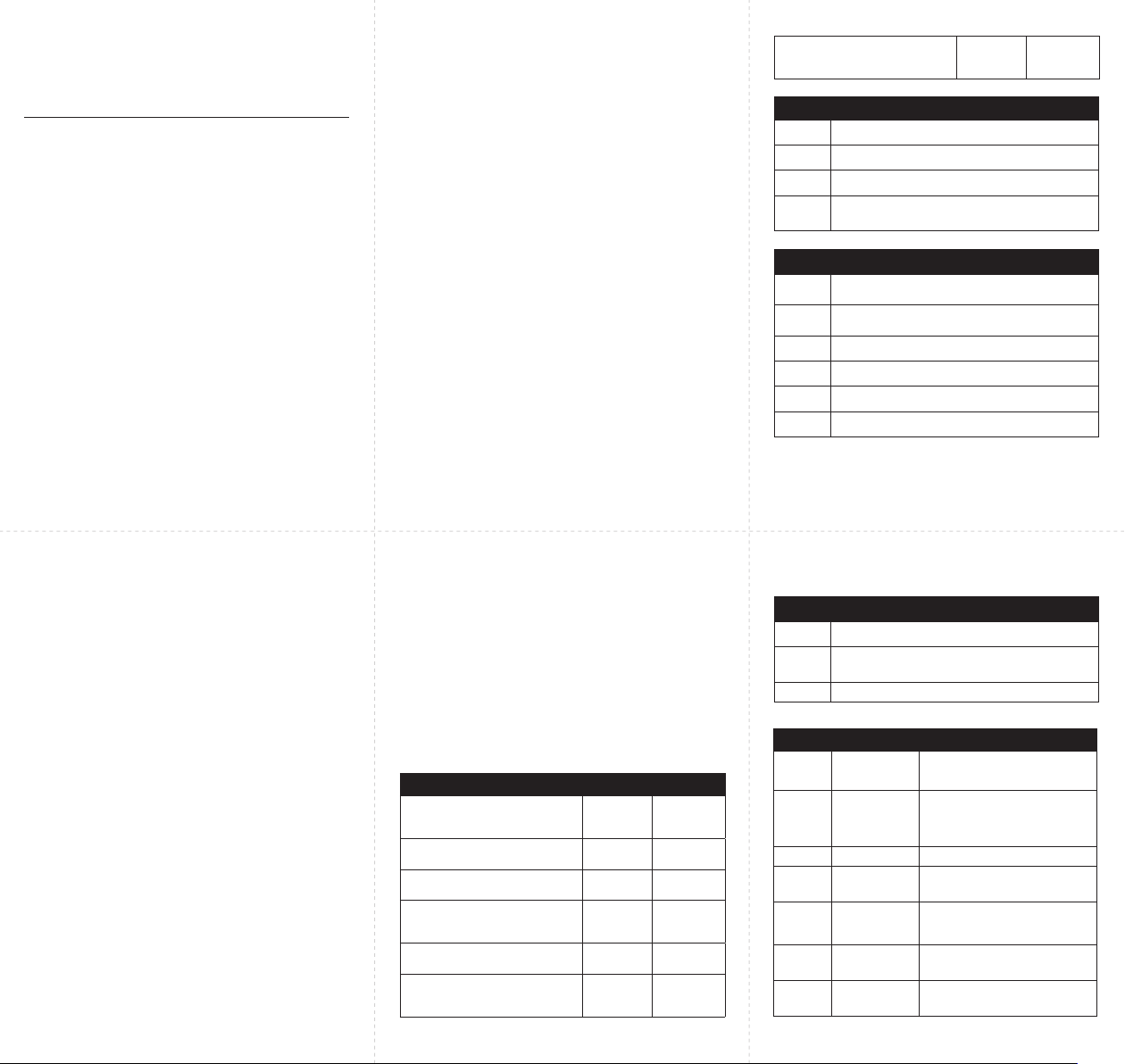

Lens markings

Scale number (filters only) – Identification of

Manufacturer – Optical class – symbol of mechanical

resistance – Field(s) of use (if applicable) CE marking.

Markings on frames

Identification of the manufacturer – Number of

EN stan

dards – Field(s) of use (if applicable) –

Mechanical resistance – CE marking.

Scale number (filters only)

Type of filter Code

number

Filter

rating

number

EN 169

Welding filters

No code

number 1 to 16

EN 170

Ultraviolet (UV) filters 2 1,2 to 5

EN 170

Ultraviolet (UV) filters with good

color recognition

2C 1,2 to 5

EN 171

Infra-red (IR) filters 4 1,2 to 10

EN 172

Solar protection filters without

infra-red specification

51,1 to 4,1

If the symbol F, B or A is not found on both the lenses

and the frame, then the lower value is assigned to the

complete set of safety glasses. The letter T imme-

diately after the impact letter allows a use for high

speed particles at extremes of temperature. In the

absence of the letter T the protector must be used in

room temperature.

Optical Class

Code Designation

1 Optical Class

2 Intermittent work

3Occasional work

(not intended for prolonged use)

Mechanical resistance

Code Mechanical Strength

Requirements

No

symbol Minimum robustness

S Increased robustnesss (5.1 m/s)

F Low energy impact (45 m/s)

B Medium energy impact (120 m/s)

A High energy impact (190 m/s)

Marking on lens

Code Designation

K Resistance to surface damage caused by fine

particles

N Resistance to fogging

EN 172

Solar protection filters with

infra-red specification

61,1 to 4,1

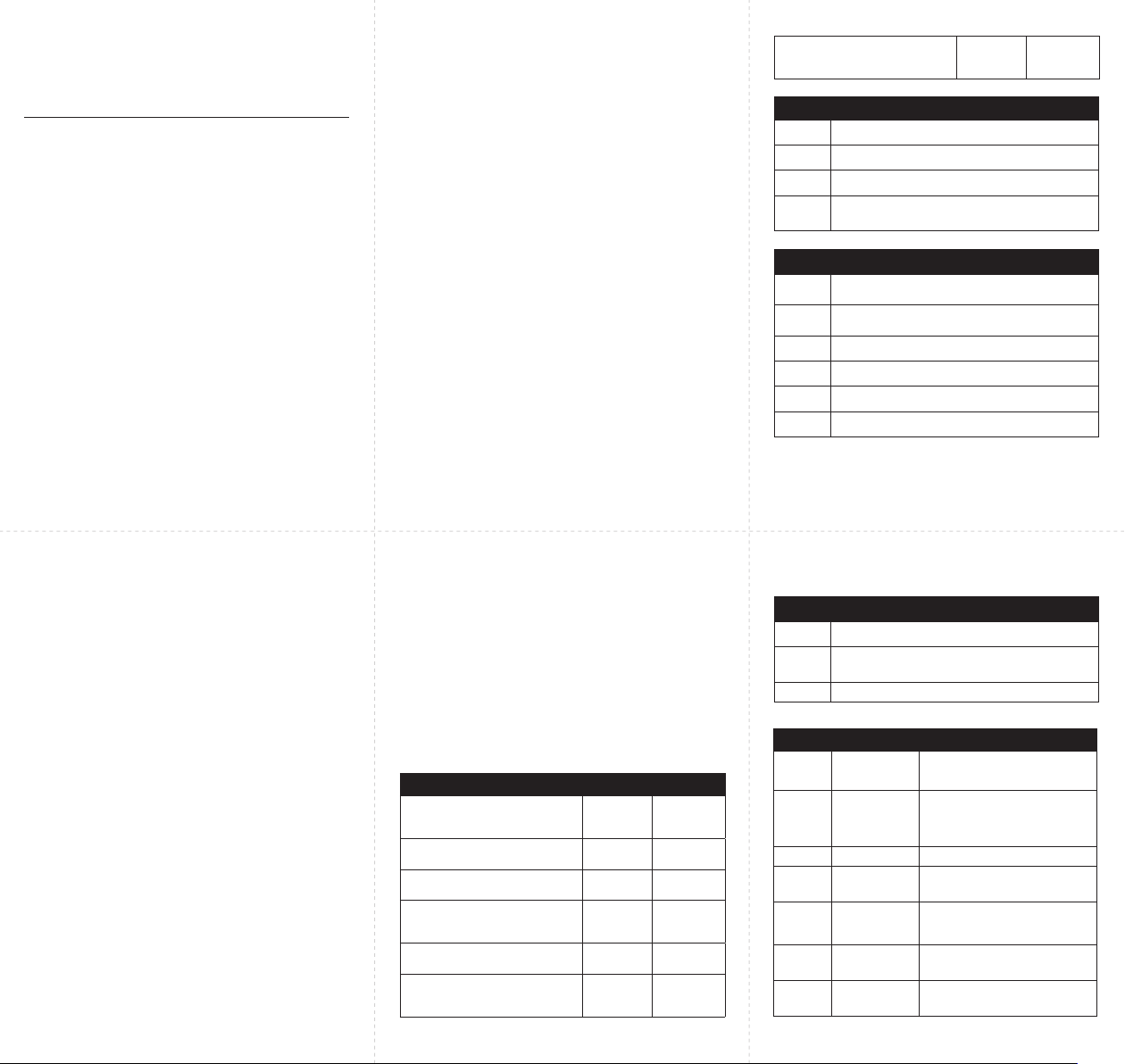

Fields of use

Code Designation Description of the field of

application

No

symbol

Basic Unspecified mechanical

hazards and dangers from

ultraviolet, visible, infra-red

and solar radiation

3 Liquids Liquids (droplets and splashes)

4 Large dust

particles

Dust with a particle size > 5 μm

5 Gas particles

and fine

powder

Gases, vapours, sprays, smoke

and dust with a particle size

<5 μm

8 Short circuit

electric arc

Short circuit electric arc in

electrical devices

9 Molten metal

and hot solids

Splashes of molten metal and

the penetration of hot solids